engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1336 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-16

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection procedure 1

Speedometer inoperative (other meters are operated)

Probable cause

Failure may occur on engine-ECU system, harnesses, connectors, meter

assembly.DEngine-ECU fault

DHarness or connector fault

DMeter assembly fault

NO

MUT-IISelf-Diag. Code

Is diagnostic code P0500 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting)

OK

NG

Check the following connectors:

Repair

OK

Check trouble symptom.

NG

NG

RepairCheck harnesses:

DCombination meter to engine-ECU.

Check trouble symptom.

NG

Replace meter assembly.

OK

Check for input signal from ETACS-ECU with MUT-II

DVehicle speed signal (engine-ECU)NGReplace engine-ECU

NOTE

When vehicle speed signal is checked with MUT-IIin the ETACS-ECU input signal test, drive the vehicle

with MUT-IIconnected to diagnostic connector. When the buzzer sounds, this test is evaluated OK.

Inspection procedure 2

Tachometer inoperative (other meters are operated)

Probable cause

No input of ignition signal from engine, or failure may occur on power and earth

circuits of meter.DHarness or connector fault

DMeter assembly fault

OK

NO

MUT-IISelf-Diag. Code

Is DTC P0300 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting.)

NG

NG

RepairRepair

Check trouble symptom.

OK

Check the following connectors:

Replace meter assembly.Check harnesses:

