coolant temperature MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 670 of 1449

MPI -On-vehicle Service13A-138

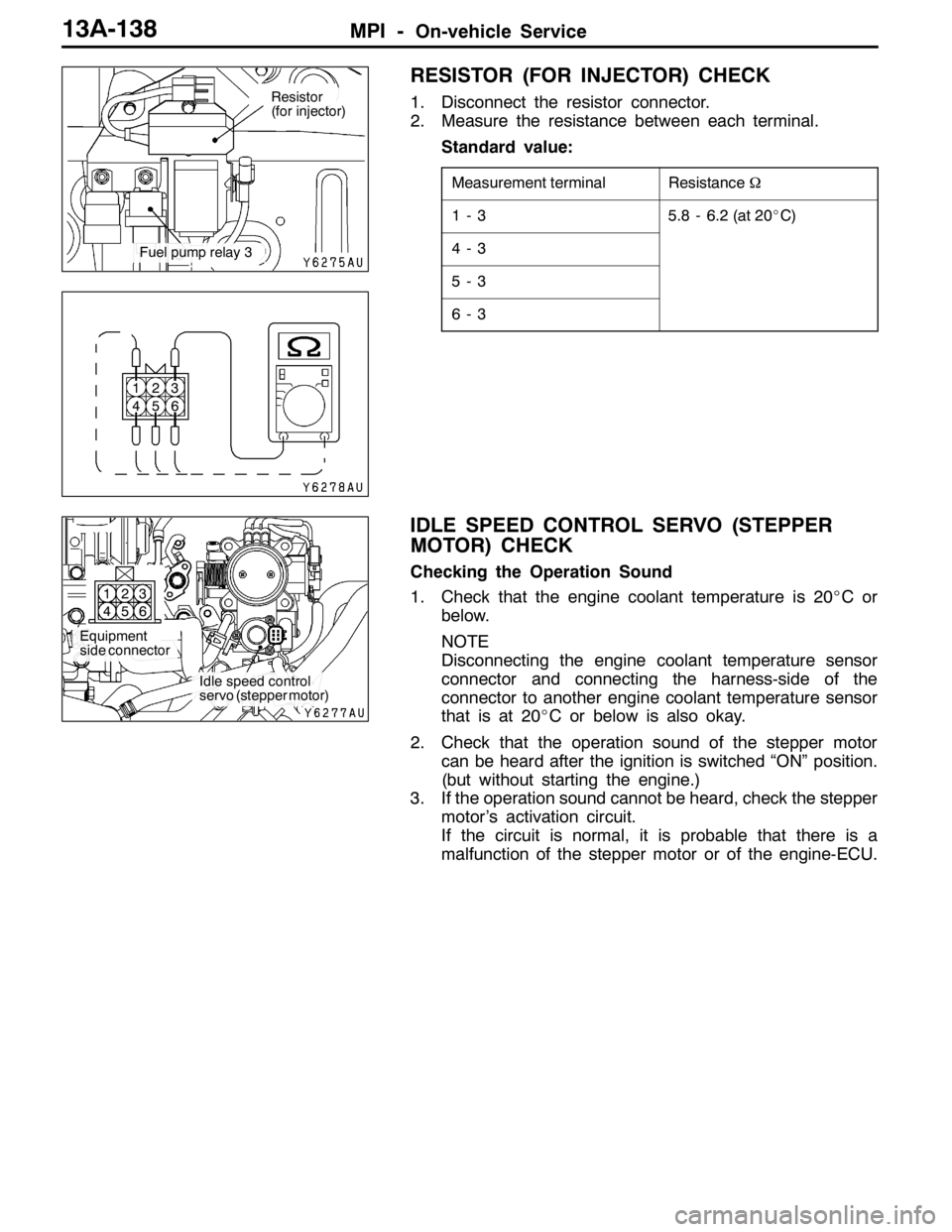

RESISTOR (FOR INJECTOR) CHECK

1. Disconnect the resistor connector.

2. Measure the resistance between each terminal.

Standard value:

Measurement terminalResistanceΩ

1-35.8 - 6.2 (at 20_C)

4-3

5-3

6-3

IDLE SPEED CONTROL SERVO (STEPPER

MOTOR) CHECK

Checking the Operation Sound

1. Check that the engine coolant temperature is 20_Cor

below.

NOTE

Disconnecting the engine coolant temperature sensor

connector and connecting the harness-side of the

connector to another engine coolant temperature sensor

that is at 20_C or below is also okay.

2. Check that the operation sound of the stepper motor

can be heard after the ignition is switched “ON” position.

(but without starting the engine.)

3. If the operation sound cannot be heard, check the stepper

motor’s activation circuit.

If the circuit is normal, it is probable that there is a

malfunction of the stepper motor or of the engine-ECU.

Resistor

(for injector)

Fuel pump relay 3

1

42

53

6

Equipment

side connector

Idle speed control

servo (stepper motor) 1

42

53

6

Page 690 of 1449

ENGINE COOLING -GeneralInformation/

Service Specifications/Lubricant/Sealant14-2

GENERAL INFORMATION

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.The water pump is of the centrifugal type and is

driven by the drive belt from the crankshaft.

The radiator is the corrugated fin, down flow type.

The cooling fan is controlled by the radiator fan

controller and engine-ECU depend on driving

conditions.

