engine MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 872 of 1449

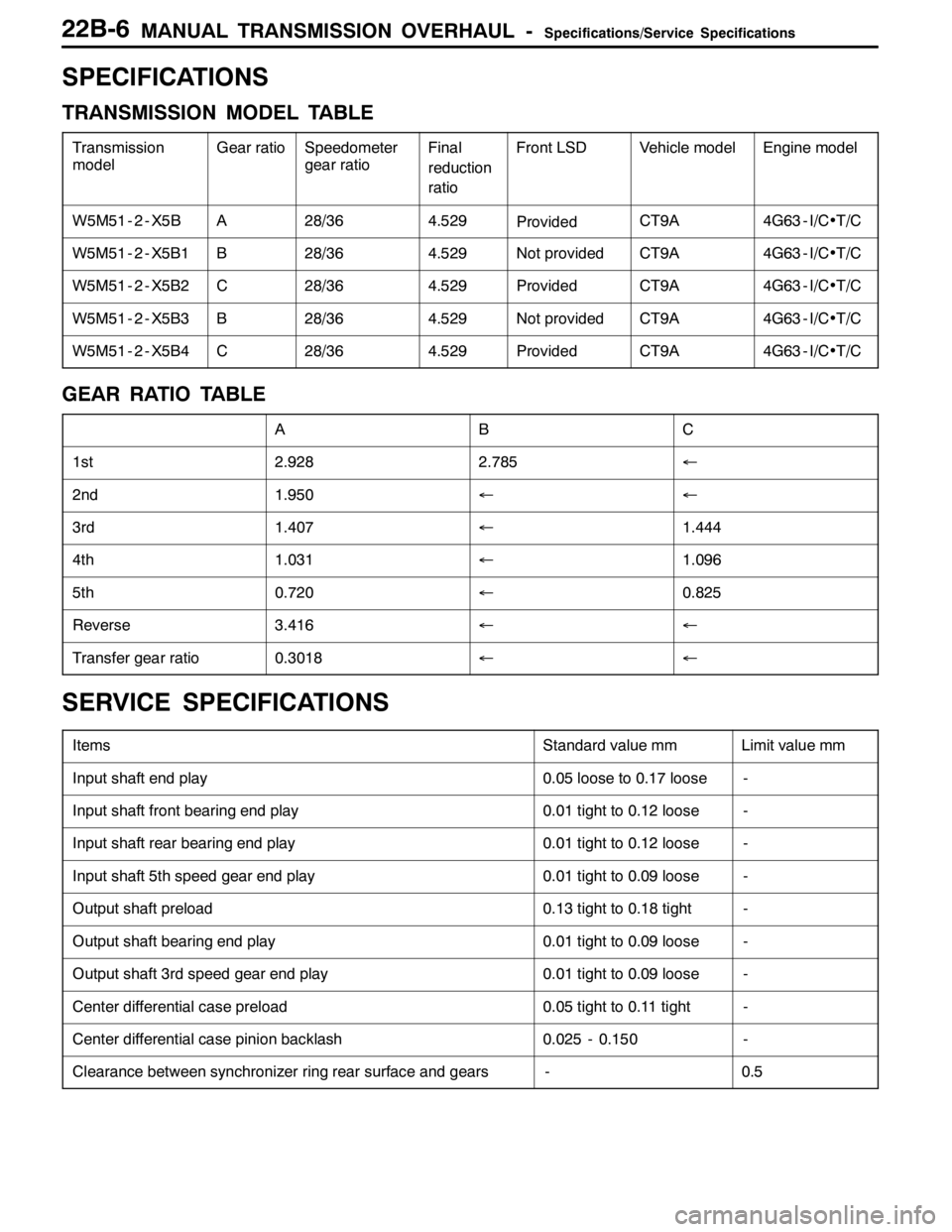

MANUAL TRANSMISSION OVERHAUL -Specifications/Service Specifications22B-6

SPECIFICATIONS

TRANSMISSION MODEL TABLE

Transmission

modelGear ratioSpeedometer

gear ratioFinal

reduction

ratioFront LSDVehicle modelEngine model

W5M51 - 2 - X5BA28/364.529CT9A4G63 - I/C•T/C

W5M51 - 2 - X5B1B28/364.529Not providedCT9A4G63 - I/C •T/C

W5M51 - 2 - X5B2C28/364.529ProvidedCT9A4G63 - I/C •T/C

W5M51 - 2 - X5B3B28/364.529Not providedCT9A4G63 - I/C •T/C

W5M51 - 2 - X5B4C28/364.529ProvidedCT9A4G63 - I/C •T/C

GEAR RATIO TABLE

ABC

1st2.9282.785←

2nd1.950←←

3rd1.407←1.444

4th1.031←1.096

5th0.720←0.825

Reverse3.416←←

Transfer gear ratio0.3018←←

SERVICE SPECIFICATIONS

ItemsStandard value mmLimit value mm

Input shaft end play0.05 loose to 0.17 loose-

Input shaft front bearing end play0.01 tight to 0.12 loose-

Input shaft rear bearing end play0.01 tight to 0.12 loose-

Input shaft 5th speed gear end play0.01 tight to 0.09 loose-

Output shaft preload0.13 tight to 0.18 tight-

Output shaft bearing end play0.01 tight to 0.09 loose-

Output shaft 3rd speed gear end play0.01 tight to 0.09 loose-

Center differential case preload0.05 tight to 0.11 tight-

Center differential case pinion backlash0.025 - 0.150-

Clearance between synchronizer ring rear surface and gears-0.5

