change wheel MITSUBISHI LANCER EVOLUTION 2015 10.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2015, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2015 10.GPages: 338, PDF Size: 43.12 MB

Page 264 of 338

How to change a tire

For emergencies 8-7

8

N00849701326

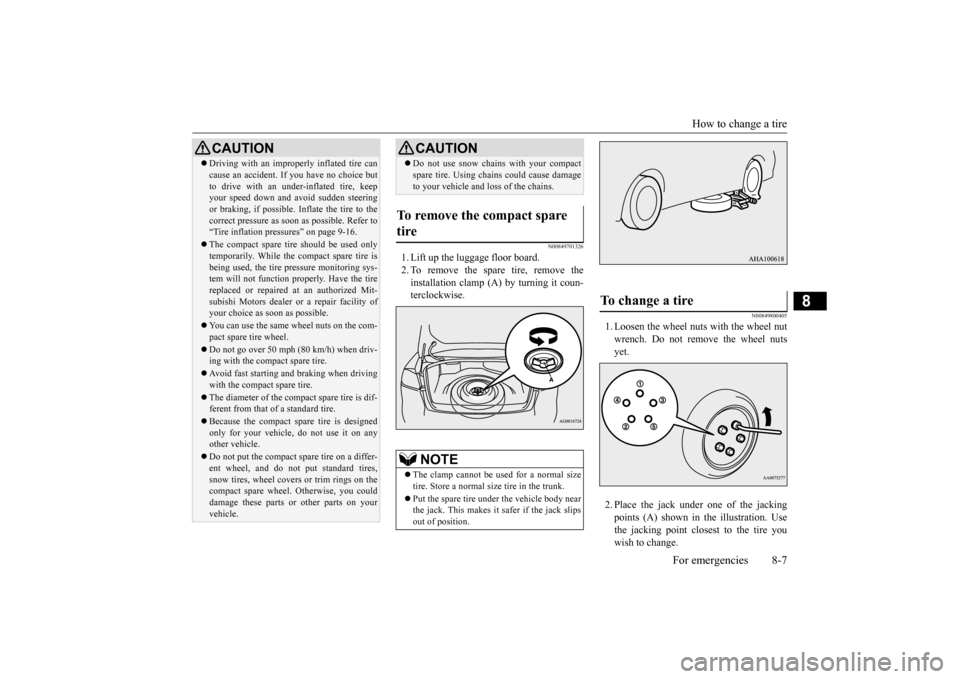

1. Lift up the luggage floor board. 2. To remove the spare tire, remove theinstallation clamp (A) by turning it coun- terclockwise.