ItemSpecification

Radiator performance kJ/h216,700

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Radiator cap opening pressure kPa93 - 12383

Range of coolant antifreeze concentration of radiator %30 - 60-

ThermostatValve opening temperature of thermostat_C80±1.5-

Full-opening temperature of thermostat_C93-

Valve lift (at 93_C) mm9.5 or more-

LUBRICANT

ItemSpecified coolantQuantity L

Engine coolantMITSUBISHI GENUINE COOLANT or equivalent6.0Enginecoolant

(including reserve tank)

MITSUBISHIGENUINECOOLANTorequivalent6.0

SEALANT

ItemSpecified sealantRemark

Cylinder block drain plug3M Nut Locking Part No. 4171 or equivalentDrying sealant

Page 692 of 1449

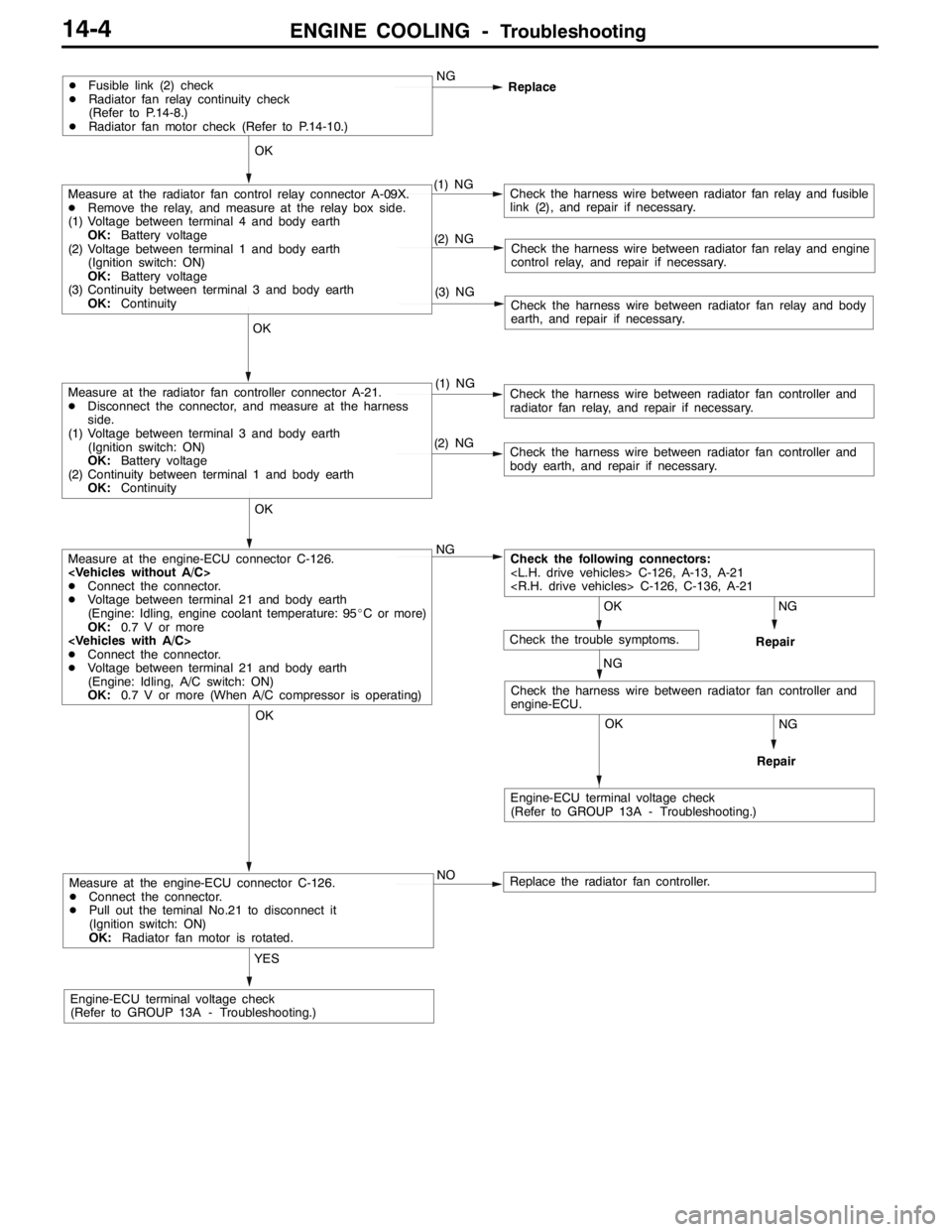

ENGINE COOLING -Troubleshooting14-4

Measure at the engine-ECU connector C-126.

DConnect the connector.

DPull out the teminal No.21 to disconnect it

(Ignition switch: ON)

OK:Radiator fan motor is rotated.

YES

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)NO

Replace the radiator fan controller.

NG

Repair

OK

NG

Repair

OK

Check the harness wire between radiator fan controller and

engine-ECU.

Measure at the engine-ECU connector C-126.

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, engine coolant temperature: 95_C or more)

OK:0.7 V or more

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, A/C switch: ON)

OK:0.7 V or more (When A/C compressor is operating)NG

(2) NGCheck the harness wire between radiator fan controller and

body earth, and repair if necessary.

OK

Measure at the radiator fan controller connector A-21.

DDisconnect the connector, and measure at the harness

side.

(1) Voltage between terminal 3 and body earth

(Ignition switch: ON)

OK:Battery voltage

(2) Continuity between terminal 1 and body earth

OK:Continuity(1) NGCheck the harness wire between radiator fan controller and

radiator fan relay, and repair if necessary.

(3) NGCheck the harness wire between radiator fan relay and body

earth, and repair if necessary.

(2) NGCheck the harness wire between radiator fan relay and engine

control relay, and repair if necessary.