Provided

Page 954 of 1449

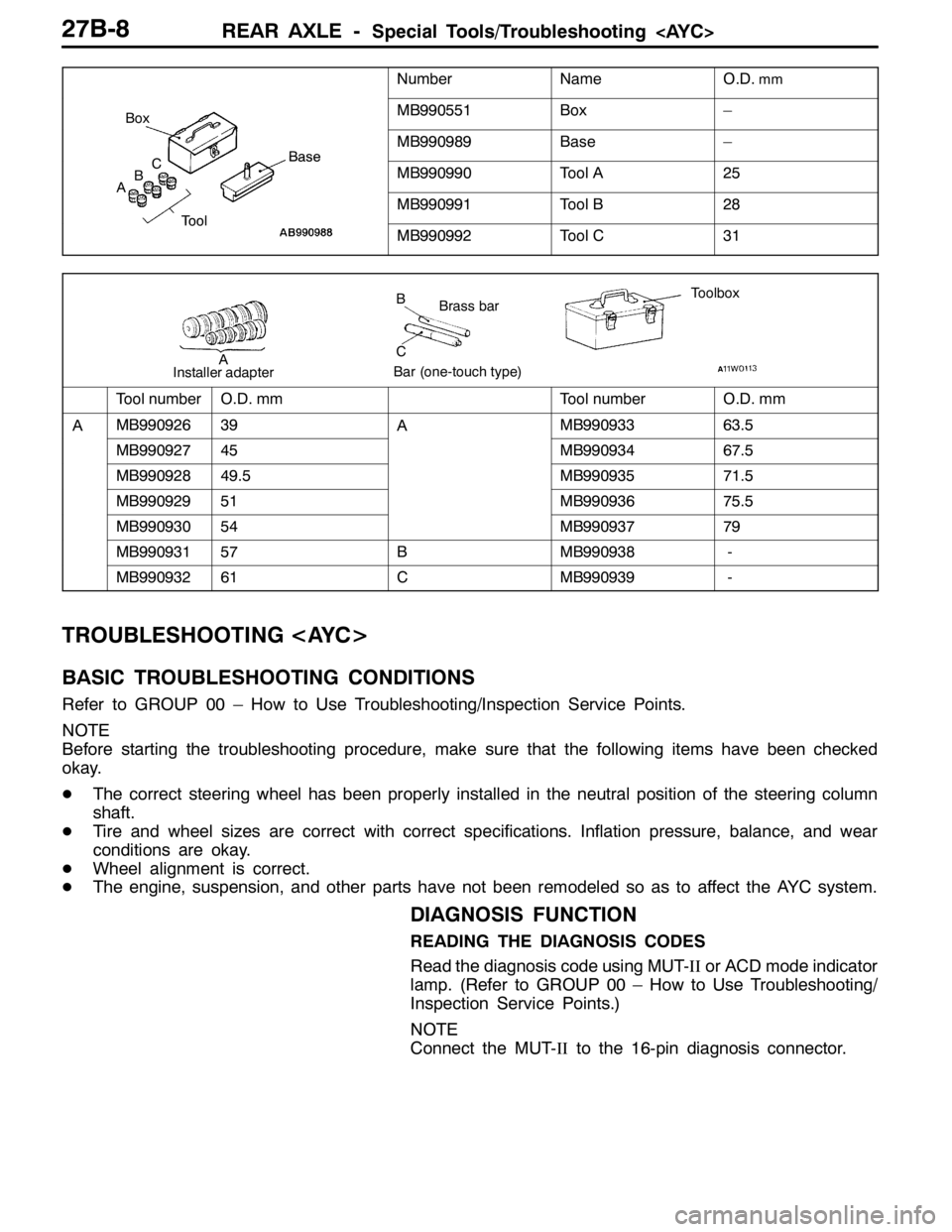

REAR AXLE -Special Tools/Troubleshooting

NumberNameO.D.mm

BoxMB990551Box–

CBaseMB990989Base–

ABCBase

MB990990Tool A25A

Tool

MB990991Tool B28

ToolMB990992Tool C31

Installer adapterBrass bar

Bar (one-touch type) AB

C

Toolbox

Tool numberO.D.mmTool numberO.D.mm

AMB99092639AMB99093363.5

MB99092745MB99093467.5

MB99092849.5MB99093571.5

MB99092951MB99093675.5

MB99093054MB99093779

MB99093157BMB990938-

MB99093261CMB990939-

TROUBLESHOOTING

BASIC TROUBLESHOOTING CONDITIONS

Refer to GROUP 00 – How to Use Troubleshooting/Inspection Service Points.

NOTE

Before starting the troubleshooting procedure, make sure that the following items have been checked

okay.

DThe correct steering wheel has been properly installed in the neutral position of the steering column

shaft.

DTire and wheel sizes are correct with correct specifications. Inflation pressure, balance, and wear

conditions are okay.

DWheel alignment is correct.

DThe engine, suspension, and other parts have not been remodeled so as to affect the AYC system.

DIAGNOSIS FUNCTION

READING THE DIAGNOSIS CODES

Read the diagnosis code using MUT-IIor ACD mode indicator

lamp. (Refer to GROUP 00 – How to Use Troubleshooting/

Inspection Service Points.)

NOTE

Connect the MUT-IIto the 16-pin diagnosis connector.

