diagram MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1108 of 1449

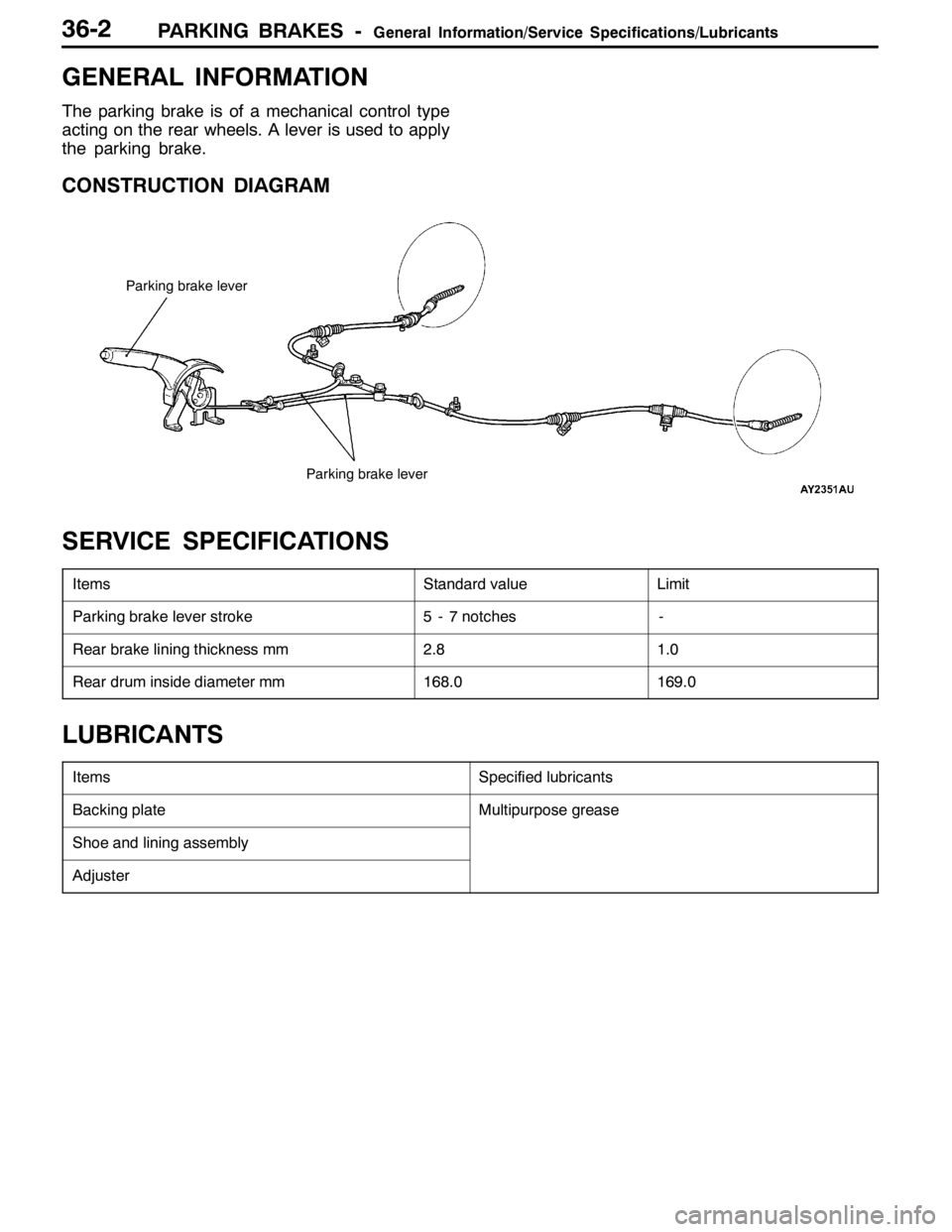

PARKING BRAKES -General Information/Service Specifications/Lubricants36-2

GENERAL INFORMATION

The parking brake is of a mechanical control type

acting on the rear wheels. A lever is used to apply

the parking brake.

