service MITSUBISHI LANCER EVOLUTION X 2008 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 173 of 241

TRIMS

TSB Revision

INTERIOR52A-12

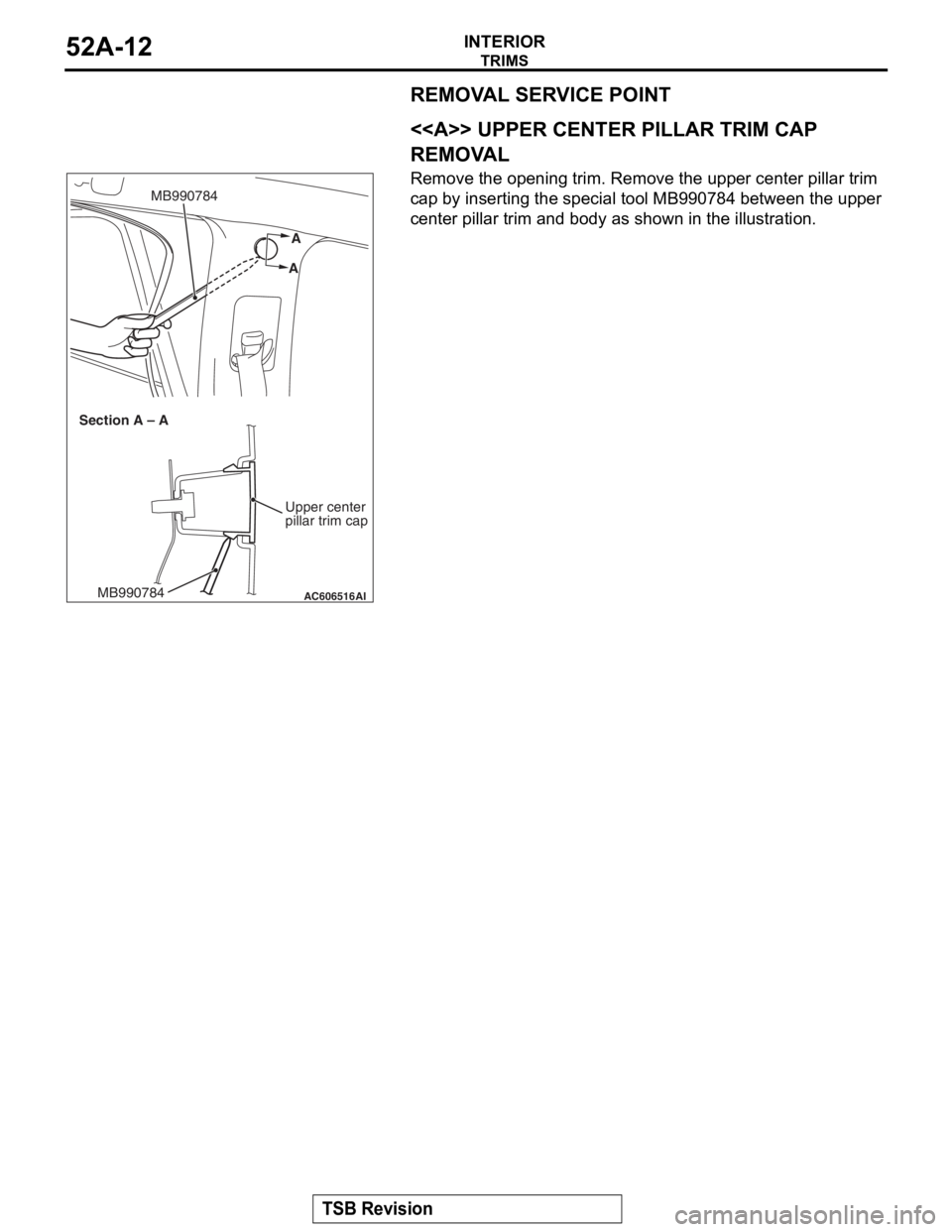

REMOVAL SERVICE POINT

.

<> UPPER CENTER PILLAR TRIM CAP

REMOVAL

Remove the opening trim. Remove the upper center pillar trim

cap by inserting the special tool MB990784 between the upper

center pillar trim and body as shown in the illustration.

AC606516

A

A

MB990784

AIMB990784

Section A – A

Upper center

pillar trim cap

Page 177 of 241

HEADLINING

TSB Revision

INTERIOR52A-16

Required Special Tool:

•MB990784: Ornament Remover

REMOVAL SERVICE POINTS

.

<> SUN VISOR HOLDER REMOVAL

Insert the special tool MB990784 into side claws of the sun

visor holder through the both sides of the sun visor holder to

remove the hinges.

.

<> HEADLINING ASSEMBLY REMOVAL

To remove the clip, insert a vinyl cord into a clearance between

the clip and the headlining, and pass it around the clip. Then,

pull out the clip downwards while pulling the vinyl cord.