Page 960 of 1449

REAR AXLE -Troubleshooting

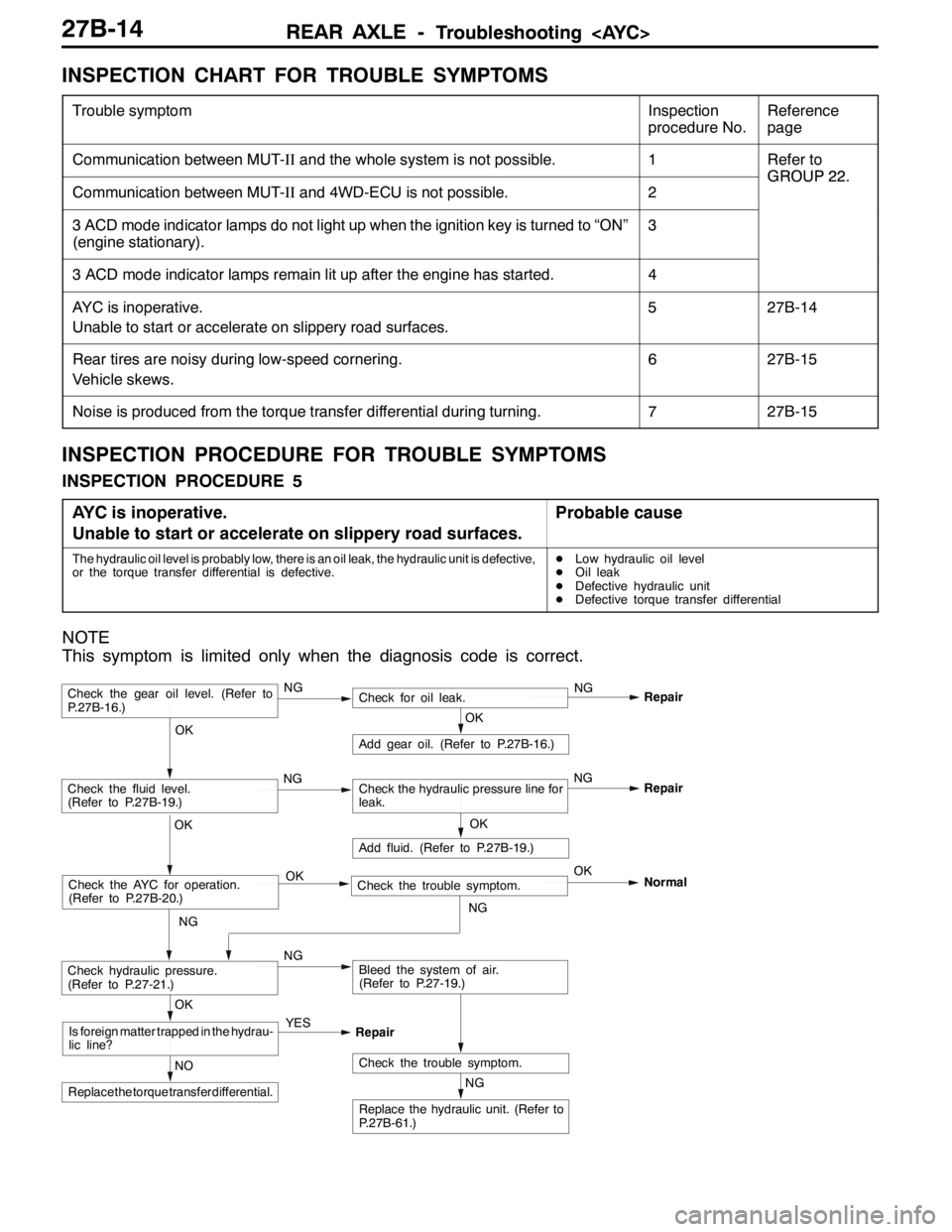

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

Communication between MUT-IIand the whole system is not possible.1Refer to

GROUP22

Communication between MUT-IIand 4WD-ECU is not possible.2

GROUP22.

3 ACD mode indicator lamps do not light up when the ignition key is turned to “ON”

(engine stationary).3

3 ACD mode indicator lamps remain lit up after the engine has started.4

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.527B-14

Rear tires are noisy during low-speed cornering.

Vehicle skews.627B-15

Noise is produced from the torque transfer differential during turning.727B-15

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

INSPECTION PROCEDURE 5

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.

Probable cause

The hydraulic oil level is probably low, there is an oil leak, the hydraulic unit is defective,

or the torque transfer differential is defective.DLow hydraulic oil level

DOil leak

DDefective hydraulic unit

DDefective torque transfer differential

NOTE

This symptom is limited only when the diagnosis code is correct.

NG

Replace the hydraulic unit. (Refer to

P.27B-61.)

NG

Add fluid. (Refer to P.27B-19.)

OKRepair

Check the trouble symptom.NO

Replace the torque transfer differential.

OK

Is foreign matter trapped in the hydrau-

lic line?YES

Repair

OK

Check the fluid level.

(Refer to P.27B-19.)Check the hydraulic pressure line for

leak.

OK

Add gear oil. (Refer to P.27B-16.)

OK

Check hydraulic pressure.

(Refer to P.27-21.)NGBleed the system of air.

(Refer to P.27-19.)

Check the gear oil level. (Refer to

P.27B-16.)NGCheck for oil leak.NG

Repair

Check the AYC for operation.