DCombination meter to engine-ECU

Page 1340 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-20

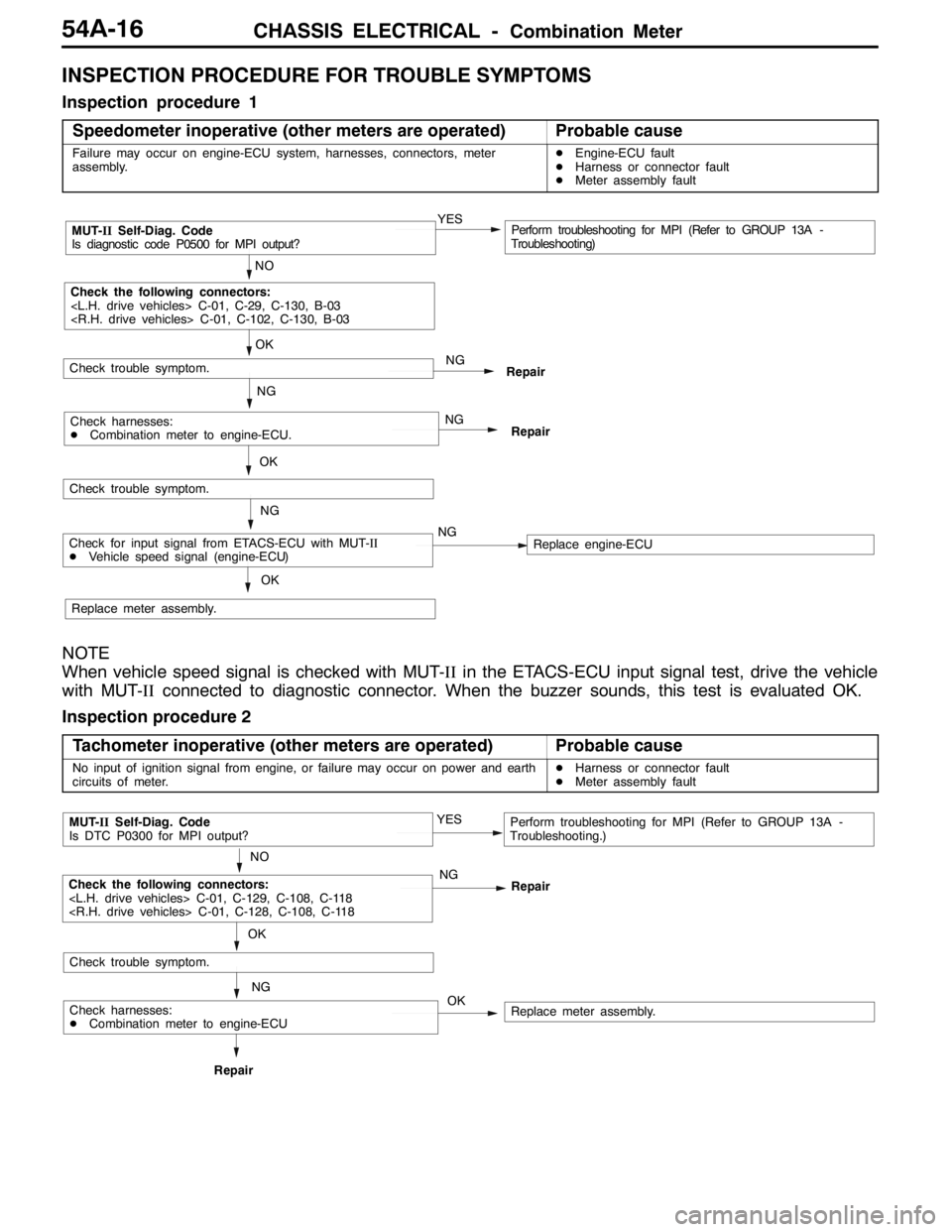

TACHOMETER CHECK

1. Insert paper clip (Zem clip) from harness side of the probe

for detection of engine speed to connect engine speed

indicator.

2. Compare measured values of individual engine speed

with tachometer values, and ensure that indication

allowance is within standard value.

Standard value:

Engine speed (rpm)Indication allowance of tachometer

rpm

700±70

2,000- 100 +150

3,000- 100 +225

4,000- 125 +275

5,000- 125 +325

6,000- 125 +375

7,000- 100 +400

8,000+400

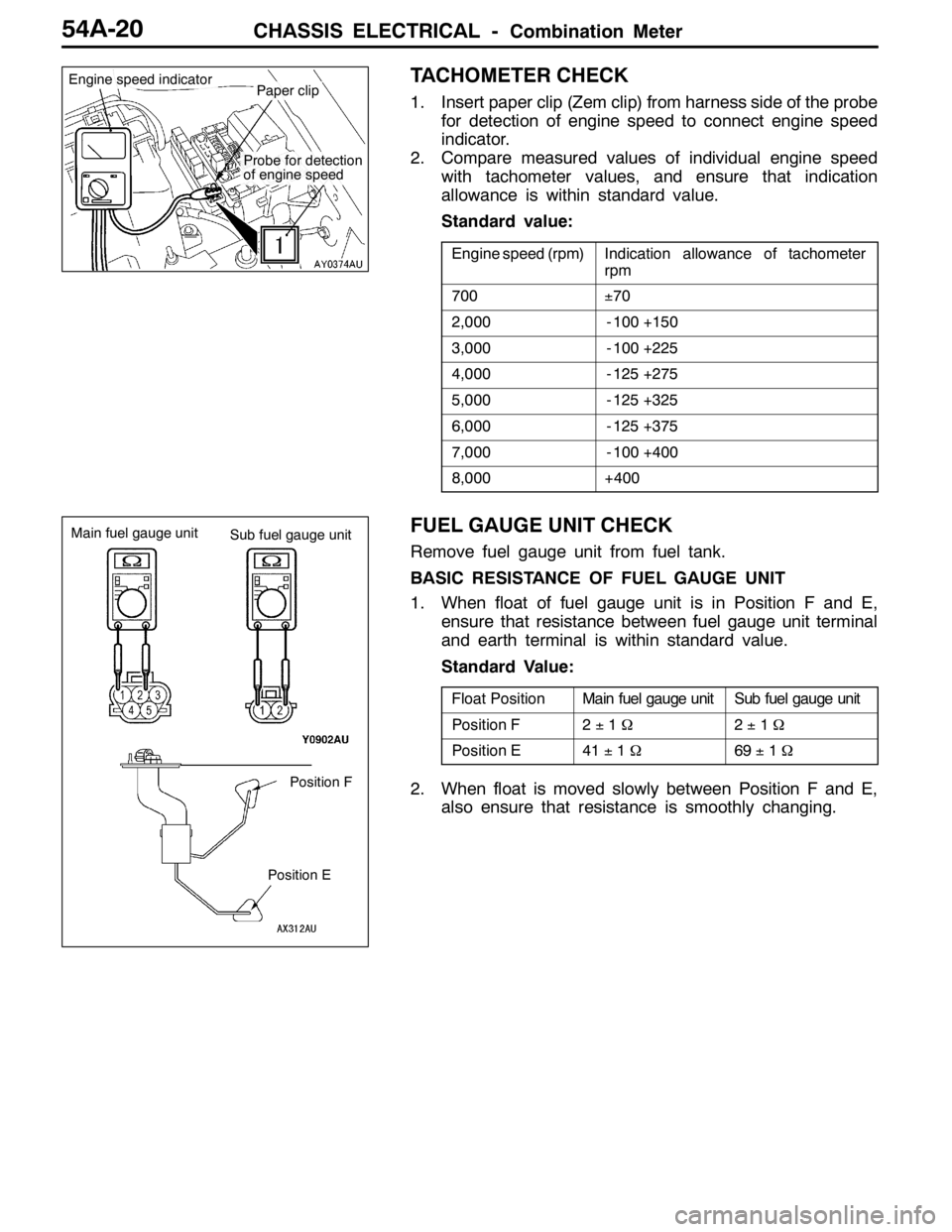

FUEL GAUGE UNIT CHECK

Remove fuel gauge unit from fuel tank.

