idle MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 416 of 1449

ENGINE -On-vehicle ServiceENGINE -On-vehicle Service11A-10

Standard value: 5_BTDC±3_

5. Run the engine at idle for 2 minutes.

6. Check the idle speed. Select item No. 22 and take a

reading of the idle speed.

Curb idle speed: 850±100 r/min

NOTE

The idle speed is controlled automatically by the idle speed

control (ISC) system.

7. If the idle speed is outside the standard value, check

the MPI components by referring to GROUP 13A -

Troubleshooting.

8. Remove the timing light.

9. Turn the ignition switch to the “LOCK” (OFF) position

and then remove the MUT-II.

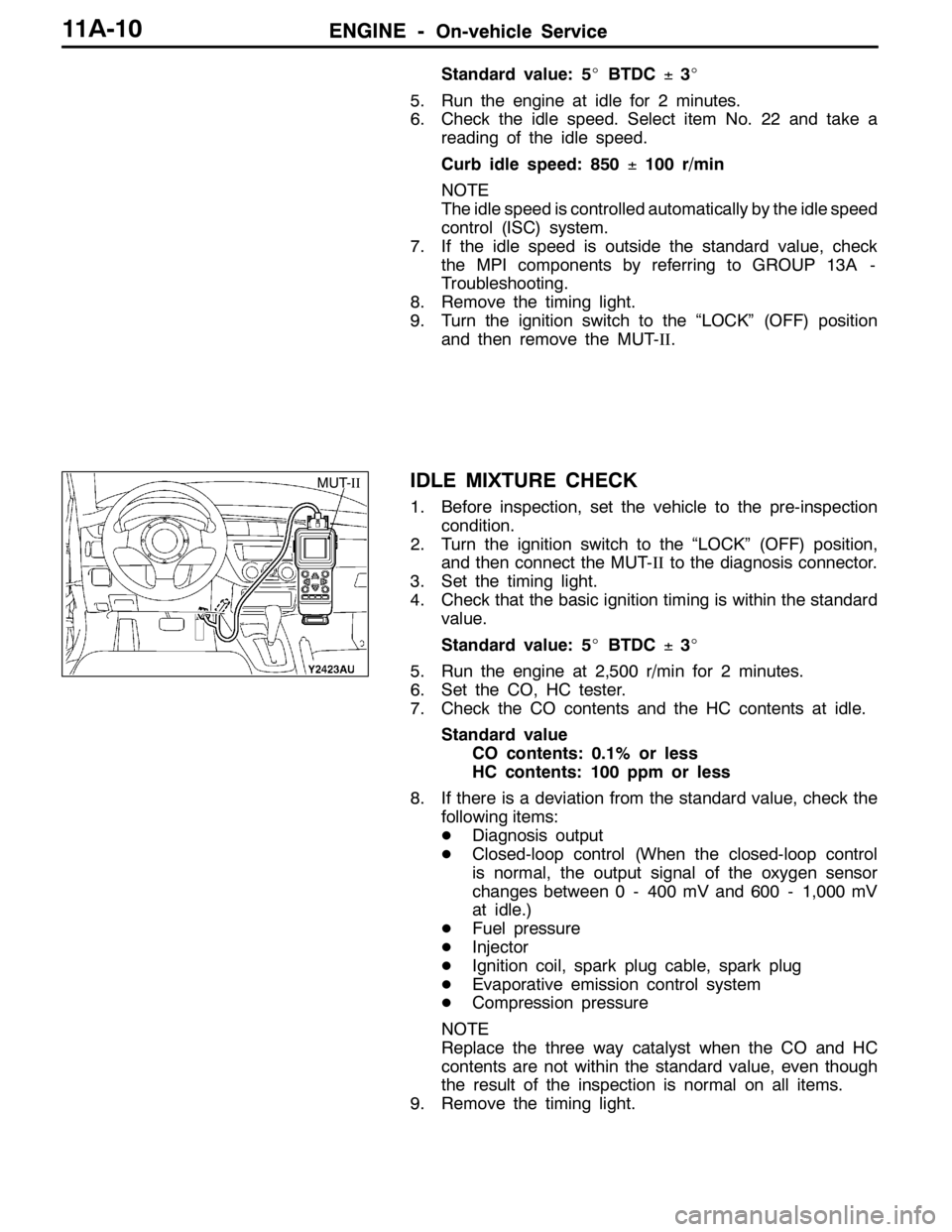

IDLE MIXTURE CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Turn the ignition switch to the “LOCK” (OFF) position,

and then connect the MUT-IIto the diagnosis connector.

3. Set the timing light.

4. Check that the basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3_

5. Run the engine at 2,500 r/min for 2 minutes.

6. Set the CO, HC tester.

7. Check the CO contents and the HC contents at idle.

Standard value

CO contents: 0.1% or less

HC contents: 100 ppm or less

8. If there is a deviation from the standard value, check the

following items:

DDiagnosis output

DClosed-loop control (When the closed-loop control

is normal, the output signal of the oxygen sensor

changes between 0 - 400 mV and 600 - 1,000 mV

at idle.)

DFuel pressure

DInjector

DIgnition coil, spark plug cable, spark plug

DEvaporative emission control system

DCompression pressure

NOTE

Replace the three way catalyst when the CO and HC

contents are not within the standard value, even though

the result of the inspection is normal on all items.