N00849800405

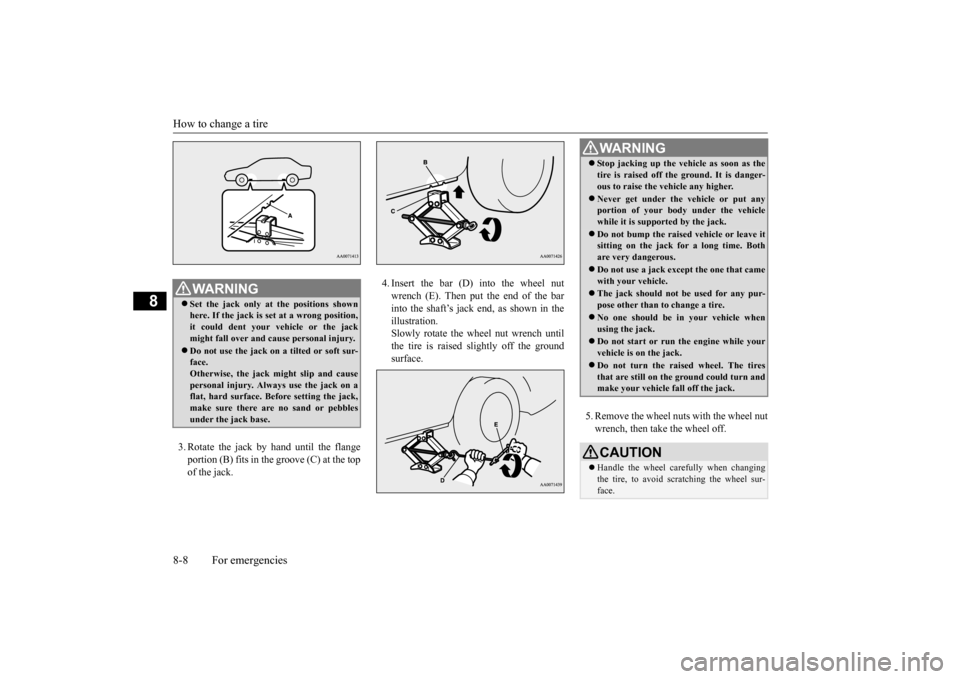

1. Loosen the wheel nuts with the wheel nut wrench. Do not remove the wheel nutsyet. 2. Place the jack under

one of the jacking

points (A) shown in the illustration. Usethe jacking point closest to the tire you wish to change.

Driving with an improperly inflated tire can cause an accident. If you have no choice but to drive with an under-inflated tire, keep your speed down and avoid sudden steering or braking, if possible

. Inflate the tire to the

correct pressure as soon as possible. Refer to “Tire inflation pressures” on page 9-16. The compact spare tire should be used only temporarily. While the compact spare tire is being used, the tire pressure monitoring sys-tem will not function properly. Have the tire replaced or repaired at an authorized Mit- subishi Motors dealer

or a repair facility of

your choice as soon as possible. You can use the same wheel nuts on the com- pact spare tire wheel. Do not go over 50 mph (80 km/h) when driv- ing with the compact spare tire. Avoid fast starting and braking when driving with the compact spare tire. The diameter of the compact spare tire is dif- ferent from that of a standard tire. Because the compact spare tire is designed only for your vehicle, do not use it on any other vehicle. Do not put the compact spare tire on a differ- ent wheel, and do not put standard tires, snow tires, wheel covers or trim rings on the compact spare wheel. Otherwise, you could damage these parts or other parts on yourvehicle.CAUTION

Do not use snow chains with your compact spare tire. Using chains could cause damage to your vehicle and loss of the chains.

To remove the compact spare tire

NOTE

The clamp cannot be us

ed for a normal size

tire. Store a normal size tire in the trunk. Put the spare tire under the vehicle body near the jack. This makes it safer if the jack slipsout of position.CAUTION

To change a tire

BK0210800US.bo

ok 7 ページ 2014年4月8日 火曜日 午前11時28分

Page 265 of 338

How to change a tire 8-8 For emergencies

8

3. Rotate the jack by hand until the flange portion (B) fits in the groove (C) at the top of the jack.

4. Insert the bar (D) into the wheel nut wrench (E). Then put the end of the barinto the shaft’s jack end, as shown in the illustration. Slowly rotate the wheel nut wrench untilthe tire is raised slightly off the ground surface.

5. Remove the wheel nuts with the wheel nut wrench, then take the wheel off.

WA R N I N G Set the jack only at the positions shown here. If the jack is set at a wrong position, it could dent your vehicle or the jack might fall over and cause personal injury. Do not use the jack on a tilted or soft sur- face.Otherwise, the jack might slip and cause personal injury. Always use the jack on a flat, hard surface. Before setting the jack,make sure there are no sand or pebbles under the jack base.

WA R N I N G Stop jacking up the vehicle as soon as the tire is raised off the ground. It is danger- ous to raise the vehicle any higher. Never get under the vehicle or put any portion of your body under the vehicle while it is supported by the jack. Do not bump the raised vehicle or leave it sitting on the jack for a long time. Both are very dangerous. Do not use a jack except the one that came with your vehicle. The jack should not be used for any pur- pose other than to change a tire. No one should be in your vehicle when using the jack. Do not start or run the engine while your vehicle is on the jack. Do not turn the raised wheel. The tires that are still on the ground could turn andmake your vehicle fall off the jack. CAUTION Handle the wheel carefully when changing the tire, to avoid scratching the wheel sur- face.

