airbag MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 864 of 1449

MANUAL TRANSMISSION -Sensor, Switch and Relay

SENSOR, SWITCH AND RELAY

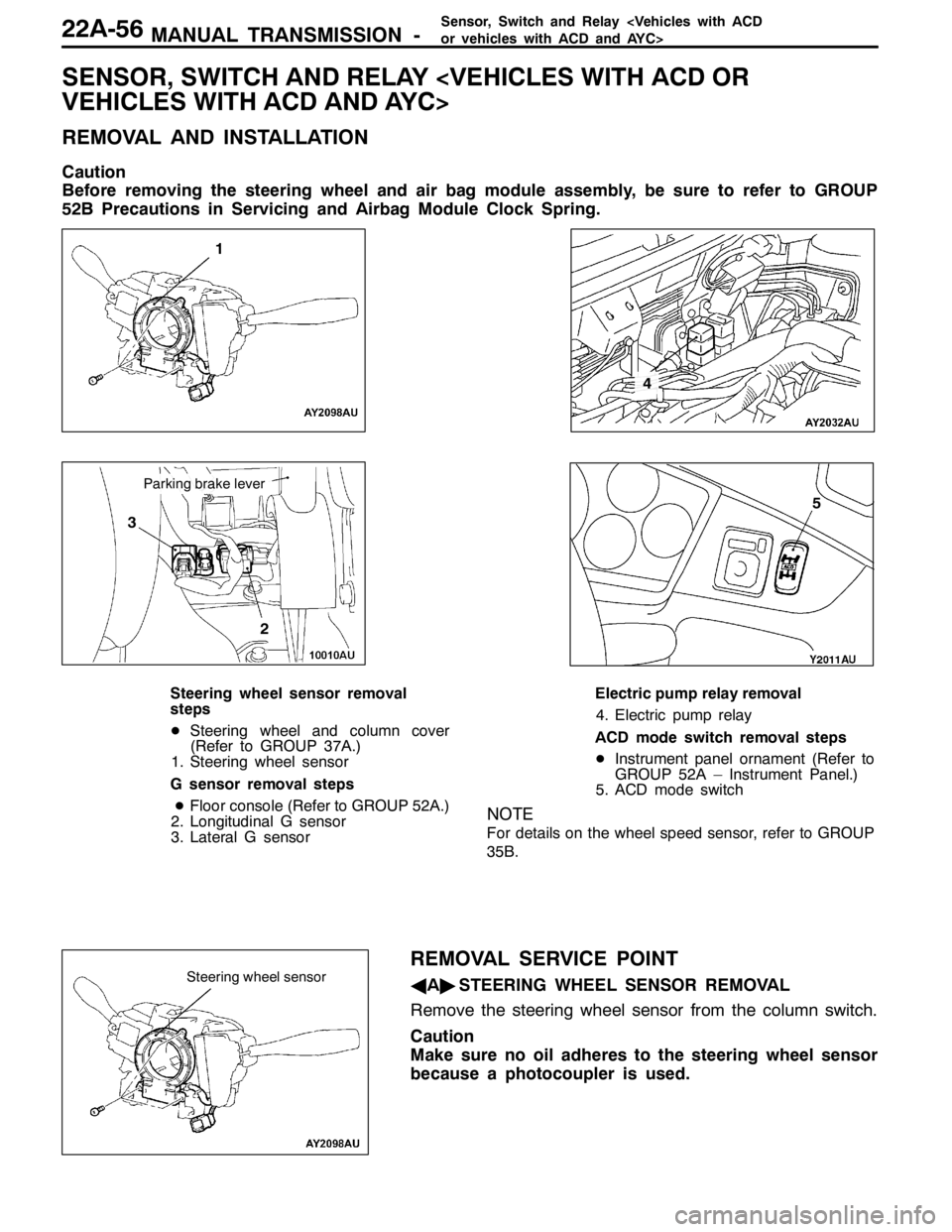

REMOVAL AND INSTALLATION

Caution

Before removing the steering wheel and air bag module assembly, be sure to refer to GROUP

52B Precautions in Servicing and Airbag Module Clock Spring.

1

3

2

4

5

Parking brake lever

Steering wheel sensor removal

steps

DSteering wheel and column cover

(Refer to GROUP 37A.)

1. Steering wheel sensor

G sensor removal steps

DFloor console (Refer to GROUP 52A.)

2. Longitudinal G sensor

3. Lateral G sensorElectric pump relay removal

4. Electric pump relay

ACD mode switch removal steps

DInstrument panel ornament (Refer to

GROUP 52A – Instrument Panel.)

5. ACD mode switch

NOTE

For details on the wheel speed sensor, refer to GROUP

35B.

REMOVAL SERVICE POINT

AA"STEERING WHEEL SENSOR REMOVAL

Remove the steering wheel sensor from the column switch.