CONSTRUCTION DIAGRAM

Parking brake lever

Parking brake lever

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Parking brake lever stroke5 - 7 notches-

Rear brake lining thickness mm2.81.0

Rear drum inside diameter mm168.0169.0

LUBRICANTS

ItemsSpecified lubricants

Backing plateMultipurpose grease

Shoe and lining assembly

Adjuster

Page 1117 of 1449

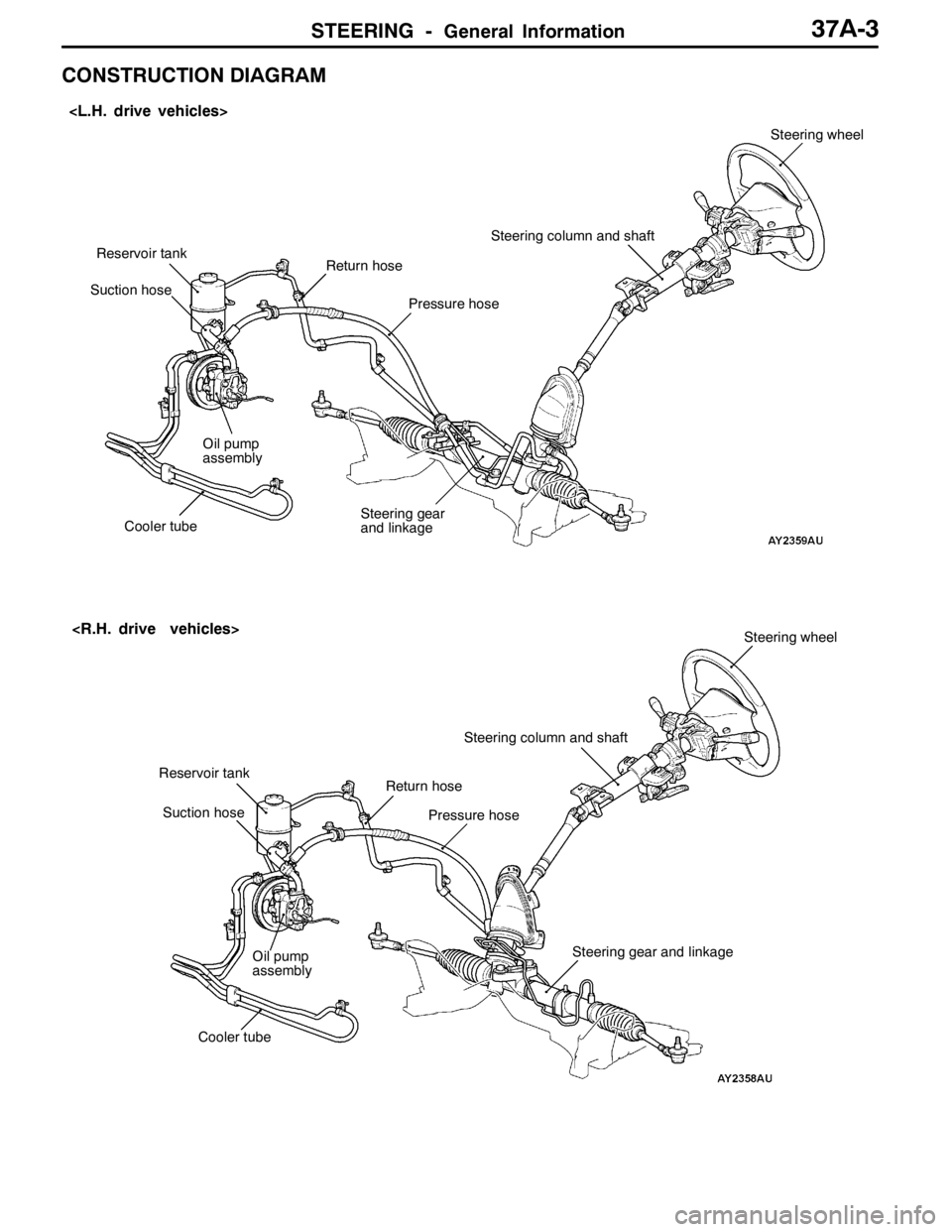

STEERING -General Information37A-3

CONSTRUCTION DIAGRAM

Reservoir tank

Reservoir tank

Steering gear and linkage Return hose

Suction hose