(Refer to P.27B-20.)Check the trouble symptom. OKOK

NGNormal

NGNG

Page 966 of 1449

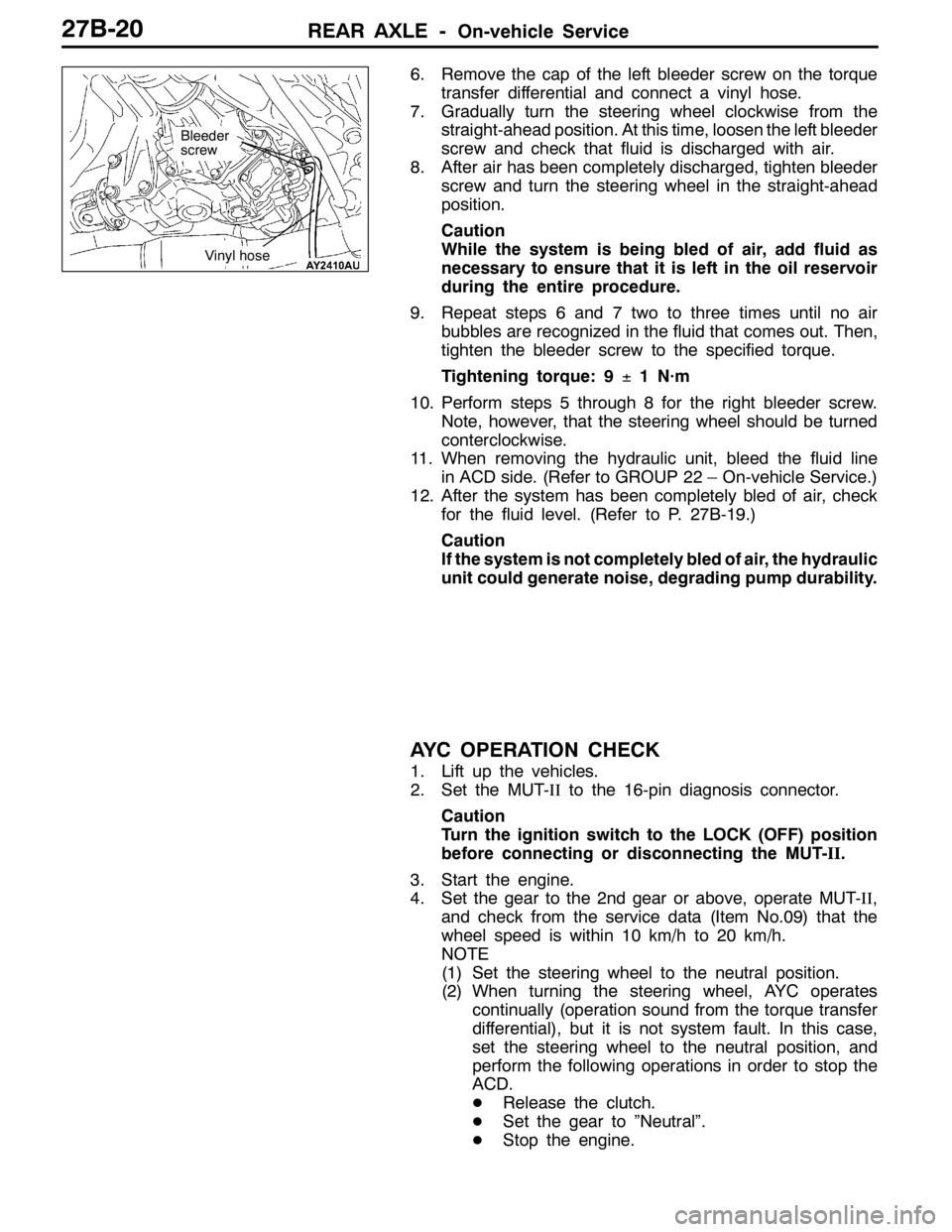

REAR AXLE -On-vehicle Service27B-20

6. Remove the cap of the left bleeder screw on the torque

transfer differential and connect a vinyl hose.

7. Gradually turn the steering wheel clockwise from the

straight-ahead position. At this time, loosen the left bleeder

screw and check that fluid is discharged with air.

8. After air has been completely discharged, tighten bleeder

screw and turn the steering wheel in the straight-ahead

position.

Caution

While the system is being bled of air, add fluid as

necessary to ensure that it is left in the oil reservoir

during the entire procedure.

9. Repeat steps 6 and 7 two to three times until no air

bubbles are recognized in the fluid that comes out. Then,

tighten the bleeder screw to the specified torque.

Tightening torque: 9±1 N·m

10. Perform steps 5 through 8 for the right bleeder screw.

Note, however, that the steering wheel should be turned

conterclockwise.

11. When removing the hydraulic unit, bleed the fluid line

in ACD side. (Refer to GROUP 22 – On-vehicle Service.)

12. After the system has been completely bled of air, check

for the fluid level. (Refer to P. 27B-19.)

Caution

If the system is not completely bled of air, the hydraulic

unit could generate noise, degrading pump durability.

AYC OPERATION CHECK

1. Lift up the vehicles.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the LOCK (OFF) position

before connecting or disconnecting the MUT-II.

3. Start the engine.

4. Set the gear to the 2nd gear or above, operate MUT-II,

and check from the service data (Item No.09) that the

wheel speed is within 10 km/h to 20 km/h.

NOTE

(1) Set the steering wheel to the neutral position.

(2) When turning the steering wheel, AYC operates

continually (operation sound from the torque transfer

differential), but it is not system fault. In this case,

set the steering wheel to the neutral position, and

perform the following operations in order to stop the

ACD.

DRelease the clutch.

DSet the gear to ”Neutral”.

DStop the engine.