BK0210800US.bo

ok 8 ページ 2014年4月8日 火曜日 午前11時28分

Page 266 of 338

How to change a tire

For emergencies 8-9

8

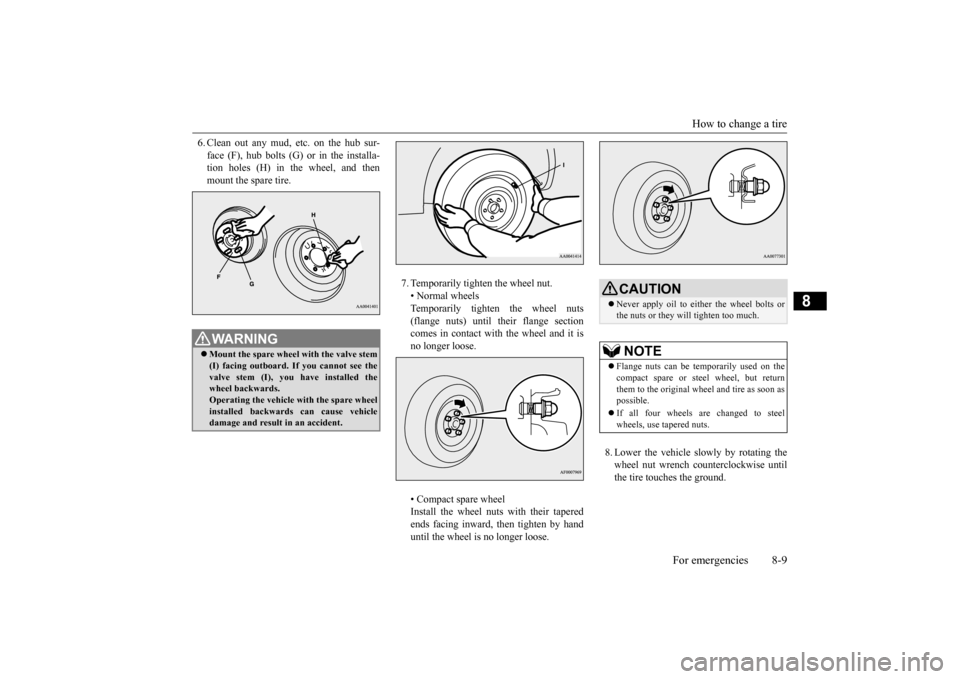

6. Clean out any mud, etc. on the hub sur- face (F), hub bolts (G) or in the installa- tion holes (H) in the wheel, and then mount the spare tire.

7. Temporarily tighten the wheel nut. • Normal wheels Temporarily tighten the wheel nuts(flange nuts) until their flange section comes in contact with the wheel and it is no longer loose. • Compact spare wheel Install the wheel nuts with their taperedends facing inward, then tighten by hand until the wheel is no longer loose.

8. Lower the vehicle slowly by rotating the wheel nut wrench counterclockwise until the tire touches the ground.

WA R N I N G Mount the spare wheel with the valve stem (I) facing outboard. If you cannot see the valve stem (I), you have installed the wheel backwards.Operating the vehicle with the spare wheel installed backwards can cause vehicle damage and result in an accident.

CAUTION Never apply oil to either the wheel bolts or the nuts or they will tighten too much.NOTE

Flange nuts can be temporarily used on the compact spare or steel wheel, but returnthem to the original wheel and tire as soon as possible. If all four wheels are changed to steel wheels, use tapered nuts.

BK0210800US.bo

ok 9 ページ 2014年4月8日 火曜日 午前11時28分

Page 287 of 338

Tires 9-16 Vehicle care and maintenance

9

under controlled conditions on speci- fied government test surfaces of asphalt and concrete. A tire marked C may have poor traction perfor- mance. The temperature grades are A (the highest), B and C, representing the tire’s resistance to the generation ofheat and its ability to dissipate heat when tested under controlled condi- tions on a specified indoor laboratorytest wheel. Sustained high tempera- ture can cause the material of the tire to degenerate and reduce tire life, andexcessive temperature can lead to sudden tire failure. The grade C cor- responds to a level of performancewhich all passenger car tires must meet under the Federal Motor Vehi- cle Safety Standard No. 109. Grades B and A represent higher levels of performance on the laboratory testwheel than the minimum required by law.