Removal steps

1.Assist grip

2.Rear dome light assembly

3.Front dome light

4.Sun visor assembly

<>5.Sun visor holder

6.Sunroof lid inner weather strip rear

<>7.Headlining

8.Assist grip bracket

9.Front side roof energy absorption box

10.Rear side roof energy absorption box

Removal steps (Continued)

AC005512

MB990784

MB990784

Sun visor holder

AF

AC600751AD

Clip

Headlining Vinyl cord

Page 178 of 241

INSIDE REAR VIEW MIRROR

TSB Revision

INTERIOR52A-17

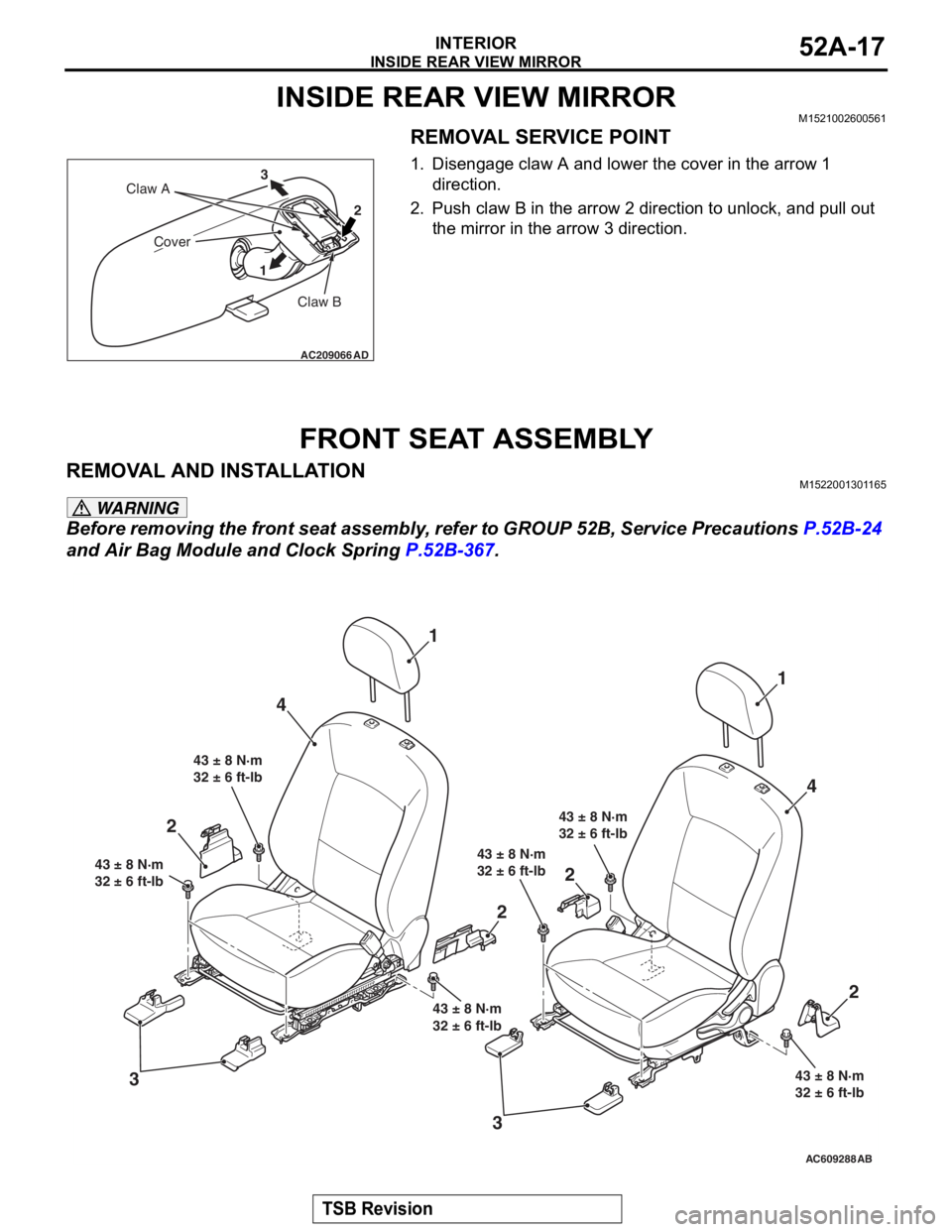

INSIDE REAR VIEW MIRRORM1521002600561

REMOVAL SERVICE POINT

1. Disengage claw A and lower the cover in the arrow 1 direction.

2. Push claw B in the arrow 2 direction to unlock, and pull out the mirror in the arrow 3 direction.

FRONT SEAT ASSEMBLY

REMOVAL AND INSTALLATIONM1522001301165

WARNING

Before removing the front seat assembly, refer to GROUP 52B, Service Precautions P.52B-24

and Air Bag Module and Clock Spring P.52B-367.