9. Remove the timing light.

MUT-II

Page 418 of 1449

ENGINE -On-vehicle Service11A-12

12. Install the ignition coils and spark plugs.

13. Use the MUT-IIto erase the self-diagnosis codes or

disconnect the battery cable from the battery ( - ) terminal

for 10 seconds or more and then reconnect the cable.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

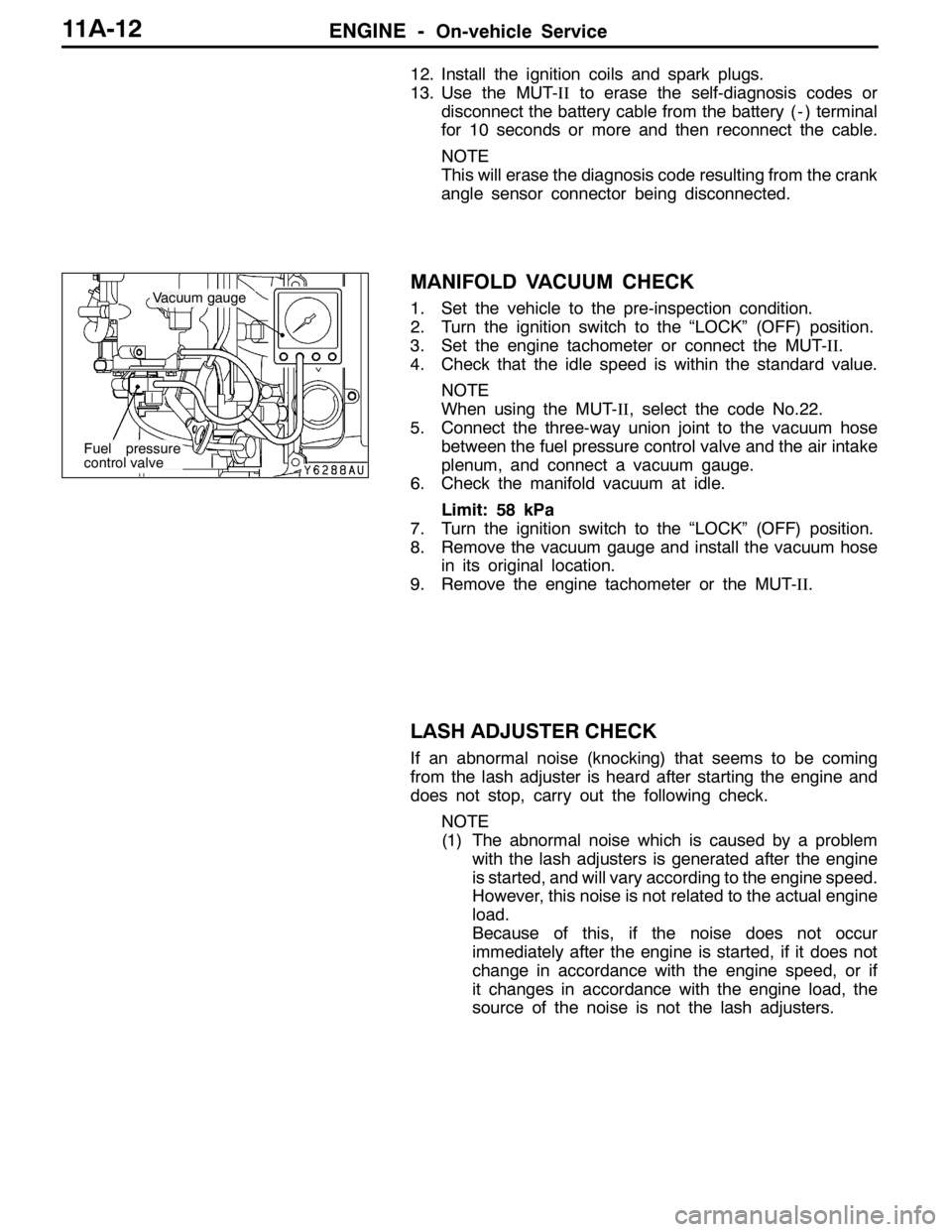

MANIFOLD VACUUM CHECK

1. Set the vehicle to the pre-inspection condition.

2. Turn the ignition switch to the “LOCK” (OFF) position.

3. Set the engine tachometer or connect the MUT-II.

4. Check that the idle speed is within the standard value.

NOTE

When using the MUT-II, select the code No.22.

5. Connect the three-way union joint to the vacuum hose

between the fuel pressure control valve and the air intake

plenum, and connect a vacuum gauge.

6. Check the manifold vacuum at idle.

Limit: 58 kPa

7. Turn the ignition switch to the “LOCK” (OFF) position.

8. Remove the vacuum gauge and install the vacuum hose

in its original location.

9. Remove the engine tachometer or the MUT-II.

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, and will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not the lash adjusters.

Vacuum gauge

Fuel pressure

control valve

Page 419 of 1449

ENGINE -On-vehicle Service11A-13

(2) If there is a problem with the lash adjusters, the noise

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

3. While the engine is idling, check that the noise level does

not change when the engine load is varied.

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If the noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters.

(Refer to GROUP 11B - Rocker Arms and Camshaft.)

NOTE

(1) If the vehicle is parked on a slope for a long period

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

(2) After parking the vehicle for long periods, the oil drains

out of the oil passage, and it takes time for the oil

to be supplied to the lash adjuster, so air can get

into the high pressure chamber.

(3) If either of the above situations occur, the abnormal

noise can be eliminated by bleeding the air from inside

the lash adjusters.

