idle MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 110 of 1449

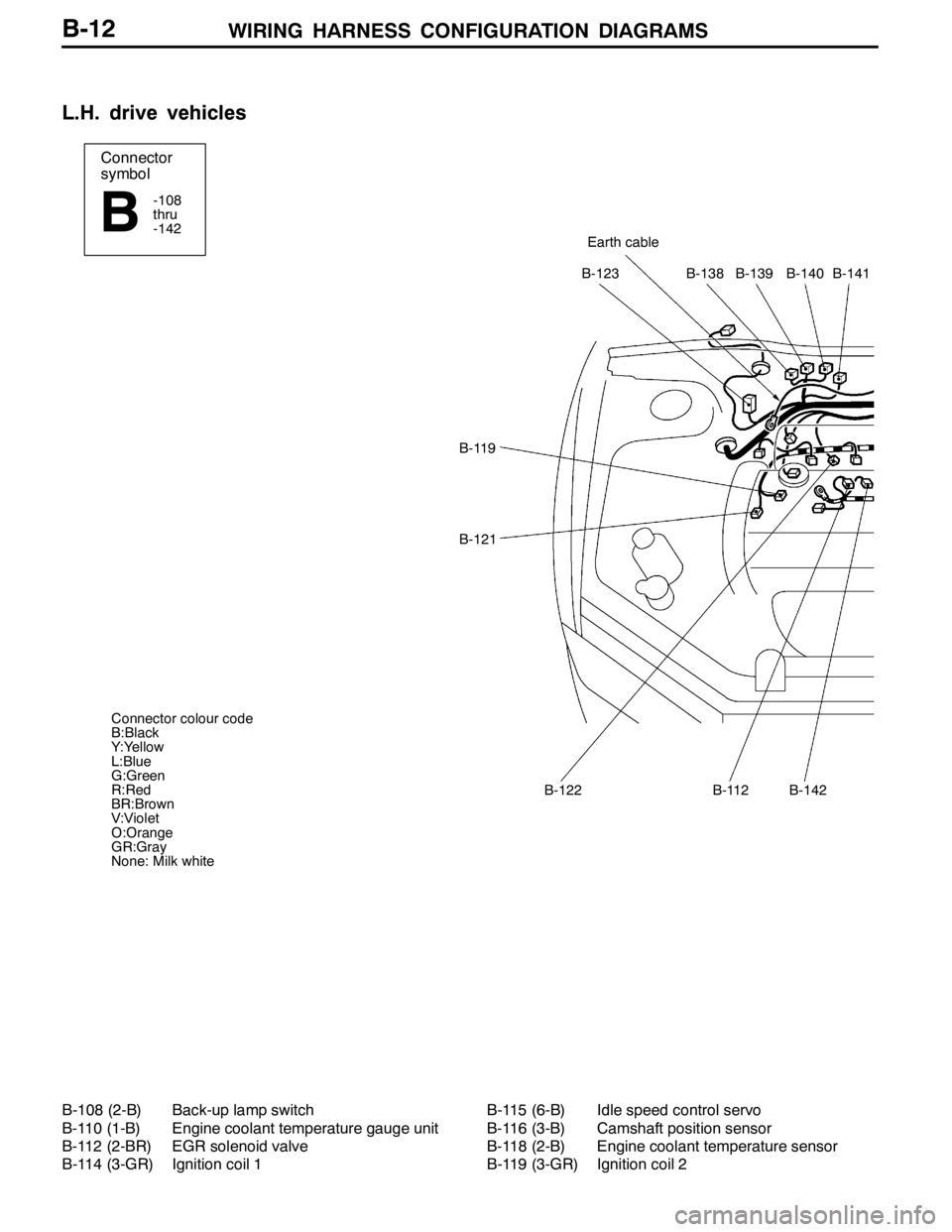

WIRING HARNESS CONFIGURATION DIAGRAMS

Connector

symbol

-108

thru

-142

BEarth cable

B-123B-138B-139B-140B-141

B-119

B-121

B-122B-112B-142

Connector colour code

B:Black

Y:Yellow

L:Blue

G:Green

R:Red

BR:Brown

V:Violet

O:Orange

GR:Gray

None: Milk white

B-12

L.H. drive vehicles

B-108 (2-B) Back-up lamp switch

B-110 (1-B) Engine coolant temperature gauge unit

B-112 (2-BR) EGR solenoid valve

B-114 (3-GR) Ignition coil 1B-115 (6-B) Idle speed control servo

B-116 (3-B) Camshaft position sensor

B-118 (2-B) Engine coolant temperature sensor

B-119 (3-GR) Ignition coil 2

Page 114 of 1449

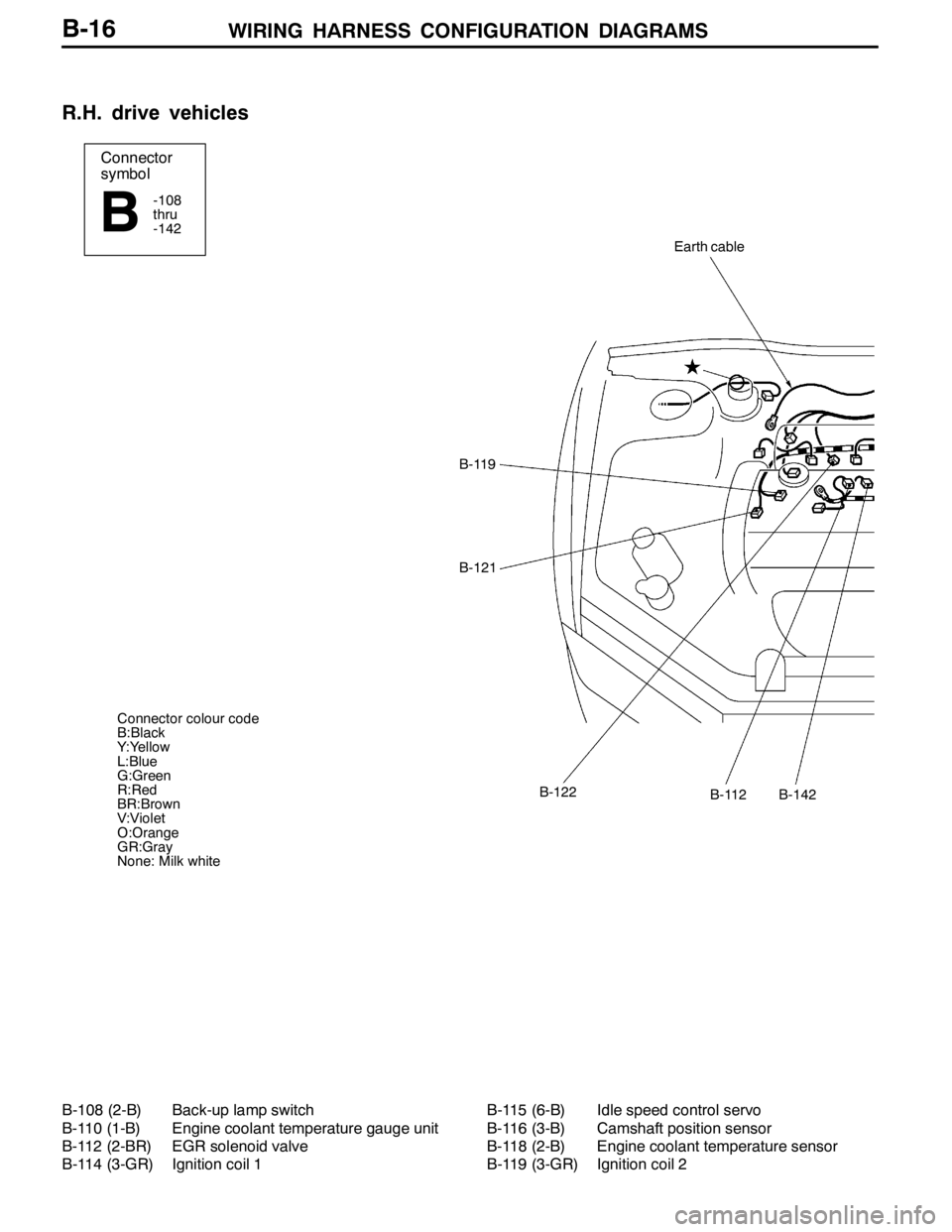