Caution

Make sure no oil adheres to the steering wheel sensor

because a photocoupler is used.Steering wheel sensor

Page 1116 of 1449

STEERING -General Information37A-2

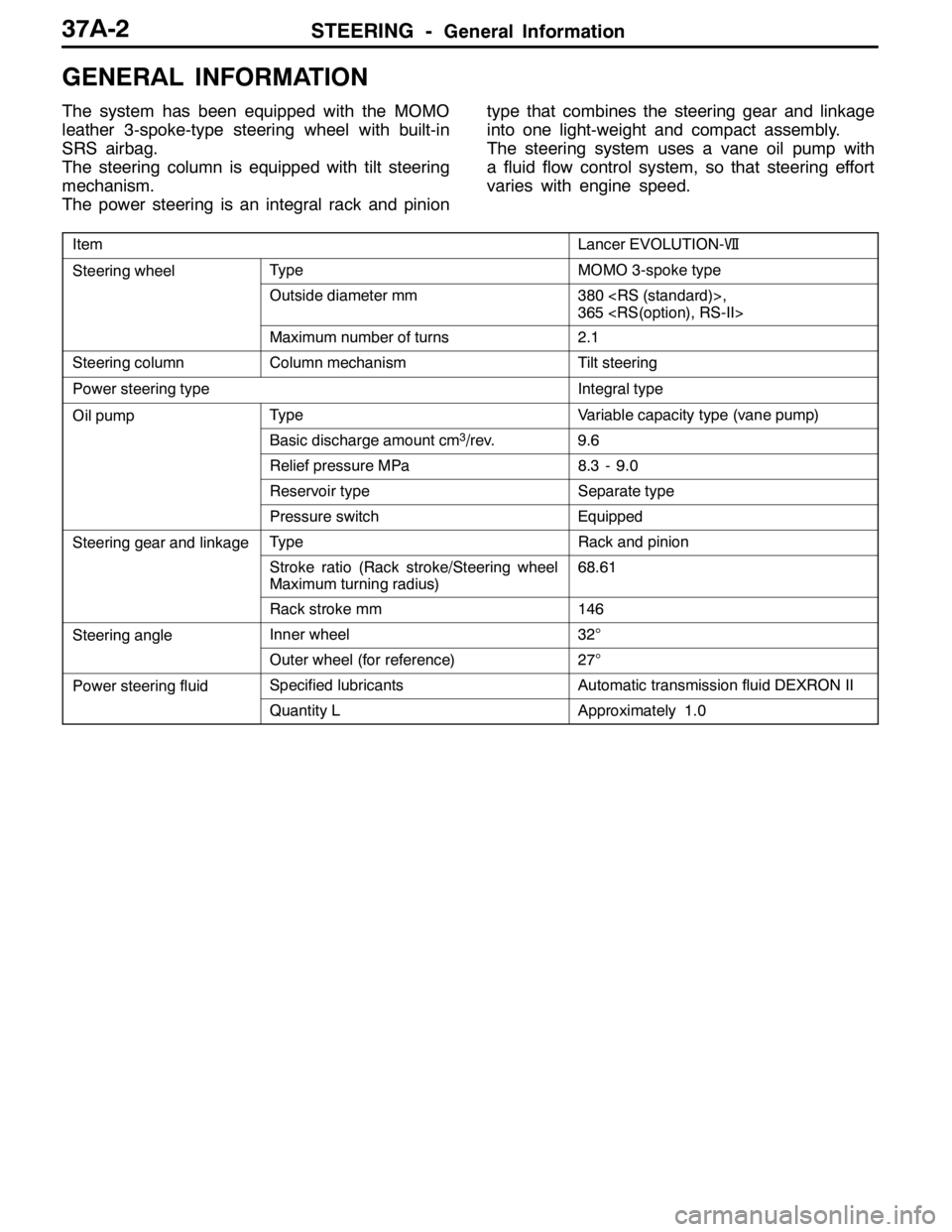

GENERAL INFORMATION

The system has been equipped with the MOMO

leather 3-spoke-type steering wheel with built-in

SRS airbag.

The steering column is equipped with tilt steering

mechanism.

The power steering is an integral rack and piniontype that combines the steering gear and linkage

into one light-weight and compact assembly.

The steering system uses a vane oil pump with

a fluid flow control system, so that steering effort

varies with engine speed.