Page 420 of 1449

ENGINE -On-vehicle Service11A-14

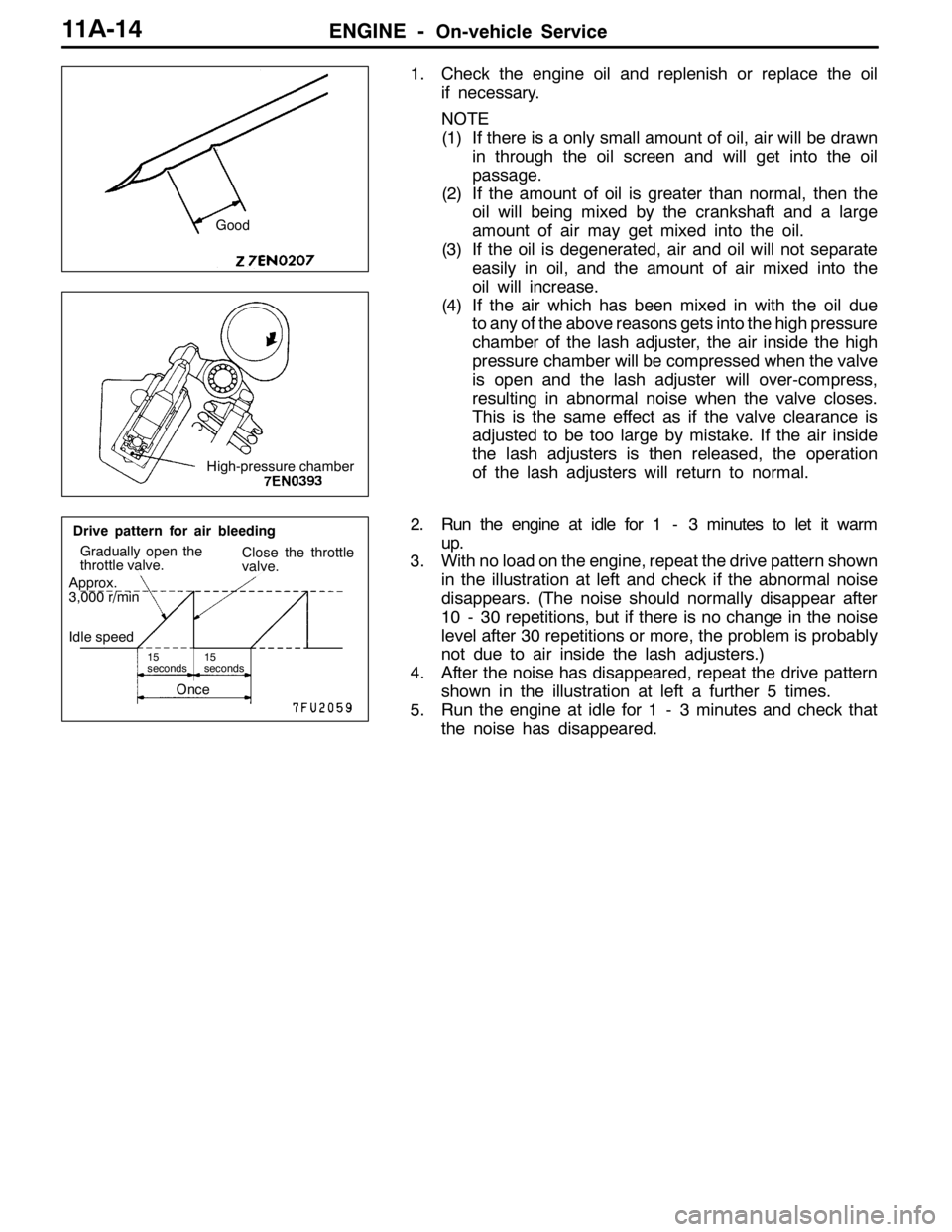

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft and a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

(4) If the air which has been mixed in with the oil due

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Good

High-pressure chamber

Gradually open the

throttle valve.

Drive pattern for air bleeding

Close the throttle

valve.

Approx.