Bleeder

screw

Vinyl hose

Page 970 of 1449

REAR AXLE -On-vehicle Service27B-24

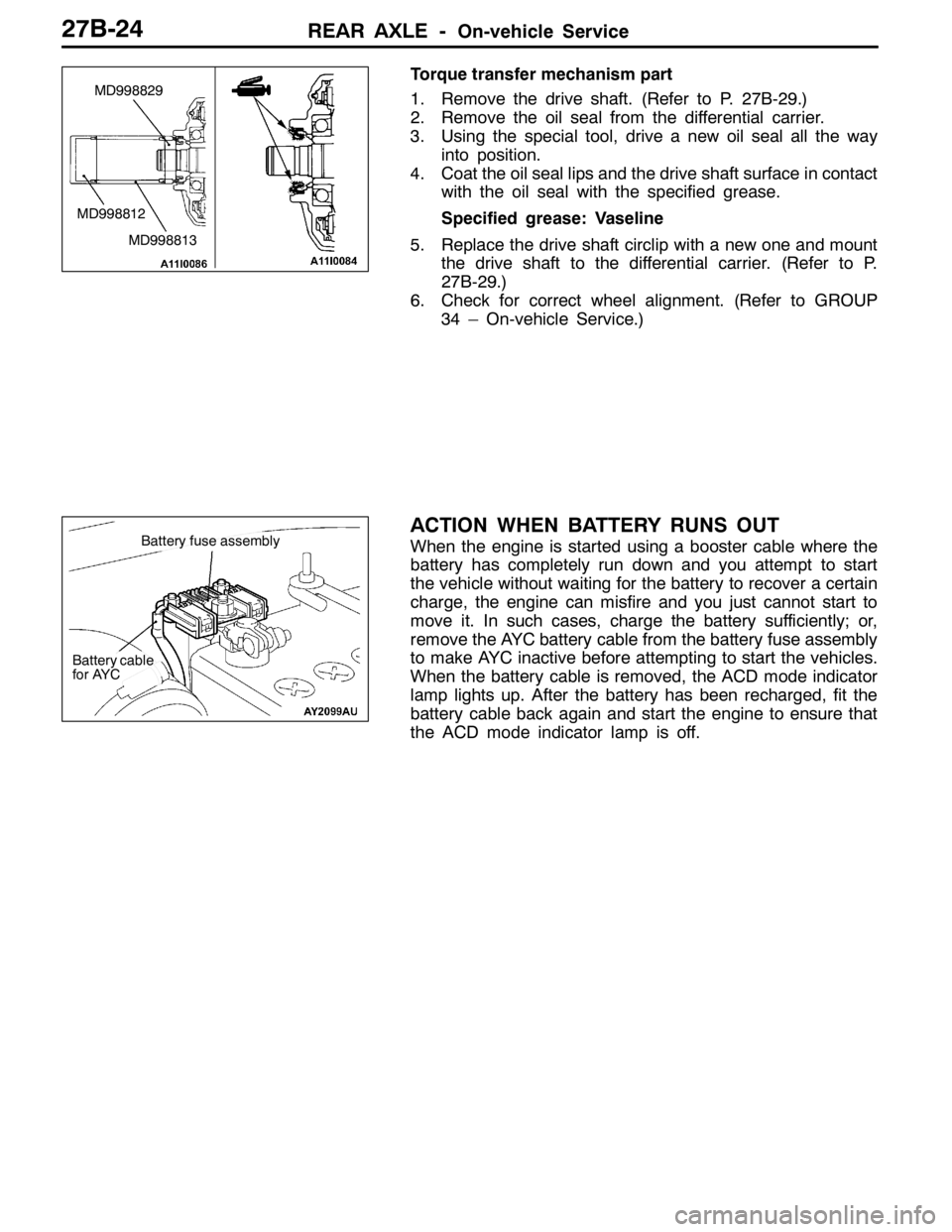

Torque transfer mechanism part

1. Remove the drive shaft. (Refer to P. 27B-29.)

2. Remove the oil seal from the differential carrier.

3. Using the special tool, drive a new oil seal all the way

into position.

4. Coat the oil seal lips and the drive shaft surface in contact

with the oil seal with the specified grease.

Specified grease: Vaseline

5. Replace the drive shaft circlip with a new one and mount

the drive shaft to the differential carrier. (Refer to P.

27B-29.)

6. Check for correct wheel alignment. (Refer to GROUP

34 – On-vehicle Service.)

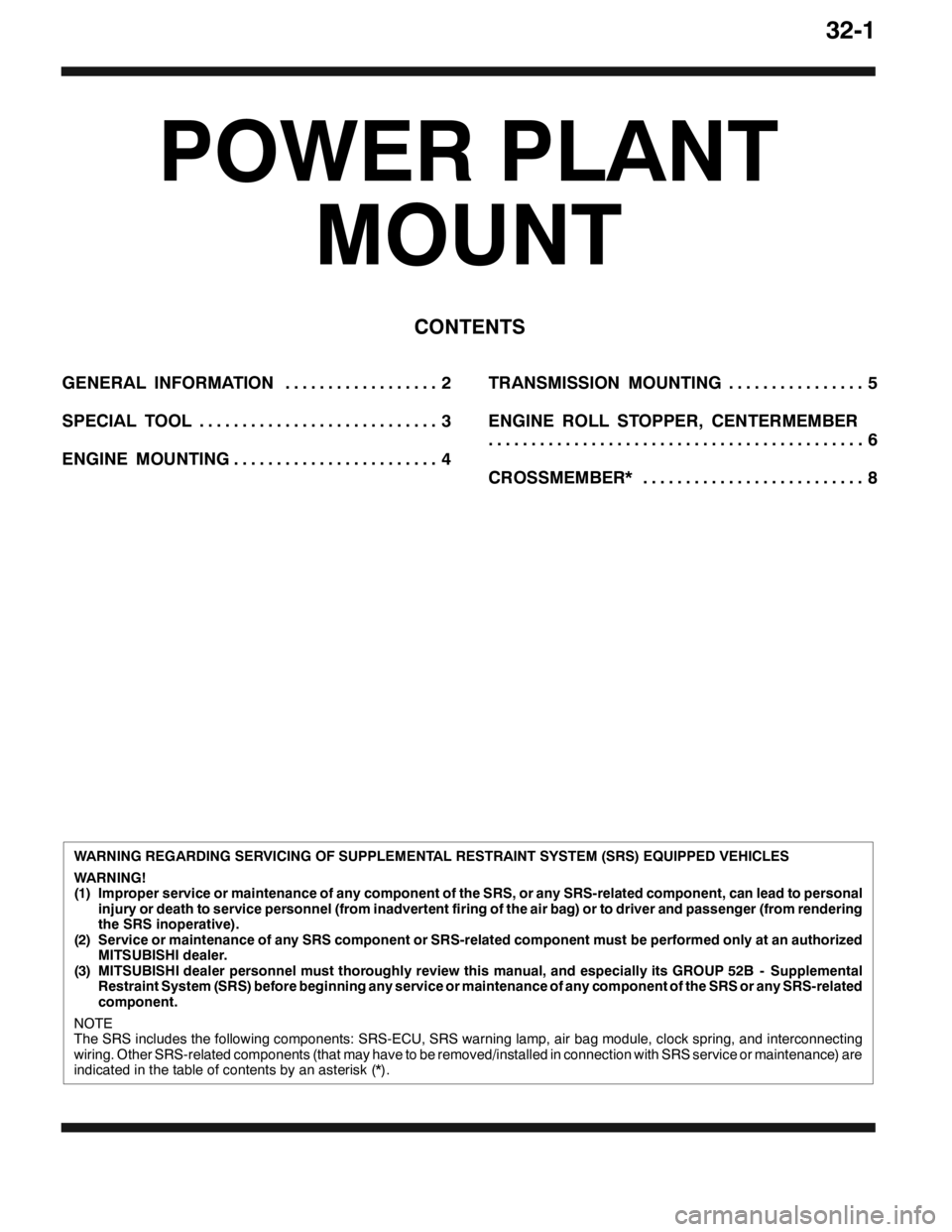

ACTION WHEN BATTERY RUNS OUT

When the engine is started using a booster cable where the

battery has completely run down and you attempt to start

the vehicle without waiting for the battery to recover a certain

charge, the engine can misfire and you just cannot start to

move it. In such cases, charge the battery sufficiently; or,

remove the AYC battery cable from the battery fuse assembly

to make AYC inactive before attempting to start the vehicles.

When the battery cable is removed, the ACD mode indicator

lamp lights up. After the battery has been recharged, fit the

battery cable back again and start the engine to ensure that

the ACD mode indicator lamp is off.

MD998829

MD998813 MD998812

Battery fuse assembly

Battery cable

for AYC

Page 1015 of 1449

32-1

POWER PLANT

MOUNT

CONTENTS

GENERAL INFORMATION 2..................

SPECIAL TOOL 3............................

ENGINE MOUNTING 4........................TRANSMISSION MOUNTING 5................