BASIC RESISTANCE OF FUEL GAUGE UNIT

1. When float of fuel gauge unit is in Position F and E,

ensure that resistance between fuel gauge unit terminal

and earth terminal is within standard value.

Standard Value:

Float PositionMain fuel gauge unitSub fuel gauge unit

Position F2±1Ω2±1Ω

Position E41±1Ω69±1Ω

2. When float is moved slowly between Position F and E,

also ensure that resistance is smoothly changing.

Paper clipEngine speed indicator

Probe for detection

of engine speed

Position F

Position E Main fuel gauge unit

Sub fuel gauge unit

Page 1341 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-21

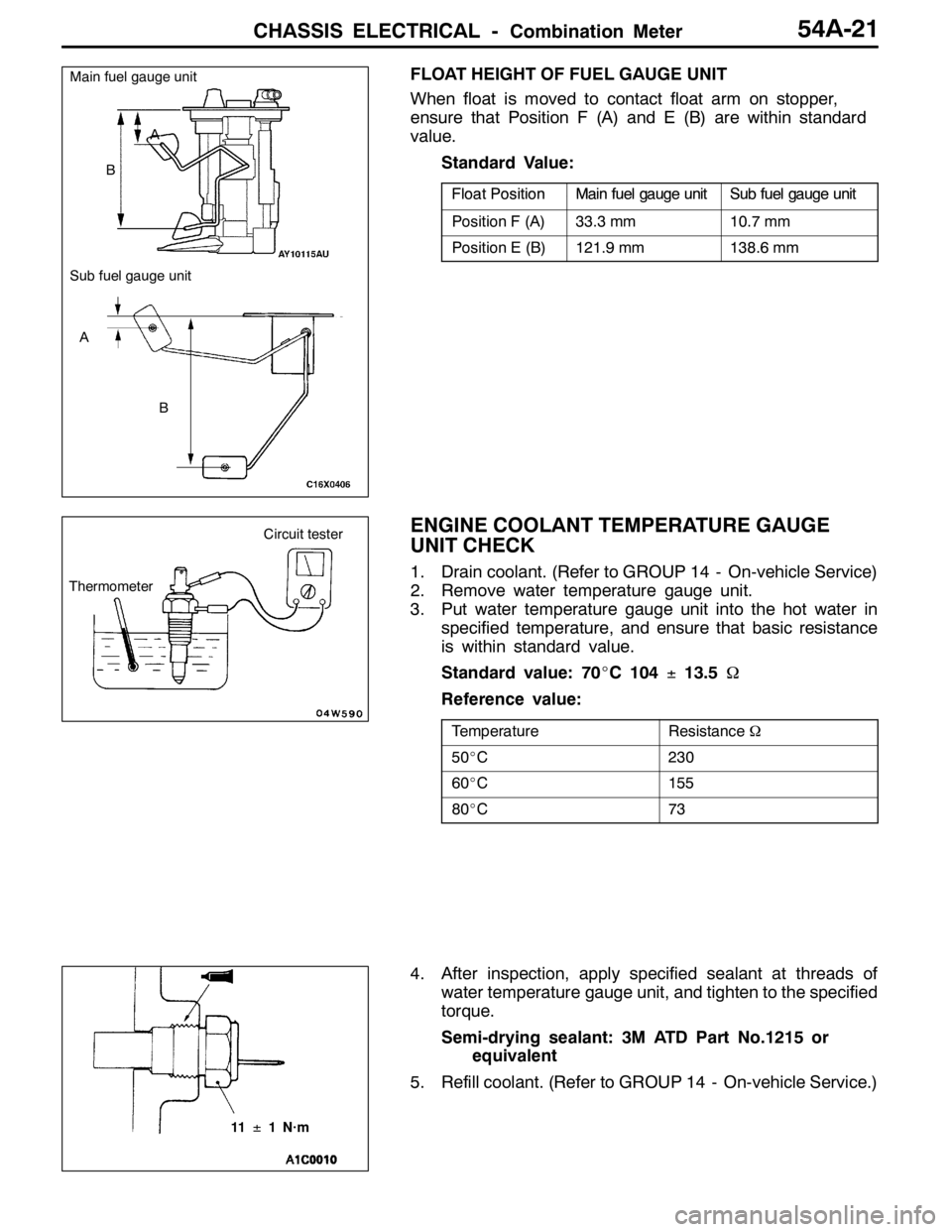

FLOAT HEIGHT OF FUEL GAUGE UNIT

When float is moved to contact float arm on stopper,

ensure that Position F (A) and E (B) are within standard

value.

