coolant temperature MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 781 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-11

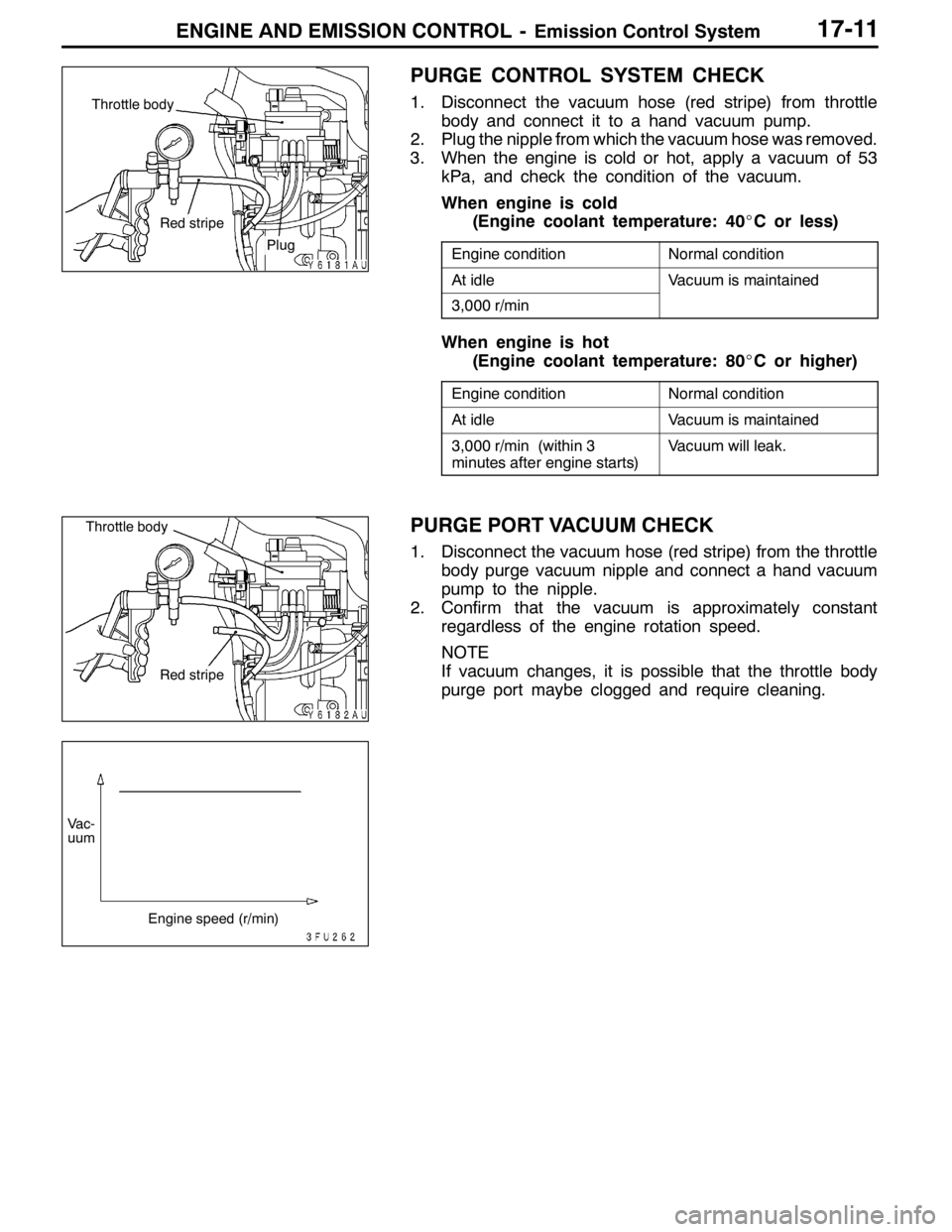

PURGE CONTROL SYSTEM CHECK

1. Disconnect the vacuum hose (red stripe) from throttle

body and connect it to a hand vacuum pump.

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53

kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40_C or less)

Engine conditionNormal condition

At idleVacuum is maintained

3,000 r/min

When engine is hot

(Engine coolant temperature: 80_C or higher)

Engine conditionNormal condition

At idleVacuum is maintained

3,000 r/min (within 3

minutes after engine starts)Vacuum will leak.