Pressure hoseSteering wheel

Steering column and shaft

Oil pump

assembly

Steering gear

and linkage Return hose

Suction hose

Pressure hoseSteering wheel

Steering column and shaft

Oil pump

assembly

Cooler tube

Cooler tube

Page 1251 of 1449

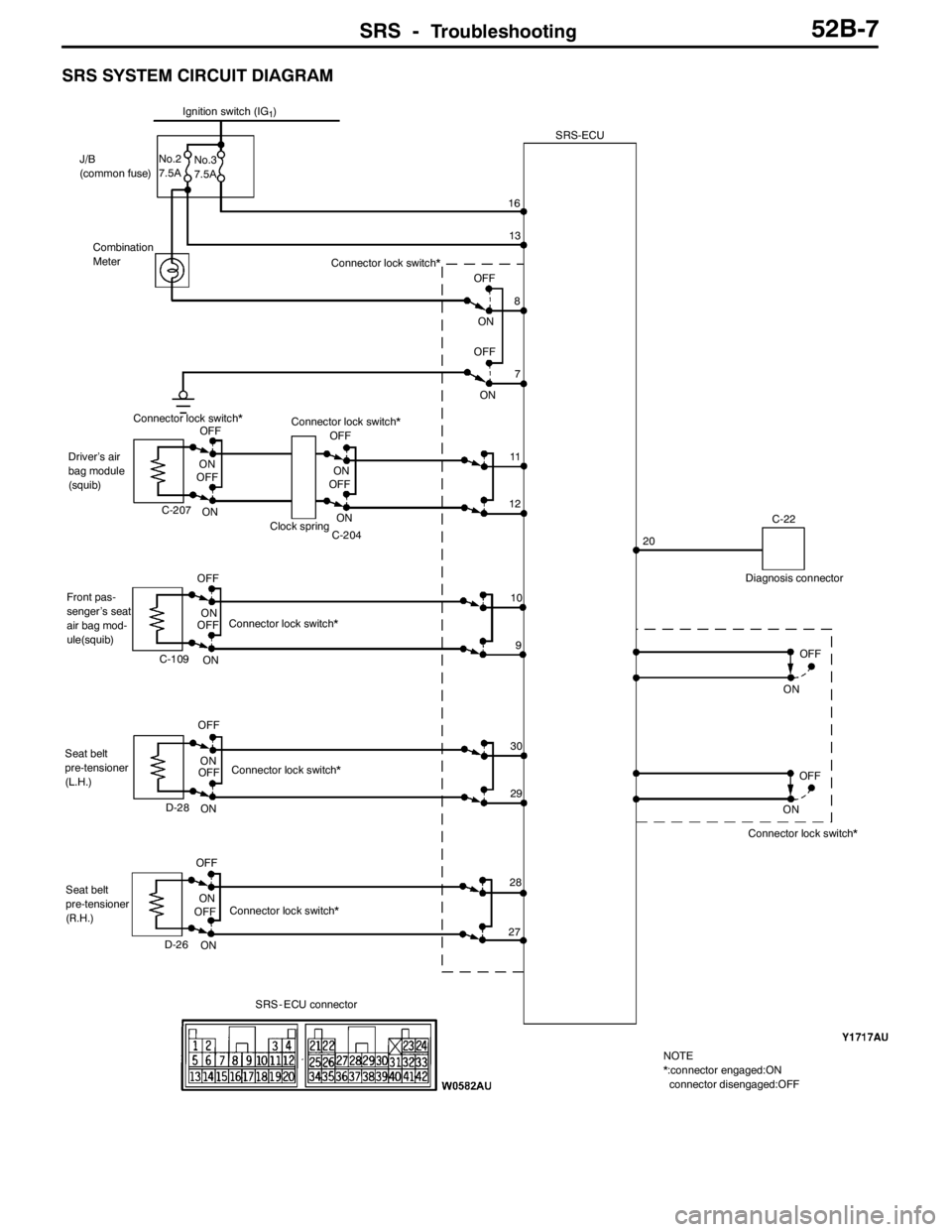

SRS -Troubleshooting52B-7

SRS SYSTEM CIRCUIT DIAGRAM

Ignition switch (IG1)

J/B

(common fuse)

Combination

Meter

Connector lock switch*

ON

ON OFF

OFF

Driver’s air

bag module

(squib)

Front pas-

senger’s seat

air bag mod-

ule(squib)

