Warning MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 591 of 1449

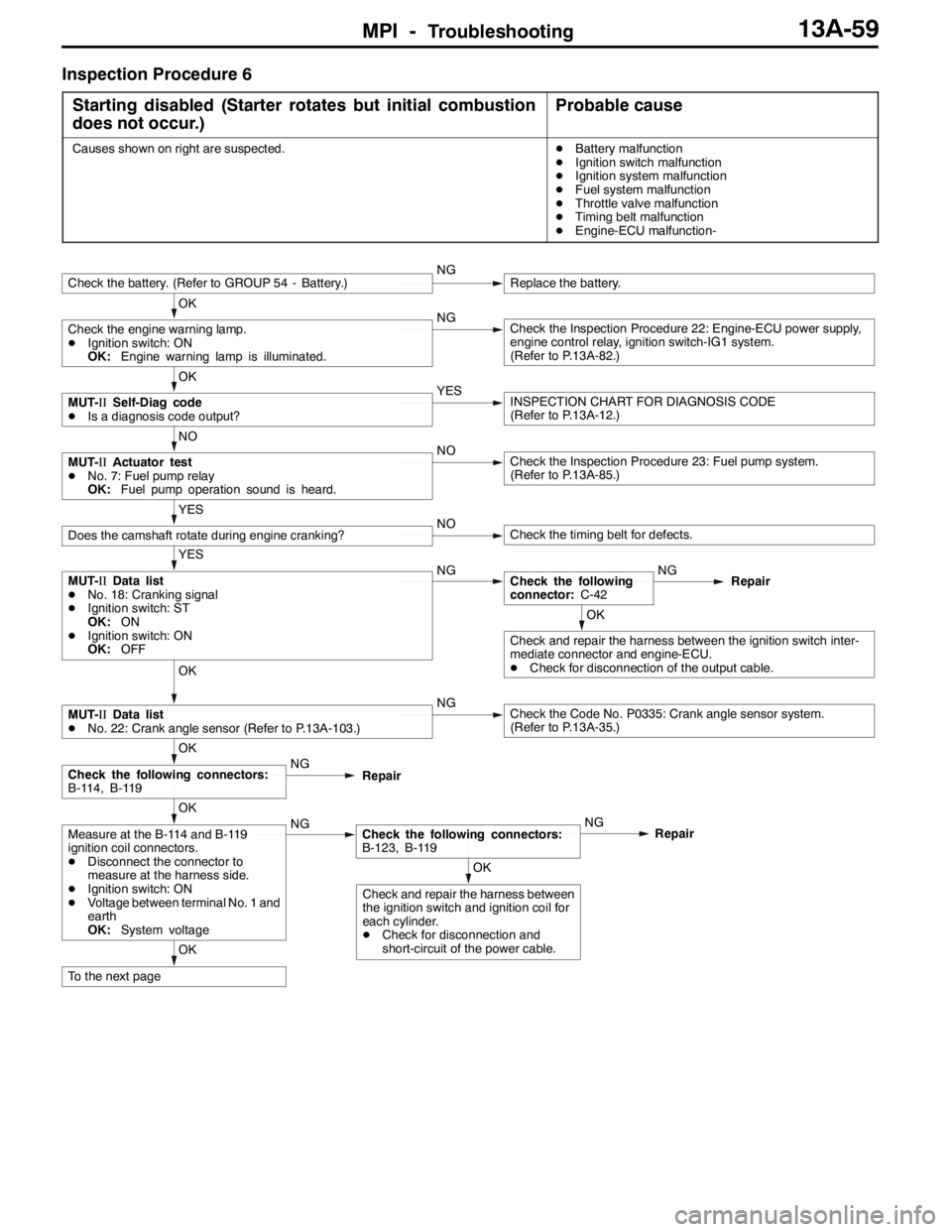

MPI -Troubleshooting13A-59

Inspection Procedure 6

Starting disabled (Starter rotates but initial combustion

does not occur.)

Probable cause

Causes shown on right are suspected.DBattery malfunction

DIgnition switch malfunction

DIgnition system malfunction

DFuel system malfunction

DThrottle valve malfunction

DTiming belt malfunction

DEngine-ECU malfunction-

OK

To the next page

OK

Check and repair the harness between

the ignition switch and ignition coil for

each cylinder.

DCheck for disconnection and

short-circuit of the power cable.

OK

Measure at the B-114 and B-119

ignition coil connectors.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-123, B-119NG

Repair

OK

Check the following connectors:

B-114, B-119NG

Repair

OK

MUT-IIData list

DNo. 22: Crank angle sensor (Refer to P.13A-103.)NGCheck the Code No. P0335: Crank angle sensor system.

(Refer to P.13A-35.)

OK

Check and repair the harness between the ignition switch inter-

mediate connector and engine-ECU.

DCheck for disconnection of the output cable.

YES

MUT-IIData list

DNo. 18: Cranking signal

DIgnition switch: ST

OK:ON

DIgnition switch: ON

OK:OFFNGCheck the following

connector:C-42NG

Repair

YES

Does the camshaft rotate during engine cranking?NOCheck the timing belt for defects.

NO

MUT-IIActuator test

DNo. 7: Fuel pump relay

OK:Fuel pump operation sound is heard.NOCheck the Inspection Procedure 23: Fuel pump system.

(Refer to P.13A-85.)

OK

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

OK

Check the engine warning lamp.

DIgnition switch: ON

OK:Engine warning lamp is illuminated.NGCheck the Inspection Procedure 22: Engine-ECU power supply,

engine control relay, ignition switch-IG1 system.

(Refer to P.13A-82.)

Check the battery. (Refer to GROUP 54 - Battery.)NGReplace the battery.