AC209066

Claw B

Claw A

Cover

12

3

AD

AC609288AB

4

3 1

43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb 43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb

1

4

2

2

2

3

2

Page 179 of 241

FRONT SEAT ASSEMBLY

TSB Revision

INTERIOR52A-18

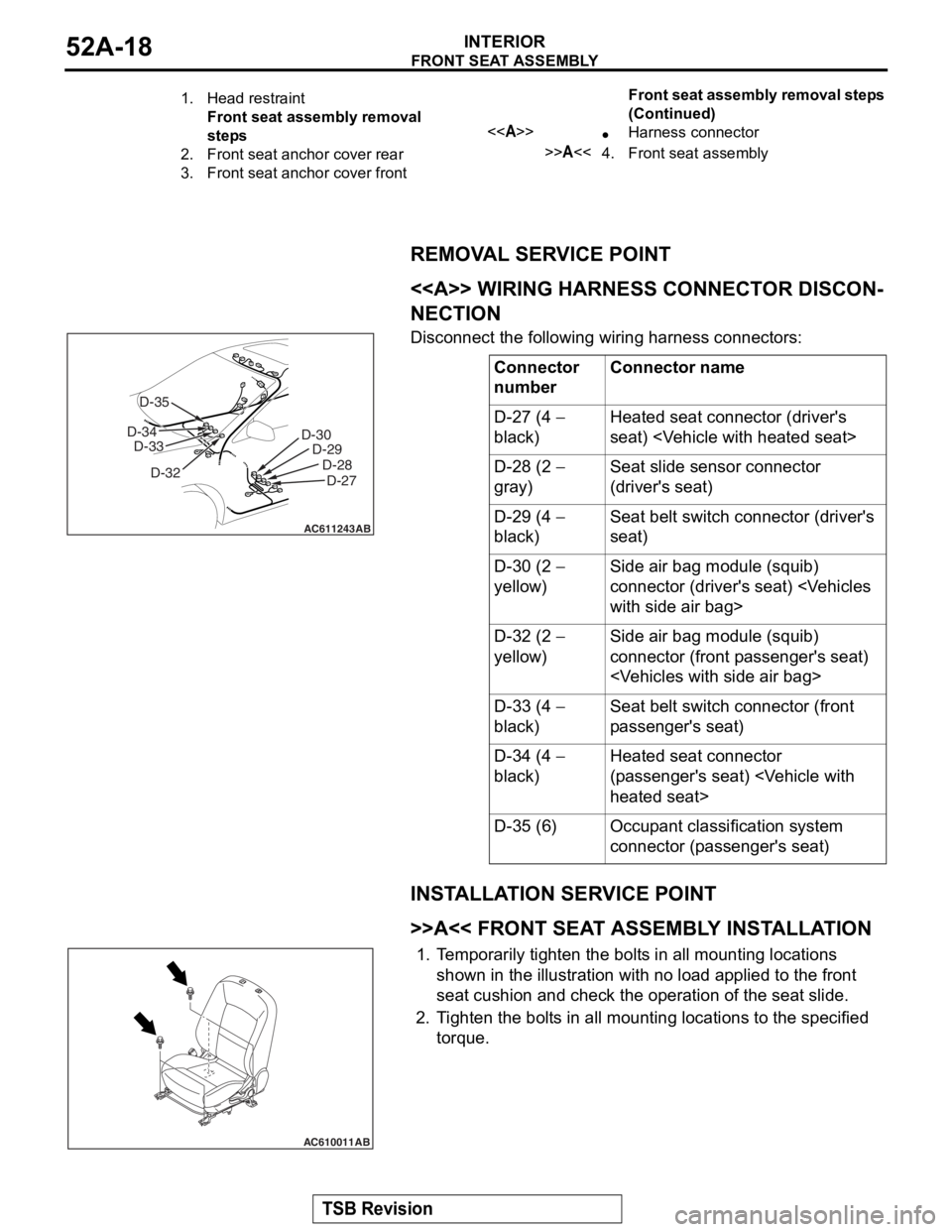

REMOVAL SERVICE POINT

.

<> WIRING HARNESS CONNECTOR DISCON-

NECTION

Disconnect the following wiring harness connectors:

INSTALLATION SERVICE POINT

.

>>A<< FRONT SEAT ASSEMBLY INSTALLATION

1.Temporarily tighten the bolts in all mounting locations

shown in the illustration with no load applied to the front

seat cushion and check the operation of the seat slide.

2. Tighten the bolts in all mounti ng locations to the specified

torque.