Seat belt

pre-tensioner

(L.H.)Clock spring

ONONOFF

OFF

Connector lock switch* Diagnosis connector SRS-ECU

No.3

7.5A No.2

7.5A

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFFON

ON

ON

ON

ON

ON

ON

ONOFF

ON

ON OFF

C-207

C-204

C-109

D-28

D-26C-22

SRS - ECU connector16

13

7 8

11

12

10

9

30

29

28

2720 Connector lock switch*

Connector lock switch*

Connector lock switch*

Connector lock switch*

Connector lock switch*

NOTE

*:connector engaged:ON

connector disengaged:OFF Seat belt

pre-tensioner

(R.H.)

Page 1274 of 1449

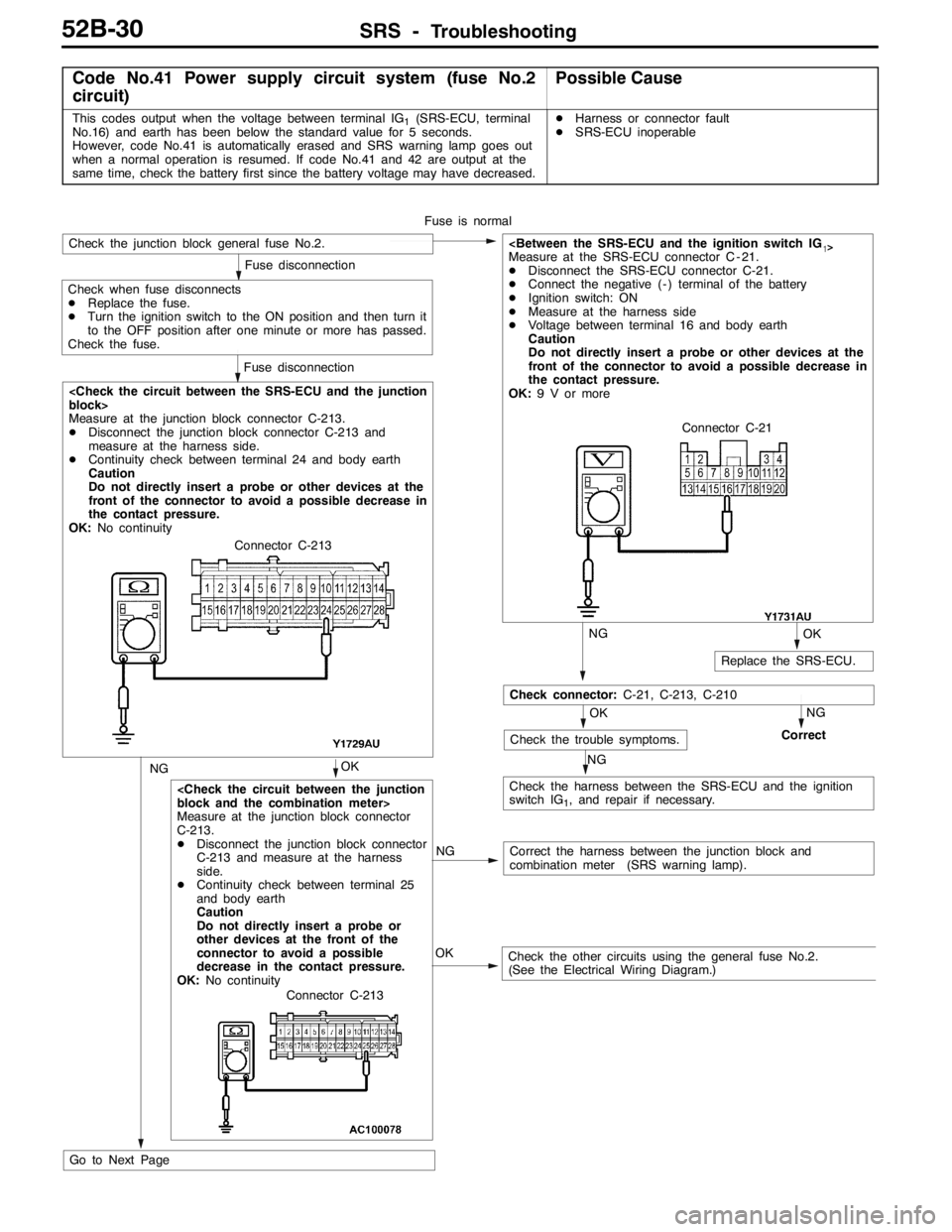

SRS -Troubleshooting52B-30

Code No.41 Power supply circuit system (fuse No.2

circuit)Possible Cause

This codes output when the voltage between terminal IG1(SRS-ECU, terminal

No.16) and earth has been below the standard value for 5 seconds.