Page 642 of 1449

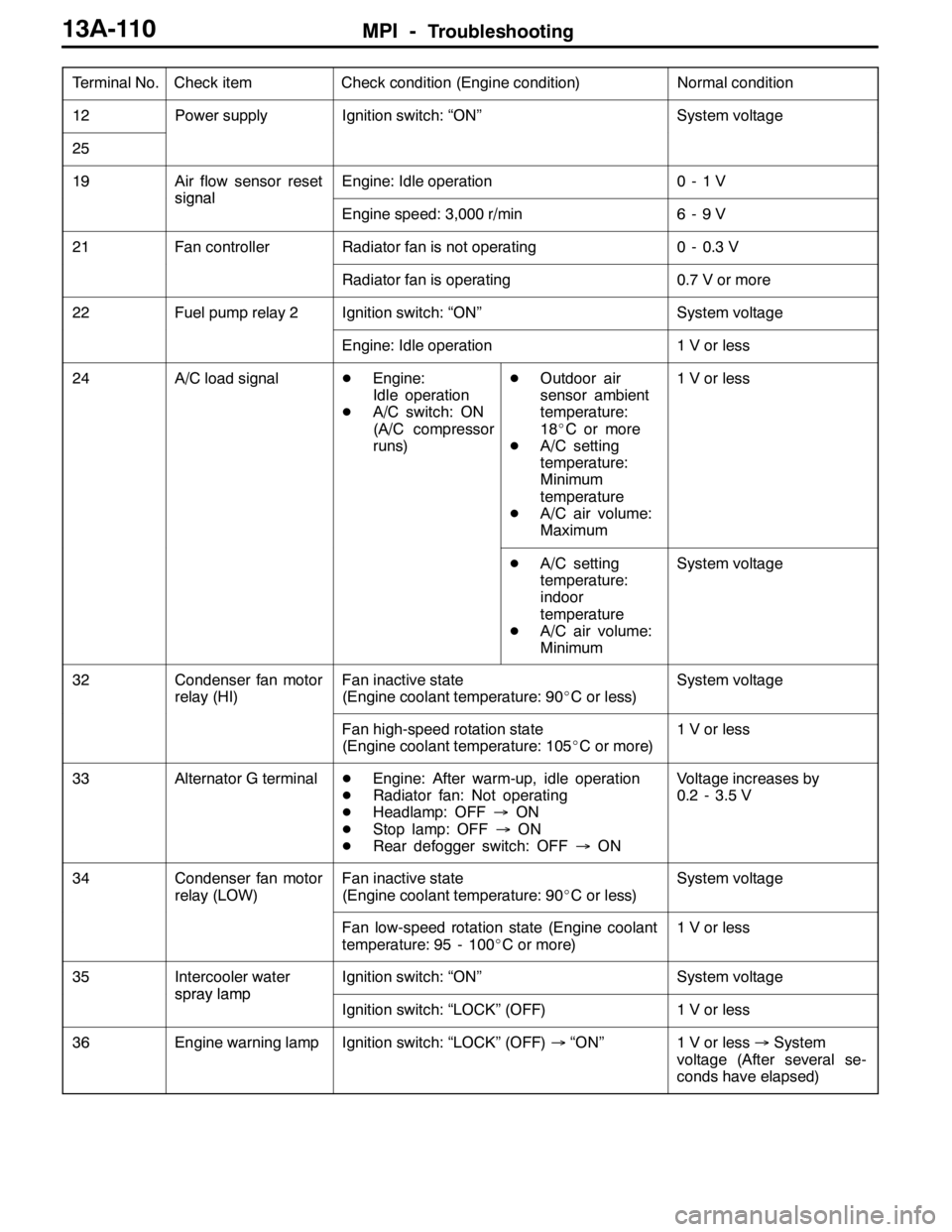

MPI -Troubleshooting13A-110

Terminal No.Normal condition Check condition (Engine condition) Check item

12Power supplyIgnition switch: “ON”System voltage

25

19Air flow sensor reset

signal

Engine: Idle operation0-1V

signal

Engine speed: 3,000 r/min6-9V

21Fan controllerRadiator fan is not operating0 - 0.3 V

Radiator fan is operating0.7 V or more

22Fuel pump relay 2Ignition switch: “ON”System voltage

Engine: Idle operation1 V or less

24A/C load signalDEngine:

Idle operation

DA/C switch: ON

(A/C compressor

runs)DOutdoor air

sensor ambient

temperature:

18_C or more

DA/C setting

temperature:

Minimum

temperature

DA/C air volume:

Maximum1 V or less

DA/C setting

temperature:

indoor

temperature

DA/C air volume:

MinimumSystem voltage

32Condenser fan motor

relay (HI)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan high-speed rotation state

(Engine coolant temperature: 105_C or more)1 V or less

33Alternator G terminalDEngine: After warm-up, idle operation

DRadiator fan: Not operating

DHeadlamp: OFF→ON

DStop lamp: OFF→ON

DRear defogger switch: OFF→ONVoltage increases by

0.2 - 3.5 V

34Condenser fan motor

relay (LOW)Fan inactive state

(Engine coolant temperature: 90_C or less)System voltage

Fan low-speed rotation state (Engine coolant

temperature: 95 - 100_C or more)1 V or less

35Intercooler water

spraylamp

Ignition switch: “ON”System voltage

spraylamp

Ignition switch: “LOCK” (OFF)1 V or less

36Engine warning lampIgnition switch: “LOCK” (OFF)→“ON”1 V or less→System

voltage (After several se-

conds have elapsed)