WIRING HARNESS CONFIGURATION DIAGRAMS

Connector

symbol

-108

thru

-142

B

Earth cable

B-119

B-121

B-112B-122B-142

Connector colour code

B:Black

Y:Yellow

L:Blue

G:Green

R:Red

BR:Brown

V:Violet

O:Orange

GR:Gray

None: Milk white

B-16

R.H. drive vehicles

B-108 (2-B) Back-up lamp switch

B-110 (1-B) Engine coolant temperature gauge unit

B-112 (2-BR) EGR solenoid valve

B-114 (3-GR) Ignition coil 1B-115 (6-B) Idle speed control servo

B-116 (3-B) Camshaft position sensor

B-118 (2-B) Engine coolant temperature sensor

B-119 (3-GR) Ignition coil 2

Page 359 of 1449

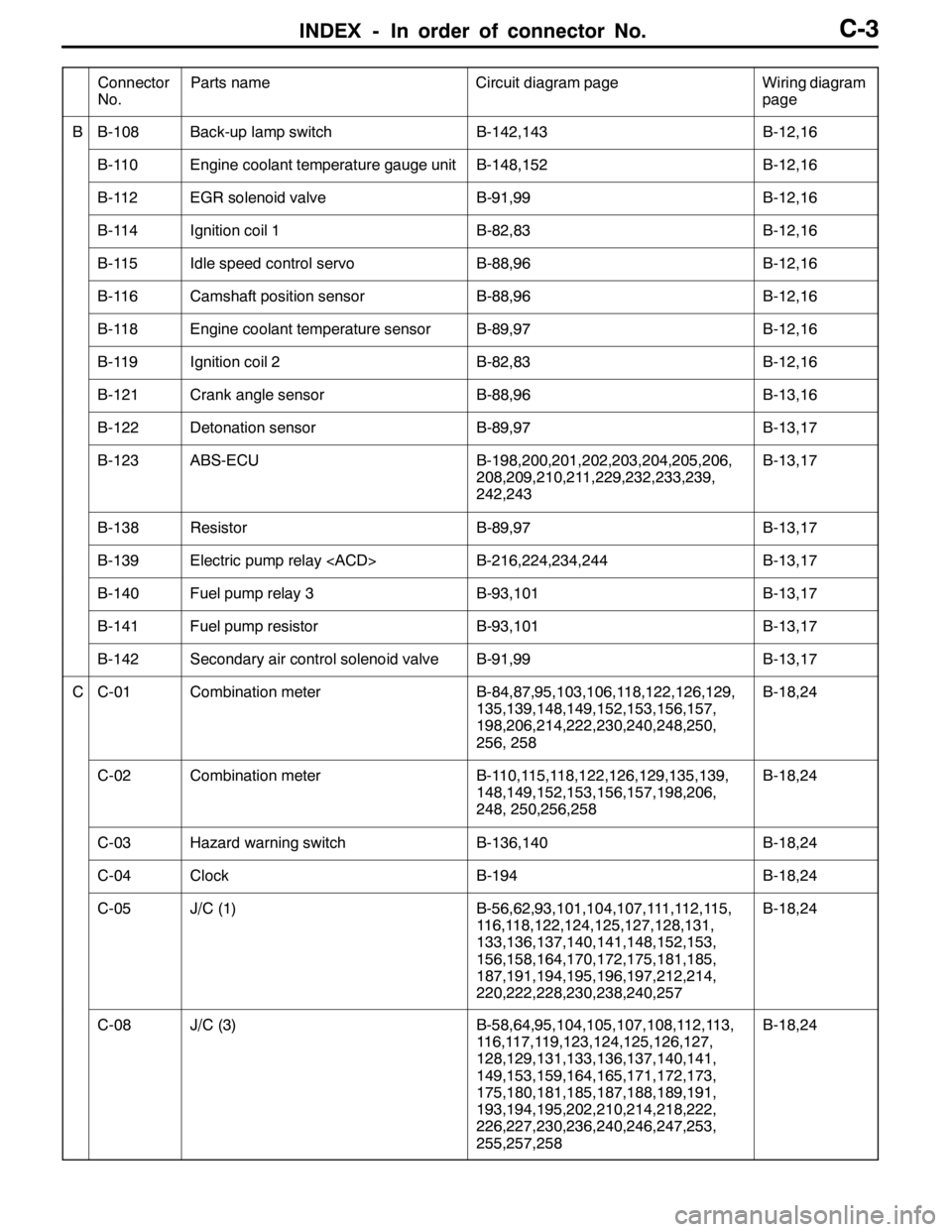

INDEX - In order of connector No.C-3

Wiring diagram

page Circuit diagram page Parts name Connector

No.