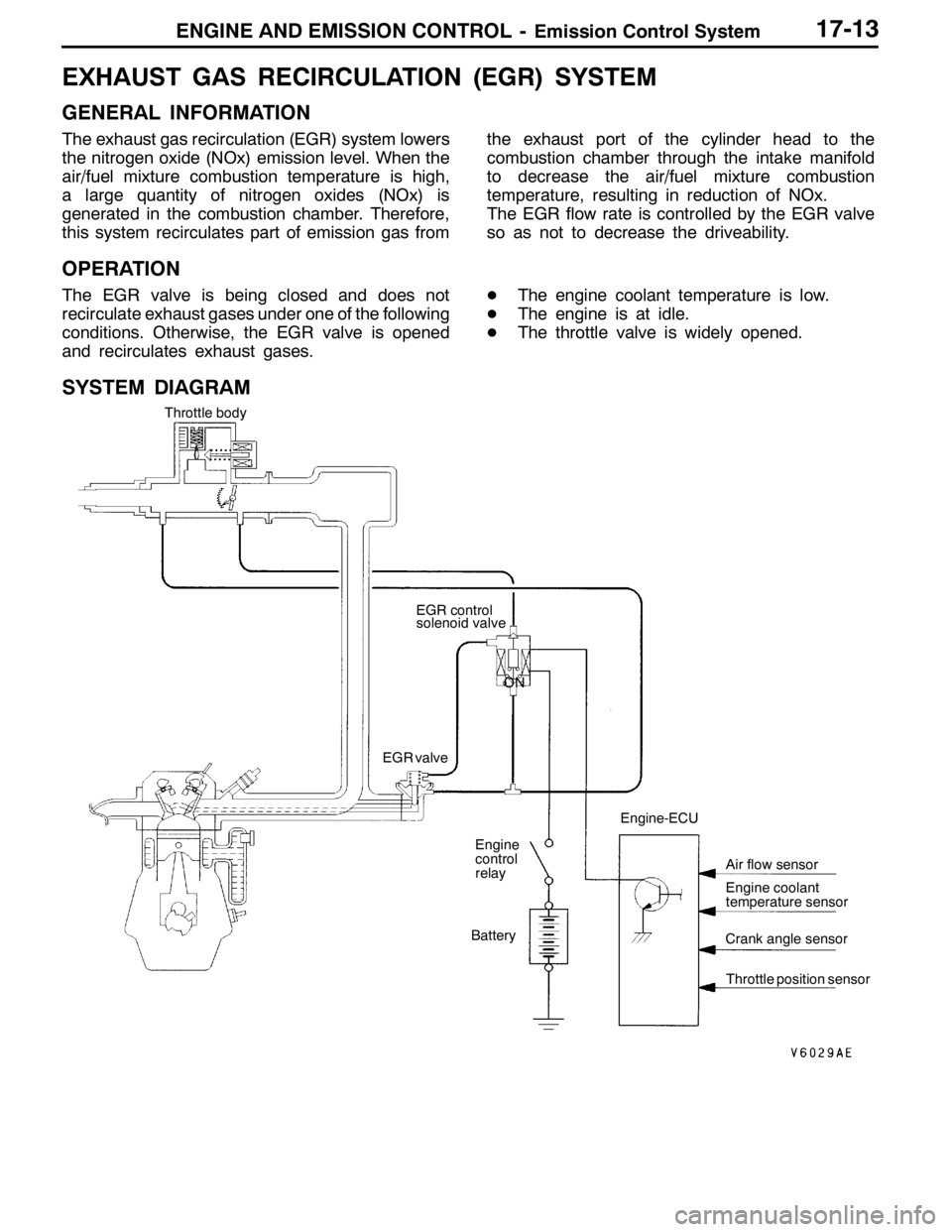

PURGE PORT VACUUM CHECK

1. Disconnect the vacuum hose (red stripe) from the throttle

body purge vacuum nipple and connect a hand vacuum

pump to the nipple.

2. Confirm that the vacuum is approximately constant

regardless of the engine rotation speed.

NOTE

If vacuum changes, it is possible that the throttle body

purge port maybe clogged and require cleaning.