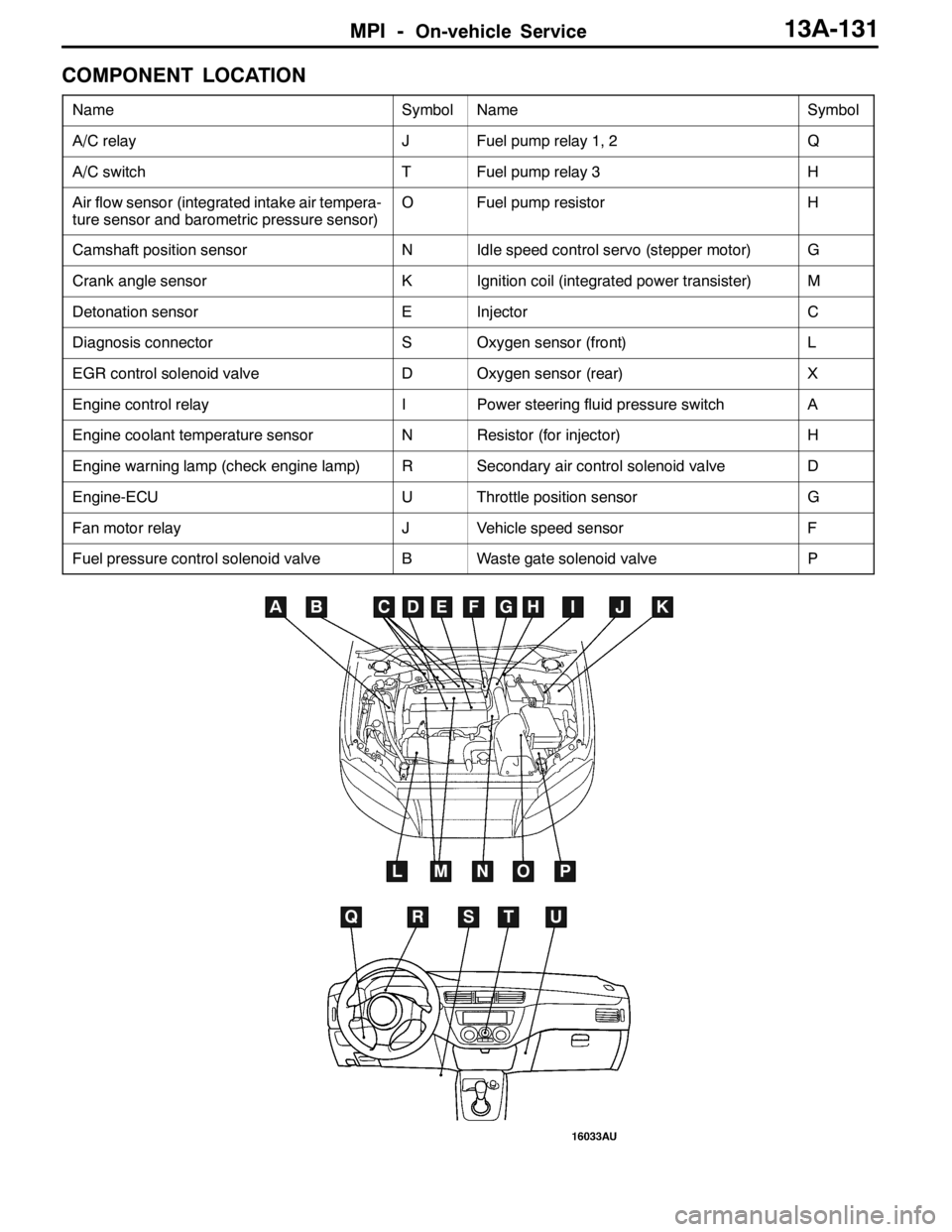

Page 663 of 1449

MPI -On-vehicle Service13A-131

COMPONENT LOCATION

NameSymbolNameSymbol

A/C relayJFuel pump relay 1, 2Q

A/C switchTFuel pump relay 3H

Air flow sensor (integrated intake air tempera-

ture sensor and barometric pressure sensor)OFuel pump resistorH

Camshaft position sensorNIdle speed control servo (stepper motor)G

Crank angle sensorKIgnition coil (integrated power transister)M

Detonation sensorEInjectorC

Diagnosis connectorSOxygen sensor (front)L

EGR control solenoid valveDOxygen sensor (rear)X

Engine control relayIPower steering fluid pressure switchA

Engine coolant temperature sensorNResistor (for injector)H

Engine warning lamp (check engine lamp)RSecondary air control solenoid valveD

Engine-ECUUThrottle position sensorG

Fan motor relayJVehicle speed sensorF

Fuel pressure control solenoid valveBWaste gate solenoid valveP

ABCDEFGHIJK

LMNOP

QRSTU

Page 734 of 1449

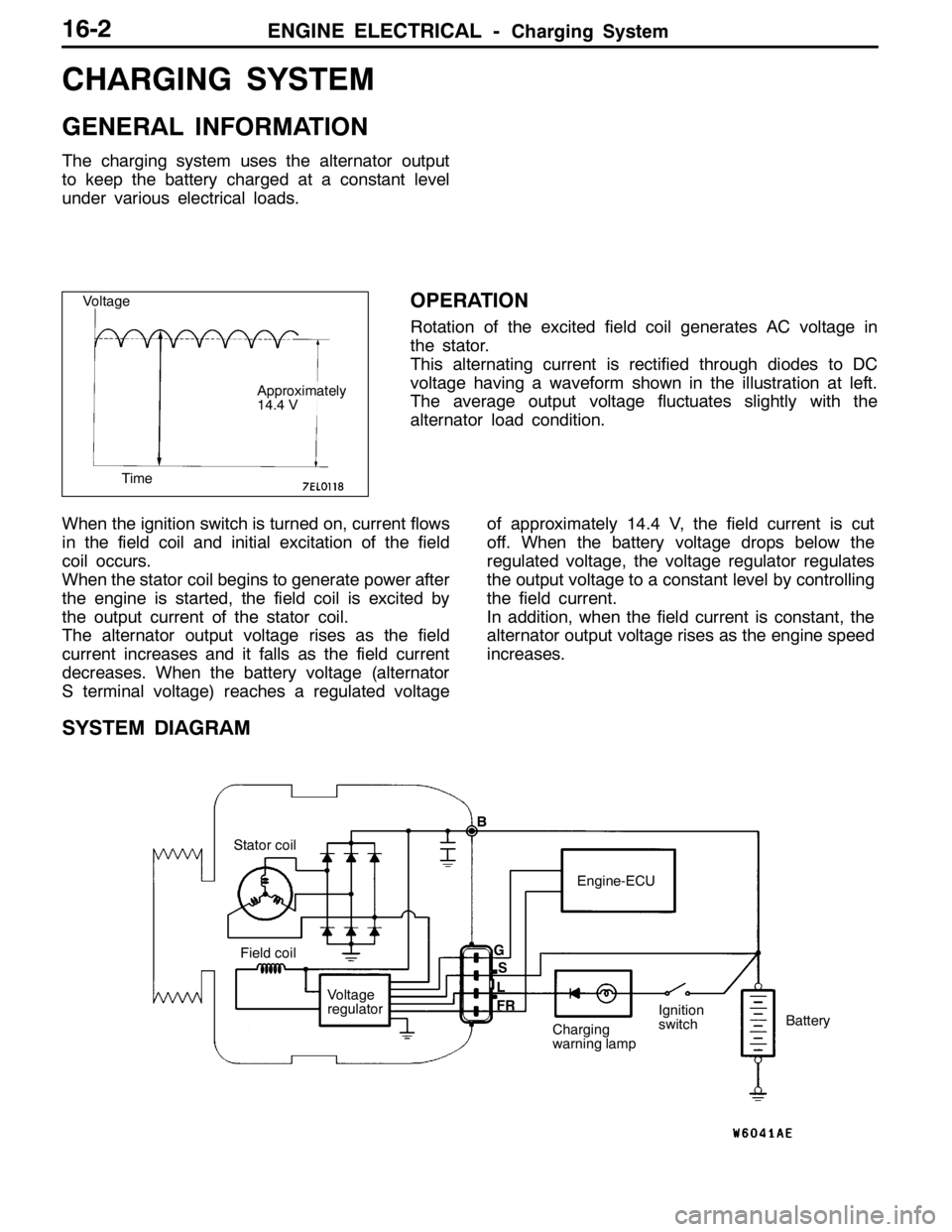

ENGINE ELECTRICAL -Charging System16-2

CHARGING SYSTEM

GENERAL INFORMATION

The charging system uses the alternator output

to keep the battery charged at a constant level

under various electrical loads.