BB-108Back-up lamp switchB-142,143B-12,16

B-110Engine coolant temperature gauge unitB-148,152B-12,16

B-112EGR solenoid valveB-91,99B-12,16

B-114Ignition coil 1B-82,83B-12,16

B-115Idle speed control servoB-88,96B-12,16

B-116Camshaft position sensorB-88,96B-12,16

B-118Engine coolant temperature sensorB-89,97B-12,16

B-119Ignition coil 2B-82,83B-12,16

B-121Crank angle sensorB-88,96B-13,16

B-122Detonation sensorB-89,97B-13,17

B-123ABS-ECUB-198,200,201,202,203,204,205,206,

208,209,210,211,229,232,233,239,

242,243B-13,17

B-138ResistorB-89,97B-13,17

B-139Electric pump relay

B-140Fuel pump relay 3B-93,101B-13,17

B-141Fuel pump resistorB-93,101B-13,17

B-142Secondary air control solenoid valveB-91,99B-13,17

CC-01Combination meterB-84,87,95,103,106,118,122,126,129,

135,139,148,149,152,153,156,157,

198,206,214,222,230,240,248,250,

256, 258B-18,24

C-02Combination meterB-110,115,118,122,126,129,135,139,

148,149,152,153,156,157,198,206,

248, 250,256,258B-18,24

C-03Hazard warning switchB-136,140B-18,24

C-04ClockB-194B-18,24

C-05J/C (1)B-56,62,93,101,104,107,111,112,115,

116,118,122,124,125,127,128,131,

133,136,137,140,141,148,152,153,

156,158,164,170,172,175,181,185,

187,191,194,195,196,197,212,214,

220,222,228,230,238,240,257B-18,24

C-08J/C (3)B-58,64,95,104,105,107,108,112,113,

116,117,119,123,124,125,126,127,

128,129,131,133,136,137,140,141,

149,153,159,164,165,171,172,173,

175,180,181,185,187,188,189,191,

193,194,195,202,210,214,218,222,

226,227,230,236,240,246,247,253,

255,257,258B-18,24

Page 371 of 1449

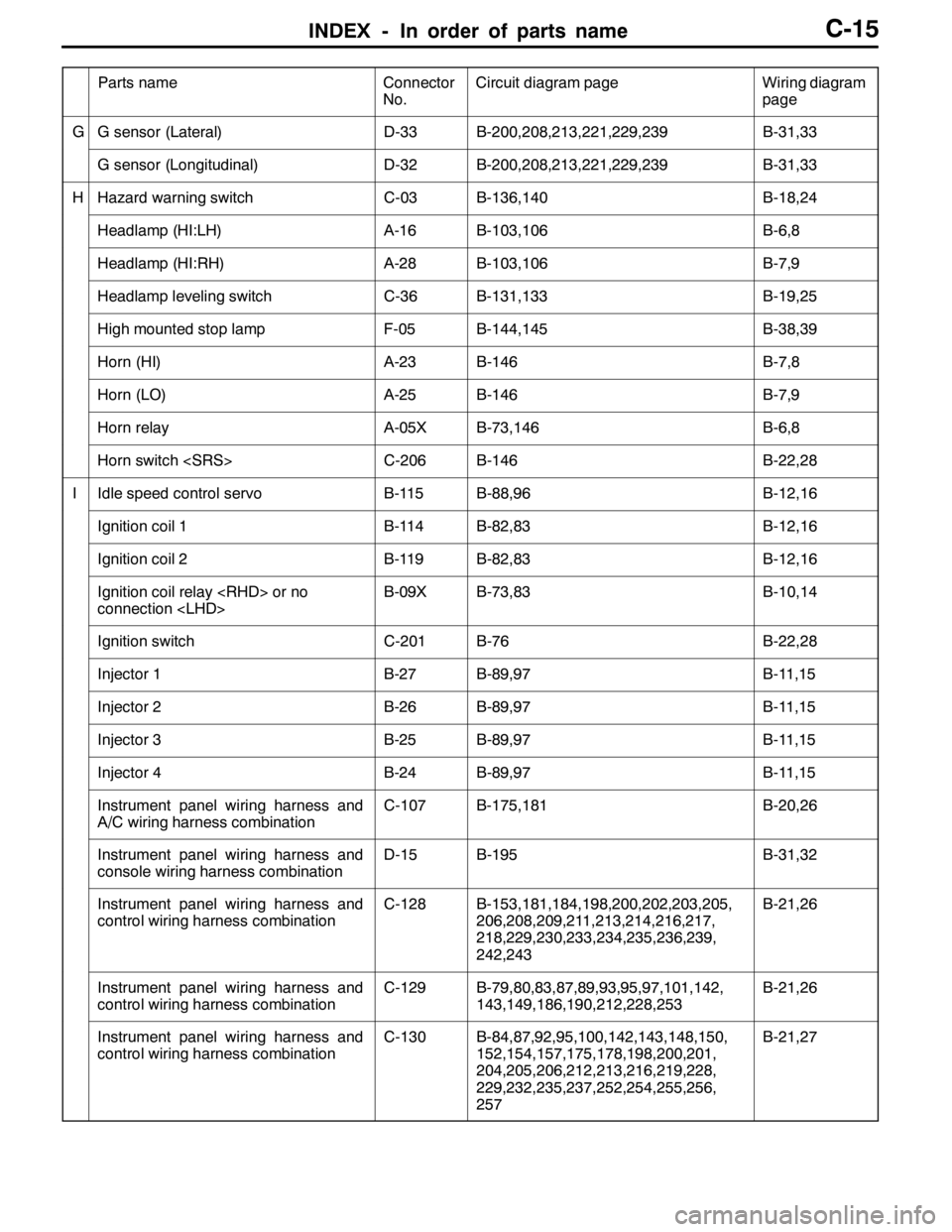

INDEX - In order of parts nameC-15

Wiring diagram

page Circuit diagram page Connector

No. Parts name

GG sensor (Lateral)D-33B-200,208,213,221,229,239B-31,33

G sensor (Longitudinal)D-32B-200,208,213,221,229,239B-31,33