Standard Value:

FloatPositionMainfuelgaugeunitSubfuelgaugeunitFloatPositionMainfuelgaugeunitSubfuelgaugeunit

Position F (A)33.3 mm10.7 mm

Position E (B)121.9 mm138.6 mm

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK

1. Drain coolant. (Refer to GROUP 14 - On-vehicle Service)

2. Remove water temperature gauge unit.

3. Put water temperature gauge unit into the hot water in

specified temperature, and ensure that basic resistance

is within standard value.

Standard value: 70_C 104±13.5Ω

Reference value:

TemperatureResistanceΩ

50_C230

60_C155

80_C73

4. After inspection, apply specified sealant at threads of

water temperature gauge unit, and tighten to the specified

torque.

Semi-drying sealant: 3M ATD Part No.1215 or

equivalent

5. Refill coolant. (Refer to GROUP 14 - On-vehicle Service.)

Main fuel gauge unit

Sub fuel gauge unit

A

B

A

B

ThermometerCircuit tester

11±1 N·m

Page 1348 of 1449

CHASSIS ELECTRICAL -Headlamp Assembly54A-28

HEADLAMP INTENSITY MEASUREMENT

1. Using a photometer, and following its manufacture’s

instruction manual.

2. Maintain an engine speed of 2,000 r/min., with the battery

in the charging condition

3. Set the headlamps to high beam

4. Measure the headlamp centre intensity (a point of H line

and V line) and check to be sure that the limit value

is satisfied.

Limit:

High beam 30,000 cd or more per one headlamp

NOTE

1. There may be special local regulations pertaining to

headlamp intensity, be sure to make any adjustments

necessary to satisfy such regulations.

2. If an illuminometer is used to make the measurements,

convert its values to photometer values by using the

following formula.

I=Er

2Where:

I=intensity (cd)

E=illumination (lux)

r=distance (m) from headlamps to illuminometer

Caution

1. On the headlamp not yet adjusted, perform aiming

with connector removed and the lamps switched off,

if applicable. In addition, care should be taken to

prevent a change of optical axis when connector is

reconnected.

2. Plastic outer lens are equipped with headlamps. When

lens surface is covered with materials for not

penetrating light, headlamp operation time should be

within 3 minutes. In addition, masking such as taping

should not be performed.