OK

Measure at the radiator fan control relay connector A-09X.

DRemove the relay, and measure at the relay box side.

(1) Voltage between terminal 4 and body earth

OK:Battery voltage

(2) Voltage between terminal 1 and body earth

(Ignition switch: ON)

OK:Battery voltage

(3) Continuity between terminal 3 and body earth

OK:Continuity(1) NGCheck the harness wire between radiator fan relay and fusible

link (2), and repair if necessary.

DFusible link (2) check

DRadiator fan relay continuity check

(Refer to P.14-8.)

DRadiator fan motor check (Refer to P.14-10.)NG

Replace

OK

OK

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)

Check the following connectors:

NG

Check the trouble symptoms.

Page 693 of 1449

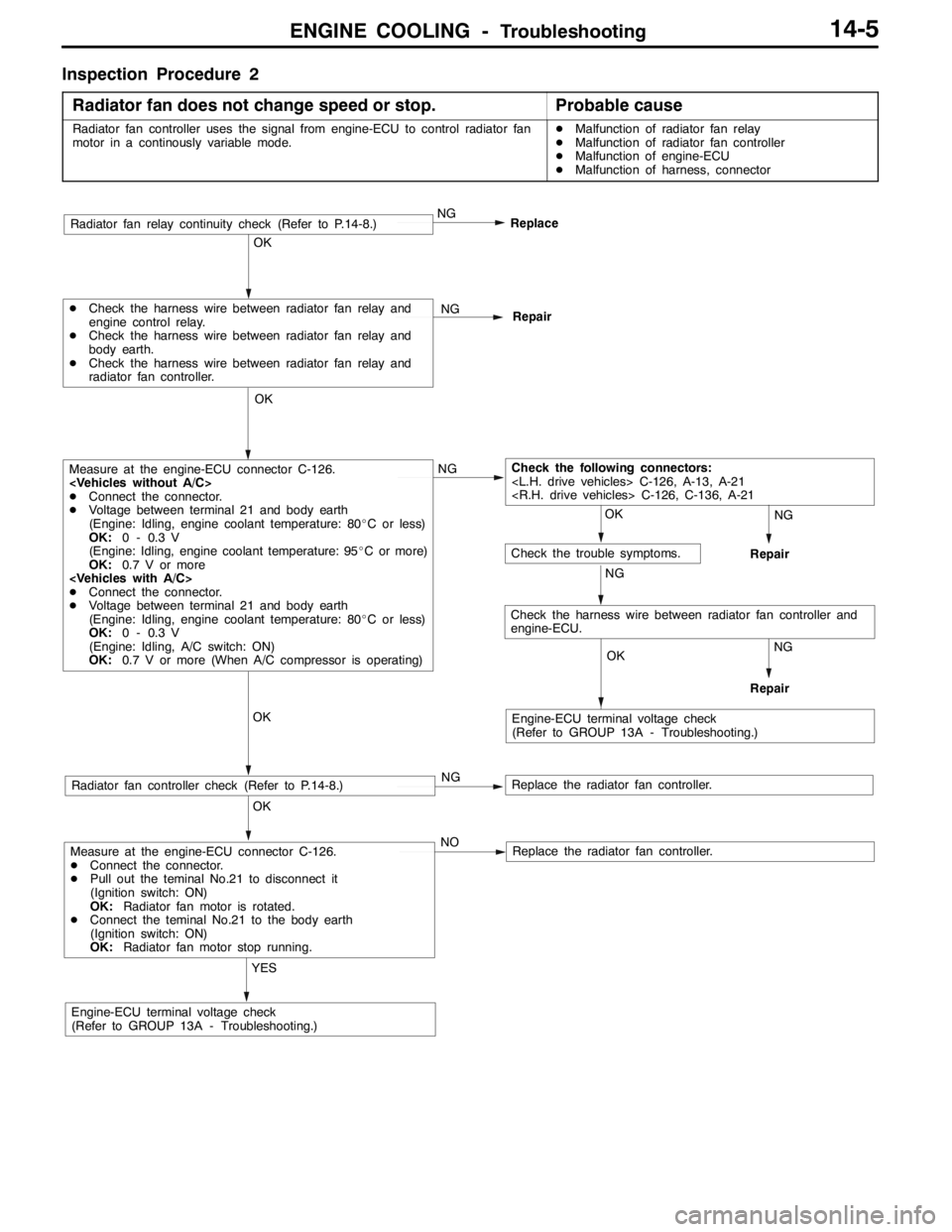

ENGINE COOLING -Troubleshooting14-5

Inspection Procedure 2

Radiator fan does not change speed or stop.

Probable cause

Radiator fan controller uses the signal from engine-ECU to control radiator fan

motor in a continously variable mode.DMalfunction of radiator fan relay

DMalfunction of radiator fan controller

DMalfunction of engine-ECU

DMalfunction of harness, connector

Measure at the engine-ECU connector C-126.

DConnect the connector.

DPull out the teminal No.21 to disconnect it

(Ignition switch: ON)

OK:Radiator fan motor is rotated.

DConnect the teminal No.21 to the body earth

(Ignition switch: ON)

OK:Radiator fan motor stop running.

YES

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)NO

Replace the radiator fan controller.

OK

Radiator fan controller check (Refer to P.14-8.)NGReplace the radiator fan controller.

OK

Measure at the engine-ECU connector C-126.