Red stripe

Plug

Throttle body

Red stripe

Throttle body

Vac-

uum

Engine speed (r/min)

Page 783 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-13

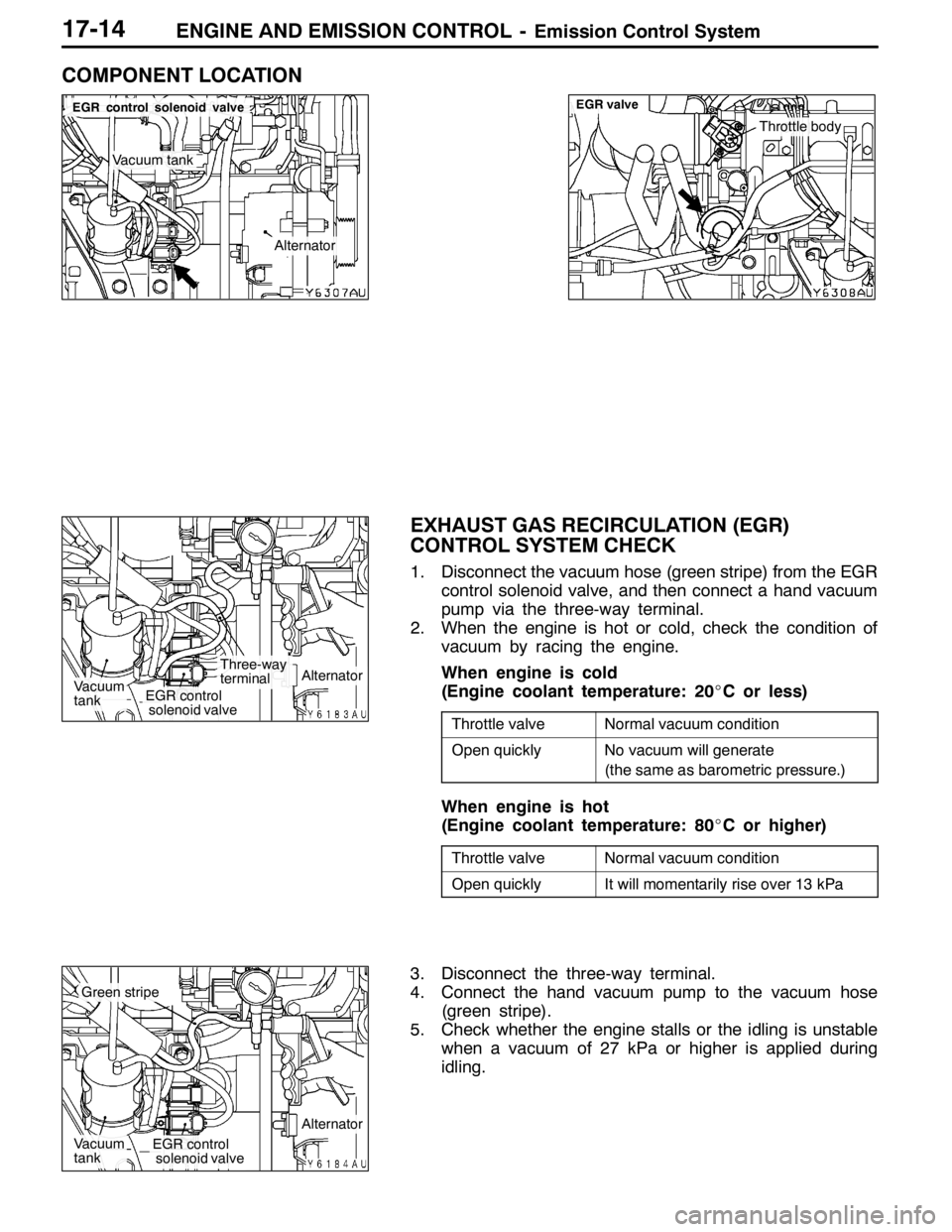

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

GENERAL INFORMATION

The exhaust gas recirculation (EGR) system lowers

the nitrogen oxide (NOx) emission level. When the

air/fuel mixture combustion temperature is high,

a large quantity of nitrogen oxides (NOx) is

generated in the combustion chamber. Therefore,

this system recirculates part of emission gas fromthe exhaust port of the cylinder head to the

combustion chamber through the intake manifold

to decrease the air/fuel mixture combustion

temperature, resulting in reduction of NOx.

The EGR flow rate is controlled by the EGR valve

so as not to decrease the driveability.

OPERATION

The EGR valve is being closed and does not

recirculate exhaust gases under one of the following

conditions. Otherwise, the EGR valve is opened

and recirculates exhaust gases.DThe engine coolant temperature is low.

DThe engine is at idle.

DThe throttle valve is widely opened.