HHazard warning switchC-03B-136,140B-18,24

Headlamp (HI:LH)A-16B-103,106B-6,8

Headlamp (HI:RH)A-28B-103,106B-7,9

Headlamp leveling switchC-36B-131,133B-19,25

High mounted stop lampF-05B-144,145B-38,39

Horn (HI)A-23B-146B-7,8

Horn (LO)A-25B-146B-7,9

Horn relayA-05XB-73,146B-6,8

Horn switch

IIdle speed control servoB-115B-88,96B-12,16

Ignition coil 1B-114B-82,83B-12,16

Ignition coil 2B-119B-82,83B-12,16

Ignition coil relay

connection

Ignition switchC-201B-76B-22,28

Injector 1B-27B-89,97B-11,15

Injector 2B-26B-89,97B-11,15

Injector 3B-25B-89,97B-11,15

Injector 4B-24B-89,97B-11,15

Instrument panel wiring harness and

A/C wiring harness combinationC-107B-175,181B-20,26

Instrument panel wiring harness and

console wiring harness combinationD-15B-195B-31,32

Instrument panel wiring harness and

control wiring harness combinationC-128B-153,181,184,198,200,202,203,205,

206,208,209,211,213,214,216,217,

218,229,230,233,234,235,236,239,

242,243B-21,26

Instrument panel wiring harness and

control wiring harness combinationC-129B-79,80,83,87,89,93,95,97,101,142,

143,149,186,190,212,228,253B-21,26

Instrument panel wiring harness and

control wiring harness combinationC-130B-84,87,92,95,100,142,143,148,150,

152,154,157,175,178,198,200,201,

204,205,206,212,213,216,219,228,

229,232,235,237,252,254,255,256,

257B-21,27

Page 386 of 1449

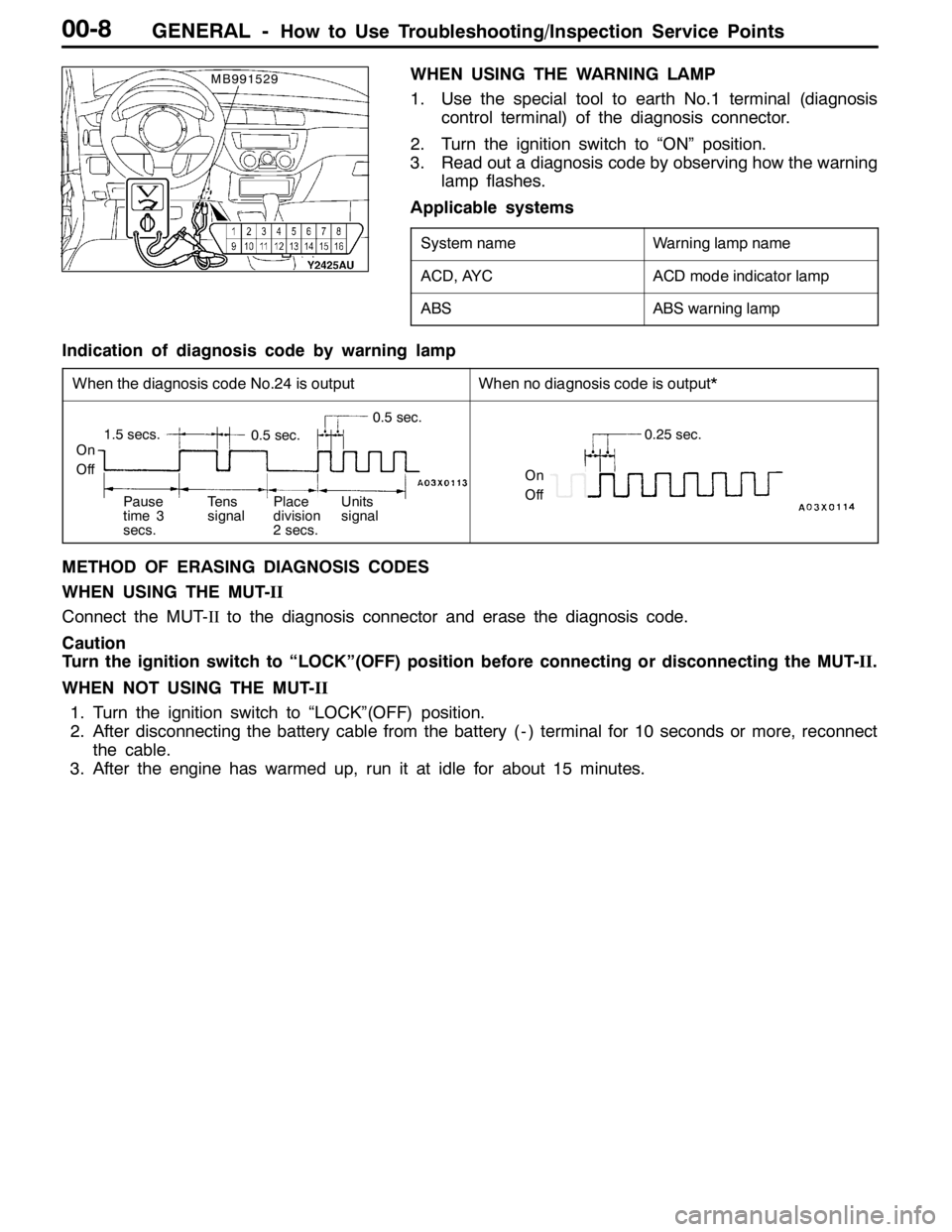

GENERAL -How to Use Troubleshooting/Inspection Service Points00-8

WHEN USING THE WARNING LAMP

1. Use the special tool to earth No.1 terminal (diagnosis

control terminal) of the diagnosis connector.

2. Turn the ignition switch to “ON” position.

3. Read out a diagnosis code by observing how the warning

lamp flashes.

Applicable systems