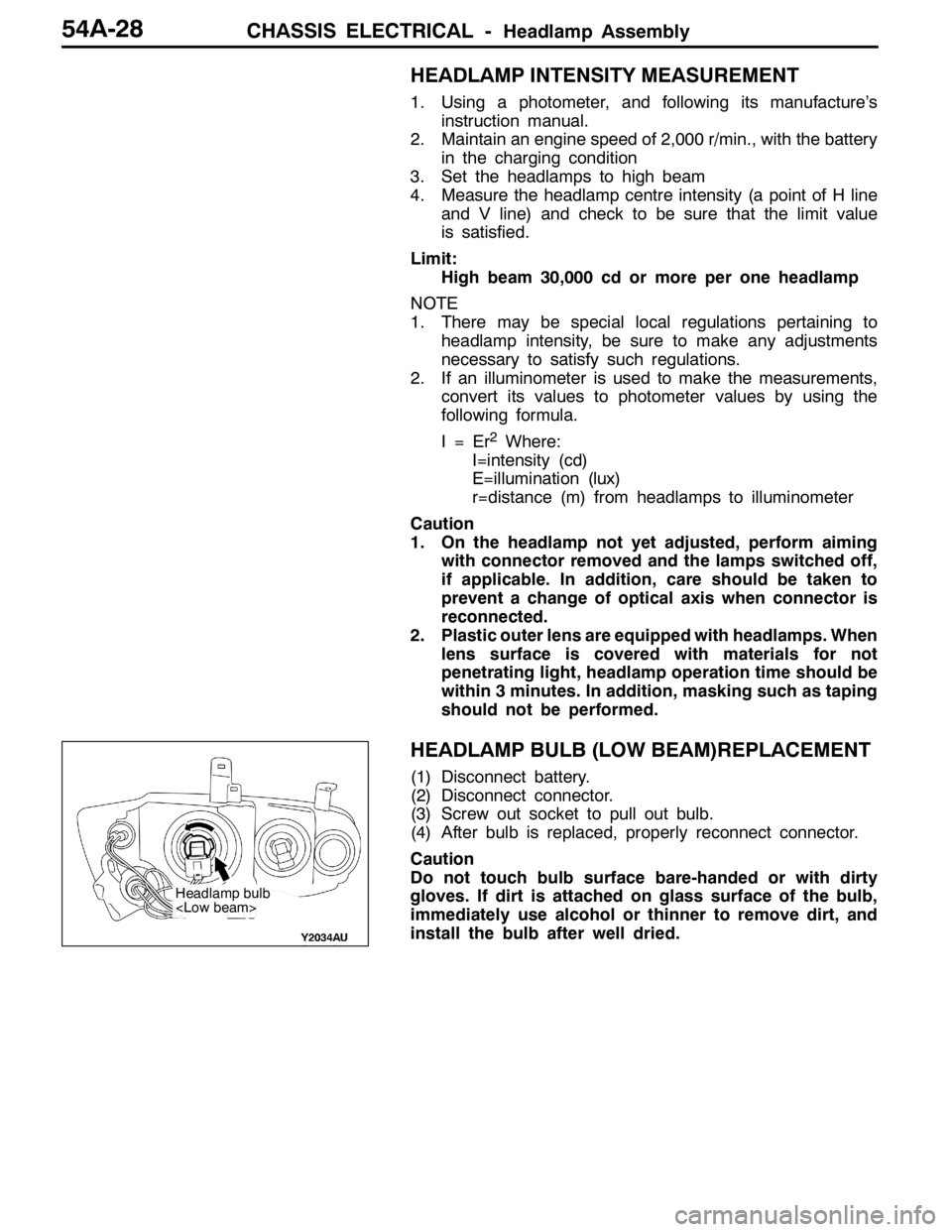

HEADLAMP BULB (LOW BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

Headlamp bulb

Page 1363 of 1449

CHASSIS ELECTRICAL -Defogger54A-43

ON-VEHICLE SERVICE

PRINTED HEATER CHECK

(1) With engine running at 2,000 rpm and battery in charging

mode, check print heater for normal operation.

(2) With defogger switch in “ON” position, use circuit tester

to measure voltage of individual print heaters at the center

point A of rear window glass. When the tester indicates

approx. 6V, the print heater is evaluated normal.

(3) When the measured value at Position A is 12V, open

circuit occurs between Position A and minus terminal.

In this case, carefully move test bar to minus terminal

side to detect a rapid voltage drop point (0V). This voltage

drop point indicates open circuit section.

(4) When voltage at Position A is 0V, open circuit occurs

between Position A and plus terminal. According to the

previous step, detect a rapid voltage increase point (12V).

DEFOGGER RELAY CONTINUITY CHECK

Battery voltageTerminal No.yg

1345

De-energized

Energized

DEFOGGER SWITCH

REMOVAL, INSTALLATION AND CHECK

Refer to GROUP 55 - Heater Control Assembly, A/C Switch

and Fresh/Recirculated Air Switch.

(–) Terminal

(–) Terminal

A (Mid point): Approx. 6 V

Normal characteristics of print heater

Abnormal characteristics of print heater

Voltage

Voltage

(+) Terminal

(+) Terminal

Print heater length

Print heater length

Open section

Defogger relay

04Z0001

\

Page 1409 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-7

Inspection procedure 5

Cold air not coming out from the air outlet

Probable cause

If cold air does not come out from the air outlet, the amount of refrigerant may

be inappropriate or the compressor circuit system may be defective.DRefrigerant line fault

DAmount of refrigerant fault

DCompressor fault

DCompressor relay fault

DDual pressure switch fault

DEngine-ECUfault

DA/C-ECU fault

OK

NG

Repair

NG

Check the harness between the A/C compressor relay and the

ignition switch (IG2), and repair if necessary.

OK

Check the trouble

symptoms.

Check the following connectors:

Repair

Check the following connectors:

OK

OK

Check the trouble

symptoms.

NG

OK

NG

Replace

OK

OK

OK

NG

Check the harness between the battery and the A/C

compressor relay., and repair if necessary.

OK

Check the trouble

symptoms.

Check the following connectors:

RepairNG

(2) NG

OK

Check the dual pressure switch.