SYSTEM DIAGRAM

ON Throttle body

EGR control

solenoid valve

Engine

control

relay

Battery EGR valve

Crank angle sensor

Throttle position sensor Engine-ECU

Engine coolant

temperature sensor Air flow sensor

Page 784 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System

EGR control solenoid valve

Vacuum tank

Alternator

EGR valve

Throttle body

17-14

COMPONENT LOCATION

EXHAUST GAS RECIRCULATION (EGR)

CONTROL SYSTEM CHECK

1. Disconnect the vacuum hose (green stripe) from the EGR

control solenoid valve, and then connect a hand vacuum

pump via the three-way terminal.

2. When the engine is hot or cold, check the condition of

vacuum by racing the engine.

When engine is cold

(Engine coolant temperature: 20_C or less)

Throttle valveNormal vacuum condition

Open quicklyNo vacuum will generate

(the same as barometric pressure.)

When engine is hot

(Engine coolant temperature: 80_C or higher)

Throttle valveNormal vacuum condition

Open quicklyIt will momentarily rise over 13 kPa

3. Disconnect the three-way terminal.

4. Connect the hand vacuum pump to the vacuum hose

(green stripe).

5. Check whether the engine stalls or the idling is unstable

when a vacuum of 27 kPa or higher is applied during

idling.

Three-way

terminal

EGR control

solenoid valveVacuum

tankAlternator

EGR control

solenoid valveVacuum

tank

Alternator

Green stripe

Page 1322 of 1449

54A-2

CHASSIS

ELECTRICAL

CONTENTS

BATTERY 4..............................

SERVICE SPECIFICATION 4....................

ON-VEHICLE SERVICE 4......................

Fluid Level and Specific Gravity Check 4........

Charging 4.................................

Battery Testing Procedure 5...................

IGNITION SWITCH AND IMMOBILIZER

SYSTEM 6...............................

SPECIAL TOOLS 6............................

TROUBLESHOOTING 6........................

IMMOBILIZER-ECU CHECK 10.................

IGNITION SWITCH 11..........................

COMBINATION METER 14................

SERVICE SPECIFICATIONS 14.................

SEALANT 14..................................

SPECIAL TOOLS 15...........................

TROUBLESHOOTING 15.......................

ON-VEHICLE SERVICE 19.....................Speedometer Check 19......................

Tachometer Check 20........................

Fuel Gauge Unit Check 20....................

Engine Coolant Temperature Gauge

Unit Check 21...............................

COMBINATION METER 22.....................

HEADLAMP ASSEMBLY 24...............

SERVICE SPECIFICATIONS 24.................

TROUBLESHOOTING 24.......................

ON-VEHICLE SERVICE 24.....................

Headlamp Aiming 24.........................

Headlamp Intensity Measurement 28...........

Headlamp Bulb(low beam)Replacement28 ....

Headlamp Bulb(high beam)Replacement29 ...

Position Lamp Bulb Replacement29 ...........

Front Turn Signal Lamp Bulb Replacement29 ...

Headlamp Auto Cut Adjustment Procedure29 ...

HeadlampAuto Cut Function Check 29.........

HEADLAMP ASSEMBLY 30....................