OPERATION

Rotation of the excited field coil generates AC voltage in

the stator.

This alternating current is rectified through diodes to DC

voltage having a waveform shown in the illustration at left.

The average output voltage fluctuates slightly with the

alternator load condition.

When the ignition switch is turned on, current flows

in the field coil and initial excitation of the field

coil occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by

the output current of the stator coil.

The alternator output voltage rises as the field

current increases and it falls as the field current

decreases. When the battery voltage (alternator

S terminal voltage) reaches a regulated voltageof approximately 14.4 V, the field current is cut

off. When the battery voltage drops below the

regulated voltage, the voltage regulator regulates

the output voltage to a constant level by controlling

the field current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

SYSTEM DIAGRAM

Stator coil

Field coil

Voltage

regulatorEngine-ECU

Charging

warning lampIgnition

switchBattery B

G

L

FRS

Voltage

Time

Approximately

14.4 V

Page 737 of 1449

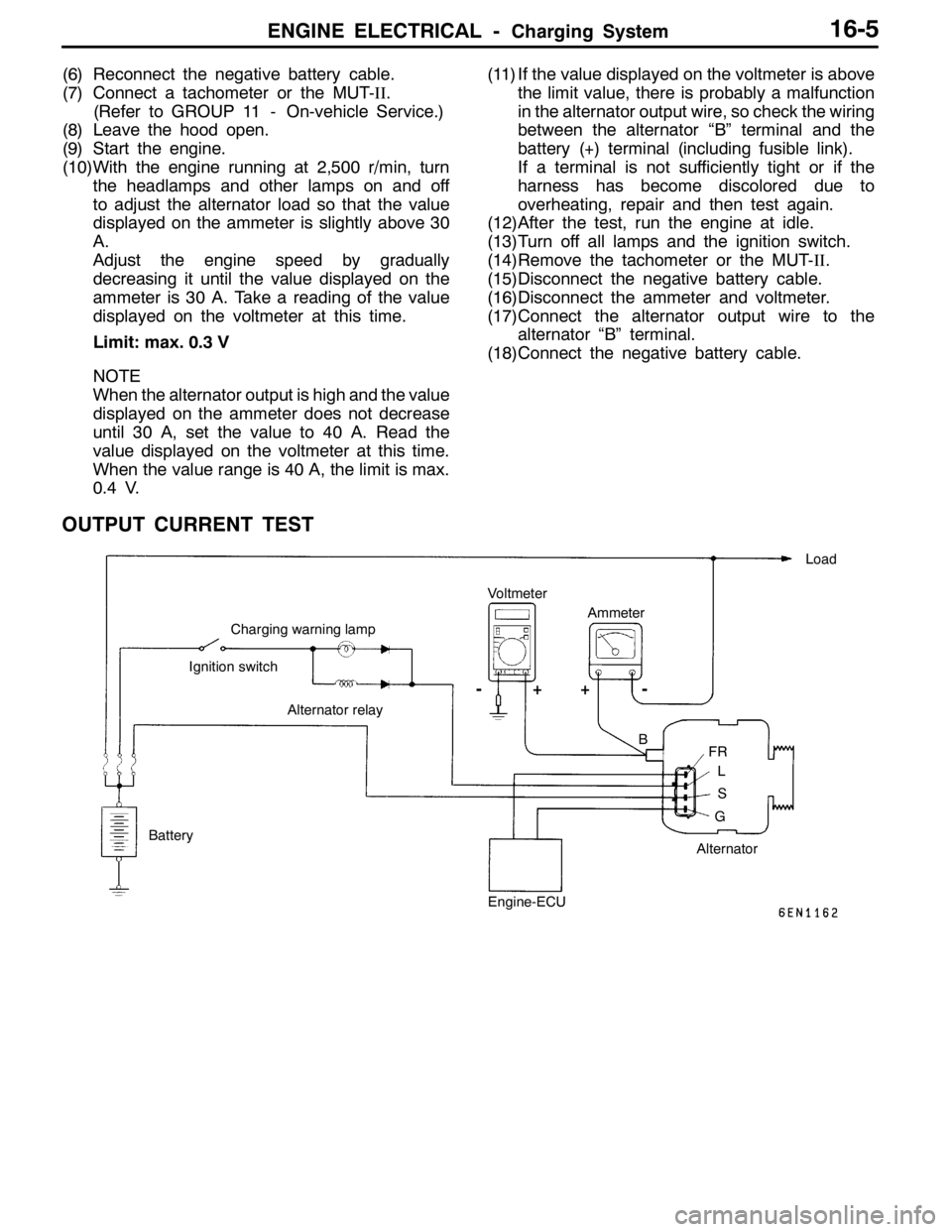

ENGINE ELECTRICAL -Charging System16-5

(6) Reconnect the negative battery cable.

(7) Connect a tachometer or the MUT-II.

(Refer to GROUP 11 - On-vehicle Service.)

(8) Leave the hood open.

(9) Start the engine.

(10)With the engine running at 2,500 r/min, turn

the headlamps and other lamps on and off

to adjust the alternator load so that the value

displayed on the ammeter is slightly above 30

A.

Adjust the engine speed by gradually

decreasing it until the value displayed on the

ammeter is 30 A. Take a reading of the value

displayed on the voltmeter at this time.

Limit: max. 0.3 V

NOTE

When the alternator output is high and the value

displayed on the ammeter does not decrease

until 30 A, set the value to 40 A. Read the

value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is max.

0.4 V.(11) If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction

in the alternator output wire, so check the wiring

between the alternator “B” terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

(12)After the test, run the engine at idle.

(13)Turn off all lamps and the ignition switch.

(14)Remove the tachometer or the MUT-II.

(15)Disconnect the negative battery cable.

(16)Disconnect the ammeter and voltmeter.

(17)Connect the alternator output wire to the

alternator “B” terminal.

(18)Connect the negative battery cable.