3,000 r/min

15

seconds15

seconds

Idle speed

Once

Page 435 of 1449

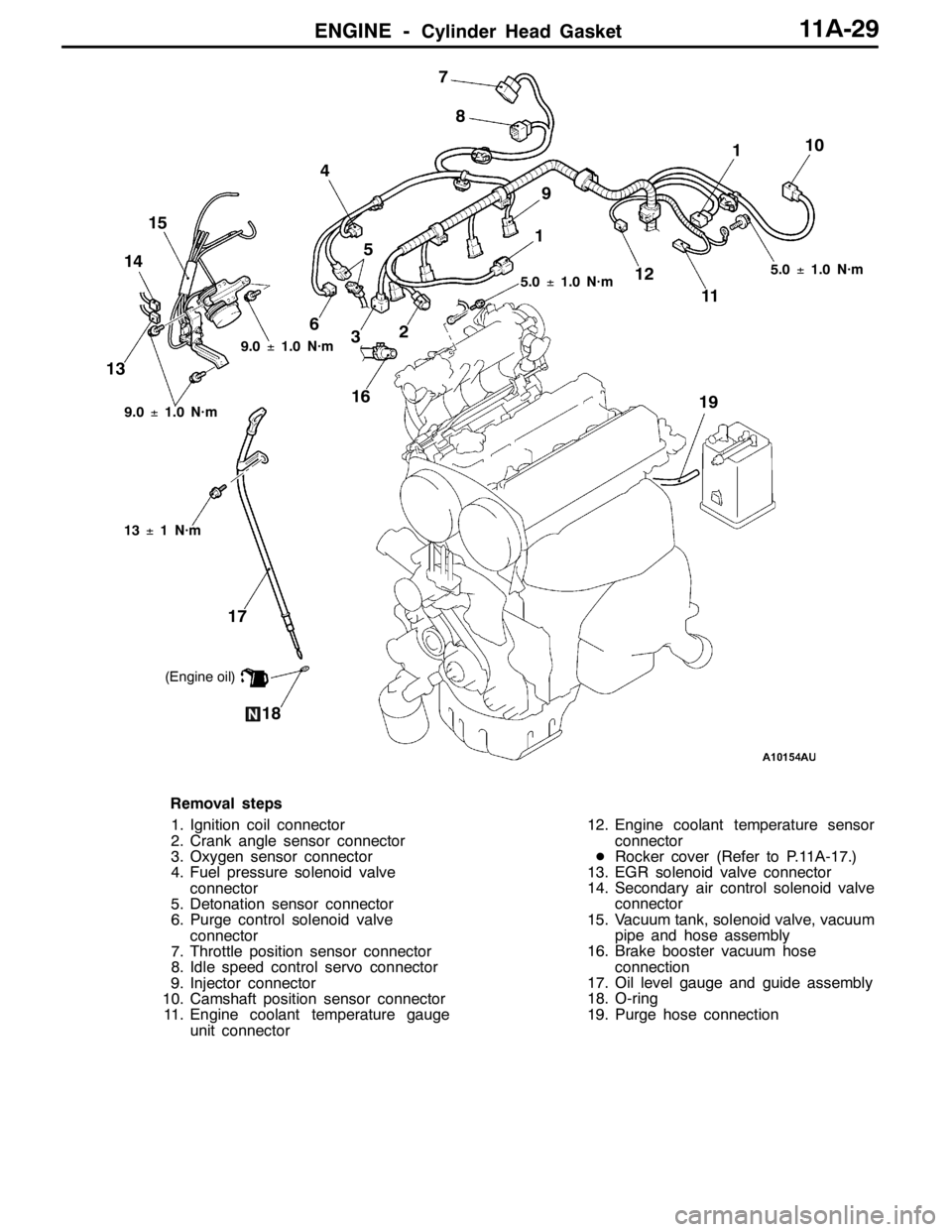

ENGINE -Cylinder Head Gasket11A-29

5.0±1.0 N·m

61

2

3 4

57

8

910

11 12

1314

13±1 N·m

15

16

17

5.0±1.0 N·m

1819

9.0±1.0 N·m

9.0±1.0 N·m

(Engine oil)

1

Removal steps

1. Ignition coil connector

2. Crank angle sensor connector

3. Oxygen sensor connector

4. Fuel pressure solenoid valve

connector

5. Detonation sensor connector

6. Purge control solenoid valve

connector

7. Throttle position sensor connector

8. Idle speed control servo connector

9. Injector connector

10. Camshaft position sensor connector

11. Engine coolant temperature gauge

unit connector12. Engine coolant temperature sensor

connector

DRocker cover (Refer to P.11A-17.)