ItemLancer EVOLUTION-

Steering wheelTypeMOMO 3-spoke typeg

Outside diameter mm380

365

Maximum number of turns2.1

Steering columnColumn mechanismTilt steering

Power steering typeIntegral type

Oil pumpTypeVariable capacity type (vane pump)pp

Basic discharge amount cm3/rev.9.6

Relief pressure MPa8.3 - 9.0

Reservoir typeSeparate type

Pressure switchEquipped

Steering gear and linkageTypeRack and pinionggg

Stroke ratio (Rack stroke/Steering wheel

Maximum turning radius)68.61

Rack stroke mm146

Steering angleInner wheel32°gg

Outer wheel (for reference)27°

Power steering fluidSpecified lubricantsAutomatic transmission fluid DEXRON IIg

Quantity LApproximately 1.0

Page 1127 of 1449

STEERING -Steering Wheel37A-13

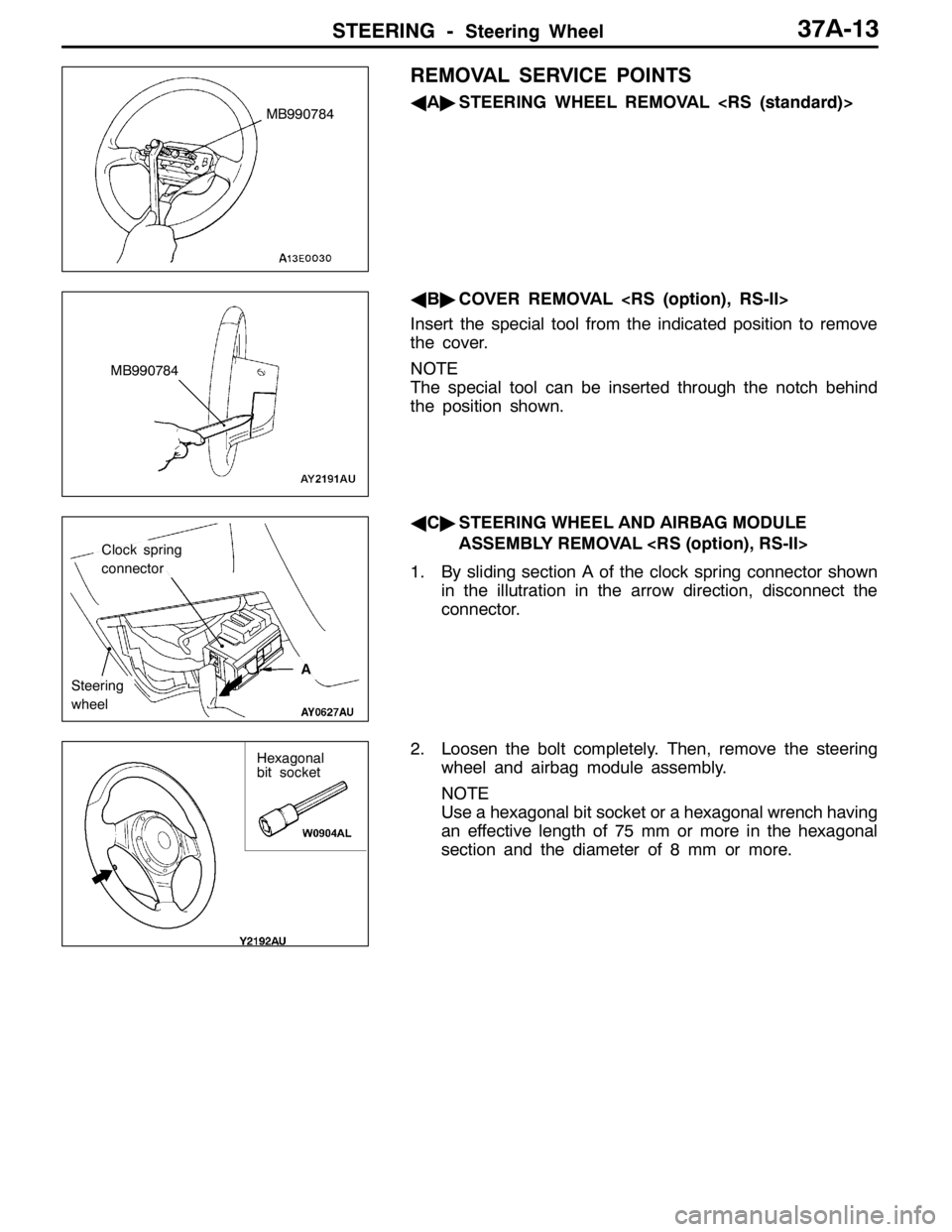

REMOVAL SERVICE POINTS

AA"STEERING WHEEL REMOVAL

AB"COVER REMOVAL

Insert the special tool from the indicated position to remove

the cover.

NOTE

The special tool can be inserted through the notch behind

the position shown.

AC"STEERING WHEEL AND AIRBAG MODULE

ASSEMBLY REMOVAL

1. By sliding section A of the clock spring connector shown

in the illutration in the arrow direction, disconnect the

connector.

2. Loosen the bolt completely. Then, remove the steering

wheel and airbag module assembly.

NOTE

Use a hexagonal bit socket or a hexagonal wrench having

an effective length of 75 mm or more in the hexagonal

section and the diameter of 8 mm or more.MB990784

MB990784

Clock spring

connector

Steering

wheel

A

Hexagonal

bit socket

Page 1255 of 1449

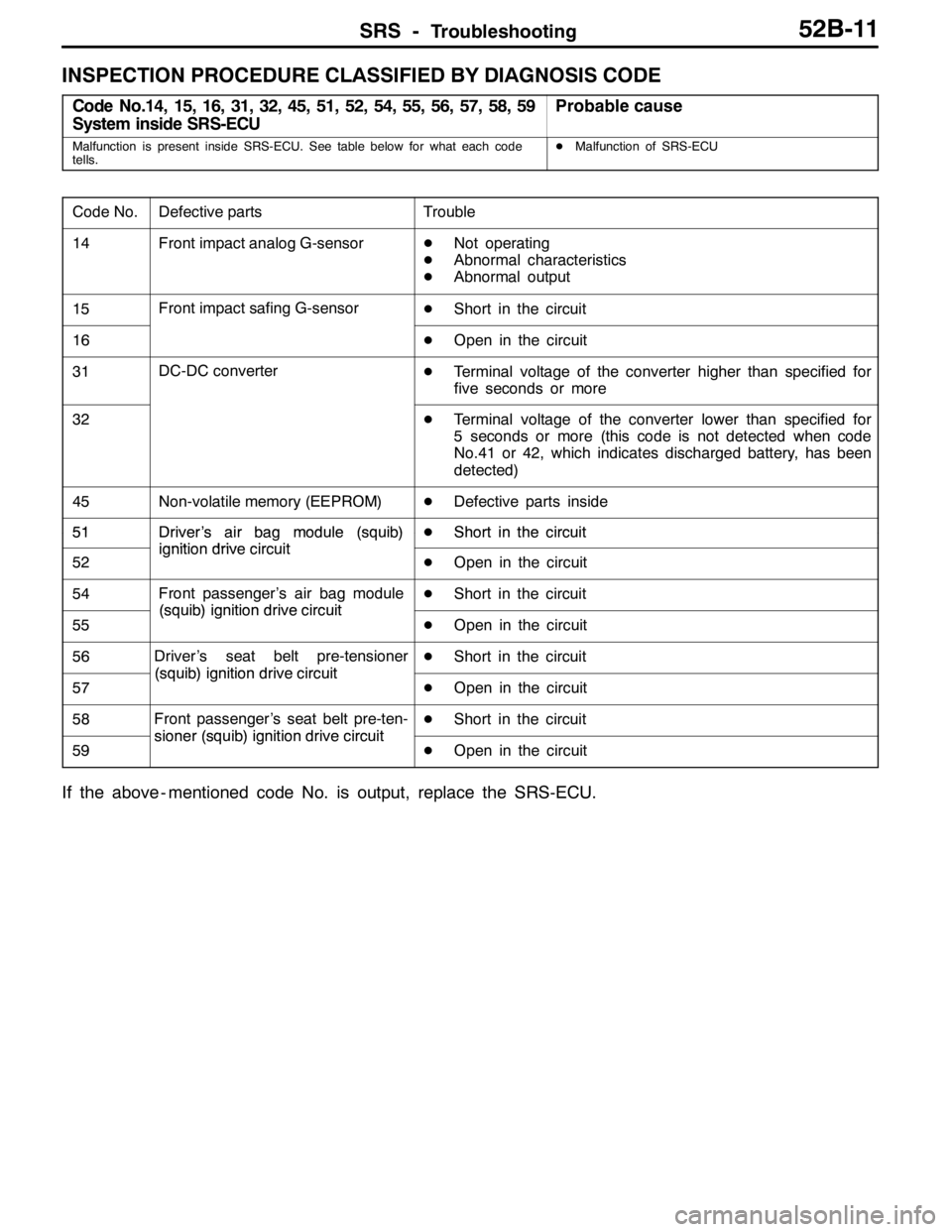

SRS -Troubleshooting52B-11

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

Code No.14, 15, 16, 31, 32, 45, 51, 52, 54, 55, 56, 57, 58, 59

System inside SRS-ECUProbable cause

Malfunction is present inside SRS-ECU. See table below for what each code

tells.DMalfunction of SRS-ECU

Code No.Defective partsTrouble

14Front impact analog G-sensorDNot operating

DAbnormal characteristics

DAbnormal output

15Front impact safing G-sensorDShort in the circuit

16DOpen in the circuit

31DC-DC converterDTerminal voltage of the converter higher than specified for

five seconds or more

32DTerminal voltage of the converter lower than specified for

5 seconds or more (this code is not detected when code

No.41 or 42, which indicates discharged battery, has been

detected)

45Non-volatile memory (EEPROM)DDefective parts inside

51Driver’sairbagmodule(squib)DShortinthecircuit51Driver’sairbag module(squib)

ignitiondrivecircuit

DShortinthecircuit

52ignition drive circuitDOpen in the circuit

54Front passenger’s air bag module

(squib)ignitiondrivecircuit

DShort in the circuit

55(squib)ignitiondrive circuitDOpen in the circuit

56Driver’s seat belt pre-tensioner

(squib)ignitiondrivecircuit

DShort in the circuit

57(squib)ignitiondrive circuitDOpen in the circuit

58Front passenger’s seat belt pre-ten-

sioner(squib)ignitiondrivecircuit

DShort in the circuit

59sioner(squib)ignitiondrive circuitDOpen in the circuit

If the above - mentioned code No. is output, replace the SRS-ECU.