N00939300802

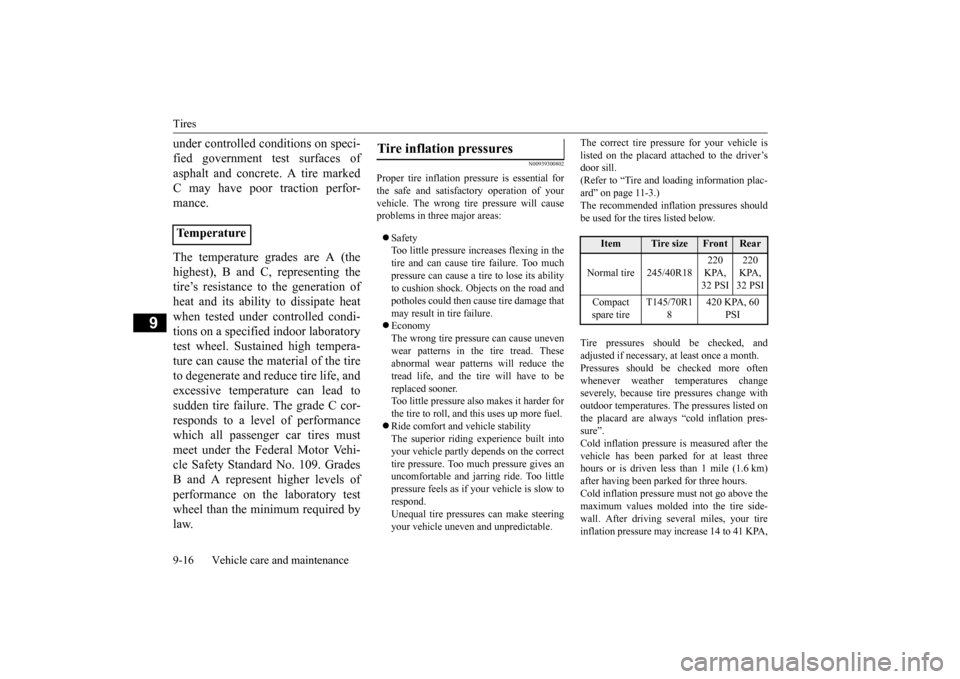

Proper tire inflation pressure is essential for the safe and satisfactory operation of yourvehicle. The wrong tire pressure will cause problems in three major areas: Safety Too little pressure increases flexing in thetire and can cause tire failure. Too muchpressure can cause a tire to lose its ability to cushion shock. Objects on the road and potholes could then cause tire damage thatmay result in tire failure. Economy The wrong tire pressure can cause unevenwear patterns in the tire tread. These abnormal wear patterns will reduce the tread life, and the tire will have to bereplaced sooner. Too little pressure also makes it harder for the tire to roll, and this uses up more fuel. Ride comfort and vehicle stability The superior riding experience built into your vehicle partly depends on the correcttire pressure. Too much pressure gives an uncomfortable and jarring ride. Too little pressure feels as if your vehicle is slow torespond. Unequal tire pressures can make steering your vehicle uneven and unpredictable.

The correct tire pressure for your vehicle is listed on the placard attached to the driver’s door sill. (Refer to “Tire and loading information plac-ard” on page 11-3.) The recommended inflation pressures should be used for the tires listed below. Tire pressures should be checked, and adjusted if necessary, at least once a month. Pressures should be checked more oftenwhenever weather temperatures change severely, because tire pressures change with outdoor temperatures. The pressures listed onthe placard are always “cold inflation pres- sure”. Cold inflation pressure is measured after thevehicle has been parked for at least three hours or is driven less than 1 mile (1.6 km) after having been parked for three hours.Cold inflation pressure must not go above the maximum values molded into the tire side- wall. After driving several miles, your tireinflation pressure may increase 14 to 41 KPA,