13. EGR solenoid valve connector

14. Secondary air control solenoid valve

connector

15. Vacuum tank, solenoid valve, vacuum

pipe and hose assembly

16. Brake booster vacuum hose

connection

17. Oil level gauge and guide assembly

18. O-ring

19. Purge hose connection

Page 440 of 1449

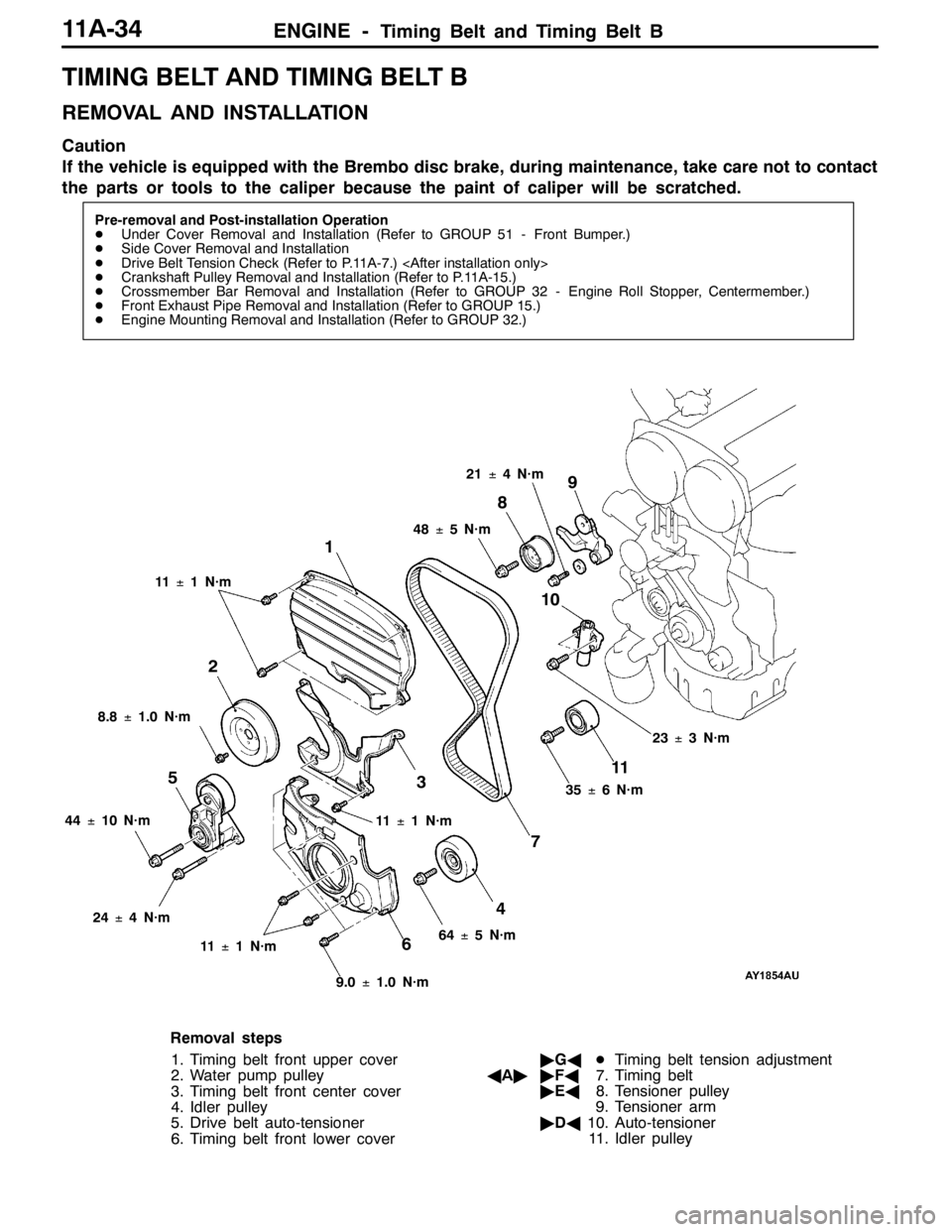

ENGINE -Timing Belt and Timing Belt B11A-34

TIMING BELT AND TIMING BELT B

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DSide Cover Removal and Installation

DDrive Belt Tension Check (Refer to P.11A-7.)

DCrankshaft Pulley Removal and Installation (Refer to P.11A-15.)

DCrossmember Bar Removal and Installation (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

DFront Exhaust Pipe Removal and Installation (Refer to GROUP 15.)

DEngine Mounting Removal and Installation (Refer to GROUP 32.)

1

2

3

4 5

67 89

10

11±1 N·m

8.8±1.0 N·m

44±10 N·m

24±4 N·m

11±1 N·m

9.0±1.0 N·m64±5 N·m 11±1 N·m48±5 N·m21±4 N·m

23±3 N·m

11

35±6 N·m

Removal steps

1. Timing belt front upper cover

2. Water pump pulley

3. Timing belt front center cover

4. Idler pulley

5. Drive belt auto-tensioner

6. Timing belt front lower cover"GADTiming belt tension adjustment

AA""FA7. Timing belt

"EA8. Tensioner pulley

9. Tensioner arm

"DA10. Auto-tensioner

11. Idler pulley

Page 445 of 1449

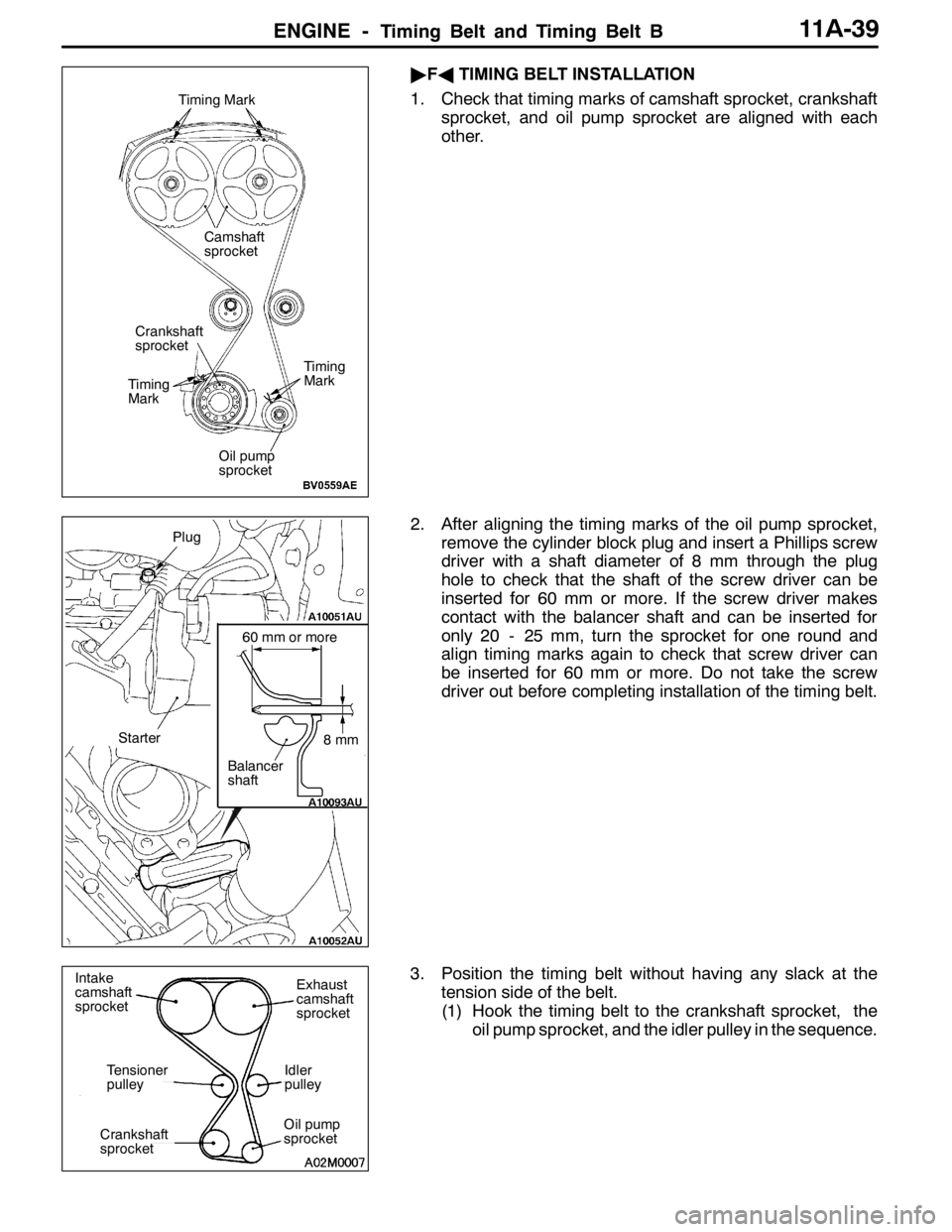

ENGINE -Timing Belt and Timing Belt B11A-39

"FATIMING BELT INSTALLATION

1. Check that timing marks of camshaft sprocket, crankshaft

sprocket, and oil pump sprocket are aligned with each

other.