Page 1308 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-64

AIR BAG MODULE AND SEAT BELT PRE-TENSIONER DISPOSAL

PROCEDURES

Carry out the following procedure of air bag

deployment and seat belt pre-tensioner operation

before disposing the air bag module and seat beltwith pre-tensioner or the vehicle with SRS air bag

and seat belt with pre-tensioner.

DISPOSAL OF AIR BAG MODULE BEFORE

DEPLOYMENT OR SEAT BELT WITH

PRE-TENSIONER BEFORE OPERATION

Caution

1. Carry out deployment of all the air bag modules and

operation of all seat belt pre-tensioners before

disposing the vehicle with SRS air bag and seat belt

with pre-tensioner inside the vehicle.

2. Carry out deployment of the used air bag or operation

of the used seat belt pre-tensioner outside the vehicle

when replacing the air bag module or the seat belt with

pre-tensioner.

3. Carry out deployment of air bag or operation of seat

belt pre-tensioner in a well ventilated place since a lot

of smoke is generated .Do not carry out operation near

a smoke detector.

4. Avoid carrying out operation in a residential area as

much as possible and give a warning when any person

is near by since air bag deployment or seat belt

pre-tensioner operation causes loud operation sound.

5. Prepare ear plugs for those are engaged in air bag

deployment or seat belt pre-tensioner operation or for

those who are near by.

DEPLOYMENT OR OPERATION INSIDE THE VEHICLE

1. Move the vehicle to flat and isolated spot.

2. Disconnect the negative (–) and positive (+) battery cables

from the battery terminals, and then remove the battery

from the vehicle.

Caution

Wait at least 60 seconds after the disconnection of the

battery cables before any further job. (Refer to

P.52B-3.)

3. Carry out deployment of the air bag module and operation

of the seat belt pre-tensioner according to the following

procedure.