1.Head restraint

Front seat assembly removal

steps

2.Front seat anchor cover rear

3.Front seat anchor cover front

<>•Harness connector

>>A<<4.Front seat assembly

Front seat assembly removal steps

(Continued)

Connector

numberConnector name

D-27 (4 −

black)Heated seat connector (driver's

seat)

D-28 (2 −

gray)Seat slide sensor connector

(driver's seat)

D-29 (4 −

black)Seat belt switch connector (driver's

seat)

D-30 (2 −

yellow)Side air bag module (squib)

connector (driver's seat)

D-32 (2 −

yellow)Side air bag module (squib)

connector (front passenger's seat)

D-33 (4 −

black)Seat belt switch connector (front

passenger's seat)

D-34 (4 −

black)Heated seat connector

(passenger's seat)

D-35 (6)Occupant classification system

connector (passenger's seat)

AC611243

D-30 D-29

D-28D-27

AB

D-32

D-33

D-34 D-35

AC610011AB

Page 183 of 241

FRONT SEAT ASSEMBLY

TSB Revision

INTERIOR52A-22

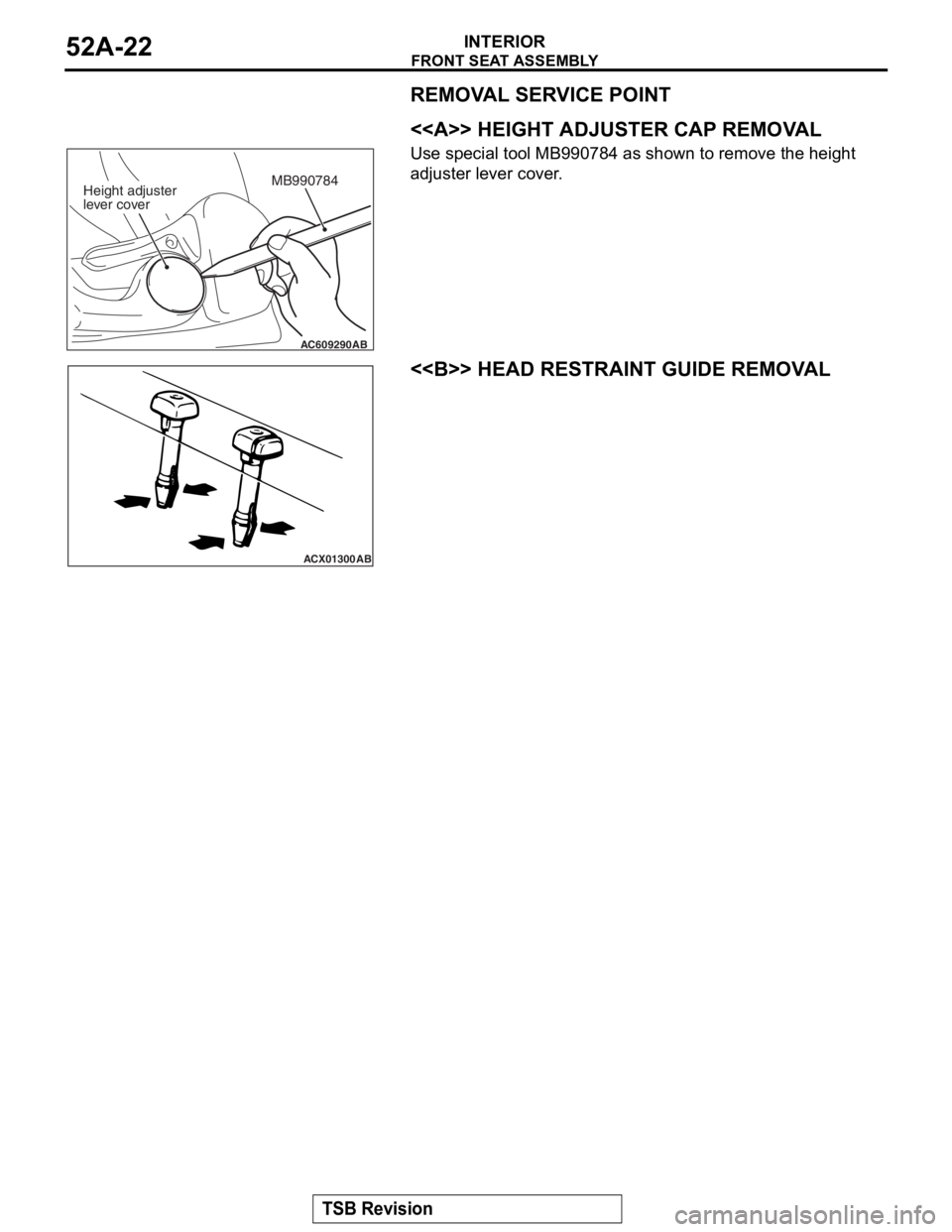

REMOVAL SERVICE POINT

.

<> HEIGHT ADJUSTER CAP REMOVAL

Use special tool MB990784 as shown to remove the height

adjuster lever cover.

.

<> HEAD RESTRAINT GUIDE REMOVAL

AC609290

MB990784

AB

Height adjuster

lever cover

ACX01300AB

Page 186 of 241

REAR SEAT ASSEMBLY

TSB Revision

INTERIOR52A-25

INSTALLATION SERVICE POINTS

.