OUTPUT CURRENT TEST

Charging warning lampVoltmeter

Ammeter

Ignition switch

Alternator relayLoad

Battery

Engine-ECUAlternatorFR

L

S

G

+ -+-

B

Page 742 of 1449

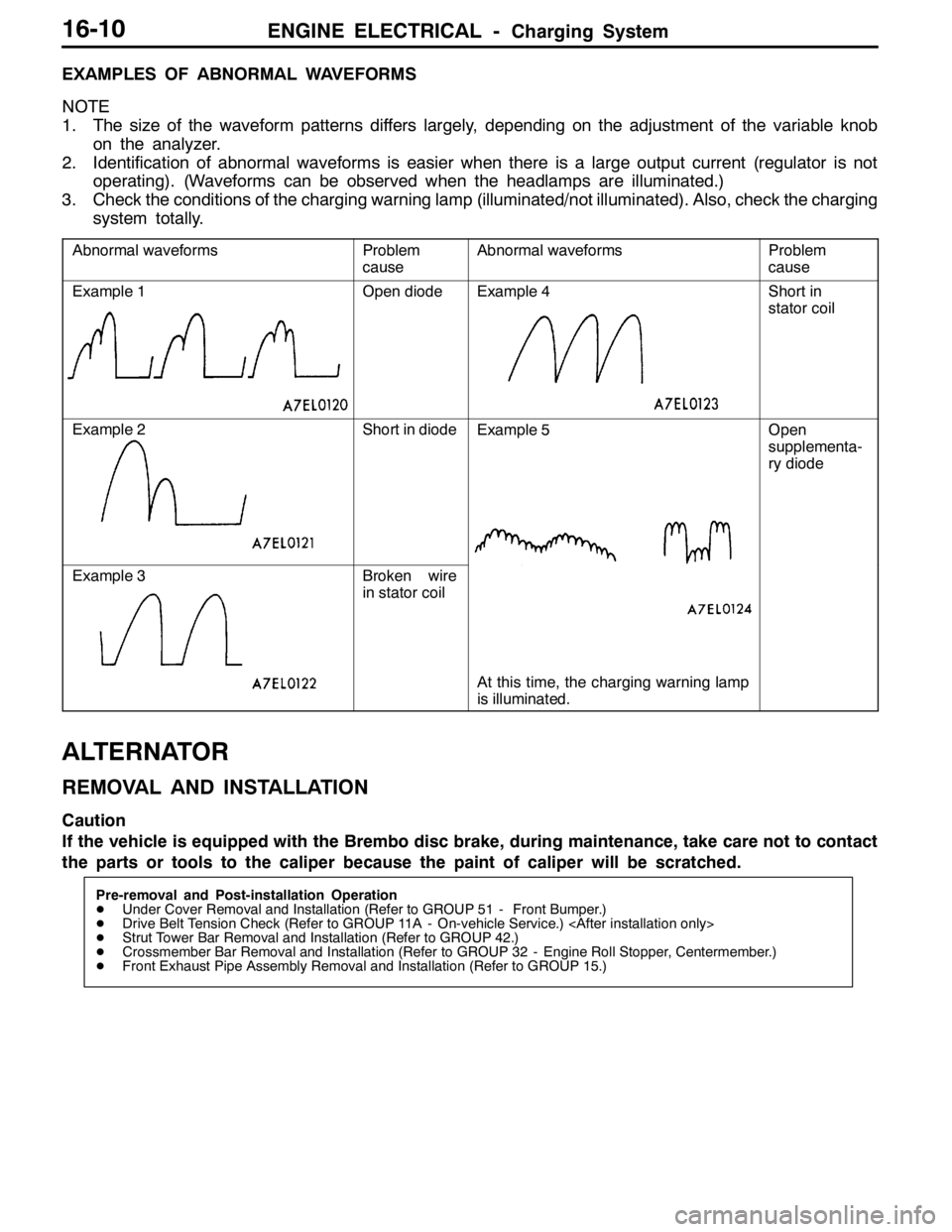

ENGINE ELECTRICAL -Charging System16-10

EXAMPLES OF ABNORMAL WAVEFORMS

NOTE

1. The size of the waveform patterns differs largely, depending on the adjustment of the variable knob

on the analyzer.

2. Identification of abnormal waveforms is easier when there is a large output current (regulator is not

operating). (Waveforms can be observed when the headlamps are illuminated.)

3. Check the conditions of the charging warning lamp (illuminated/not illuminated). Also, check the charging

system totally.

Abnormal waveformsProblem

causeAbnormal waveformsProblem

cause

Example 1Open diodeExample 4Short in

stator coil

Example 2Short in diodeExample 5Open

supplementa-

ry diode

Example 3Broken wire

in stator coil

At this time, the charging warning lamp

is illuminated.

ALTERNATOR

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DDrive Belt Tension Check (Refer to GROUP 11A - On-vehicle Service.)

DStrut Tower Bar Removal and Installation (Refer to GROUP 42.)

DCrossmember Bar Removal and Installation (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DFront Exhaust Pipe Assembly Removal and Installation (Refer to GROUP 15.)