Temperature

Tire inflation pressures

Item

Tire size

Front

Rear

Normal tire 245/40R18

220 KPA, 32 PSI

220 KPA, 32 PSI

Compact spare tire

T145/70R1

8

420 KPA, 60

PSI

BK0210800US.bo

ok 16 ページ 2014年4月8日 火曜日 午前11時28分

Page 290 of 338

Clutch pedal free play (if so equipped) Vehicle care and maintenance 9-19

9

N00940000359

In some areas of the country, snow tires are required for winter driving. If snow tires arerequired in your area, you must choose snow tires of the same size and type as the original tires provided with your vehicle. Snow tiresshould also be installed on all four wheels. Otherwise your safety and vehicle handling can be reduced.Even where laws may permit it, snow tiresshould not be operated at sustained speeds over 75 mph (120 km/h).

N00940100015 N00940201097

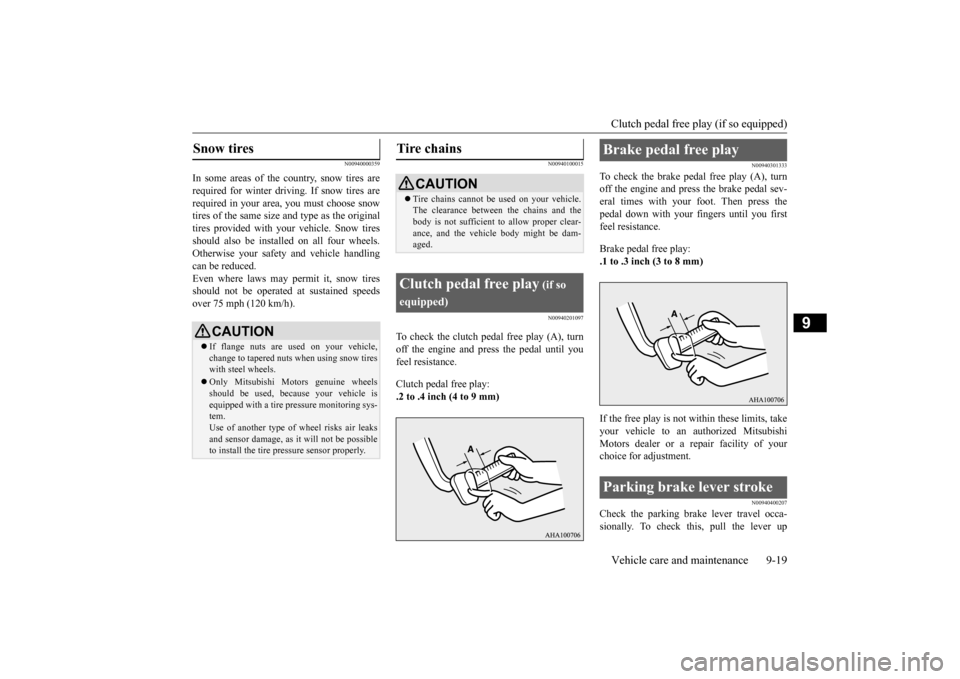

To check the clutch pedal free play (A), turn off the engine and press the pedal until you feel resistance. Clutch pedal free play: .2 to .4 inch (4 to 9 mm)

N00940301333

To check the brake pedal free play (A), turnoff the engine and press the brake pedal sev-eral times with your foot. Then press the pedal down with your fingers until you first feel resistance. Brake pedal free play: .1 to .3 inch (3 to 8 mm) If the free play is not within these limits, take your vehicle to an authorized Mitsubishi Motors dealer or a repair facility of your choice for adjustment.

N00940400207

Check the parking brake lever travel occa-sionally. To check this, pull the lever up

Snow tires

CAUTION If flange nuts are used on your vehicle, change to tapered nuts when using snow tireswith steel wheels. Only Mitsubishi Motors genuine wheels should be used, because your vehicle is equipped with a tire pressure monitoring sys- tem.Use of another type of wheel risks air leaks and sensor damage, as it will not be possible to install the tire pressure sensor properly.

Tire chains

CAUTION Tire chains cannot be used on your vehicle. The clearance between the chains and the body is not sufficient to allow proper clear- ance, and the vehicle body might be dam-aged.