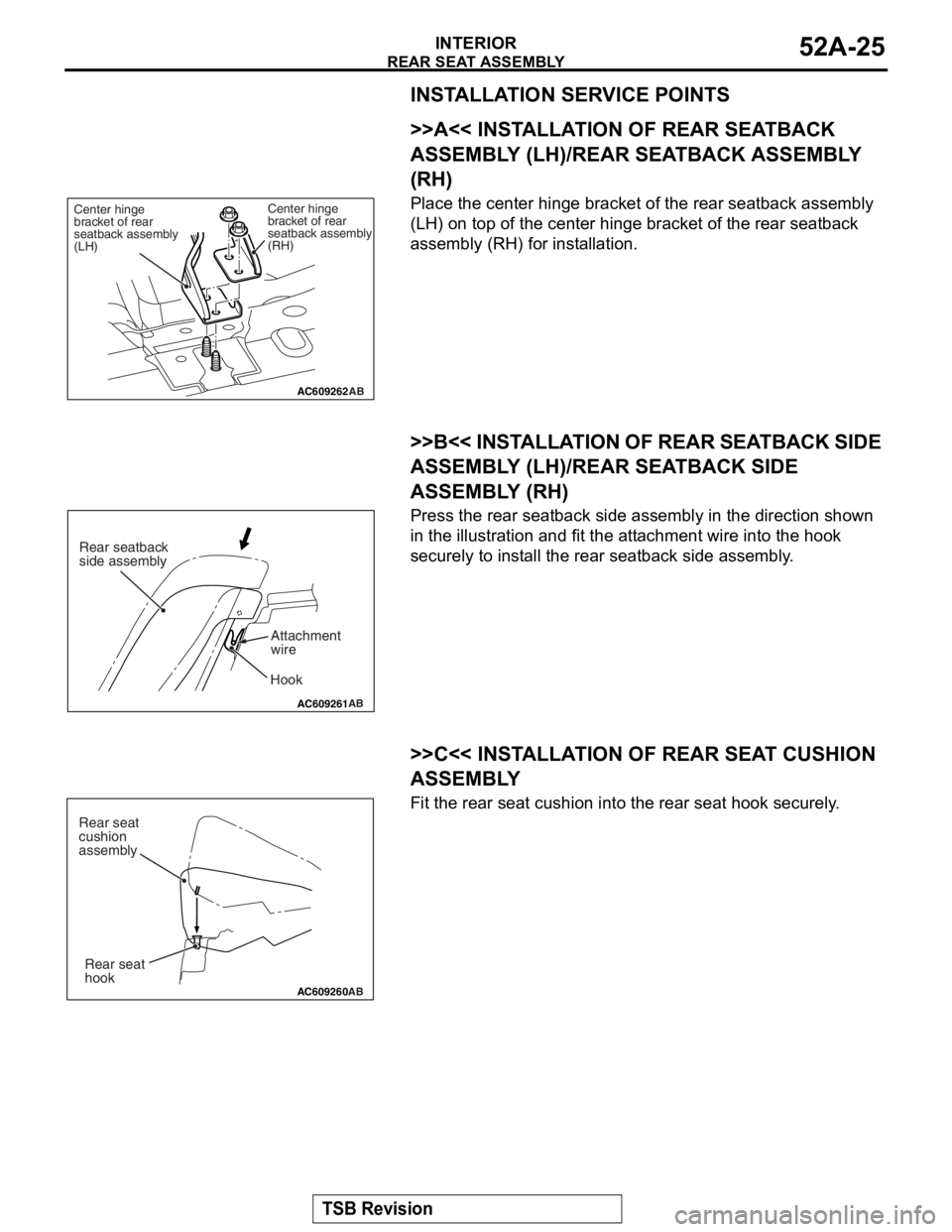

>>A<< INSTALLATION OF REAR SEATBACK

ASSEMBLY (LH)/REAR SEATBACK ASSEMBLY

(RH)

Place the center hinge bracket of the rear seatback assembly

(LH) on top of the center hinge bracket of the rear seatback

assembly (RH) for installation.

.

>>B<< INSTALLATION OF REAR SEATBACK SIDE

ASSEMBLY (LH)/RE AR SEATBACK SIDE

ASSEMBLY (RH)

Press the rear seatback side as sembly in the direction shown

in the illustration and fit the attachment wire into the hook

securely to install the rear seatback side assembly.

.

>>C<< INSTALLATION OF REAR SEAT CUSHION

ASSEMBLY

Fit the rear seat cushion into the rear seat hook securely.

AC609262

Center hinge

bracket of rear

seatback assembly

(RH)

Center hinge

bracket of rear

seatback assembly

(LH)