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, engine coolant temperature: 80_C or less)

OK:0 - 0.3 V

(Engine: Idling, engine coolant temperature: 95_C or more)

OK:0.7 V or more

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, engine coolant temperature: 80_C or less)

OK:0 - 0.3 V

(Engine: Idling, A/C switch: ON)

OK:0.7 V or more (When A/C compressor is operating)NG

OK

DCheck the harness wire between radiator fan relay and

engine control relay.

DCheck the harness wire between radiator fan relay and

body earth.

DCheck the harness wire between radiator fan relay and

radiator fan controller.NG

Repair

NG

Replace

OK

OK

OK

Check the following connectors:

NG

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)

Check the trouble symptoms.

NG

NG

Repair

Repair

Radiator fan relay continuity check (Refer to P.14-8.)

Check the harness wire between radiator fan controller and

engine-ECU.

Page 695 of 1449

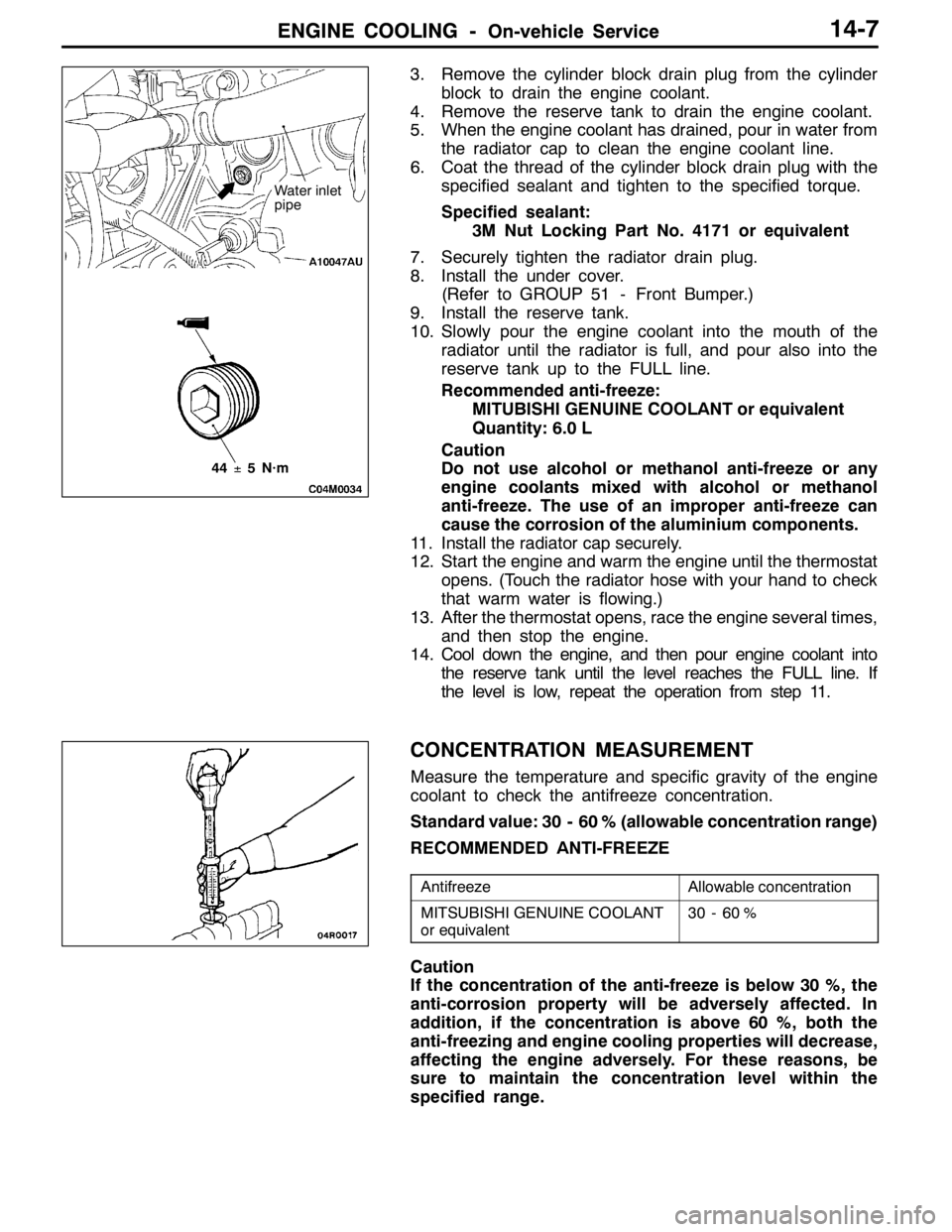

ENGINE COOLING -On-vehicle ServiceENGINE COOLING -On-vehicle Service14-7

3. Remove the cylinder block drain plug from the cylinder

block to drain the engine coolant.

4. Remove the reserve tank to drain the engine coolant.

5. When the engine coolant has drained, pour in water from

the radiator cap to clean the engine coolant line.

6. Coat the thread of the cylinder block drain plug with the

specified sealant and tighten to the specified torque.

Specified sealant:

3M Nut Locking Part No. 4171 or equivalent

7. Securely tighten the radiator drain plug.

8. Install the under cover.

(Refer to GROUP 51 - Front Bumper.)

9. Install the reserve tank.

10. Slowly pour the engine coolant into the mouth of the

radiator until the radiator is full, and pour also into the

reserve tank up to the FULL line.

Recommended anti-freeze:

MITUBISHI GENUINE COOLANT or equivalent

Quantity: 6.0 L

Caution

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze can

cause the corrosion of the aluminium components.

11. Install the radiator cap securely.

12. Start the engine and warm the engine until the thermostat

opens. (Touch the radiator hose with your hand to check

that warm water is flowing.)