However, code No.41 is automatically erased and SRS warning lamp goes out

when a normal operation is resumed. If code No.41 and 42 are output at the

same time, check the battery first since the battery voltage may have decreased.DHarness or connector fault

DSRS-ECU inoperable

Measure at the junction block connector

C-213.

DDisconnect the junction block connector

C-213 and measure at the harness

side.

DContinuity check between terminal 25

and body earth

Caution

Do not directly insert a probe or

other devices at the front of the

connector to avoid a possible

decrease in the contact pressure.

OK:No continuity

Measure at the junction block connector C-213.

DDisconnect the junction block connector C-213 and

measure at the harness side.

DContinuity check between terminal 24 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:No continuity

NGCorrect the harness between the junction block and

combination meter (SRS warning lamp).

NGOK

NGNG

Check the trouble symptoms.Correct

Check the harness between the SRS-ECU and the ignition

switch IG

1, and repair if necessary. Fuse is normal

NG

Fuse disconnection

Check the junction block general fuse No.2.

Fuse disconnection

Check when fuse disconnects

DReplace the fuse.

DTurn the ignition switch to the ON position and then turn it

to the OFF position after one minute or more has passed.

Check the fuse.

OK

OK

Replace the SRS-ECU.

DDisconnect the SRS-ECU connector C-21.

DConnect the negative ( - ) terminal of the battery

DIgnition switch: ON

DMeasure at the harness side

DVoltage between terminal 16 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:9 V or more

Check the other circuits using the general fuse No.2.