AB

AC609261

AB

Hook

Rear seatback

side assembly

Attachment

wire

AC609260AB

Rear seat

hook

Rear seat

cushion

assembly

Page 190 of 241

FRONT SEAT BELT

TSB Revision

INTERIOR52A-29

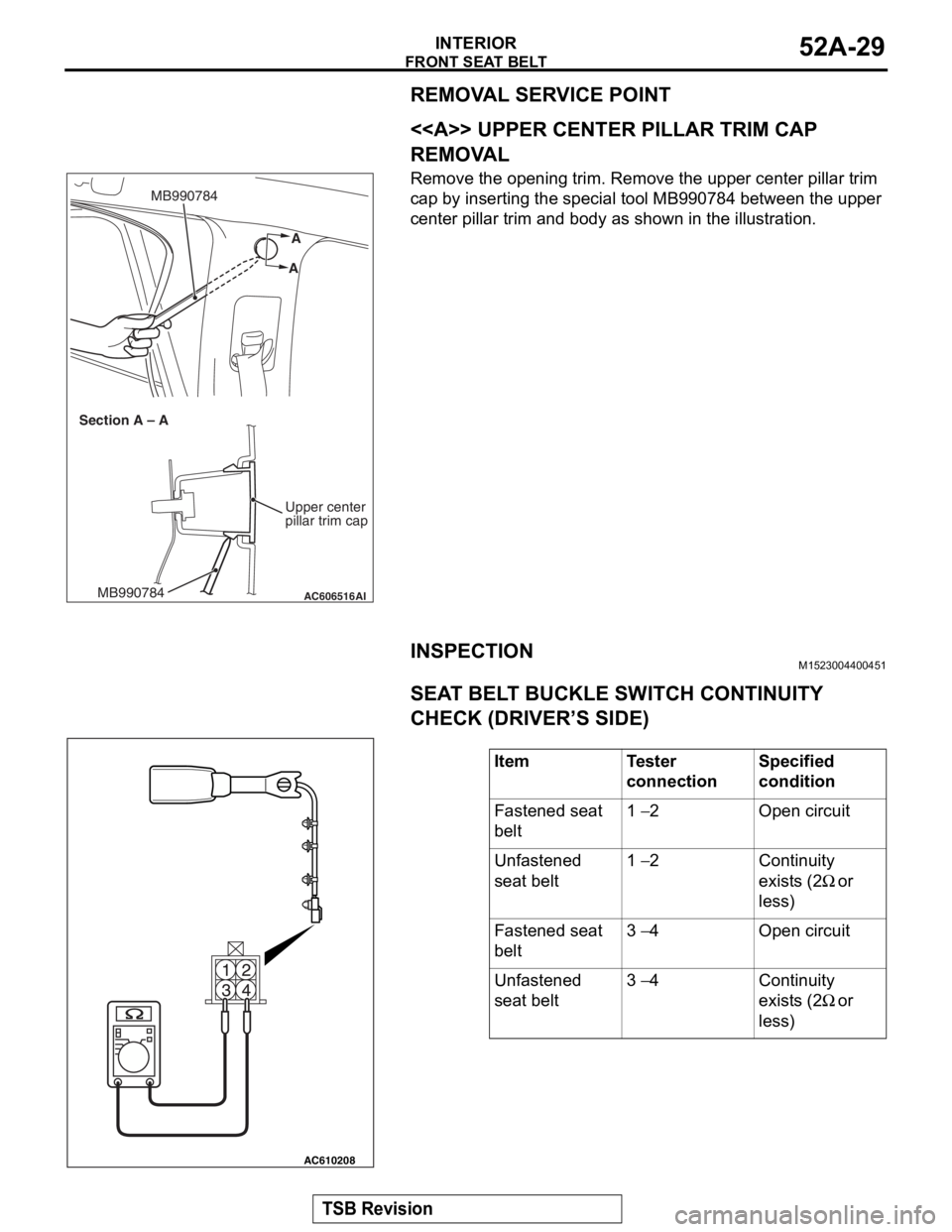

REMOVAL SERVICE POINT

.

<> UPPER CENTER PILLAR TRIM CAP

REMOVAL

Remove the opening trim. Remove the upper center pillar trim

cap by inserting the special tool MB990784 between the upper

center pillar trim and body as shown in the illustration.

INSPECTIONM1523004400451.

SEAT BELT BUCKLE SWITCH CONTINUITY

CHECK (DRIVER’S SIDE)

AC606516

A

A

MB990784

AIMB990784

Section A – A

Upper center

pillar trim cap

ItemTester

connectionSpecified

condition

Fastened seat

belt1 − 2Open circuit

Unfastened

seat belt1 − 2Continuity

exists (2

Ω or

less)

Fastened seat

belt3 − 4Open circuit

Unfastened

seat belt3 − 4Continuity

exists (2

Ω or

less)

AC610208

Page 201 of 241

GENERAL

BASIC BRAKE SYSTEM35A-2

GENERALM2350000100956

Brake systems with higher reliability and durability

have achieved distinguished braking performance.

FEATURES

.

IMPROVEMENT OF BRAKING PERFOR-

MANCE

•A 10-inch single brake booster with the variable

boost ratio mechanism has been used to assure

maximum braking force with less pedal pressure

in case of emergency.

•In addition to the 10-inch single brake booster, a

small and long stroke-type master cylinder has

been adopted to achieve downsizing and secure

assist force.

•15-inch or 16-inch ventilated disc brakes have

been adopted for the front.

•8-inch leading trailing-type drum brake, 14-inch

or 16-inch solid disc brake has been adopted for

the rear.

.

IMPROVEMENT IN SAFETY

•The 4-wheel anti-lock brake system (4ABS) has

been installed to prevent slippage resulting from

the wheel lock and assure stable vehicle posture

and driveability.