ENGINE ROLL STOPPER, CENTERMEMBER

6 ............................................

CROSSMEMBER* 8..........................

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, and interconnecting

wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or maintenance) are

indicated in the table of contents by an asterisk (*).

Page 1016 of 1449

POWER PLANT MOUNT - General Information32-2

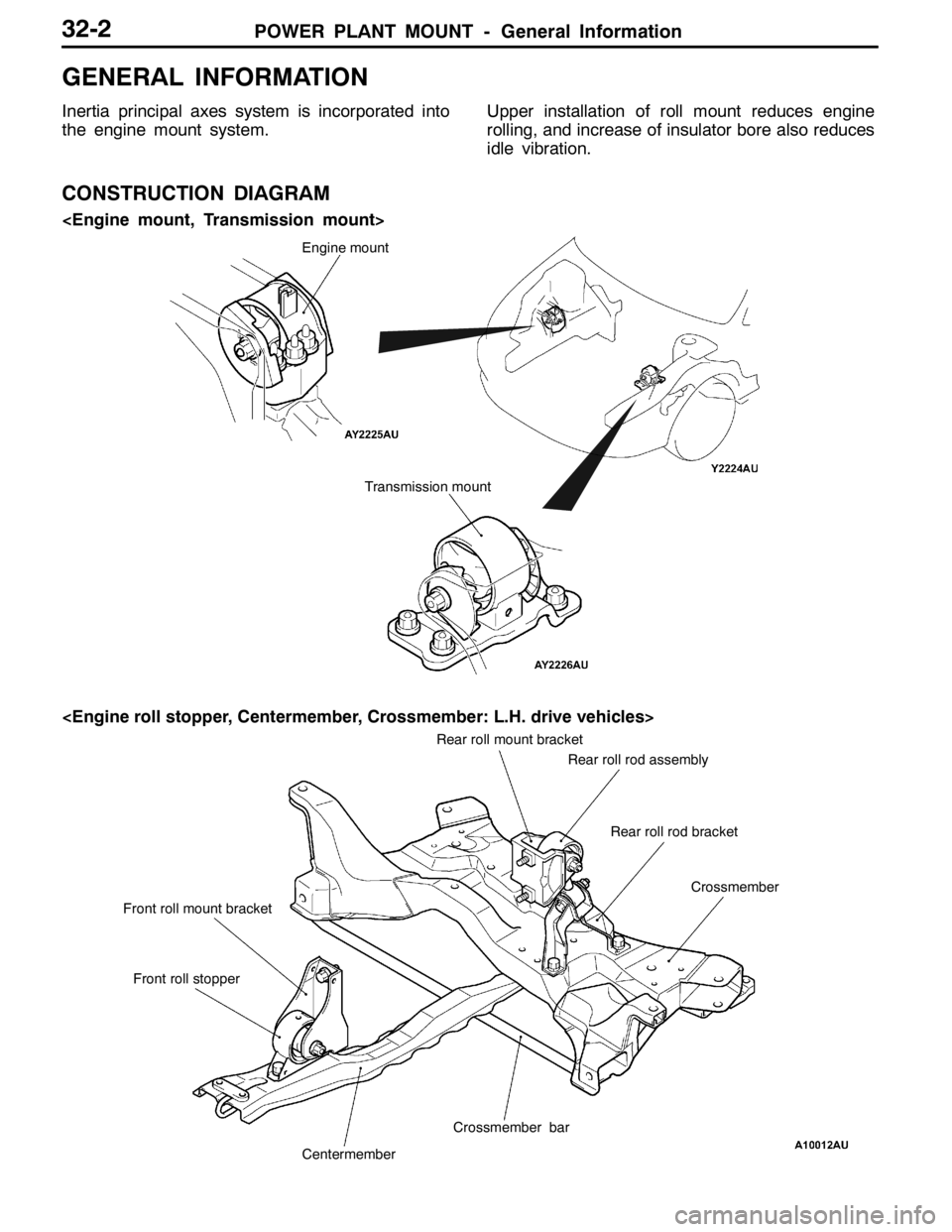

GENERAL INFORMATION

Inertia principal axes system is incorporated into

the engine mount system.Upper installation of roll mount reduces engine

rolling, and increase of insulator bore also reduces

idle vibration.