CONTINUED ON NEXT PAGE

Page 1341 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-21

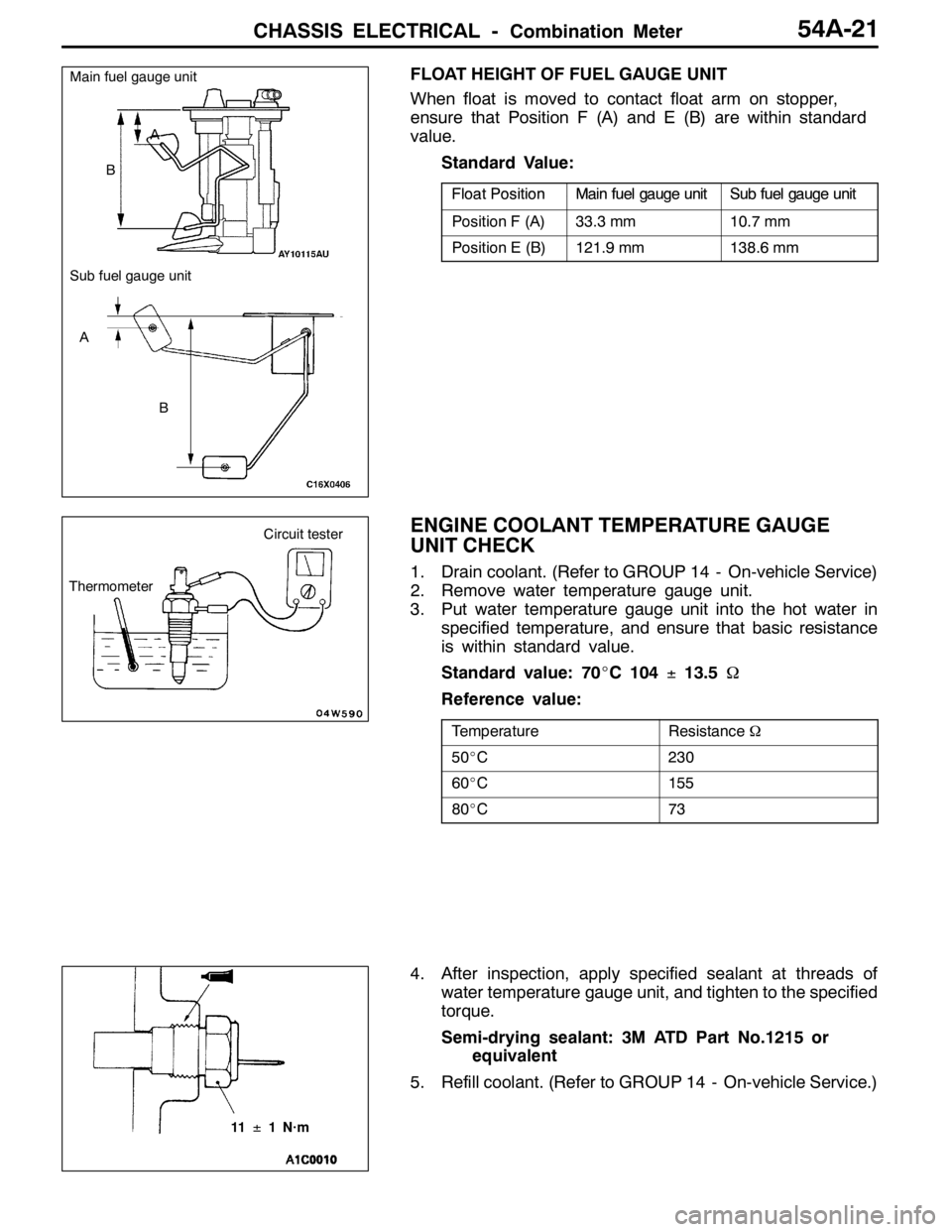

FLOAT HEIGHT OF FUEL GAUGE UNIT

When float is moved to contact float arm on stopper,

ensure that Position F (A) and E (B) are within standard

value.

Standard Value:

FloatPositionMainfuelgaugeunitSubfuelgaugeunitFloatPositionMainfuelgaugeunitSubfuelgaugeunit