Page 810 of 1449

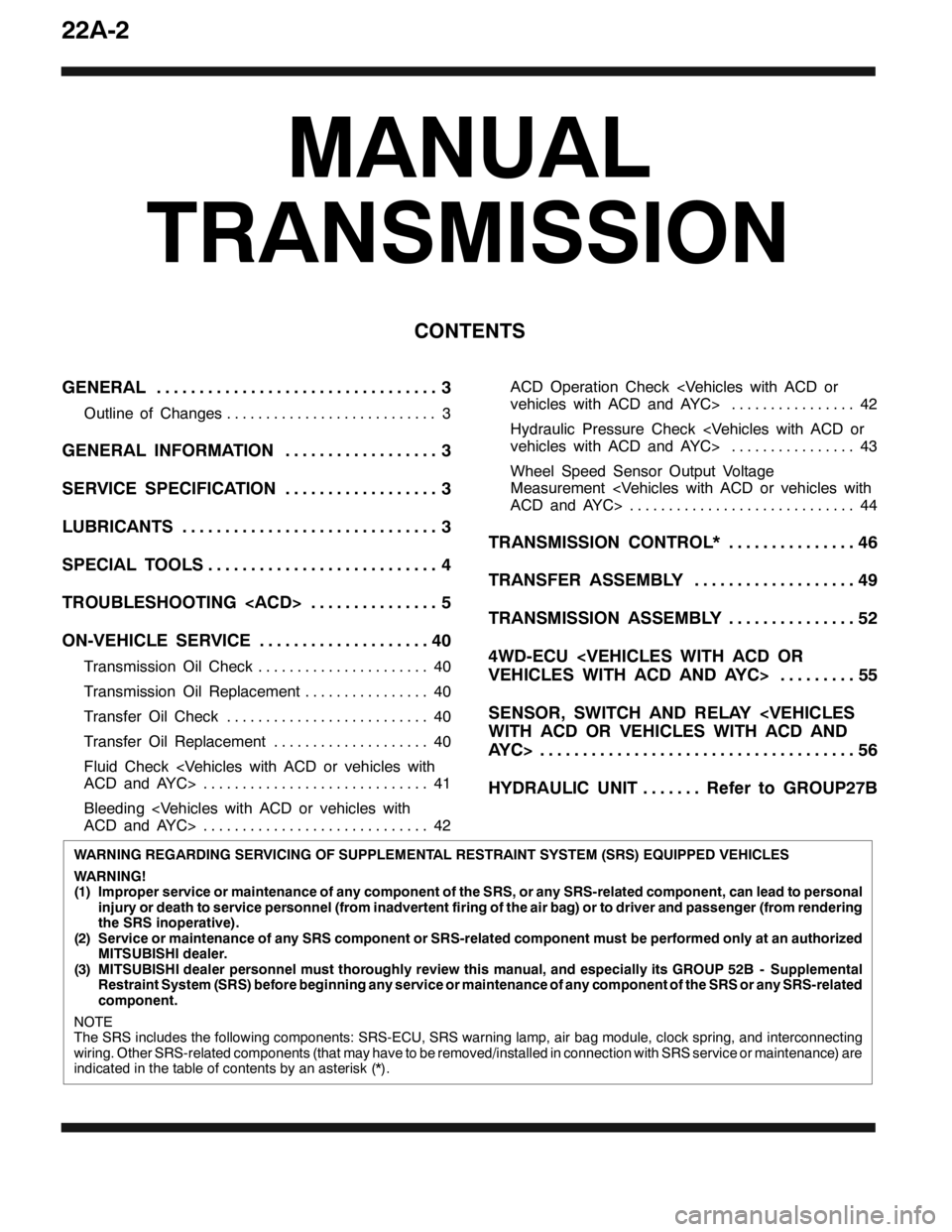

22A-2

MANUAL

TRANSMISSION

CONTENTS

GENERAL 3.................................

Outline of Changes 3...........................

GENERAL INFORMATION 3..................

SERVICE SPECIFICATION 3..................

LUBRICANTS 3..............................

SPECIAL TOOLS 4...........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 40....................

Transmission Oil Check 40......................

Transmission Oil Replacement 40................

Transfer Oil Check 40..........................

Transfer Oil Replacement 40....................

Fluid Check

Bleeding

Hydraulic Pressure Check

Wheel Speed Sensor Output Voltage

Measurement

TRANSMISSION CONTROL* 46...............

TRANSFER ASSEMBLY 49...................

TRANSMISSION ASSEMBLY 52...............

4WD-ECU

SENSOR, SWITCH AND RELAY

AYC> 56.....................................

HYDRAULIC UNIT Refer to GROUP27B.......

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 819 of 1449

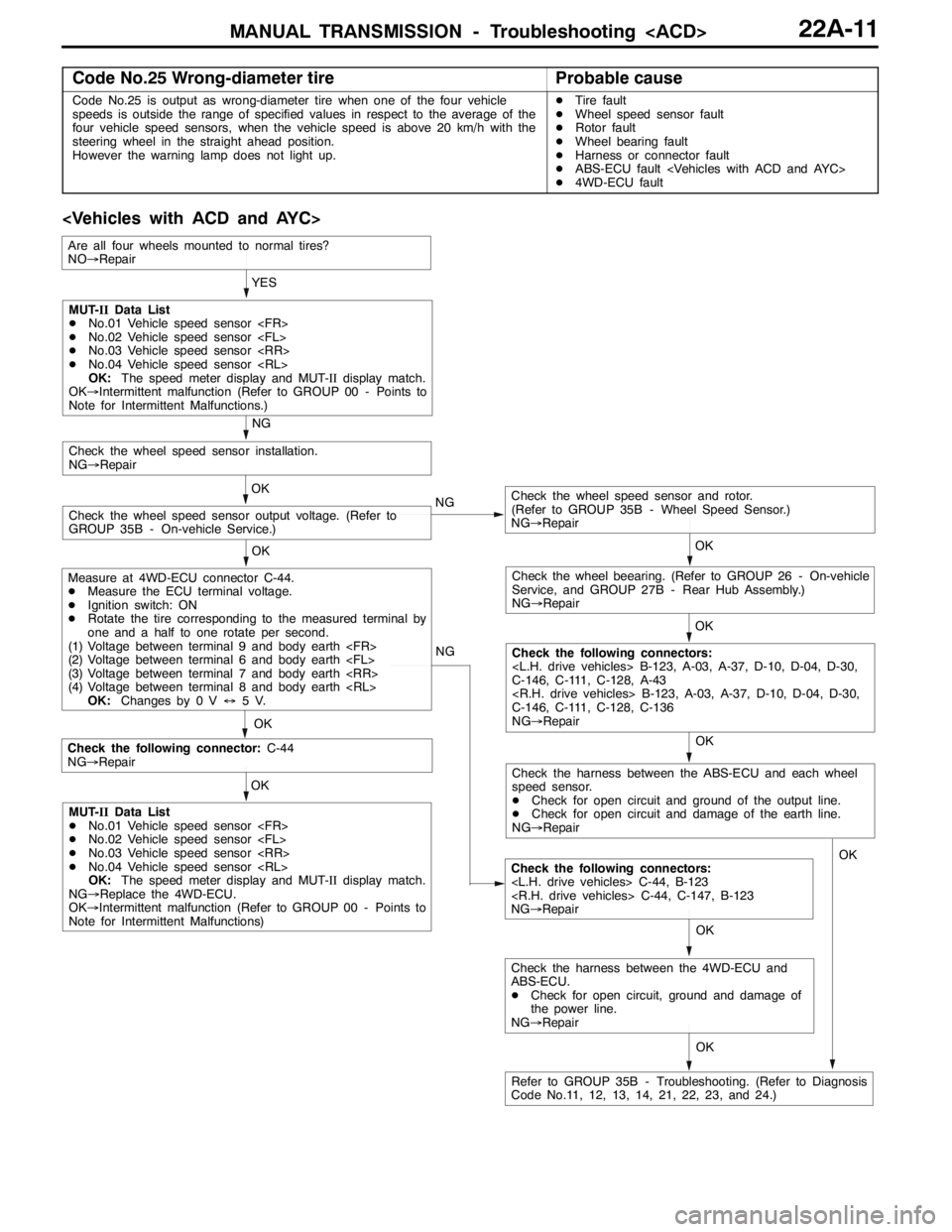

MANUAL TRANSMISSION - Troubleshooting

Code No.25 Wrong-diameter tireProbable cause

Code No.25 is output as wrong-diameter tire when one of the four vehicle

speeds is outside the range of specified values in respect to the average of the

four vehicle speed sensors, when the vehicle speed is above 20 km/h with the

steering wheel in the straight ahead position.