(See the Electrical Wiring Diagram.) OK

Check connector:C-21, C-213, C-210

Go to Next PageConnector C-21

Connector C-213

Connector C-213

Page 1276 of 1449

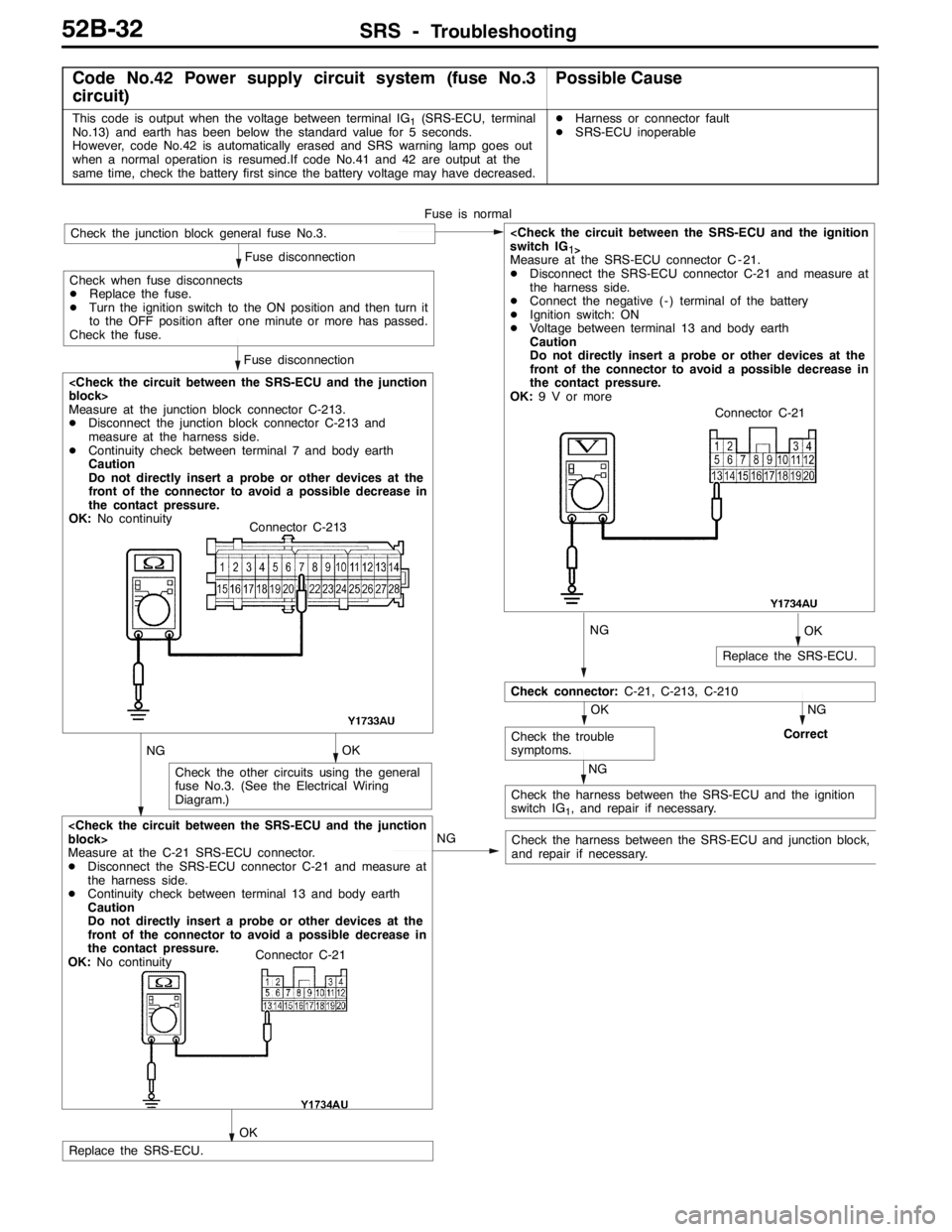

SRS -Troubleshooting52B-32

Code No.42 Power supply circuit system (fuse No.3

circuit)Possible Cause

This code is output when the voltage between terminal IG1(SRS-ECU, terminal

No.13) and earth has been below the standard value for 5 seconds.

However, code No.42 is automatically erased and SRS warning lamp goes out

when a normal operation is resumed.If code No.41 and 42 are output at the

same time, check the battery first since the battery voltage may have decreased.DHarness or connector fault

DSRS-ECU inoperable

OK

Check the other circuits using the general

fuse No.3. (See the Electrical Wiring

Diagram.)

NGOK

NG

NG

NG

Check connector:C-21, C-213, C-210

Check the trouble

symptoms.Correct

Check the harness between the SRS-ECU and the ignition

switch IG

1, and repair if necessary.

NG

Fuse disconnection

Fuse disconnection

OK

Replace the SRS-ECU.

1

>Measure at the SRS-ECU connector C - 21.

DDisconnect the SRS-ECU connector C-21 and measure at

the harness side.

DConnect the negative ( - ) terminal of the battery

DIgnition switch: ON

DVoltage between terminal 13 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:9 V or more

OK

Check the harness between the SRS-ECU and junction block,

and repair if necessary.

Measure at the C-21 SRS-ECU connector.

DDisconnect the SRS-ECU connector C-21 and measure at

the harness side.

DContinuity check between terminal 13 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:No continuity

Replace the SRS-ECU.Fuse is normal

Check the junction block general fuse No.3.

Check when fuse disconnects

DReplace the fuse.

DTurn the ignition switch to the ON position and then turn it

to the OFF position after one minute or more has passed.

Check the fuse.

Measure at the junction block connector C-213.

DDisconnect the junction block connector C-213 and

measure at the harness side.

DContinuity check between terminal 7 and body earth

Caution

Do not directly insert a probe or other devices at the

front of the connector to avoid a possible decrease in

the contact pressure.