2. After aligning the timing marks of the oil pump sprocket,

remove the cylinder block plug and insert a Phillips screw

driver with a shaft diameter of 8 mm through the plug

hole to check that the shaft of the screw driver can be

inserted for 60 mm or more. If the screw driver makes

contact with the balancer shaft and can be inserted for

only 20 - 25 mm, turn the sprocket for one round and

align timing marks again to check that screw driver can

be inserted for 60 mm or more. Do not take the screw

driver out before completing installation of the timing belt.

3. Position the timing belt without having any slack at the

tension side of the belt.

(1) Hook the timing belt to the crankshaft sprocket, the

oil pump sprocket, and the idler pulley in the sequence.

Timing Mark

Timing

Mark

Timing

Mark

Crankshaft

sprocket

Oil pump

sprocket

Camshaft

sprocket

8mm

60 mm or more

Balancer

shaft

Plug

Starter

Intake

camshaft

sprocketExhaust

camshaft

sprocket

Idler

pulley

Oil pump

sprocketCrankshaft

sprocket

Tensioner

pulley

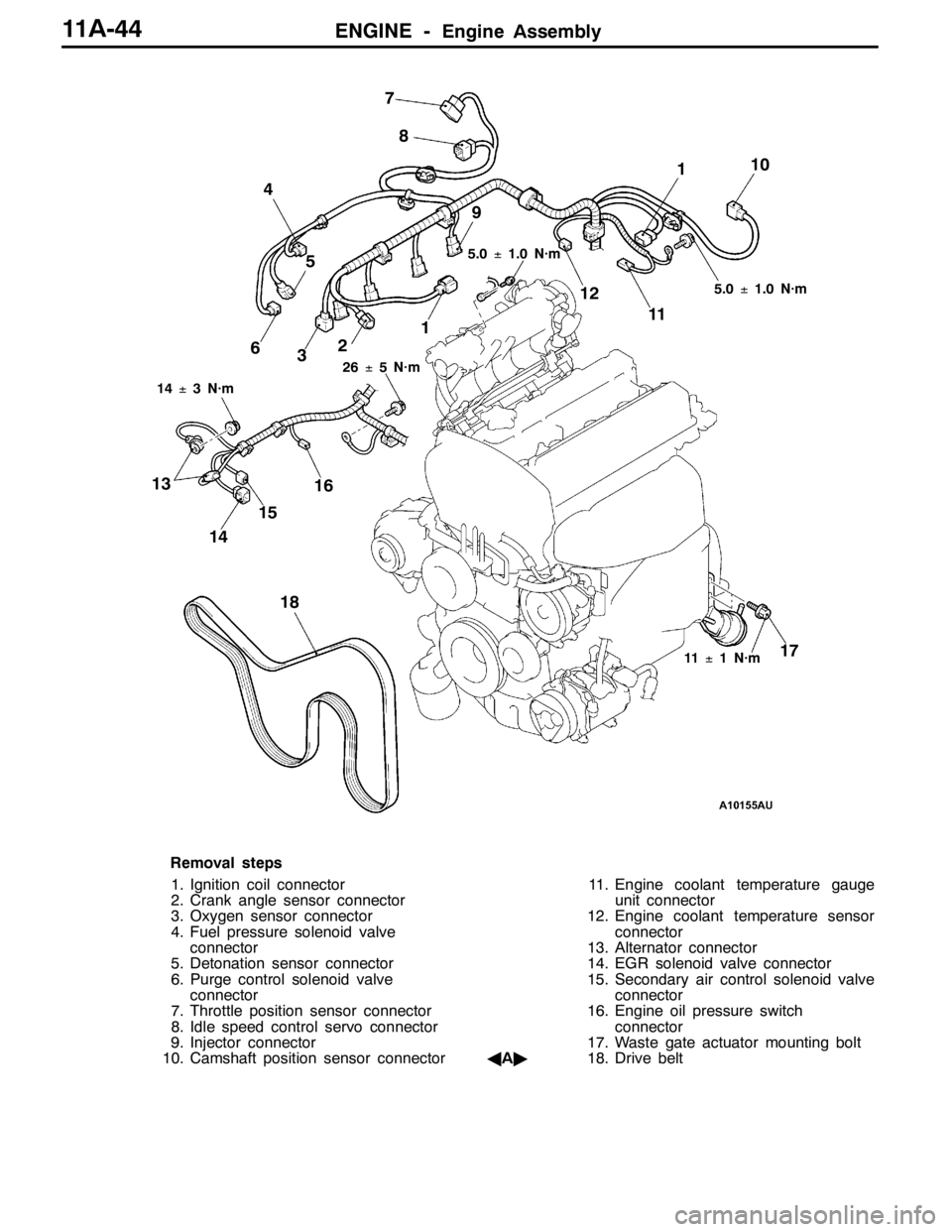

Page 450 of 1449

ENGINE -Engine Assembly11A-44

1

2

3 4

5

67

8

910

11 12

13

14

26±5 N·m

14±3 N·m

1516

18

5.0±1.0 N·m

1

5.0±1.0 N·m

11±1 N·m

17

Removal steps

1. Ignition coil connector

2. Crank angle sensor connector

3. Oxygen sensor connector

4. Fuel pressure solenoid valve

connector

5. Detonation sensor connector

6. Purge control solenoid valve

connector

7. Throttle position sensor connector