CONSTRUCTION DIAGRAM

Transmission mount Engine mount

Rear roll rod bracket

Front roll stopper

Front roll mount bracketRear roll mount bracket

Crossmember

Crossmember bar

CentermemberRear roll rod assembly

Page 1017 of 1449

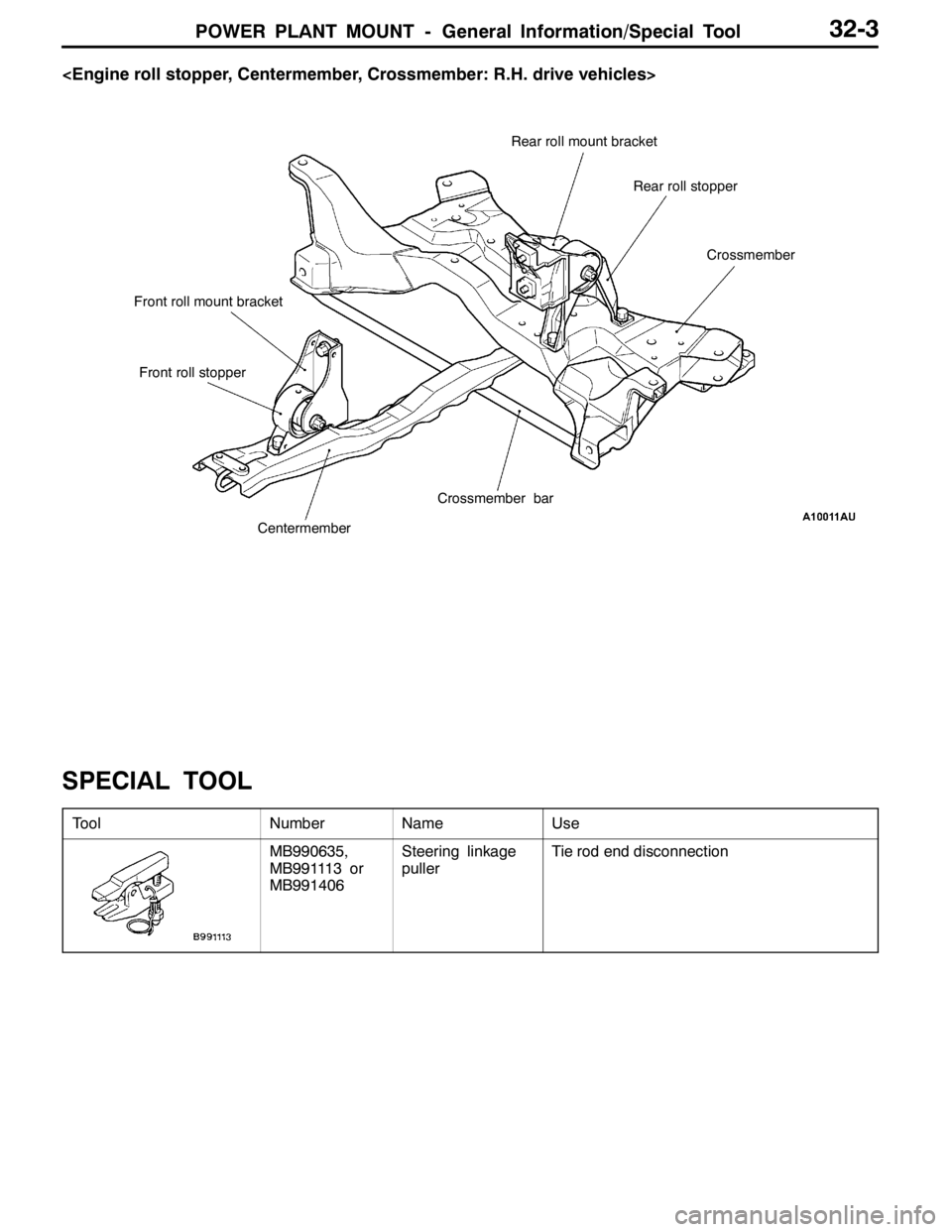

POWER PLANT MOUNT - General Information/Special Tool32-3

Front roll stopper Front roll mount bracketRear roll stopper Rear roll mount bracket

Crossmember

Crossmember bar

Centermember

SPECIAL TOOL

ToolNumberNameUse

MB990635,

MB991113 or

MB991406

Steering linkage

pullerTie rod end disconnection

Page 1018 of 1449

POWER PLANT MOUNT - Engine Mounting32-4

ENGINE MOUNTING

REMOVAL AND INSTALLATION

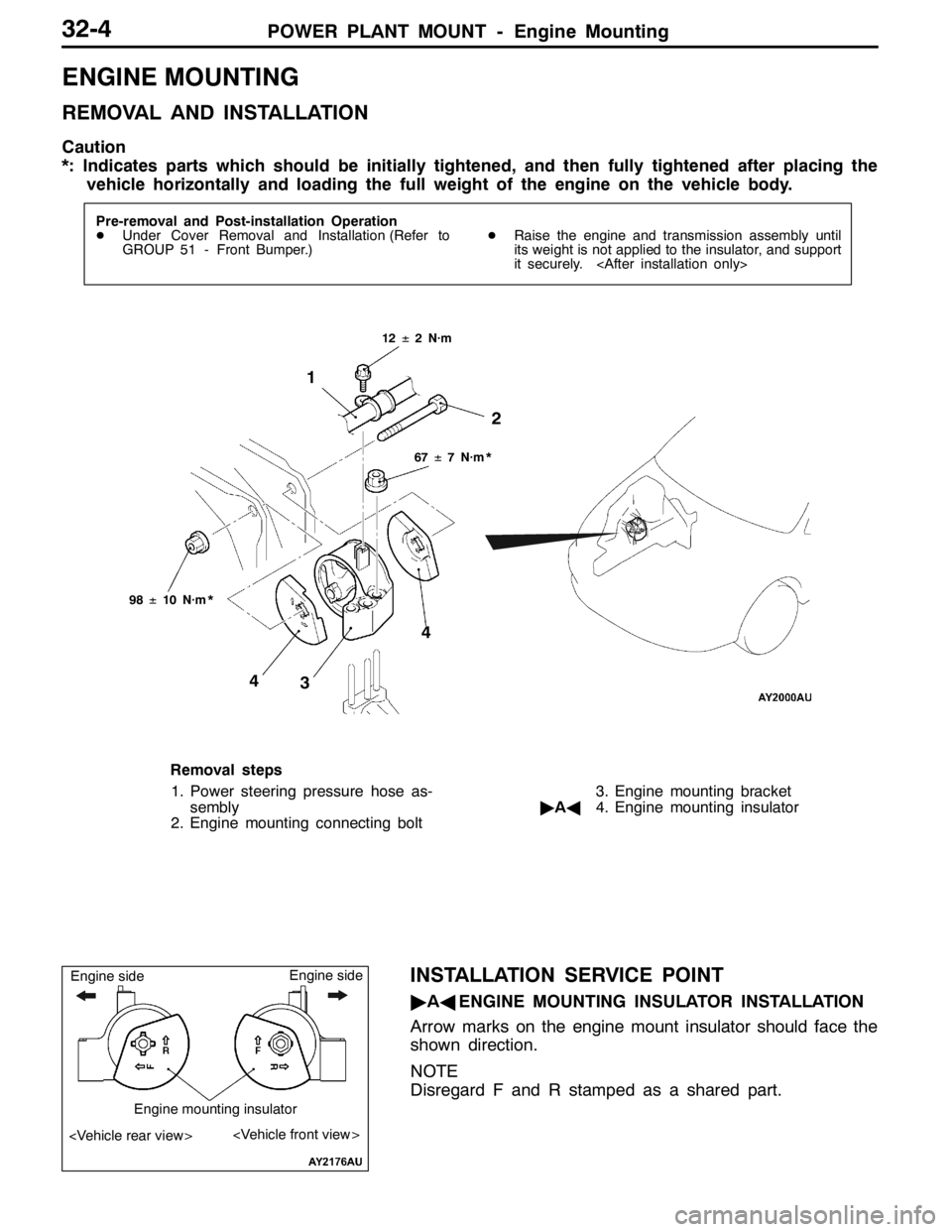

Caution

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to

GROUP 51 - Front Bumper.)DRaise the engine and transmission assembly until

its weight is not applied to the insulator, and support

it securely.