OK

NG

Repair

Check the harness between the A/Compressor relay and the

A/Compressor.

NG

Repair

Check the following connectors:B-12X, C-126.

OK

Check the trouble

symptoms.

NG

OKNG

Repair

Check the harness between the A/Compressor relay and the

Engine-ECU.

To the next page

Check refrigerant for leakage.

NG

Replace

NG

Replace

NG

NG

Replace

Check the amount of refrigerant.

Check the compressor relay.

Check the compressor magnetic clutch.

Check the refrigerant temperature switch.

Measure at the compressor relay B-12X.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

(1) Voltage between terminal 1 and body earth.

OK :Battery voltage

(2) Continuity between terminal 2 and body earth.

OK :Battery voltage

Refer to Inspection procedure 6 magnet clutch not working

normally.

Page 1410 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-8

Repair

Repair

NG

Replace the A/C-ECU .

Replace the Engine-ECU .

NG

Repair

Check the following connectors:

OK

Check the trouble

symptoms.

NG

OKNG

Check the harness between the dual pressure switch and the

Engine-ECU.

Check the following connectors:C-32, C-111, A-36.

OK

NG

OKNG

Check the harness between the dual pressure switch and the

A/C-ECU.

From the previous page

Check the trouble

symptoms.RepairNG

Inspection procedure 6

Magnet clutch not working normally

Probable cause

If the magnet clutch does not work normally, the field core or the compressor

may be defective.DCompressor fault

DField core fault

Replace the field core.

Is not the Compressor locked ?NGReplace the compressor and field core.

No

Page 1411 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-9

Inspection procedure 7

Condenser fan not working at all

Probable cause

If the condenser fan does not work at all, the condenser fan circuit system may

be defective.DCondenser fan motor fault

DHarness or connector fault

DEngine-ECU fault

NG

Check the harness betweenthe condenser fan relay (LO) and

the ignition switch (IG2) , and repair if necessary.

OK

Check the trouble

symptoms.

NG

Repair

NG

Replace

OK

Check the condenser fan motor. (Refer to P.55-40.)

NGCheck the following connectors:A-06X, C-135, C-102,

C-209, C-210.

OK

Measure at the condenser fan relay (LO) A-06X.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 2 and body earth.

OK :Battery voltage

NG

Check the harness betweenthe condenser fan motor and body

earth, and repair if necessary.

OK

Check the trouble

symptoms.Repair

NGCheck the following connectors:A-46.

NG

OK

Measure at the condenser fan motor A-46.

DDisconnect the connector and measure at the harness

side.

DContinuity between terminal 2 and body earth

OK :Continuity

NG

OK

Check the trouble

symptoms.RepairNG

Check the following connectors:

Replace the Engine-ECU.

OK

RepairNG

Check the harness betweenthe condenser fan relay (LO) and

the Engine-ECU.