Page 1309 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-65

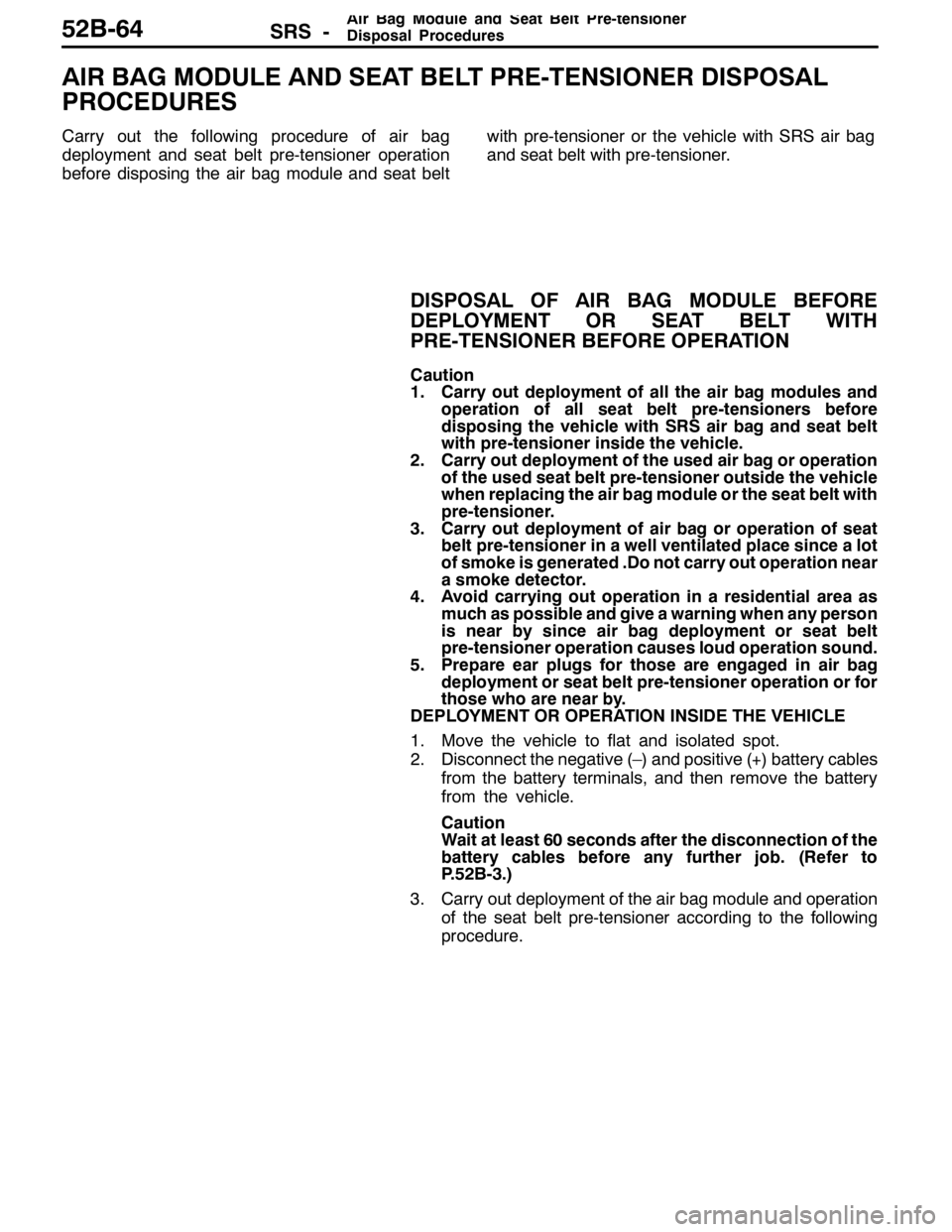

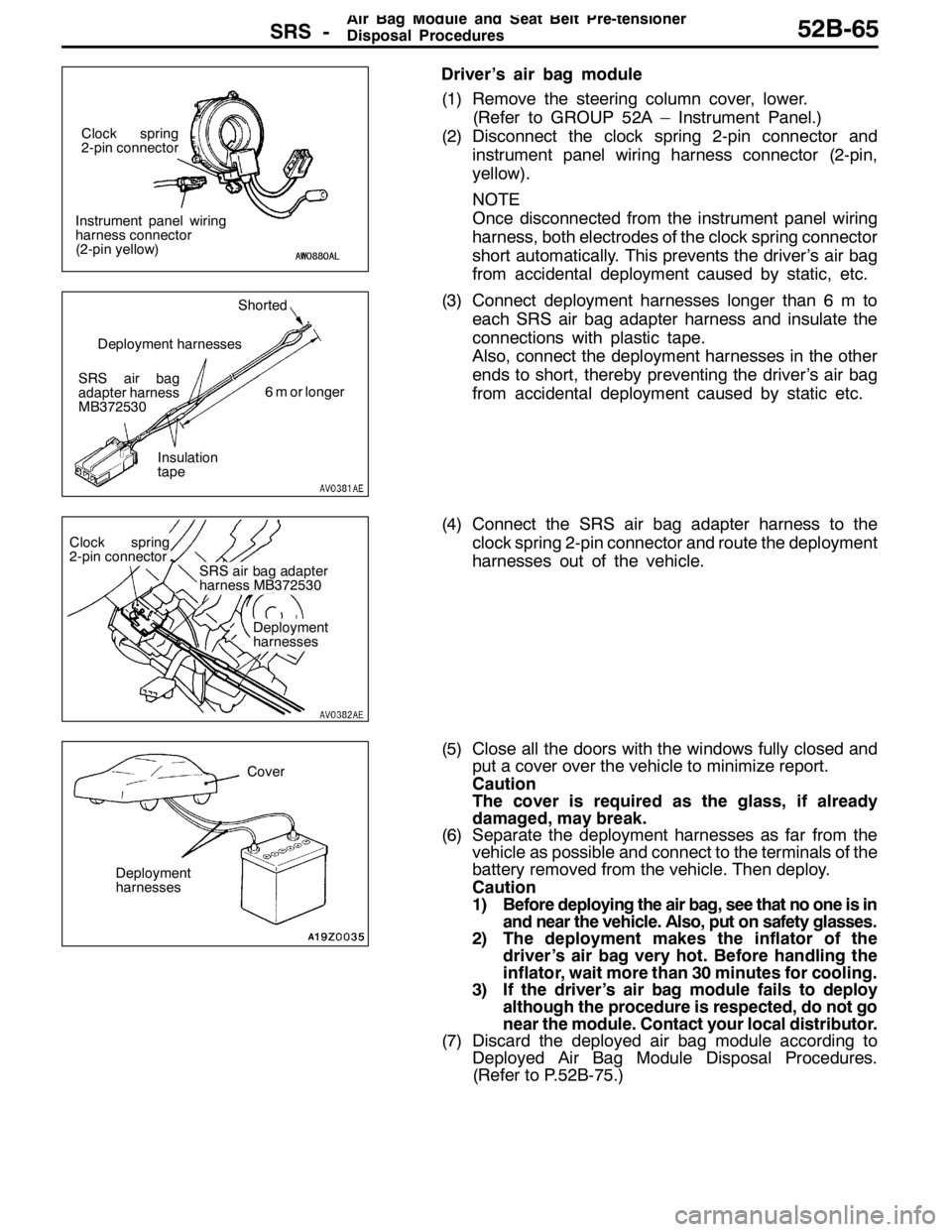

Driver’s air bag module

(1) Remove the steering column cover, lower.

(Refer to GROUP 52A – Instrument Panel.)

(2) Disconnect the clock spring 2-pin connector and

instrument panel wiring harness connector (2-pin,

yellow).

NOTE

Once disconnected from the instrument panel wiring

harness, both electrodes of the clock spring connector

short automatically. This prevents the driver’s air bag

from accidental deployment caused by static, etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the driver’s air bag

from accidental deployment caused by static etc.

(4) Connect the SRS air bag adapter harness to the

clock spring 2-pin connector and route the deployment

harnesses out of the vehicle.

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of the

battery removed from the vehicle. Then deploy.

Caution

1) Before deploying the air bag, see that no one is in

and near the vehicle. Also, put on safety glasses.

2) The deployment makes the inflator of the

driver’s air bag very hot. Before handling the

inflator, wait more than 30 minutes for cooling.

3) If the driver’s air bag module fails to deploy

although the procedure is respected, do not go

near the module. Contact your local distributor.