Position F (A)33.3 mm10.7 mm

Position E (B)121.9 mm138.6 mm

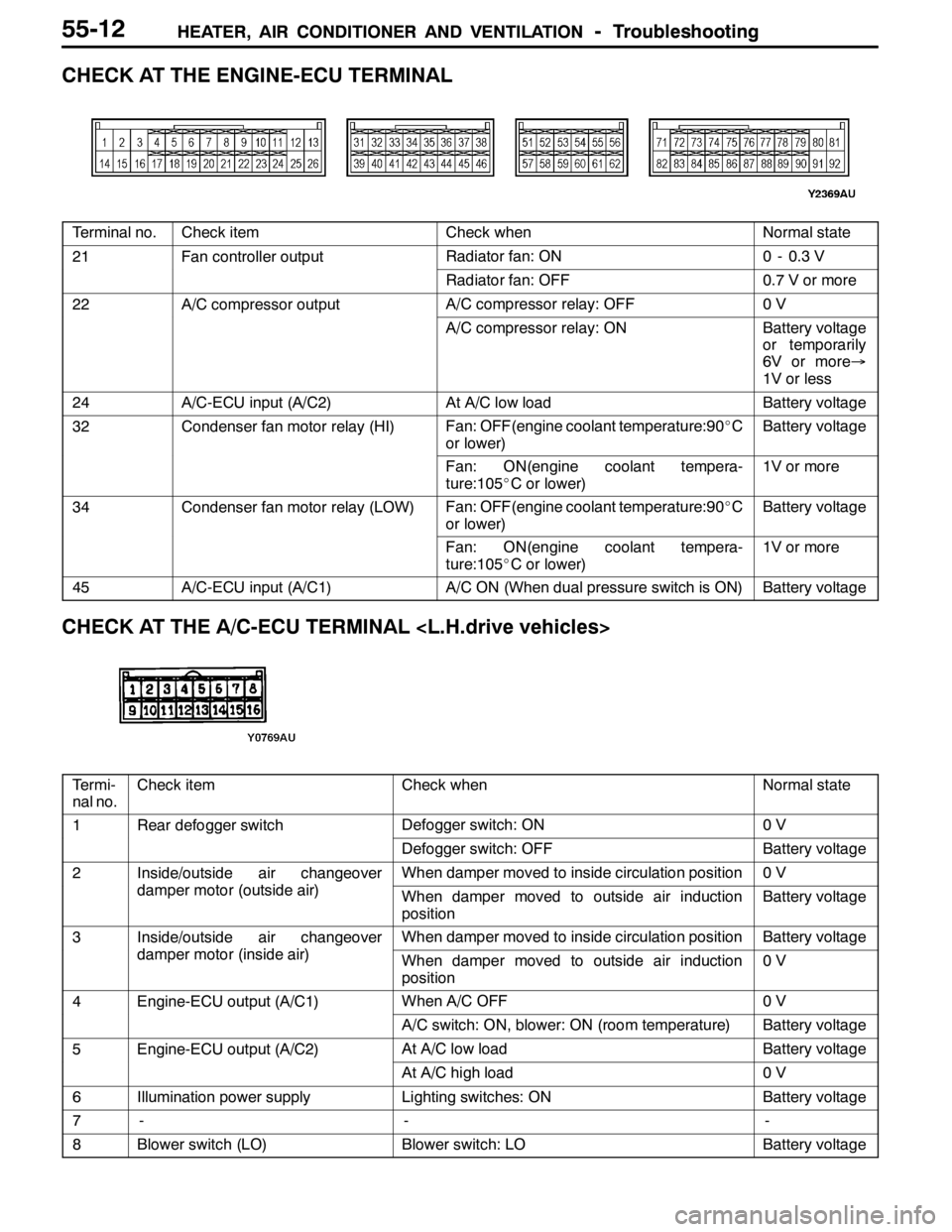

ENGINE COOLANT TEMPERATURE GAUGE

UNIT CHECK

1. Drain coolant. (Refer to GROUP 14 - On-vehicle Service)

2. Remove water temperature gauge unit.

3. Put water temperature gauge unit into the hot water in

specified temperature, and ensure that basic resistance

is within standard value.

Standard value: 70_C 104±13.5Ω

Reference value:

TemperatureResistanceΩ

50_C230

60_C155

80_C73

4. After inspection, apply specified sealant at threads of

water temperature gauge unit, and tighten to the specified

torque.

Semi-drying sealant: 3M ATD Part No.1215 or

equivalent

5. Refill coolant. (Refer to GROUP 14 - On-vehicle Service.)

Main fuel gauge unit

Sub fuel gauge unit

A

B

A

B

ThermometerCircuit tester

11±1 N·m

Page 1414 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-TroubleshootingHEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-12

CHECK AT THE ENGINE-ECU TERMINAL

Terminal no.Check itemCheck whenNormal state

21Fan controller outputRadiator fan: ON0 - 0.3 Vp

Radiator fan: OFF0.7 V or more

22A/C compressor outputA/C compressor relay: OFF0Vpp

A/C compressor relay: ONBattery voltage

or temporarily

6V or more→

1V or less

24A/C-ECU input (A/C2)At A/C low loadBattery voltage

32Condenser fan motor relay (HI)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

34Condenser fan motor relay (LOW)Fan: OFF(engine coolant temperature:90_C

or lower)Battery voltage

Fan: ON(engine coolant tempera-

ture:105_C or lower)1V or more

45A/C-ECU input (A/C1)A/C ON (When dual pressure switch is ON)Battery voltage

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

2Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

3Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

4Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

5Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

6Illumination power supplyLighting switches: ONBattery voltage

7---

8Blower switch (LO)Blower switch: LOBattery voltage

Page 1426 of 1449

HEATER, AIR CONDITIONER AND VENTILATION–On-vehicle Service55-24

IDLE-UP OPERATION CHECK

1. Set the vehicle in the pre-inspection condition:

Engine coolant temperature: 80 – 90_C

Lamps, electric cooling fan and all accessories: OFF

2. Check that the idle speed is within the standard value.

Standard value: 850±50 r/min

NOTE

The idle speed is controlled by the ISC system and should

not be adjusted.

3. The idle speed should be within the standard value when

the A/C switch is turned on and the A/C is operating.

Standard value:

850±50 r/min