System nameWarning lamp name

ACD, AYCACD mode indicator lamp

ABSABS warning lamp

Indication of diagnosis code by warning lamp

When the diagnosis code No.24 is outputWhen no diagnosis code is output*

On

Off

1.5 secs.0.5 sec.

0.5 sec.

Pause

time 3

secs.Tens

signalPlace

division

2 secs.Units

signal

On

Off

0.25 sec.

METHOD OF ERASING DIAGNOSIS CODES

WHEN USING THE MUT-II

Connect the MUT-IIto the diagnosis connector and erase the diagnosis code.

Caution

Turn the ignition switch to “LOCK”(OFF) position before connecting or disconnecting the MUT-II.

WHEN NOT USING THE MUT-II

1. Turn the ignition switch to “LOCK”(OFF) position.

2. After disconnecting the battery cable from the battery ( - ) terminal for 10 seconds or more, reconnect

the cable.

3. After the engine has warmed up, run it at idle for about 15 minutes.

MB991529

Page 408 of 1449

11A-2

ENGINE

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 4.................

SEALANTS 4................................

SPECIAL TOOLS 5...........................

ON-VEHICLE SERVICE 7.....................

Drive Belt Tension Check 7.....................

Auto-tensioner Check 7.........................

Ignition Timing Check 9.........................

Idle Speed Check 9............................

Idle Mixture Check 10..........................

Compression Pressure Check 11................Manifold Vacuum Check 12.....................

Lash Adjuster Check 12........................

CRANKSHAFT PULLEY 15....................

CAMSHAFT AND CAMSHAFT OIL

SEAL 16.....................................

OIL PAN 23..................................

CRANKSHAFT OIL SEAL 26..................

CYLINDER HEAD GASKET 28................

TIMING BELT AND TIMING BELT B 34.......

ENGINE ASSEMBLY 43.......................