Page 1412 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-10

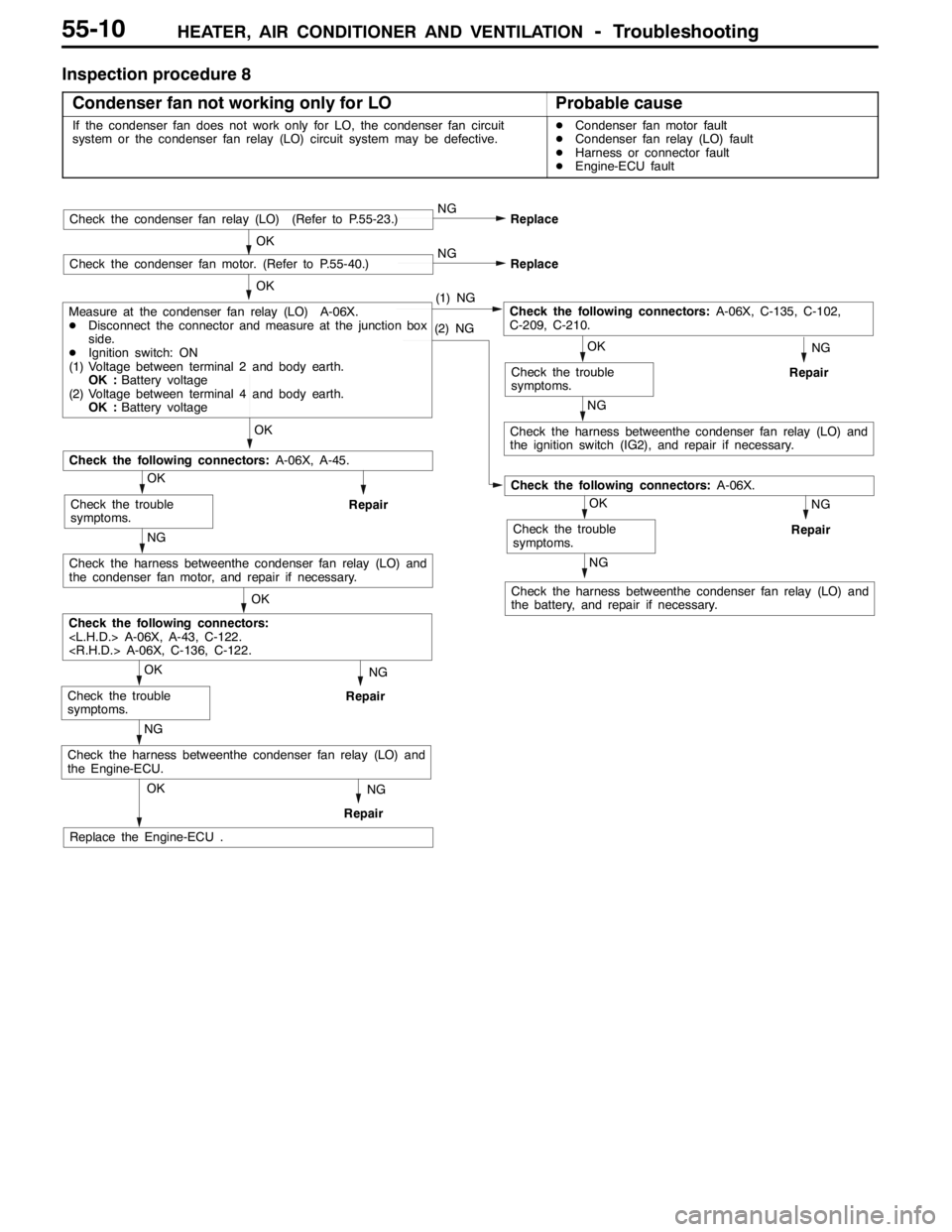

Inspection procedure 8

Condenser fan not working only for LO

Probable cause

If the condenser fan does not work only for LO, the condenser fan circuit

system or the condenser fan relay (LO) circuit system may be defective.DCondenser fan motor fault

DCondenser fan relay (LO) fault

DHarness or connector fault

DEngine-ECU fault

NG

Check the harness betweenthe condenser fan relay (LO) and

the ignition switch (IG2), and repair if necessary.

OK

Check the trouble

symptoms.

NG

Repair

NG

Replace

OK

Check the condenser fan motor. (Refer to P.55-40.)

Check the following connectors:A-06X, C-135, C-102,

C-209, C-210.

OK

NG

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-06X.

NG

NG

OK

Check the trouble

symptoms.RepairNG

Check the following connectors:

Replace the Engine-ECU .

OK

RepairNG

Check the harness betweenthe condenser fan relay (LO) and

the Engine-ECU.

(2) NG

Measure at the condenser fan relay (LO) A-06X.

DDisconnect the connector and measure at the junction box

side.

DIgnition switch: ON

(1) Voltage between terminal 2 and body earth.

OK :Battery voltage

(2) Voltage between terminal 4 and body earth.

OK :Battery voltage(1) NG

NG

Replace

OK

Check the condenser fan relay (LO) (Refer to P.55-23.)

NG

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-06X, A-45.

OK

Check the harness betweenthe condenser fan relay (LO) and

the condenser fan motor, and repair if necessary.

Check the harness betweenthe condenser fan relay (LO) and

the battery, and repair if necessary.