However the warning lamp does not light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OKYES

OK

OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→Repair

Check the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the wheel speed sensor installation.

NG→Repair

NG

OK

Check the wheel beearing. (Refer to GROUP 26 - On-vehicle

Service, and GROUP 27B - Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Measure at 4WD-ECU connector C-44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes by 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Refer to GROUP 35B - Troubleshooting. (Refer to Diagnosis

Code No.11, 12, 13, 14, 21, 22, 23, and 24.)

Are all four wheels mounted to normal tires?

NO→Repair

Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit and ground of the output line.

DCheck for open circuit and damage of the earth line.

NG→Repair

OK

Check the harness between the 4WD-ECU and

ABS-ECU.

DCheck for open circuit, ground and damage of

the power line.

NG→RepairOK

Page 821 of 1449

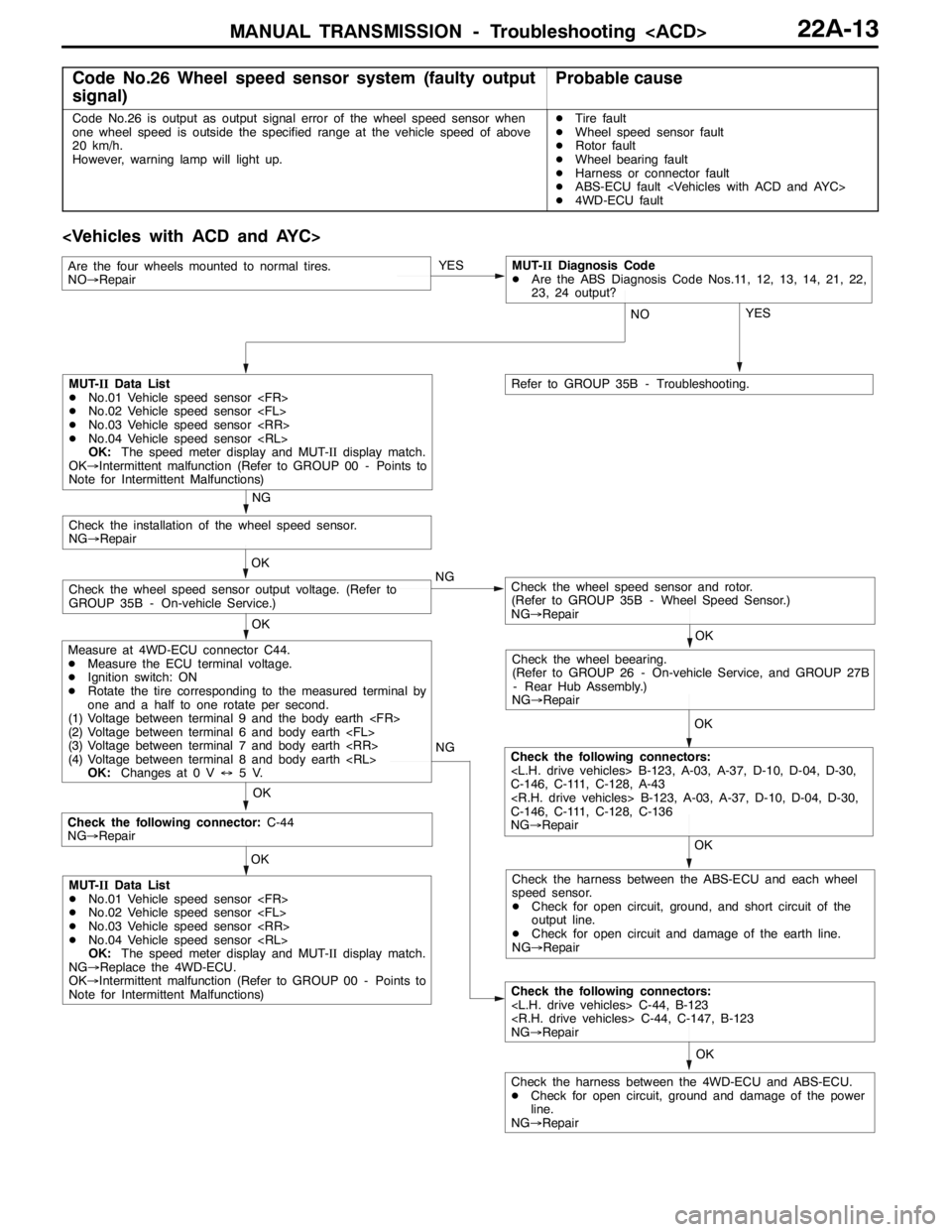

MANUAL TRANSMISSION - Troubleshooting

Code No.26 Wheel speed sensor system (faulty output

signal)Probable cause

Code No.26 is output as output signal error of the wheel speed sensor when

one wheel speed is outside the specified range at the vehicle speed of above

20 km/h.

However, warning lamp will light up.DTire fault

DWheel speed sensor fault

DRotor fault

DWheel bearing fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK NG

OK

Check the following connector:C-44

NG→Repair

Check the following connectors:

NG→Repair OK

Check the harness between the 4WD-ECU and ABS-ECU.

DCheck for open circuit, ground and damage of the power

line.

NG→RepairYES

OK OK

Check the wheel speed sensor and rotor.

(Refer to GROUP 35B - Wheel Speed Sensor.)

NG→RepairCheck the wheel speed sensor output voltage. (Refer to

GROUP 35B - On-vehicle Service.)OK

Check the installation of the wheel speed sensor.

NG→Repair

NG

OK

Check the wheel beearing.

(Refer to GROUP 26 - On-vehicle Service, and GROUP 27B

- Rear Hub Assembly.)

NG→Repair

OK

Check the following connectors:

C-146, C-111, C-128, A-43

C-146, C-111, C-128, C-136

NG→Repair NG

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)

Measure at 4WD-ECU connector C44.

DMeasure the ECU terminal voltage.

DIgnition switch: ON

DRotate the tire corresponding to the measured terminal by

one and a half to one rotate per second.

(1) Voltage between terminal 9 and the body earth

(2) Voltage between terminal 6 and body earth

(3) Voltage between terminal 7 and body earth

(4) Voltage between terminal 8 and body earth

OK:Changes at 0 V↔5V.

MUT-IIData List

DNo.01 Vehicle speed sensor

DNo.02 Vehicle speed sensor

DNo.03 Vehicle speed sensor

DNo.04 Vehicle speed sensor

OK:The speed meter display and MUT-IIdisplay match.