Clutch pedal free play

(if so

equipped)

Brake pedal free play Parking brake lever stroke

BK0210800US.bo

ok 19 ページ 2014年4月8日 火曜日 午前11時28分

Page 293 of 338

General maintenance 9-22 Vehicle care and maintenance

9

there are other parts which do not usually need regular maintenance. But, if any of these pa

rts stops working prop-

erly, your vehicle performance could suffer.Have these items checked if you notice a problem with them. See your authorized Mitsubishi Motors dealer for assistance, if you have any questions.

N00941600062

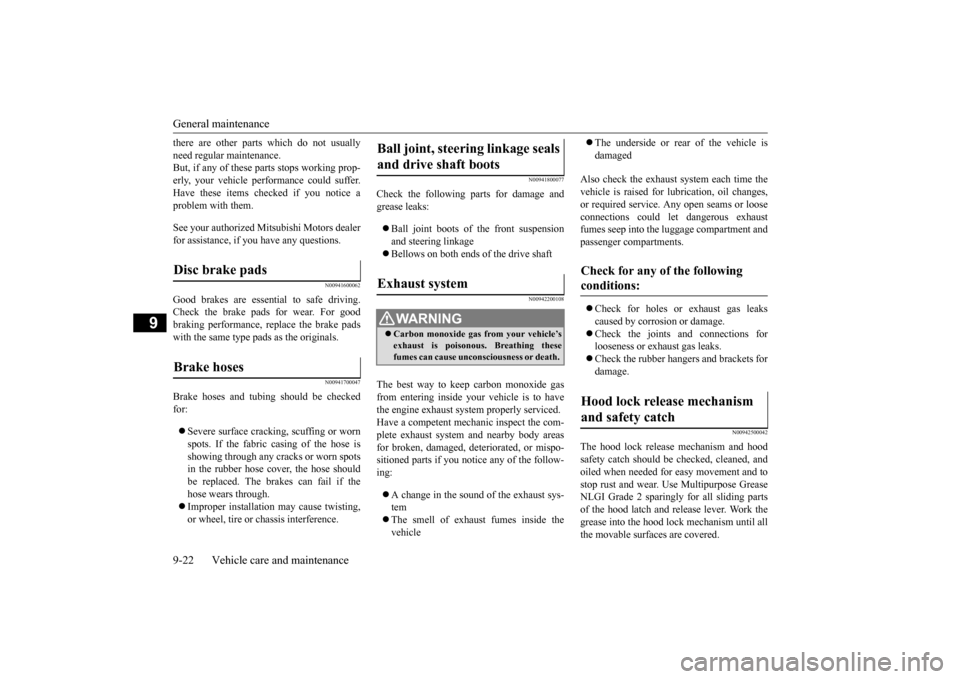

Good brakes are essential to safe driving. Check the brake pads for wear. For good braking performance, replace the brake padswith the same type pads as the originals.

N00941700047

Brake hoses and tubing should be checkedfor: Severe surface cracking, scuffing or worn spots. If the fabric casing of the hose is showing through any cracks or worn spotsin the rubber hose cover, the hose should be replaced. The brakes can fail if the hose wears through. Improper installation may cause twisting, or wheel, tire or chassis interference.

N00941800077

Check the following parts for damage and grease leaks: Ball joint boots of the front suspension and steering linkage Bellows on both ends of the drive shaft

N00942200108

The best way to k

eep carbon monoxide gas

from entering inside your vehicle is to have the engine exhaust system properly serviced. Have a competent mechanic inspect the com-plete exhaust system and nearby body areas for broken, damaged, deteriorated, or mispo- sitioned parts if you notice any of the follow-ing: A change in the sound of the exhaust sys- tem The smell of exhaust fumes inside the vehicle

The underside or rear of the vehicle is damaged

Also check the exhaust system each time the vehicle is raised for lubrication, oil changes, or required service. Any open seams or looseconnections could let dangerous exhaust fumes seep into the luggage compartment and passenger compartments. Check for holes or exhaust gas leaks caused by corrosion or damage. Check the joints and connections for looseness or exhaust gas leaks. Check the rubber hangers and brackets for damage.