Page 1413 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-11

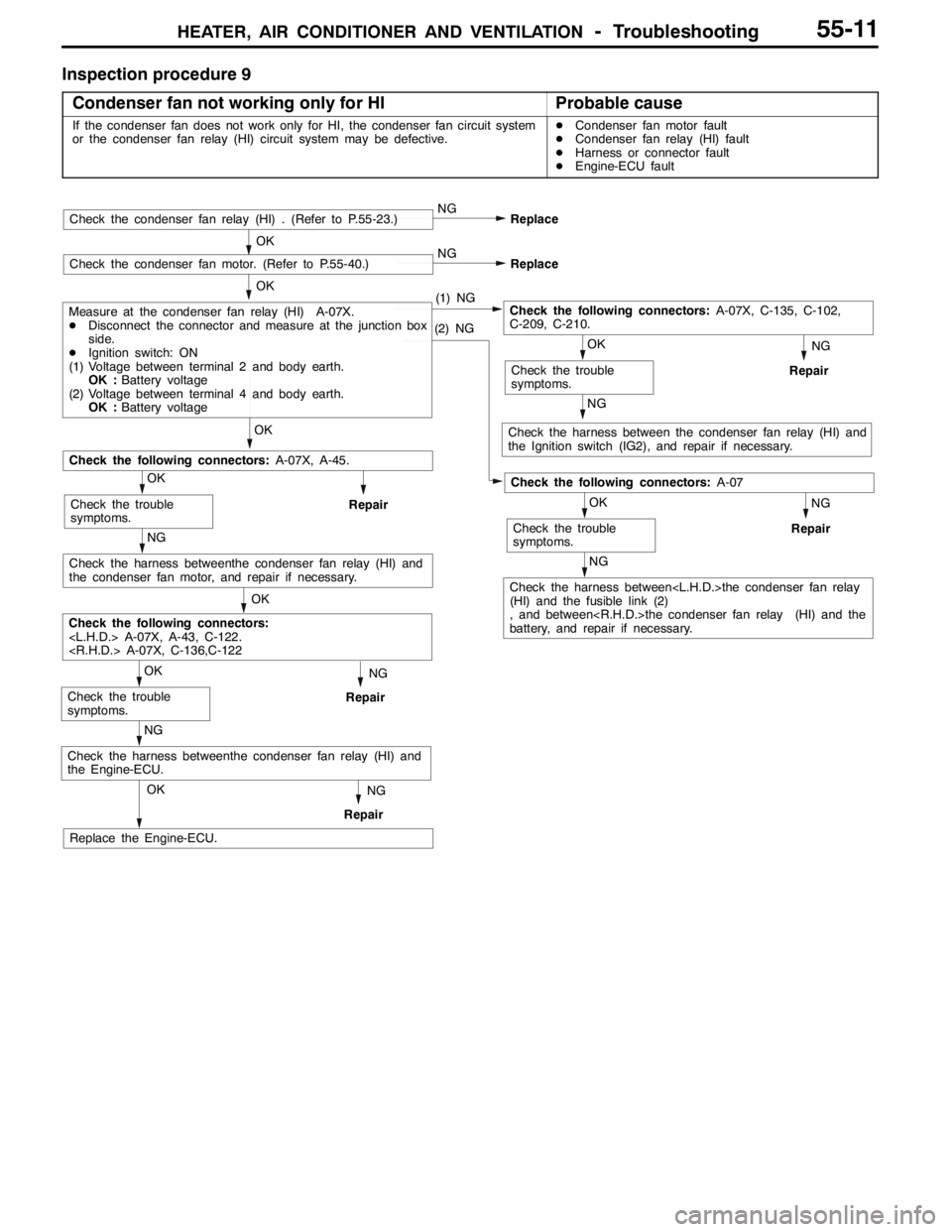

Inspection procedure 9

Condenser fan not working only for HI

Probable cause

If the condenser fan does not work only for HI, the condenser fan circuit system

or the condenser fan relay (HI) circuit system may be defective.DCondenser fan motor fault

DCondenser fan relay (HI) fault

DHarness or connector fault

DEngine-ECU fault

NG

Check the harness between the condenser fan relay (HI) and

the Ignition switch (IG2), and repair if necessary.

OK

Check the trouble

symptoms.

NG

Repair

NG

Replace

OK

Check the condenser fan motor. (Refer to P.55-40.)

Check the following connectors:A-07X, C-135, C-102,

C-209, C-210.

OK

NG

Check the harness between

(HI) and the fusible link (2)

, and between

battery, and repair if necessary.

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-07

NG

NG

OK

Check the trouble

symptoms.RepairNG

Check the following connectors:

Replace the Engine-ECU.

OK

RepairNG

Check the harness betweenthe condenser fan relay (HI) and

the Engine-ECU.

(2) NG

Measure at the condenser fan relay (HI) A-07X.

DDisconnect the connector and measure at the junction box

side.

DIgnition switch: ON

(1) Voltage between terminal 2 and body earth.

OK :Battery voltage

(2) Voltage between terminal 4 and body earth.

OK :Battery voltage(1) NG

NG

Replace

OK

Check the condenser fan relay (HI) . (Refer to P.55-23.)

NG

Check the harness betweenthe condenser fan relay (HI) and

the condenser fan motor, and repair if necessary.

OK

Check the trouble

symptoms.Repair

Check the following connectors:A-07X, A-45.

OK