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions)Check the harness between the ABS-ECU and each wheel

speed sensor.

DCheck for open circuit, ground, and short circuit of the

output line.

DCheck for open circuit and damage of the earth line.

NG→Repair YES

NO

Refer to GROUP 35B - Troubleshooting.

Are the four wheels mounted to normal tires.

NO→RepairMUT-IIDiagnosis Code

DAre the ABS Diagnosis Code Nos.11, 12, 13, 14, 21, 22,

23, 24 output?

Page 835 of 1449

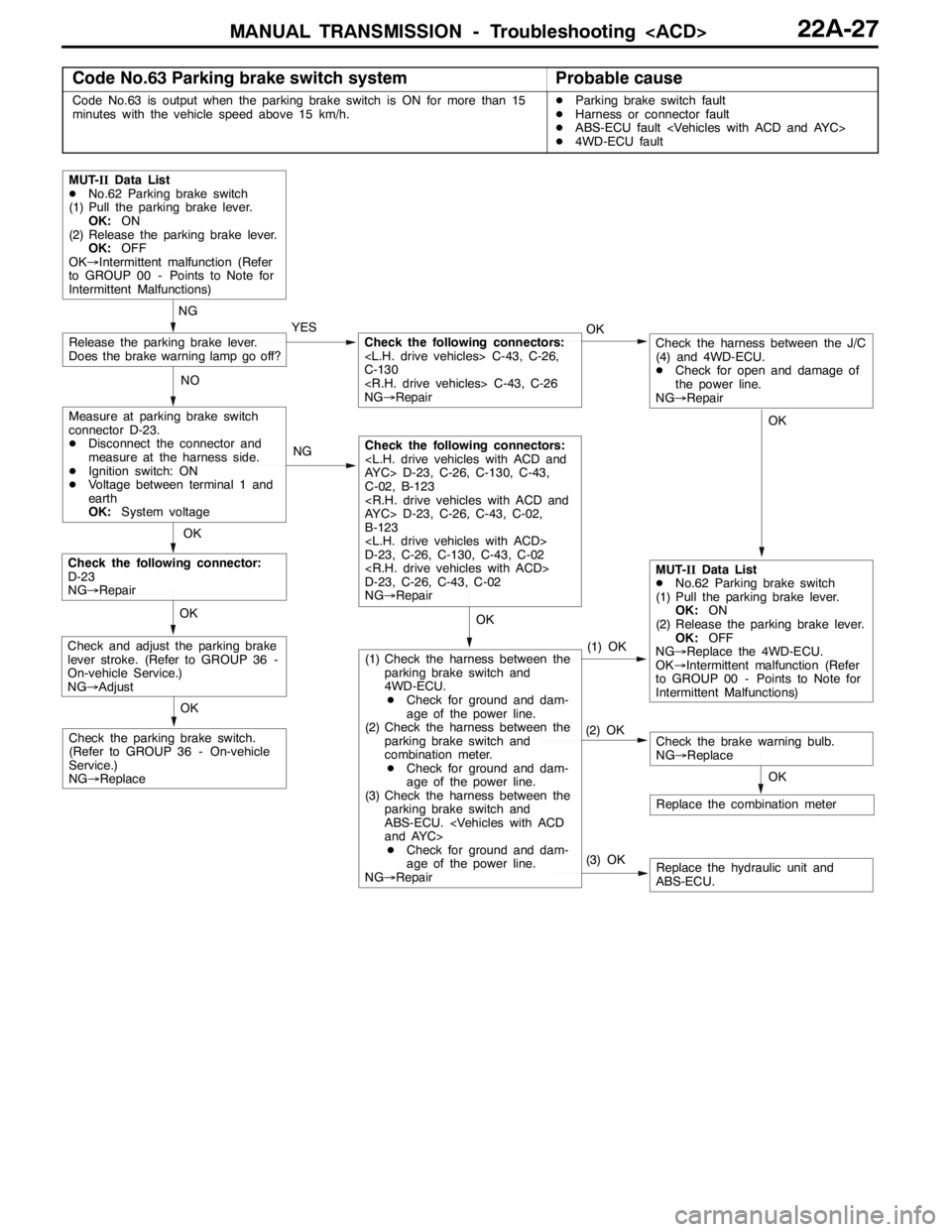

MANUAL TRANSMISSION - Troubleshooting

Code No.63 Parking brake switch systemProbable cause

Code No.63 is output when the parking brake switch is ON for more than 15

minutes with the vehicle speed above 15 km/h.DParking brake switch fault

DHarness or connector fault

DABS-ECU fault

D4WD-ECU fault

OK

NG

YES

NG

(3) OK(1) OKReplace the hydraulic unit and

ABS-ECU.

MUT-IIData List

DNo.62 Parking brake switch

(1) Pull the parking brake lever.

OK:ON

(2) Release the parking brake lever.

OK:OFF

OK→Intermittent malfunction (Refer

to GROUP 00 - Points to Note for

Intermittent Malfunctions)

Measure at parking brake switch

connector D-23.

DDisconnect the connector and

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal 1 and

earth

OK:System voltage

Release the parking brake lever.

Does the brake warning lamp go off?

OK

Check the following connector:

D-23

NG→Repair

OK

Replace the combination meter

OK

Check the brake warning bulb.

NG→ReplaceCheck the parking brake switch.

(Refer to GROUP 36 - On-vehicle

Service.)

NG→Replace

OK

Check and adjust the parking brake

lever stroke. (Refer to GROUP 36 -

On-vehicle Service.)

NG→Adjust

MUT-IIData List

DNo.62 Parking brake switch

(1) Pull the parking brake lever.

OK:ON

(2) Release the parking brake lever.

OK:OFF

NG→Replace the 4WD-ECU.

OK→Intermittent malfunction (Refer

to GROUP 00 - Points to Note for

Intermittent Malfunctions) NOOK

Check the following connectors:

C-130

NG→Repair

Check the following connectors:

C-02, B-123

B-123

D-23, C-26, C-130, C-43, C-02

D-23, C-26, C-43, C-02

NG→Repair

(2) OK

(1) Check the harness between the

parking brake switch and

4WD-ECU.

DCheck for ground and dam-

age of the power line.

(2) Check the harness between the

parking brake switch and

combination meter.

DCheck for ground and dam-

age of the power line.

(3) Check the harness between the

parking brake switch and

ABS-ECU.

DCheck for ground and dam-

age of the power line.

NG→Repair

OK

Check the harness between the J/C

(4) and 4WD-ECU.

DCheck for open and damage of

the power line.

NG→Repair