Page 410 of 1449

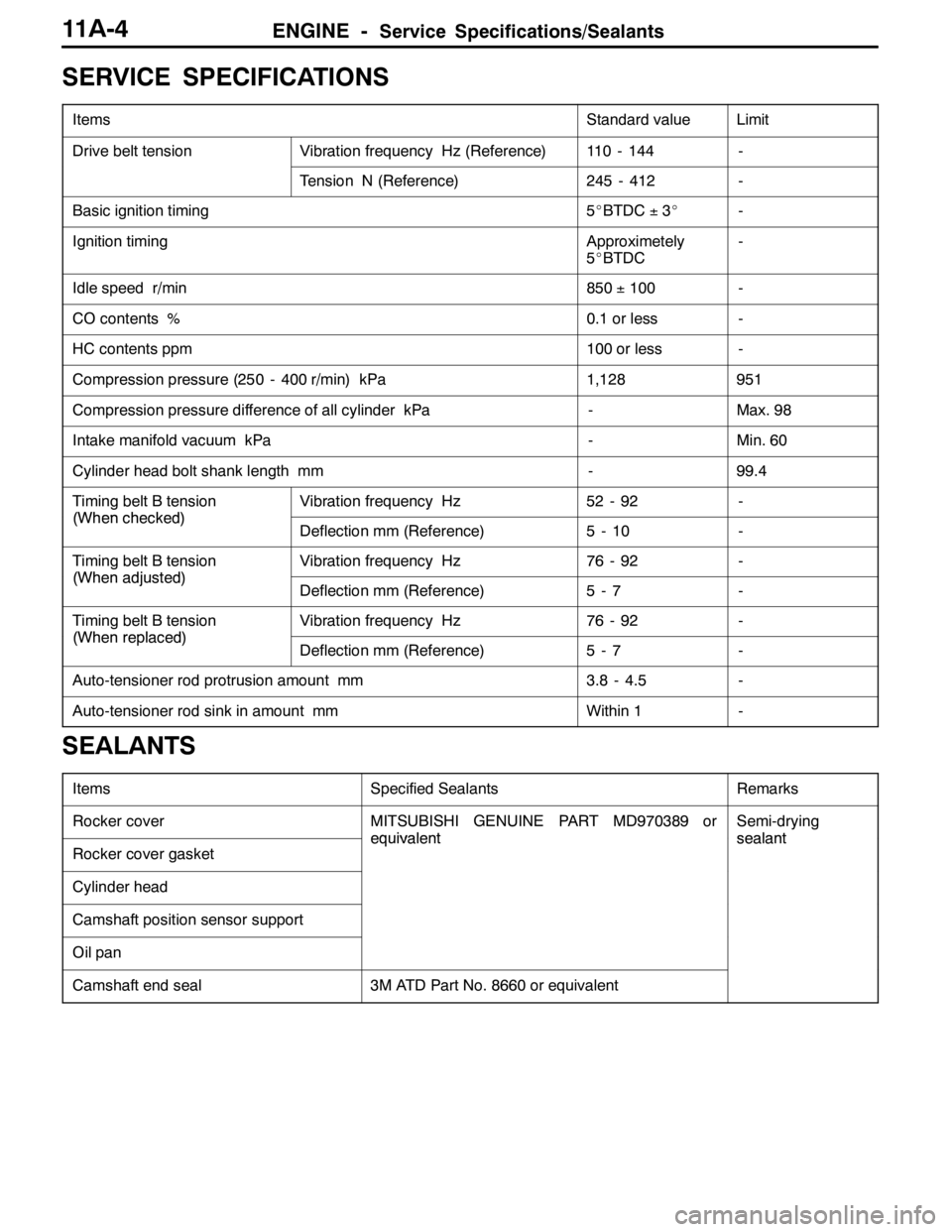

ENGINE -Service Specifications/Sealants11A-4

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Drive belt tensionVibration frequency Hz (Reference)110 - 144-

Tension N (Reference)245 - 412-

Basic ignition timing5_BTDC±3_-

Ignition timingApproximetely

5_BTDC-

Idle speed r/min850±100-

CO contents %0.1 or less-

HC contents ppm100 or less-

Compression pressure (250 - 400 r/min) kPa1,128951

Compression pressure difference of all cylinder kPa-Max. 98

Intake manifold vacuum kPa-Min. 60

Cylinder head bolt shank length mm-99.4

Timing belt B tension

(Whenchecked)

Vibration frequency Hz52 - 92-

(When checked)Deflection mm (Reference)5-10-

Timing belt B tension

(Whenadjusted)

Vibration frequency Hz76 - 92-

(When adjusted)Deflection mm (Reference)5-7-

Timing belt B tension

(Whenreplaced)