13. After the thermostat opens, race the engine several times,

and then stop the engine.

14. Cool down the engine, and then pour engine coolant into

the reserve tank until the level reaches the FULL line. If

the level is low, repeat the operation from step 11.

CONCENTRATION MEASUREMENT

Measure the temperature and specific gravity of the engine

coolant to check the antifreeze concentration.

Standard value: 30 - 60 % (allowable concentration range)

RECOMMENDED ANTI-FREEZE

AntifreezeAllowable concentration

MITSUBISHI GENUINE COOLANT

or equivalent30 - 60 %

Caution

If the concentration of the anti-freeze is below 30 %, the

anti-corrosion property will be adversely affected. In

addition, if the concentration is above 60 %, both the

anti-freezing and engine cooling properties will decrease,

affecting the engine adversely. For these reasons, be

sure to maintain the concentration level within the

specified range.

44±5N·m

Water inlet

pipe

Page 696 of 1449

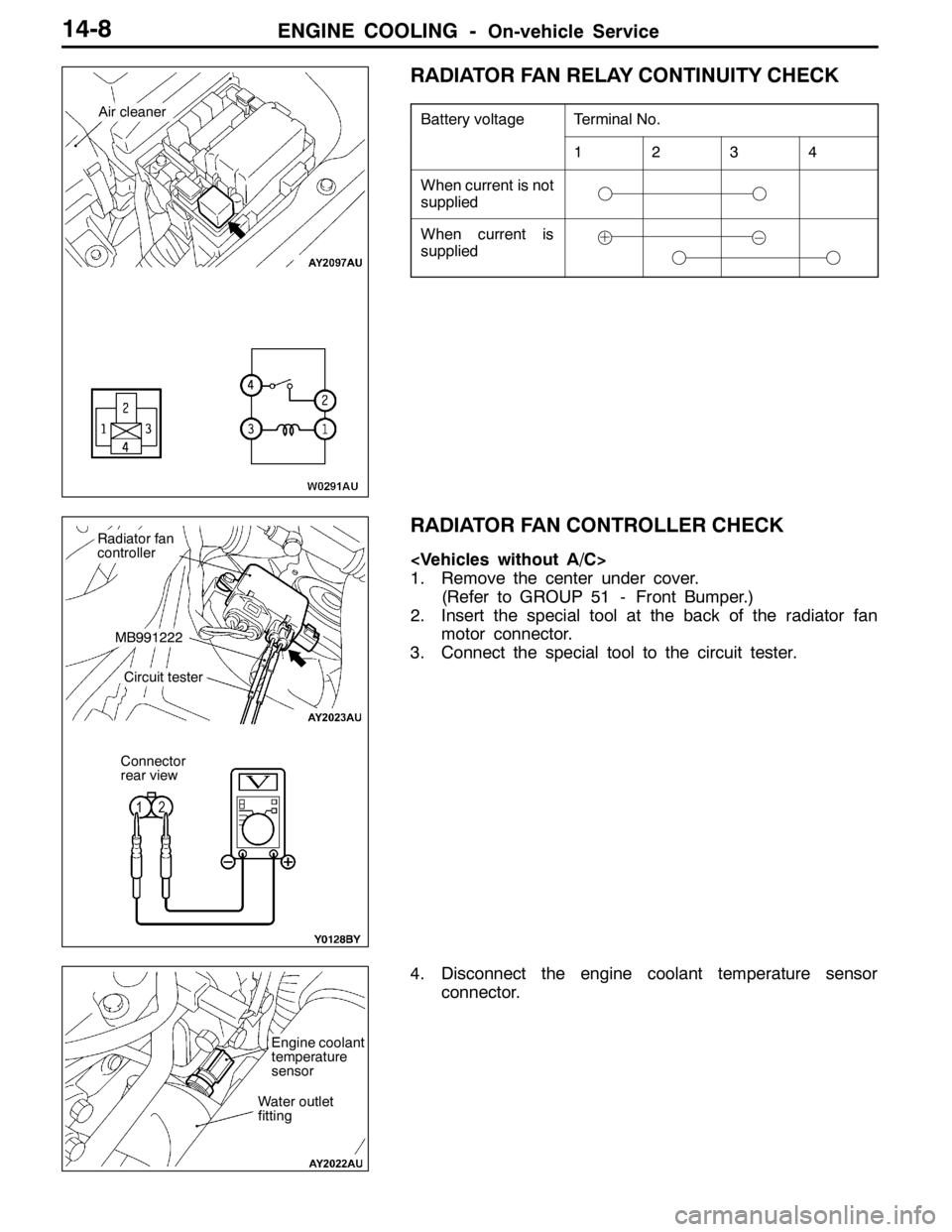

ENGINE COOLING -On-vehicle Service14-8

RADIATOR FAN RELAY CONTINUITY CHECK

Battery voltageTerminal No.

1234

When current is not

supplied

When current is

supplied

RADIATOR FAN CONTROLLER CHECK

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Insert the special tool at the back of the radiator fan

motor connector.

3. Connect the special tool to the circuit tester.

4. Disconnect the engine coolant temperature sensor

connector.

Air cleaner

Radiator fan

controller

MB991222

Circuit tester

Connector

rear view

Water outlet

fitting

Engine coolant

temperature

sensor

Page 697 of 1449

![MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the](/img/19/57084/w960_57084-696.png)

ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the special

tool (MB991658).

7. Start the engine and let it run at idle.

NOTE

Since the resistance value of the special tool (APS)

indicates a low engine coolant temperature, engine speed

increases.