(7) Discard the deployed air bag module according to

Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

Instrument panel wiring

harness connector

(2-pin yellow)Clock spring

2-pin connector

SRS air bag

adapter harness

MB372530Shorted

6 m or longer

Insulation

tape Deployment harnesses

Clock spring

2-pin connector

SRS air bag adapter

harness MB372530

Deployment

harnesses

Cover

Deployment

harnesses

Page 1310 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-66

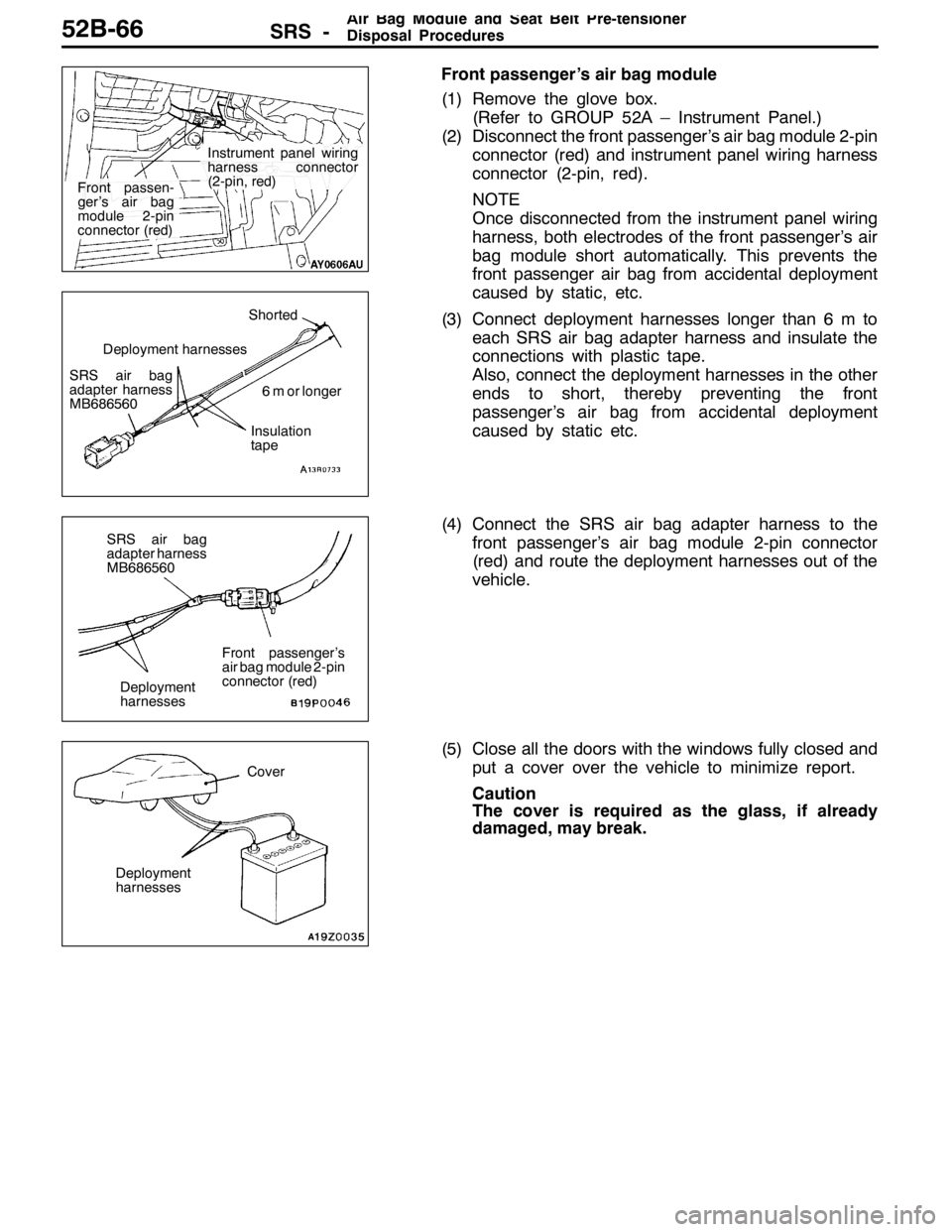

Front passenger’s air bag module

(1) Remove the glove box.

(Refer to GROUP 52A – Instrument Panel.)

(2) Disconnect the front passenger’s air bag module 2-pin

connector (red) and instrument panel wiring harness

connector (2-pin, red).

NOTE

Once disconnected from the instrument panel wiring

harness, both electrodes of the front passenger’s air

bag module short automatically. This prevents the

front passenger air bag from accidental deployment

caused by static, etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the front

passenger’s air bag from accidental deployment

caused by static etc.

(4) Connect the SRS air bag adapter harness to the

front passenger’s air bag module 2-pin connector

(red) and route the deployment harnesses out of the

vehicle.

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

Instrument panel wiring

harness connector

(2-pin, red)

Front passen-

ger’s air bag

module 2-pin

connector (red)

SRS air bag

adapter harness

MB686560Shorted

6 m or longer

Insulation

tape Deployment harnesses

Deployment

harnesses SRS air bag

adapter harness

MB686560

Front passenger’s

air bag module 2-pin

connector (red)

Cover

Deployment

harnesses

Page 1311 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-67

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of the

battery removed from the vehicle. Then deploy.

Caution

1) Before deploying the air bag, see that no one is

in and near the vehicle. Also, put on safety

glasses.

2) The deployment makes the inflator of the front

passenger’s air bag very hot. Before handling

the inflator, wait more than 30 minutes for

cooling.

3) If the front passenger’s air bag module fails to

deploy although the procedure is respected,

do not go near the module. Contact your local

distributor.

(7) Discard the deployed air bag module according to

Deployed Air Bag Module Disposal Procedures.

(Refer to P.52B-75.)