•A rear wheel early lock-prevention proportioning

valve has been used.

•Electronic control braking force distribution sys-

tem (EBD) has been adopted to assure the maxi-

mum braking force independently of the

passenger's position in the vehicle.

•X-type piping of brake lines have been adopted

for the front and rear wheels.

•Audible wear indicators are used on the front and

rear brake pads to warn the driver of wear limit.

.

SERVICE QUALITY IMPROVEMENTS

•Diagnostic function has been adopted to ABS for

easier inspection.

•Brake fluid reservoir, master cylinder, and brake

booster have been integrated for downsizing and

better serviceability.

Page 207 of 241

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-8

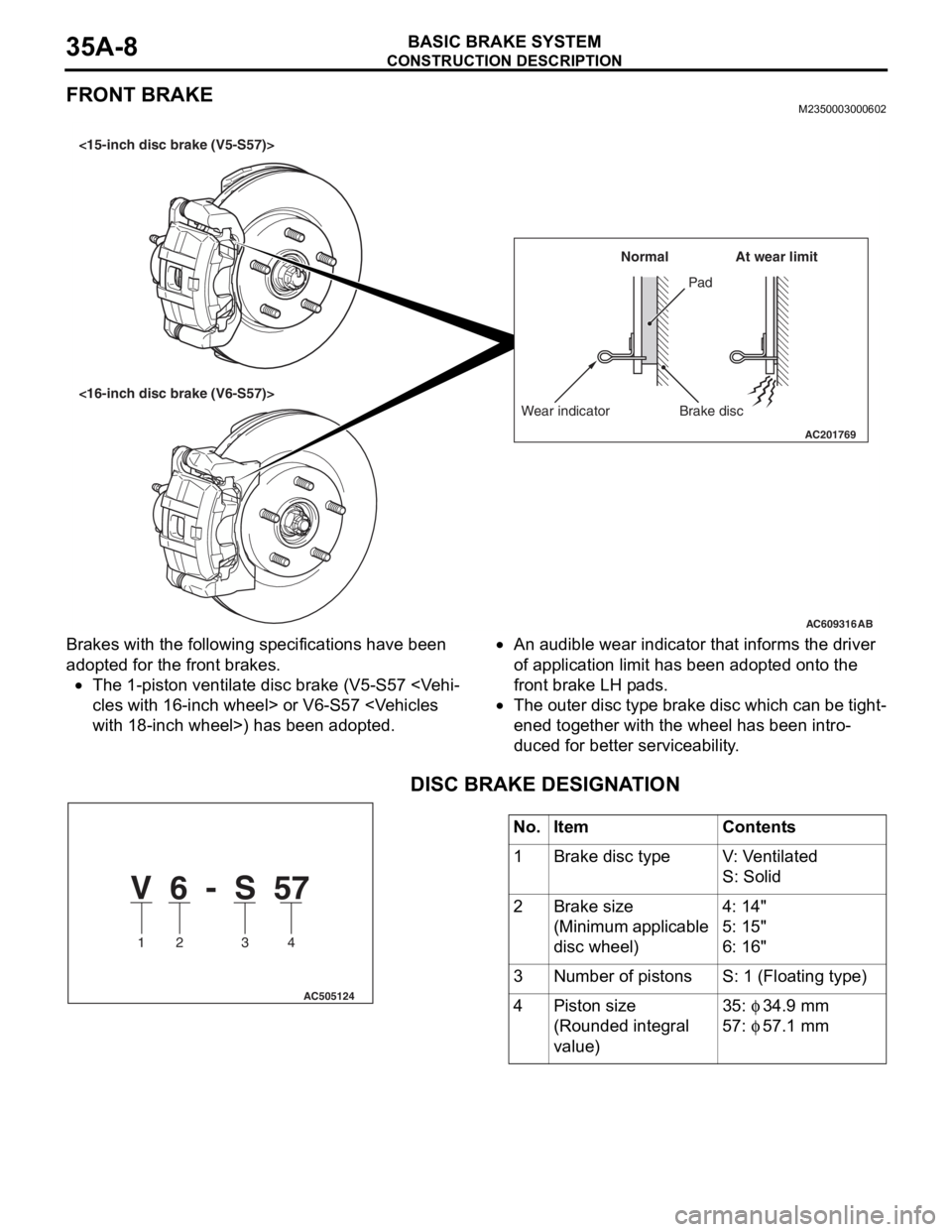

FRONT BRAKEM2350003000602

Brakes with the following specifications have been

adopted for the front brakes.

•The 1-piston ventilate disc brake (V5-S57

•An audible wear indicator that informs the driver

of application limit has been adopted onto the

front brake LH pads.

•The outer disc type brake disc which can be tight-

ened together with the wheel has been intro-

duced for better serviceability.

.