OK:No continuityConnector C-21

Connector C-213

Connector C-21

Page 1437 of 1449

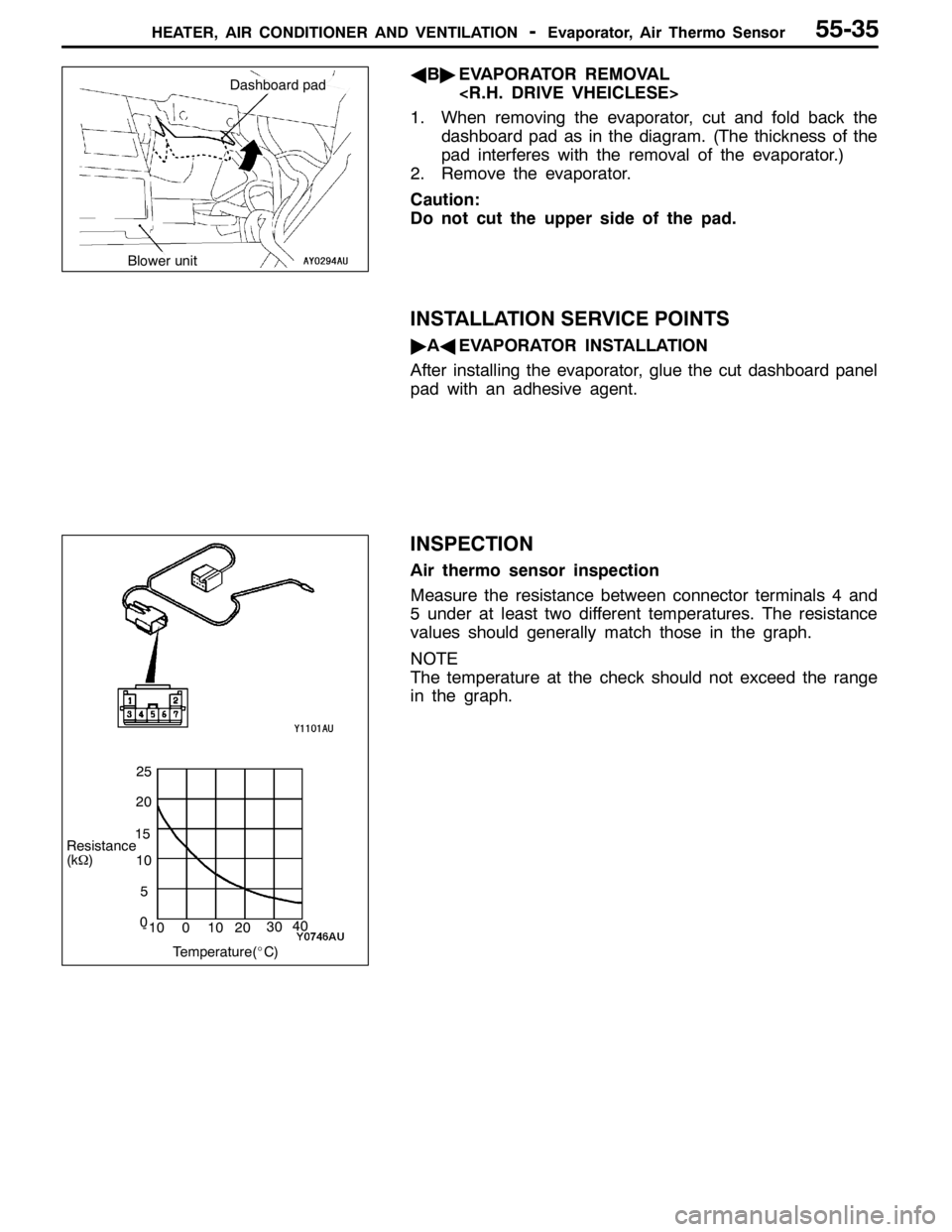

HEATER, AIR CONDITIONER AND VENTILATION-Evaporator, Air Thermo Sensor55-35

AB"EVAPORATOR REMOVAL

1. When removing the evaporator, cut and fold back the

dashboard pad as in the diagram. (The thickness of the

pad interferes with the removal of the evaporator.)

2. Remove the evaporator.

Caution:

Do not cut the upper side of the pad.

INSTALLATION SERVICE POINTS

"AAEVAPORATOR INSTALLATION

After installing the evaporator, glue the cut dashboard panel

pad with an adhesive agent.

INSPECTION

Air thermo sensor inspection

Measure the resistance between connector terminals 4 and

5 under at least two different temperatures. The resistance

values should generally match those in the graph.

NOTE

The temperature at the check should not exceed the range

in the graph.

Blower unit

Dashboard pad

Resistance

(kΩ)

Temperature(_C) 20

15

10

5

0

-10 0 1040

30

20

25