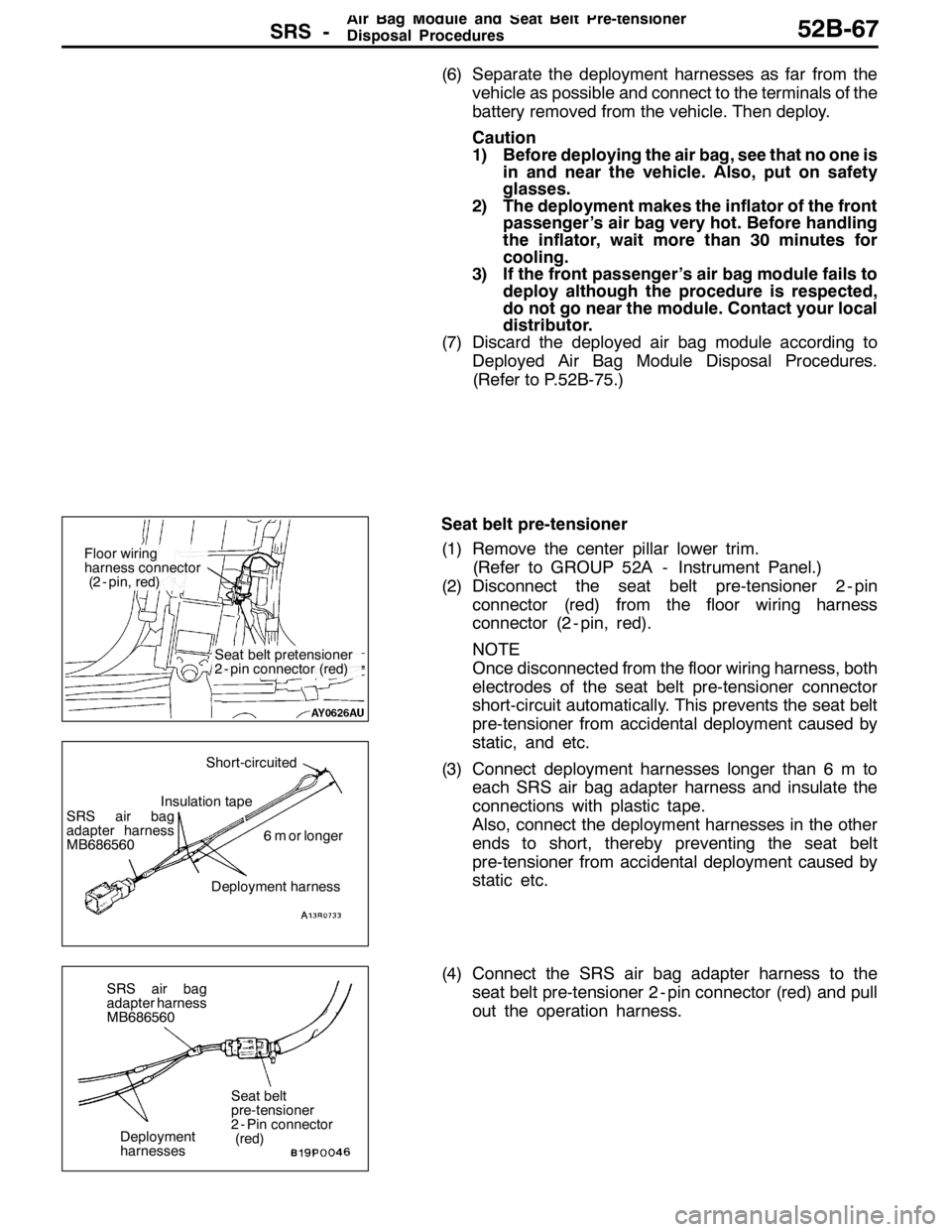

Seat belt pre-tensioner

(1) Remove the center pillar lower trim.

(Refer to GROUP 52A - Instrument Panel.)

(2) Disconnect the seat belt pre-tensioner 2 - pin

connector (red) from the floor wiring harness

connector (2 - pin, red).

NOTE

Once disconnected from the floor wiring harness, both

electrodes of the seat belt pre-tensioner connector

short-circuit automatically. This prevents the seat belt

pre-tensioner from accidental deployment caused by

static, and etc.

(3) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harnesses in the other

ends to short, thereby preventing the seat belt

pre-tensioner from accidental deployment caused by

static etc.

(4) Connect the SRS air bag adapter harness to the

seat belt pre-tensioner 2 - pin connector (red) and pull

out the operation harness.

Seat belt pretensioner

2 - pin connector (red)

Floor wiring

harness connector

(2 - pin, red)

SRS air bag

adapter harness

MB686560

Insulation tapeShort-circuited

6 m or longer

Deployment harness

Deployment

harnesses SRS air bag

adapter harness

MB686560

Seat belt

pre-tensioner

2 - Pin connector

(red)

Page 1312 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-68

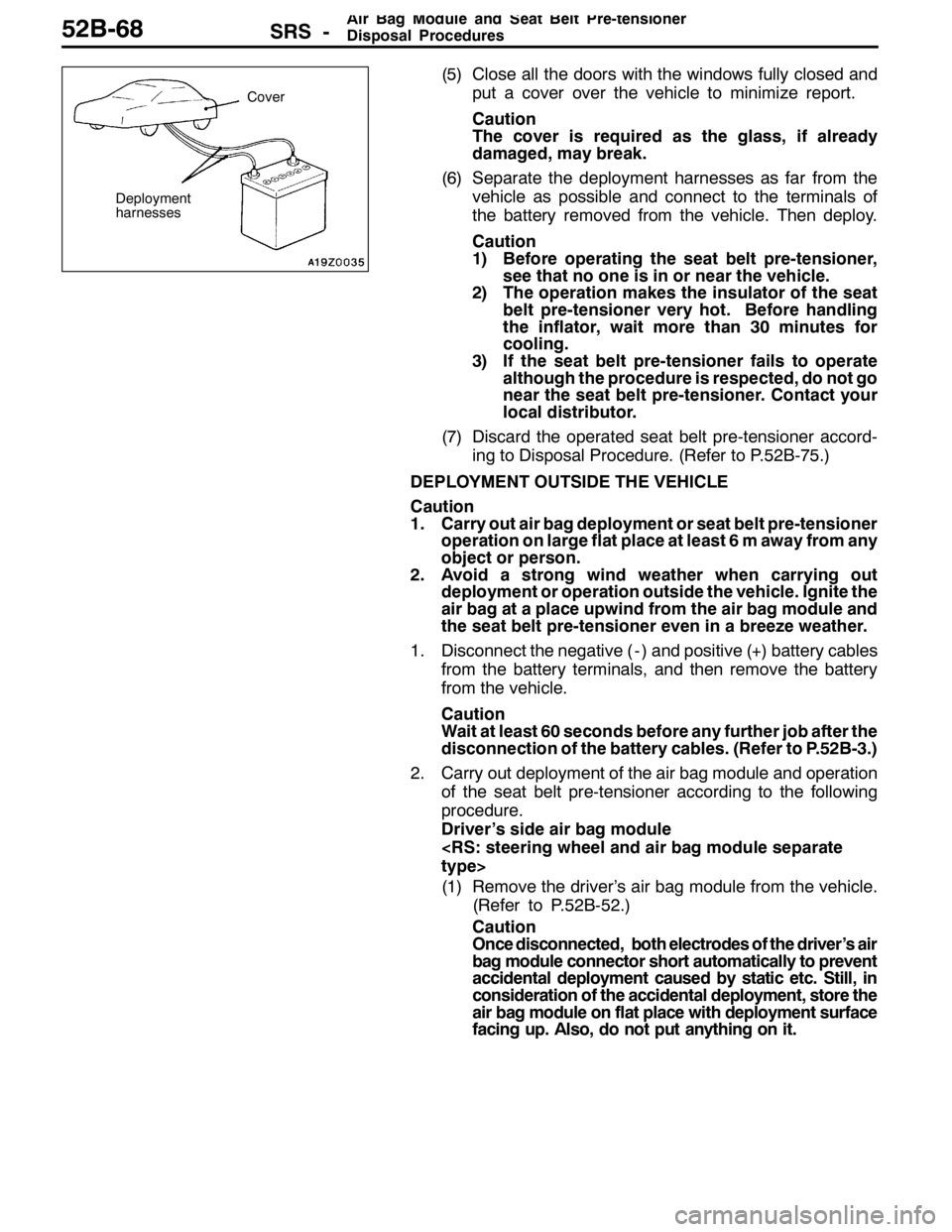

(5) Close all the doors with the windows fully closed and

put a cover over the vehicle to minimize report.

Caution

The cover is required as the glass, if already

damaged, may break.

(6) Separate the deployment harnesses as far from the

vehicle as possible and connect to the terminals of

the battery removed from the vehicle. Then deploy.

Caution

1) Before operating the seat belt pre-tensioner,

see that no one is in or near the vehicle.