DISC BRAKE DESIGNATION

AC609316

AC201769

Wear indicator Brake discPad Normal

AB

At wear limit

<15-inch disc brake (V5-S57)>

<16-inch disc brake (V6-S57)>

No.ItemContents

1Brake disc typeV: Ventilated

S: Solid

2Brake size

(Minimum applicable

disc wheel)

4: 14"

5: 15"

6: 16"

3Number of pistonsS: 1 (Floating type)

4Piston size

(Rounded integral

value)

35: φ 34.9 mm

57: φ 57.1 mm

V 6 - S 57

1 2 3 4

AC505124

Page 208 of 241

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-9

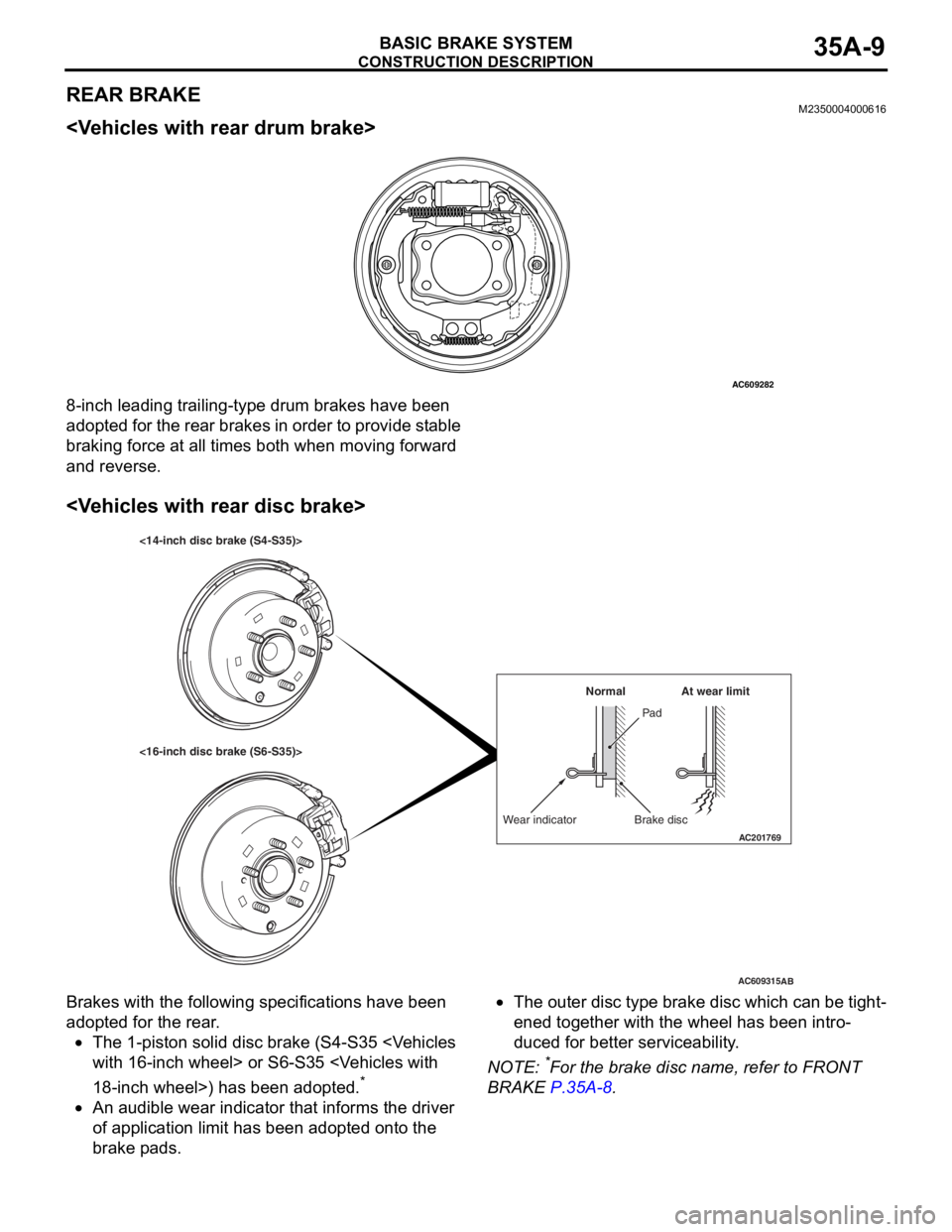

REAR BRAKEM2350004000616

8-inch leading trailing-type drum brakes have been

adopted for the rear brakes in order to provide stable

braking force at all times both when moving forward

and reverse.

Brakes with the following specifications have been

adopted for the rear.

•The 1-piston solid disc brake (S4-S35

*

•An audible wear indicator that informs the driver

of application limit has been adopted onto the

brake pads.

•The outer disc type brake disc which can be tight-

ened together with the wheel has been intro-

duced for better serviceability.

NOTE: *For the brake disc name, refer to FRONT

BRAKE

P.35A-8.

AC609282

AC609315

AC201769

Wear indicator Brake discPad Normal

AB

At wear limit

<16-inch disc brake (S6-S35)> <14-inch disc brake (S4-S35)>