Vibration frequency Hz76 - 92-

(When replaced)Deflection mm (Reference)5-7-

Auto-tensioner rod protrusion amount mm3.8 - 4.5-

Auto-tensioner rod sink in amount mmWithin 1-

SEALANTS

ItemsSpecified SealantsRemarks

Rocker coverMITSUBISHI GENUINE PART MD970389 or

equivalent

Semi-drying

sealant

Rocker cover gasket

equivalentsealant

Cylinder head

Camshaft position sensor support

Oil pan

Camshaft end seal3M ATD Part No. 8660 or equivalent

Page 411 of 1449

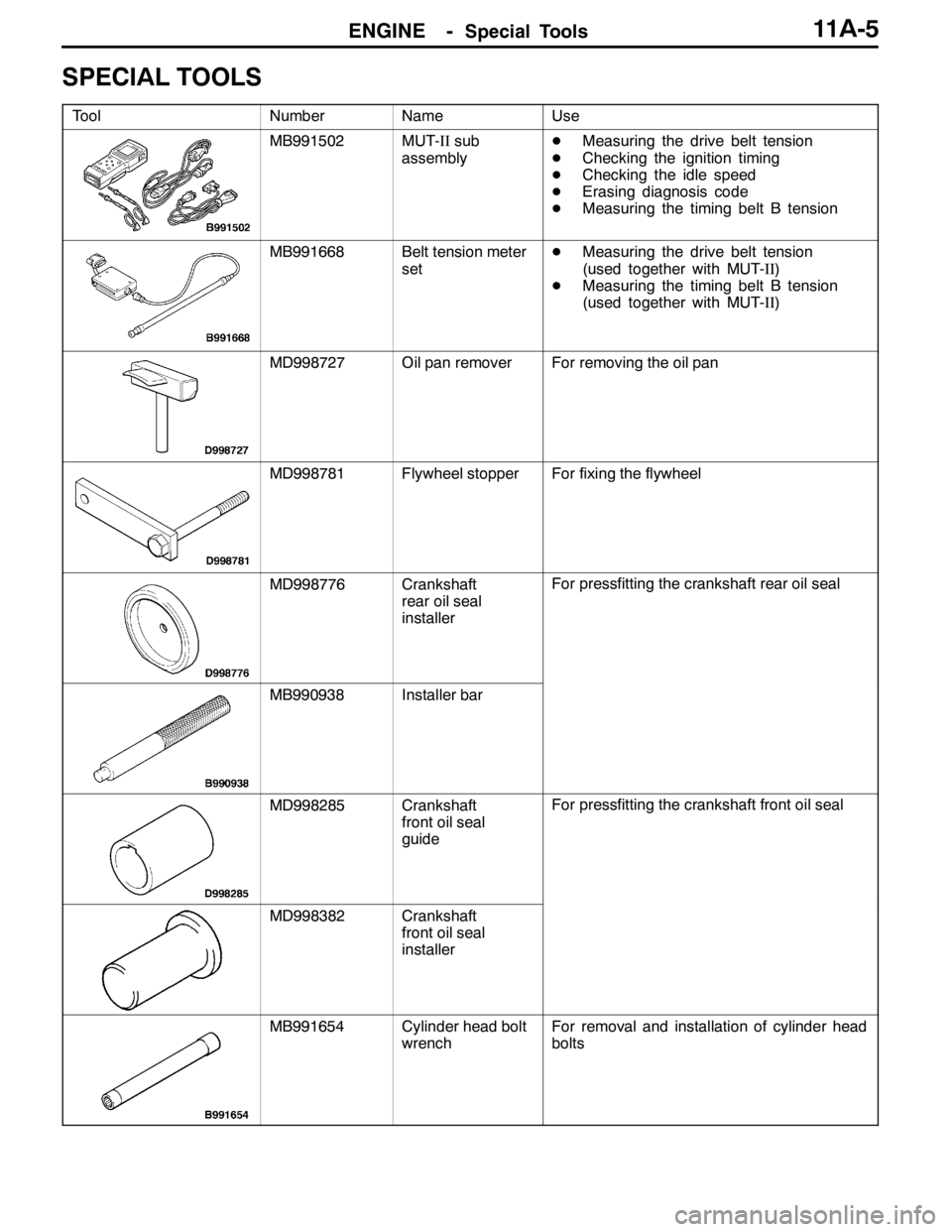

ENGINE -Special Tools11A-5

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-IIsub

assemblyDMeasuring the drive belt tension

DChecking the ignition timing

DChecking the idle speed

DErasing diagnosis code

DMeasuring the timing belt B tension

MB991668Belt tension meter

setDMeasuring the drive belt tension

(used together with MUT-II)

DMeasuring the timing belt B tension

(used together with MUT-II)