8. When the lever of the special tool (APS) is turned to

the end, check that the engine speed decreases and

the radiator fan motor rotates.

9. When the lever of the special tool (APS) is turned to

the reverse direction, check that the voltage between

terminals of the radiator fan motor connector gradually

decreases from the battery voltage to 0 V.

10. If inoperable, replace the radiator fan controller.

(Refer to P.14-15.)

11. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)

12. Connect the engine coolant temperature sensor

connector.

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Insert the special tool at the back of the radiator fan

motor connector.

3. Connect the special tool to the circuit tester.

4. Start the engine and run it at idle.

5. Turn the A/C switch to the ON position and hold the

engine coolant temperature at 80_C or lower.

6. When the voltage between the terminals of the radiator

fan motor connector, the following values of (1) - (3)

can be detected at random.

(1) 0 V

(2) 8.22.6 V

(3) Battery voltage2.6 V

7. If inoperable, replace the radiator fan controller.

(Refer to P.14-15.)

8. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)

Engine coolant

temperature sensor

connector

(harness side)

MB991791(APS)

MB991658

MB991658Lever

MB991791(APS)

Radiator fan

controller

MB991222

Circuit tester

Connector

rear view

Page 702 of 1449

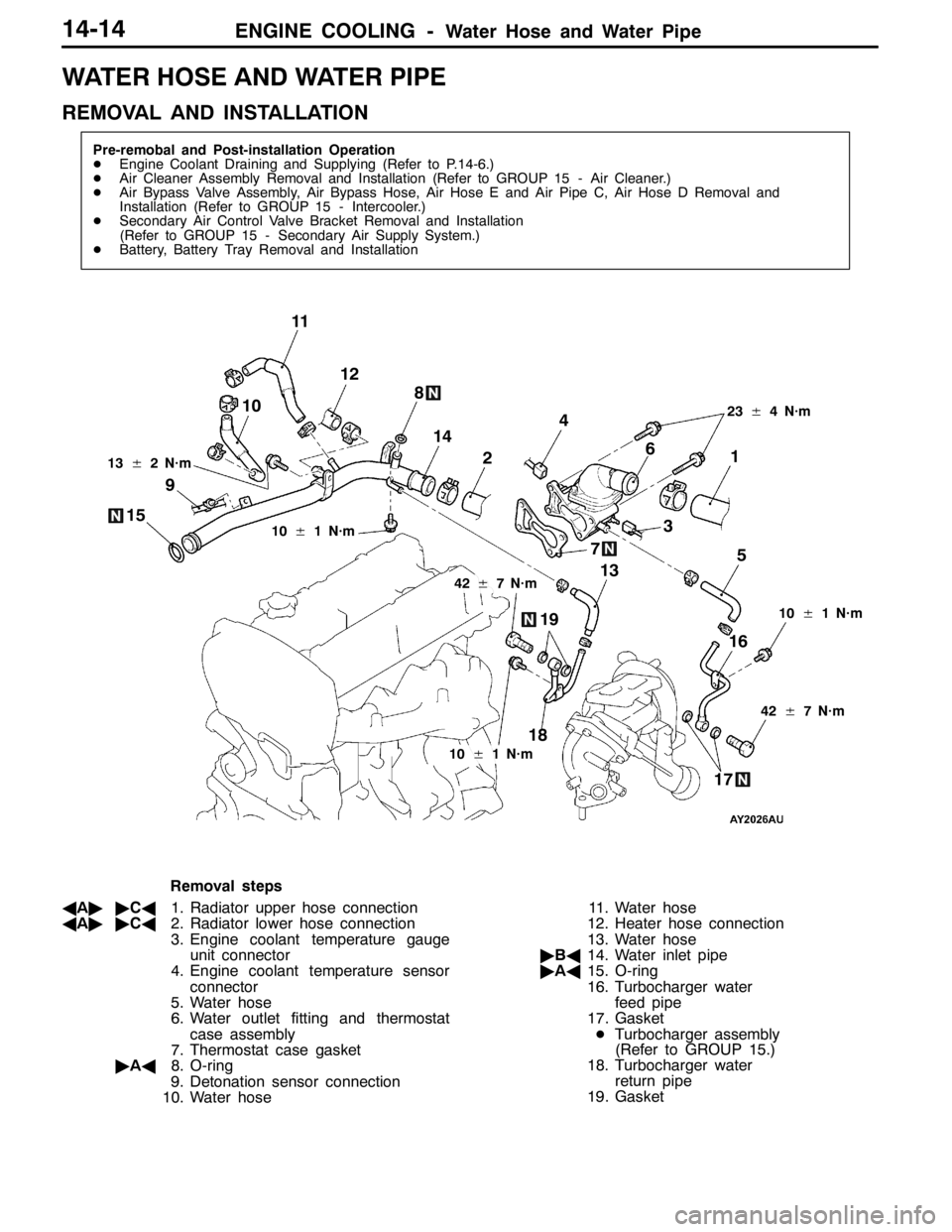

ENGINE COOLING -Water Hose and Water Pipe14-14

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15 - Air Cleaner.)

DAir Bypass Valve Assembly, Air Bypass Hose, Air Hose E and Air Pipe C, Air Hose D Removal and

Installation (Refer to GROUP 15 - Intercooler.)

DSecondary Air Control Valve Bracket Removal and Installation

(Refer to GROUP 15 - Secondary Air Supply System.)