N00942500042

The hood lock release mechanism and hood safety catch should be checked, cleaned, and oiled when needed for easy movement and tostop rust and wear. Use Multipurpose Grease NLGI Grade 2 sparingly for all sliding parts of the hood latch and release lever. Work thegrease into the hood lock mechanism until all the movable surfaces are covered.

Disc brake pads Brake hoses

Ball joint, steering linkage seals and drive shaft boots Exhaust system

WA R N I N G Carbon monoxide gas from your vehicle’s exhaust is poisonous. Breathing these fumes can cause unconsciousness or death.

Check for any of the following conditions: Hood lock release mechanism and safety catch

BK0210800US.bo

ok 22 ページ 2014年4月8日 火曜日 午前11時28分

Page 334 of 338

Alphabetical index

12-5

12

Speedometer

..................

.....................

5-89

SST (Sportronic Shift Transmission)

....

5-58

Steering

Power steering fluid

...............

9-11

, 11-5

Tilt lock lever

................

.................

5-47

Wheel lock

............................

5-19

, 5-52

Storage spaces

...................

...............

5-163

Sun visors

.....................

...................

5-160

Sunroof

......................

........................

5-44

Safety mechanism

...........................

5-45

Sunshade

..................

.....................

5-46

Timer function

...............

.................

5-45

Super-all wheel control (S-AWC)

S-AWC control mode display

..........

5-72

S-AWC control mode switch

...........

5-72

S-AWC operation display

................

5-73

S-AWC warning display

..................

5-73

Supplemental Restraint System

............

4-20

Curtain airbag system

......................

4-31

Driver's knee airbag system

.............

4-27

How the Supplement Restraint System works

.....................

.....................

4-23

Servicing

..................

.....................

4-35

Side airbag system

..........................

4-31

Warning light/display

......................

4-26

T

Tachometer

...................

.....................

5-89

Tail and stop lights

Bulb capacity

..................

...............

9-28

Replacement

...................

...............

9-36

Tail lights

Bulb capacity

..................

...............

9-28

Replacement

...................

...............

9-37

Tank capacity

...............

................

3-4

, 11-5

Theft-alarm system

System

........................

..................

5-39

Tire pressure monitoring system

..........

5-85

Warning light/display

.....................

5-86

Tires

...........................

......................

9-12

How to change a tire

.........................

8-6

Inflation pressure

............................

9-16

Maintenance

...................

...............

9-17

Quality grading

...............

...............

10-2

Replacing tires and wheels

..............

9-17

Rotation

......................

..................

9-18

Size (tire and wheel)

.......................

11-5

Snow tires

...................

..................

9-19

Tire and loading information placard

.6-7

,

11-3 Tire chains

...................

..................

9-19

Tread wear indicators

.....................

9-17

Tissue holder

...................

.................

5-165

Tools

...........................

........................

8-5

Storage

........................

....................

8-5

Towing

........................

......................

8-10

Trailer towing

.....................

...............

6-10

Transfer oil

......................

....................

9-9

Oil

..........................

......................

11-5

Trunk area light

Bulb capacity

................

.................

9-30

Replacement

..................

.................

9-40

Trunk lid

.......................

.....................

5-37

Turbocharger operation

.......................

5-55

Turn signal light

Indicators

..................

...................

5-120

Lever

........................

...................

5-129

Turn signal lights

Bulb capacity

................

.................

9-28

Twin Clutch SST

Fluid

..................

.....................

9-9

, 11-5

Gearshift lever operation

.................

5-58

Gearshift lever position display

........

5-59

Manual shift

..................

.................

5-64

Manual shift display

........................

5-67

Twin Clutch SST control mode display

....

5-64 Twin Clutch SST control mode switch

.....

5-63Warning display

.............................

5-60

Twin Clutch SST (Sportronic Shift Transmission)

..................

.................

5-58

U

USB input terminal

...........................

5-157

How to connect an iPod

.................

5-158

USB input terminal device

How to connect a USB memory

.....

5-157

BK0210800US.bo

ok 5 ページ 2014年4月8日 火曜日 午前11時28分