2) The operation makes the insulator of the seat

belt pre-tensioner very hot. Before handling

the inflator, wait more than 30 minutes for

cooling.

3) If the seat belt pre-tensioner fails to operate

although the procedure is respected, do not go

near the seat belt pre-tensioner. Contact your

local distributor.

(7) Discard the operated seat belt pre-tensioner accord-

ing to Disposal Procedure. (Refer to P.52B-75.)

DEPLOYMENT OUTSIDE THE VEHICLE

Caution

1. Carry out air bag deployment or seat belt pre-tensioner

operation on large flat place at least 6 m away from any

object or person.

2. Avoid a strong wind weather when carrying out

deployment or operation outside the vehicle. Ignite the

air bag at a place upwind from the air bag module and

the seat belt pre-tensioner even in a breeze weather.

1. Disconnect the negative ( - ) and positive (+) battery cables

from the battery terminals, and then remove the battery

from the vehicle.

Caution

Wait at least 60 seconds before any further job after the

disconnection of the battery cables. (Refer to P.52B-3.)

2. Carry out deployment of the air bag module and operation

of the seat belt pre-tensioner according to the following

procedure.

Driver’s side air bag module

(1) Remove the driver’s air bag module from the vehicle.

(Refer to P.52B-52.)

Caution

Once disconnected, both electrodes of the driver’s air

bag module connector short automatically to prevent

accidental deployment caused by static etc. Still, in

consideration of the accidental deployment, store the

air bag module on flat place with deployment surface

facing up. Also, do not put anything on it.

Cover

Deployment

harnesses

Page 1313 of 1449

SRS -AirBagModuleandSeatBeltPre-tensioner

Disposal Procedures52B-69

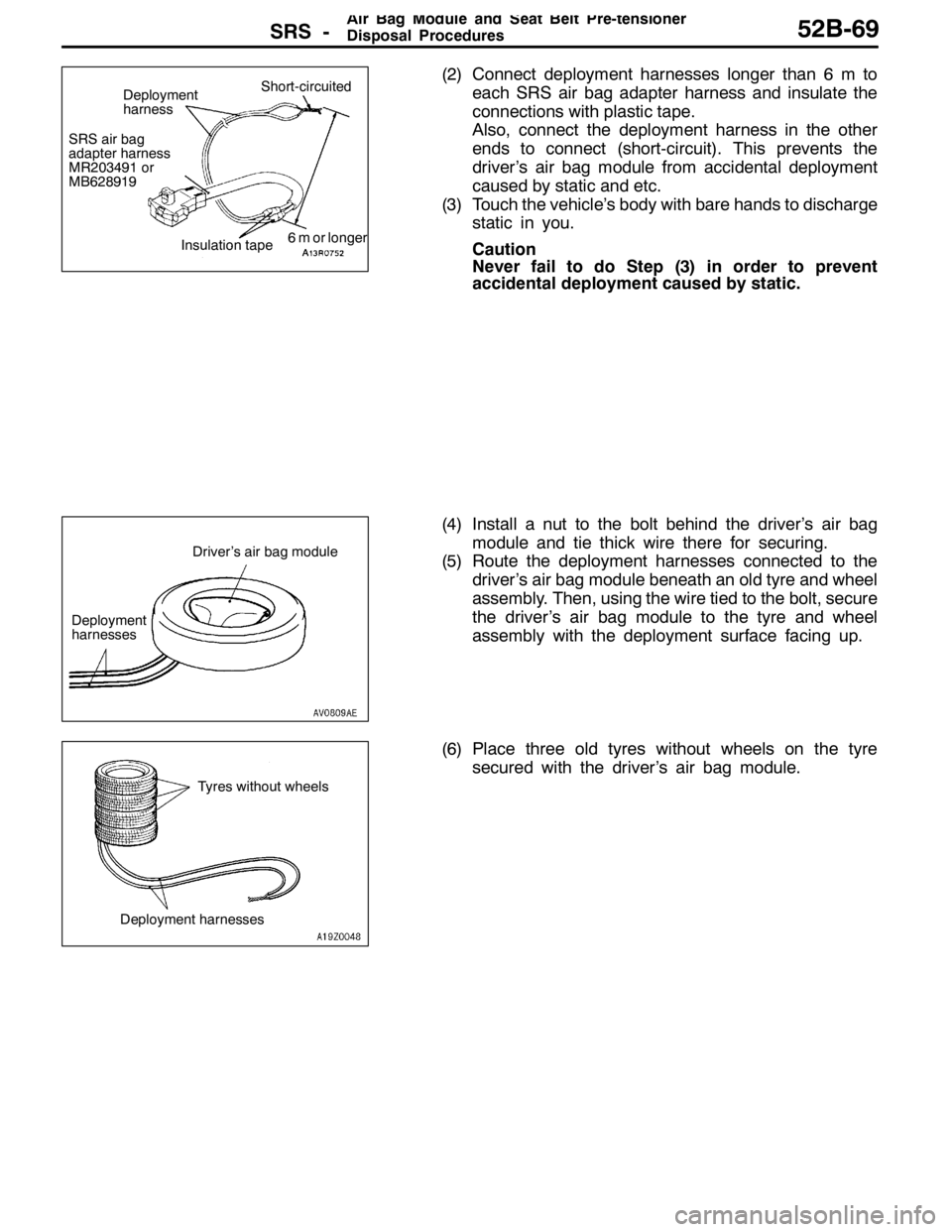

(2) Connect deployment harnesses longer than 6 m to

each SRS air bag adapter harness and insulate the

connections with plastic tape.

Also, connect the deployment harness in the other

ends to connect (short-circuit). This prevents the

driver’s air bag module from accidental deployment

caused by static and etc.

(3) Touch the vehicle’s body with bare hands to discharge

static in you.

Caution

Never fail to do Step (3) in order to prevent

accidental deployment caused by static.

(4) Install a nut to the bolt behind the driver’s air bag

module and tie thick wire there for securing.

(5) Route the deployment harnesses connected to the

driver’s air bag module beneath an old tyre and wheel

assembly. Then, using the wire tied to the bolt, secure

the driver’s air bag module to the tyre and wheel

assembly with the deployment surface facing up.

(6) Place three old tyres without wheels on the tyre

secured with the driver’s air bag module.

SRS air bag

adapter harness

MR203491 or

MB628919Deployment

harnessShort-circuited

6 m or longer

Insulation tape

Driver’s air bag module

Deployment

harnesses

Tyres without wheels

Deployment harnesses