DBattery, Battery Tray Removal and Installation

3 4

5 6

7 8

9

1012

10±1 N·m

42±7 N·m 13±2 N·m

11

1

2

23±4 N·m

18

1716 1514

13

19

10±1 N·m

42±7 N·m

10±1 N·m

Removal steps

AA""CA1. Radiator upper hose connection

AA""CA2. Radiator lower hose connection

3. Engine coolant temperature gauge

unit connector

4. Engine coolant temperature sensor

connector

5. Water hose

6. Water outlet fitting and thermostat

case assembly

7. Thermostat case gasket

"AA8. O-ring

9. Detonation sensor connection

10. Water hose11. Water hose

12. Heater hose connection

13. Water hose

"BA14. Water inlet pipe

"AA15. O-ring

16. Turbocharger water

feed pipe

17. Gasket

DTurbocharger assembly

(Refer to GROUP 15.)

18. Turbocharger water

return pipe

19. Gasket

Page 758 of 1449

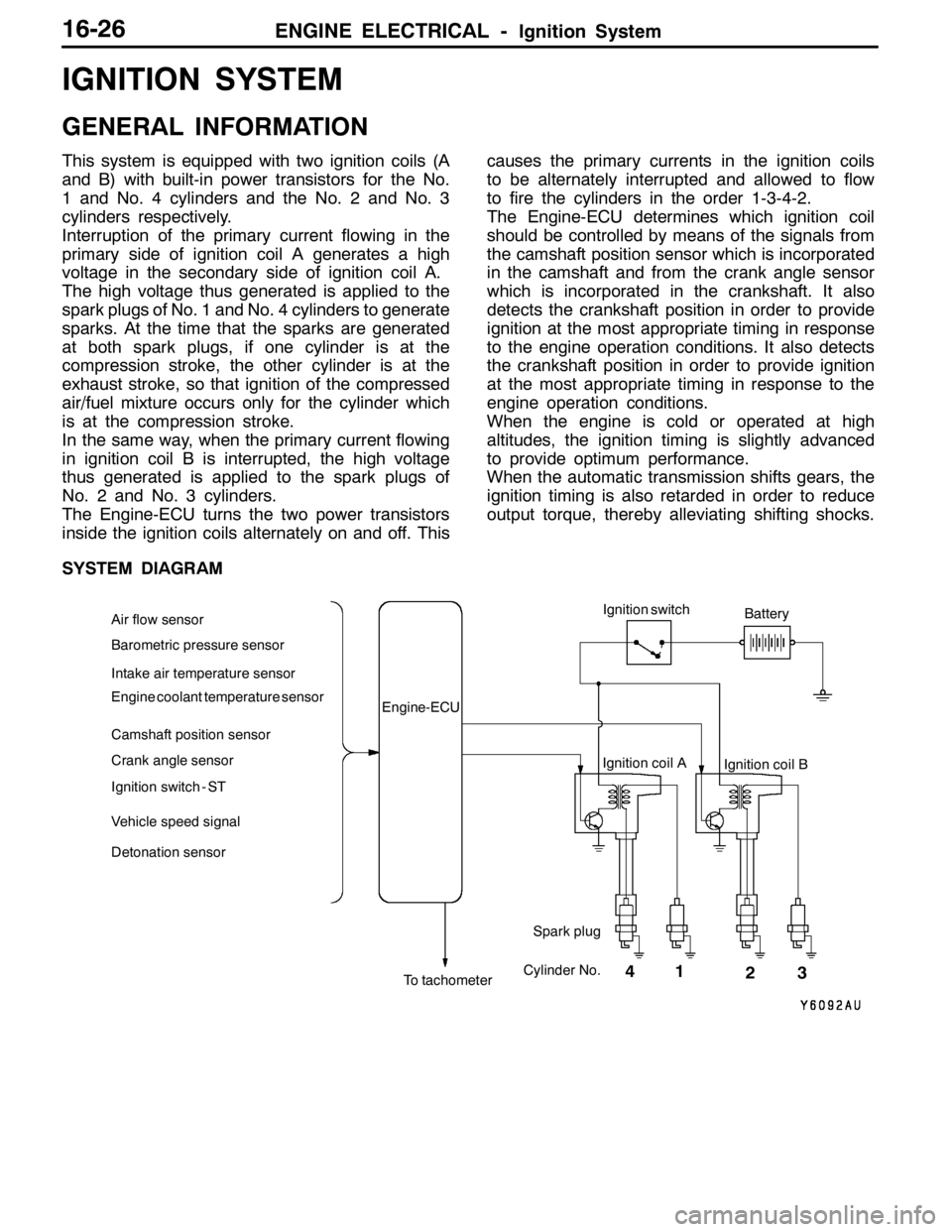

ENGINE ELECTRICAL -Ignition System16-26

IGNITION SYSTEM

GENERAL INFORMATION

This system is equipped with two ignition coils (A

and B) with built-in power transistors for the No.

1 and No. 4 cylinders and the No. 2 and No. 3

cylinders respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A.

The high voltage thus generated is applied to the

spark plugs of No. 1 and No. 4 cylinders to generate

sparks. At the time that the sparks are generated

at both spark plugs, if one cylinder is at the

compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which

is at the compression stroke.

In the same way, when the primary current flowing

in ignition coil B is interrupted, the high voltage

thus generated is applied to the spark plugs of

No. 2 and No. 3 cylinders.

The Engine-ECU turns the two power transistors

inside the ignition coils alternately on and off. Thiscauses the primary currents in the ignition coils

to be alternately interrupted and allowed to flow

to fire the cylinders in the order 1-3-4-2.