8. Idle speed control servo connector

9. Injector connector

10. Camshaft position sensor connector11. Engine coolant temperature gauge

unit connector

12. Engine coolant temperature sensor

connector

13. Alternator connector

14. EGR solenoid valve connector

15. Secondary air control solenoid valve

connector

16. Engine oil pressure switch

connector

17. Waste gate actuator mounting bolt

AA"18. Drive belt

Page 459 of 1449

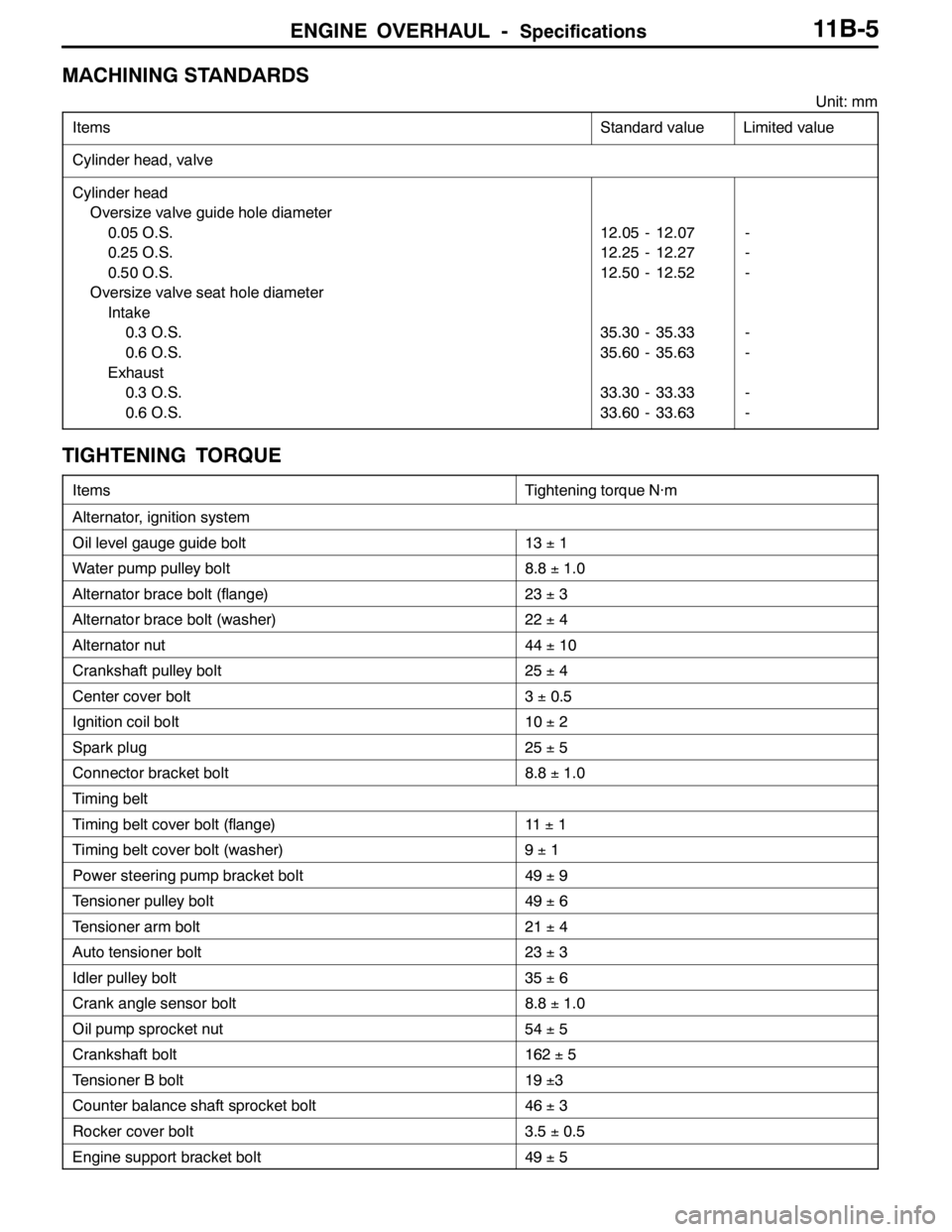

ENGINE OVERHAUL -Specifications11B-5

MACHINING STANDARDS

Unit: mm

Items

Standard valueLimited value

Cylinder head, valve

Cylinder head

Oversize valve guide hole diameter

0.05 O.S.

0.25 O.S.

0.50 O.S.

Oversize valve seat hole diameter

Intake

0.3 O.S.

0.6 O.S.

Exhaust

0.3 O.S.

0.6 O.S.

12.05 - 12.07

12.25 - 12.27

12.50 - 12.52

35.30 - 35.33

35.60 - 35.63

33.30 - 33.33

33.60 - 33.63-

-

-

-

-

-

-

TIGHTENING TORQUE

ItemsTightening torque N·m

Alternator, ignition system

Oil level gauge guide bolt13±1

Water pump pulley bolt8.8±1.0

Alternator brace bolt (flange)23±3

Alternator brace bolt (washer)22±4

Alternator nut44±10

Crankshaft pulley bolt25±4

Center cover bolt3±0.5

Ignition coil bolt10±2

Spark plug25±5

Connector bracket bolt8.8±1.0

Timing belt

Timing belt cover bolt (flange)11±1

Timing belt cover bolt (washer)9±1

Power steering pump bracket bolt49±9

Tensioner pulley bolt49±6

Tensioner arm bolt21±4

Auto tensioner bolt23±3

Idler pulley bolt35±6

Crank angle sensor bolt8.8±1.0