MD998727Oil pan removerFor removing the oil pan

MD998781Flywheel stopperFor fixing the flywheel

MD998776Crankshaft

rear oil seal

installerFor pressfitting the crankshaft rear oil seal

MB990938Installer bar

MD998285Crankshaft

front oil seal

guideFor pressfitting the crankshaft front oil seal

MD998382Crankshaft

front oil seal

installer

MB991654Cylinder head bolt

wrenchFor removal and installation of cylinder head

bolts

Page 413 of 1449

ENGINE -On-vehicle Service11A-7

ON-VEHICLE SERVICE

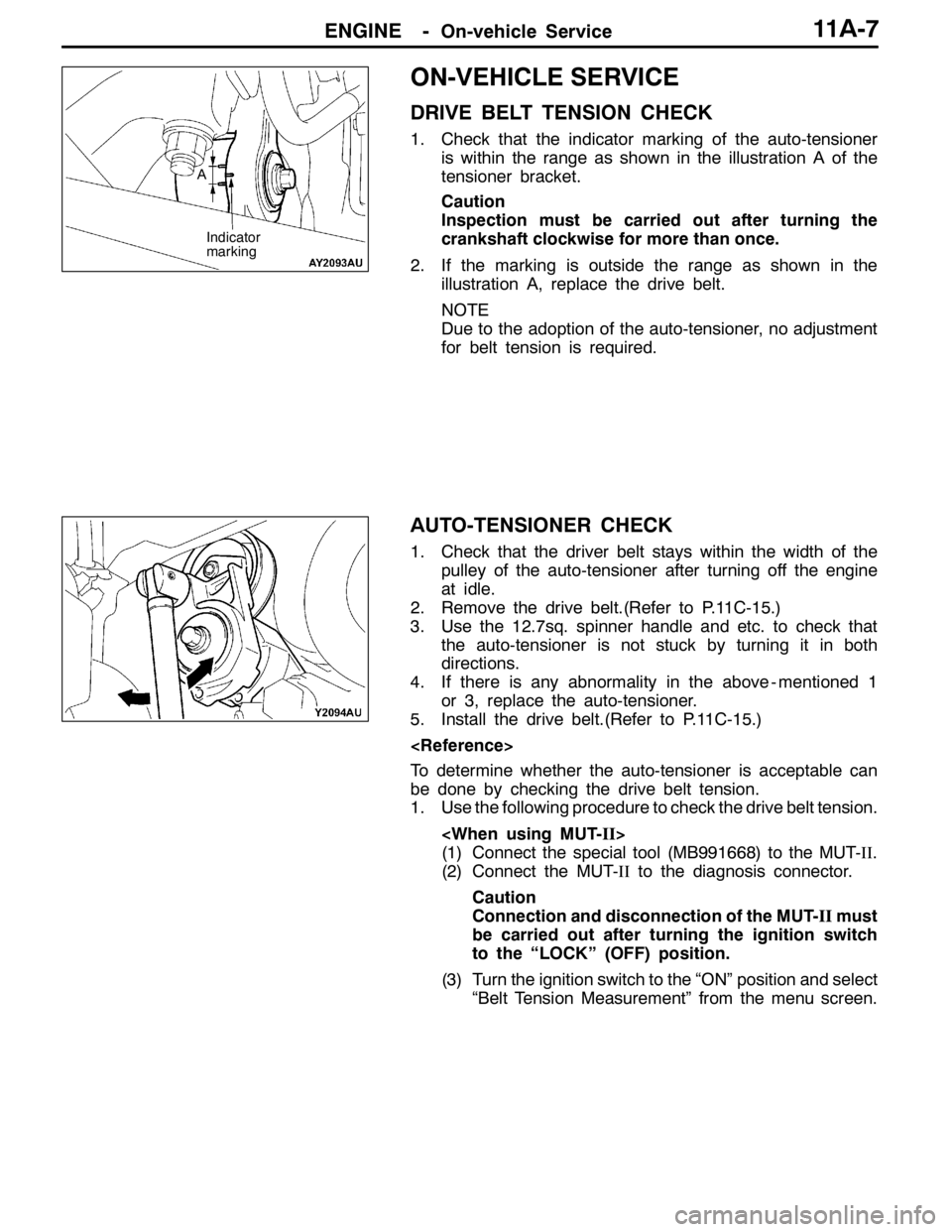

DRIVE BELT TENSION CHECK

1. Check that the indicator marking of the auto-tensioner

is within the range as shown in the illustration A of the

tensioner bracket.

Caution

Inspection must be carried out after turning the

crankshaft clockwise for more than once.

2. If the marking is outside the range as shown in the

illustration A, replace the drive belt.

NOTE

Due to the adoption of the auto-tensioner, no adjustment

for belt tension is required.

AUTO-TENSIONER CHECK

1. Check that the driver belt stays within the width of the

pulley of the auto-tensioner after turning off the engine

at idle.

2. Remove the drive belt.(Refer to P.11C-15.)

3. Use the 12.7sq. spinner handle and etc. to check that

the auto-tensioner is not stuck by turning it in both

directions.

4. If there is any abnormality in the above - mentioned 1

or 3, replace the auto-tensioner.

5. Install the drive belt.(Refer to P.11C-15.)

To determine whether the auto-tensioner is acceptable can

be done by checking the drive belt tension.

1. Use the following procedure to check the drive belt tension.

(1) Connect the special tool (MB991668) to the MUT-II.

(2) Connect the MUT-IIto the diagnosis connector.

Caution

Connection and disconnection of the MUT-IImust

be carried out after turning the ignition switch

to the “LOCK” (OFF) position.

(3) Turn the ignition switch to the “ON” position and select

“Belt Tension Measurement” from the menu screen.

Indicator

marking

A

Page 415 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-9

IGNITION TIMING CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position and

then connect the MUT-IIto the diagnosis connector.

3. Set up a timing light.

4. Start the engine and run at idle.

5. Check that engine idle speed is within the standard value.

Standard value: 850±100 r/min

6. Select No.17 of the MUT-IIActuator test.

7. Check that basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3_

8. If the basic ignition timing is outside the standard value,

inspect the MPI system while referring to GROUP 13A

- Troubleshooting.

9. Press the MUT-IIclear key (Select a forced driving cancel

mode) to release the Actuator test.

Caution

If the test is not cancelled, a forced driving will

continue for 27 minutes. Driving under this condition

may damage the engine.

10. Check that ignition timing is at the standard value.

Standard value: approximately 5_BTDC

NOTE

(1) Ignition timing is variable within about±7, even under

normal operating.

(2) And it is automatically further advanced by

approximately 5_from standard value at higher

altitudes.

11. Remove the timing light.

12. Turn the ignition switch to “LOCK” (OFF) position and

then remove the MUT-II.

IDLE SPEED CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to “LOCK” (OFF) position, and

then connect the MUT-IIto the diagnosis connector.

3. Set the timing light.

4. Check that the basic ignition timing is within the standard

value.

MUT-II

MUT-II