The Engine-ECU determines which ignition coil

should be controlled by means of the signals from

the camshaft position sensor which is incorporated

in the camshaft and from the crank angle sensor

which is incorporated in the crankshaft. It also

detects the crankshaft position in order to provide

ignition at the most appropriate timing in response

to the engine operation conditions. It also detects

the crankshaft position in order to provide ignition

at the most appropriate timing in response to the

engine operation conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced

to provide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce

output torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Camshaft position sensor

Crank angle sensor

Ignition switch - ST

Vehicle speed signalEngine-ECU

Ignition coil A

Ignition coil B Ignition switch

Spark plugBattery

To tachometerCylinder No. Air flow sensor

1 4

23

Detonation sensor

Page 780 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System

Vacuum tank

Alternator

Purge control solenoid valve

17-10

EVAPORATIVE EMISSION CONTROL SYSTEM

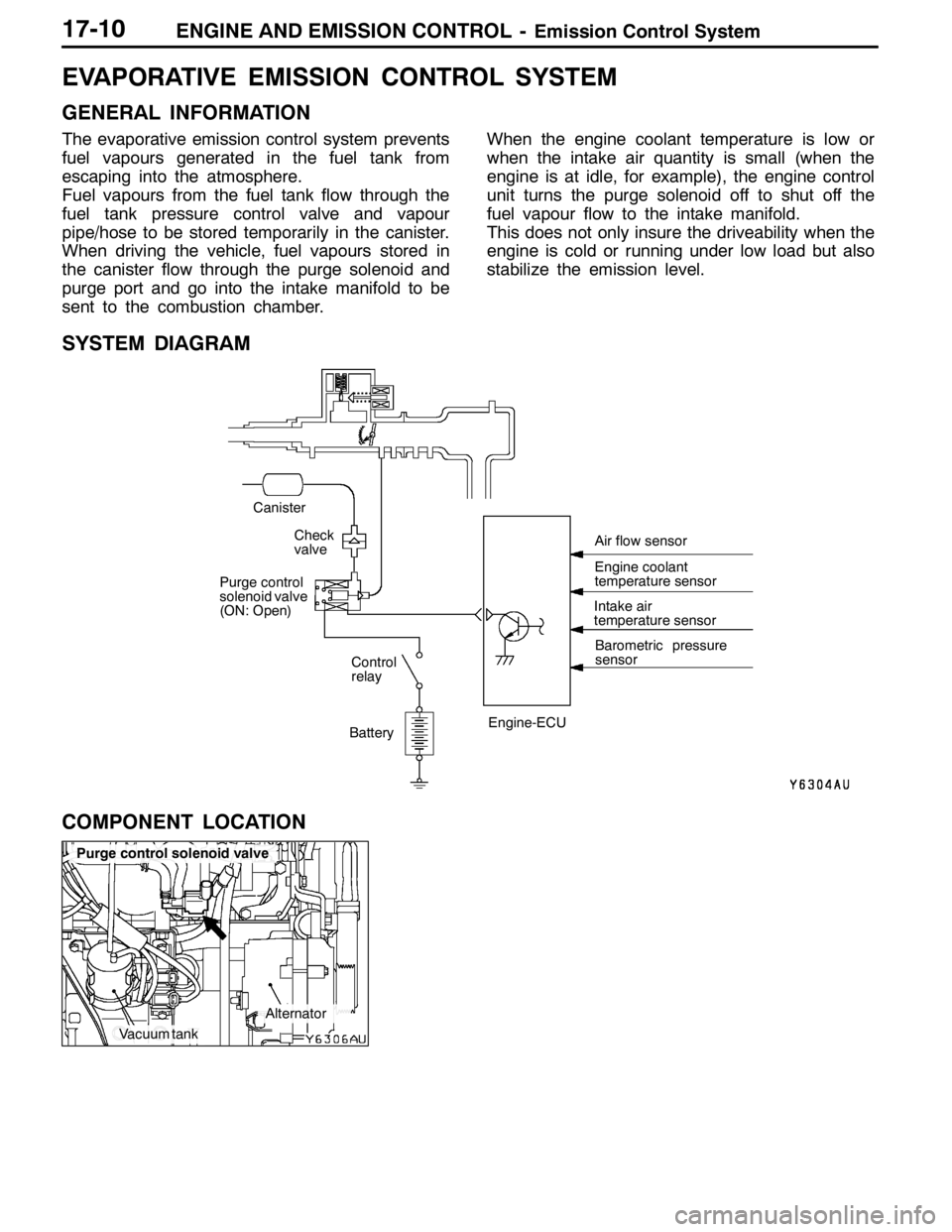

GENERAL INFORMATION

The evaporative emission control system prevents

fuel vapours generated in the fuel tank from

escaping into the atmosphere.

Fuel vapours from the fuel tank flow through the

fuel tank pressure control valve and vapour

pipe/hose to be stored temporarily in the canister.

When driving the vehicle, fuel vapours stored in

the canister flow through the purge solenoid and

purge port and go into the intake manifold to be

sent to the combustion chamber.When the engine coolant temperature is low or

when the intake air quantity is small (when the

engine is at idle, for example), the engine control

unit turns the purge solenoid off to shut off the

fuel vapour flow to the intake manifold.

This does not only insure the driveability when the

engine is cold or running under low load but also

stabilize the emission level.

SYSTEM DIAGRAM

BatteryIntake air

temperature sensor

Barometric pressure

sensor

Check

valve

Canister

Control

relay

Purge control

solenoid valve

(ON: Open)

Engine-ECUEngine coolant

temperature sensor Air flow sensor

COMPONENT LOCATION