Oil pump sprocket nut54±5

Crankshaft bolt162±5

Tensioner B bolt19±3

Counter balance shaft sprocket bolt46±3

Rocker cover bolt3.5±0.5

Engine support bracket bolt49±5

Page 467 of 1449

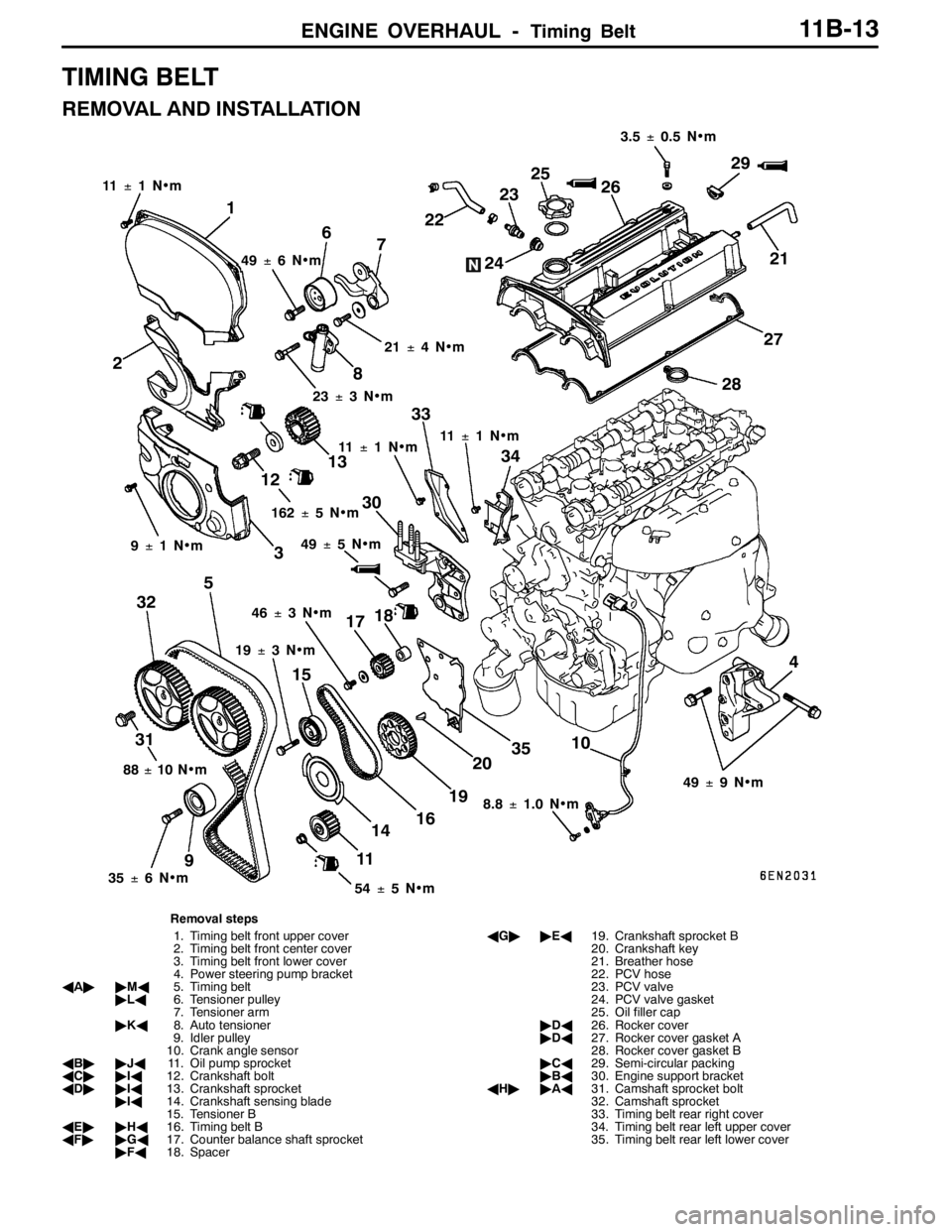

ENGINE OVERHAUL -Timing Belt11B-13

TIMING BELT

REMOVAL AND INSTALLATION

1

11±1N•m

2

3

4 56

7

8

910

11 1213

14 15

16 1718

192021 2223

2425

26

27

2829

30

313233

34

35

49±6N•m

21±4N•m

23±3N•m

11±1N•m11±1N•m

88±10 N•m

35±6N•m

54±5N•m 19±3N•m 46±3N•m 9±1N•m162±5N•m3.5±0.5 N•m

49±9N•m

8.8±1.0 N•m 49±5N•m

Removal steps

1. Timing belt front upper cover

2. Timing belt front center cover

3. Timing belt front lower cover

4. Power steering pump bracket

AA""MA5. Timing belt

"LA6. Tensioner pulley

7. Tensioner arm

"KA8. Auto tensioner

9. Idler pulley

10. Crank angle sensor

AB""JA11. Oil pump sprocket

AC""IA12. Crankshaft bolt

AD""IA13. Crankshaft sprocket

"IA14. Crankshaft sensing blade

15. Tensioner B

AE""HA16. Timing belt B

AF""GA17. Counter balance shaft sprocket

"FA18. SpacerAG""EA19. Crankshaft sprocket B

20. Crankshaft key

21. Breather hose

22. PCV hose

23. PCV valve

24. PCV valve gasket

25. Oil filler cap

"DA26. Rocker cover

"DA27. Rocker cover gasket A

28. Rocker cover gasket B

"CA29. Semi-circular packing

"BA30. Engine support bracket

AH""AA31. Camshaft sprocket bolt

32. Camshaft sprocket

33. Timing belt rear right cover

34. Timing belt rear left upper cover

35. Timing belt rear left lower cover