98±10 N·m*

67±7 N·m*

1

2

12±2 N·m

3 44

Removal steps

1. Power steering pressure hose as-

sembly

2. Engine mounting connecting bolt3. Engine mounting bracket

"AA4. Engine mounting insulator

INSTALLATION SERVICE POINT

"AAENGINE MOUNTING INSULATOR INSTALLATION

Arrow marks on the engine mount insulator should face the

shown direction.

NOTE

Disregard F and R stamped as a shared part.

Engine sideEngine side

Engine mounting insulator

Page 1019 of 1449

POWER PLANT MOUNT - Transmission Mounting32-5

TRANSMISSION MOUNTING

REMOVAL AND INSTALLATION

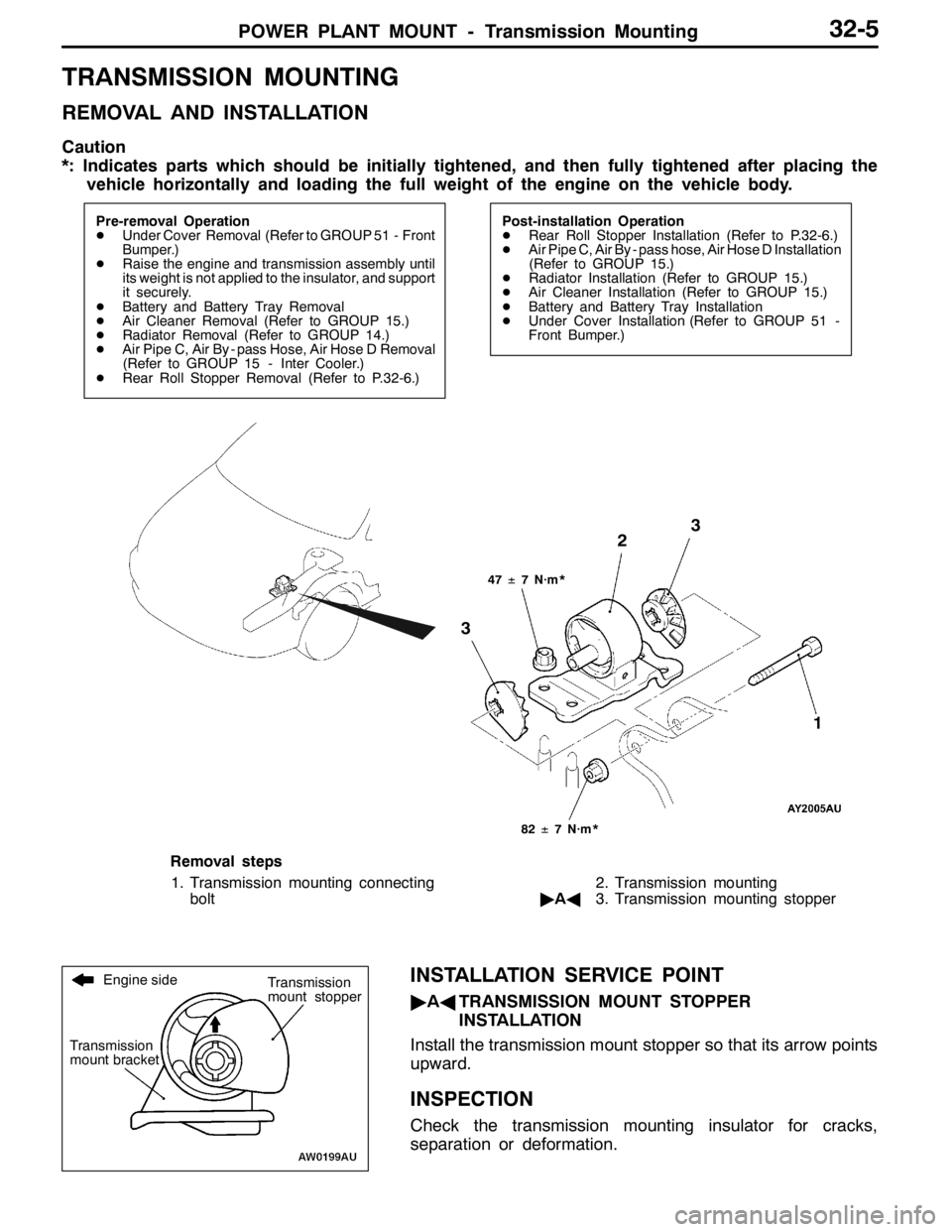

Caution

*: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

DUnder Cover Removal (Refer to GROUP 51 - Front

Bumper.)

DRaise the engine and transmission assembly until

its weight is not applied to the insulator, and support

it securely.

DBattery and Battery Tray Removal

DAir Cleaner Removal (Refer to GROUP 15.)

DRadiator Removal (Refer to GROUP 14.)

DAir Pipe C, Air By - pass Hose, Air Hose D Removal

(Refer to GROUP 15 - Inter Cooler.)

DRear Roll Stopper Removal (Refer to P.32-6.)Post-installation Operation

DRear Roll Stopper Installation (Refer to P.32-6.)

DAir Pipe C, Air By - pass hose, Air Hose D Installation

(Refer to GROUP 15.)

DRadiator Installation (Refer to GROUP 15.)

DAir Cleaner Installation (Refer to GROUP 15.)

DBattery and Battery Tray Installation

DUnder Cover Installation (Refer to GROUP 51 -

Front Bumper.)

47±7 N·m*

3

3

82±7 N·m*

2

1

Removal steps

1. Transmission mounting connecting

bolt2. Transmission mounting

"AA3. Transmission mounting stopper

INSTALLATION SERVICE POINT

"AATRANSMISSION MOUNT STOPPER

INSTALLATION

Install the transmission mount stopper so that its arrow points

upward.

INSPECTION

Check the transmission mounting insulator for cracks,

separation or deformation.

Engine side

Transmission

mount bracketTransmission

mount stopper