ECU MITSUBISHI LANCER EVOLUTION X 2008 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 50 of 241

BASE ENGINE

ENGINE MECHANICAL11A-6

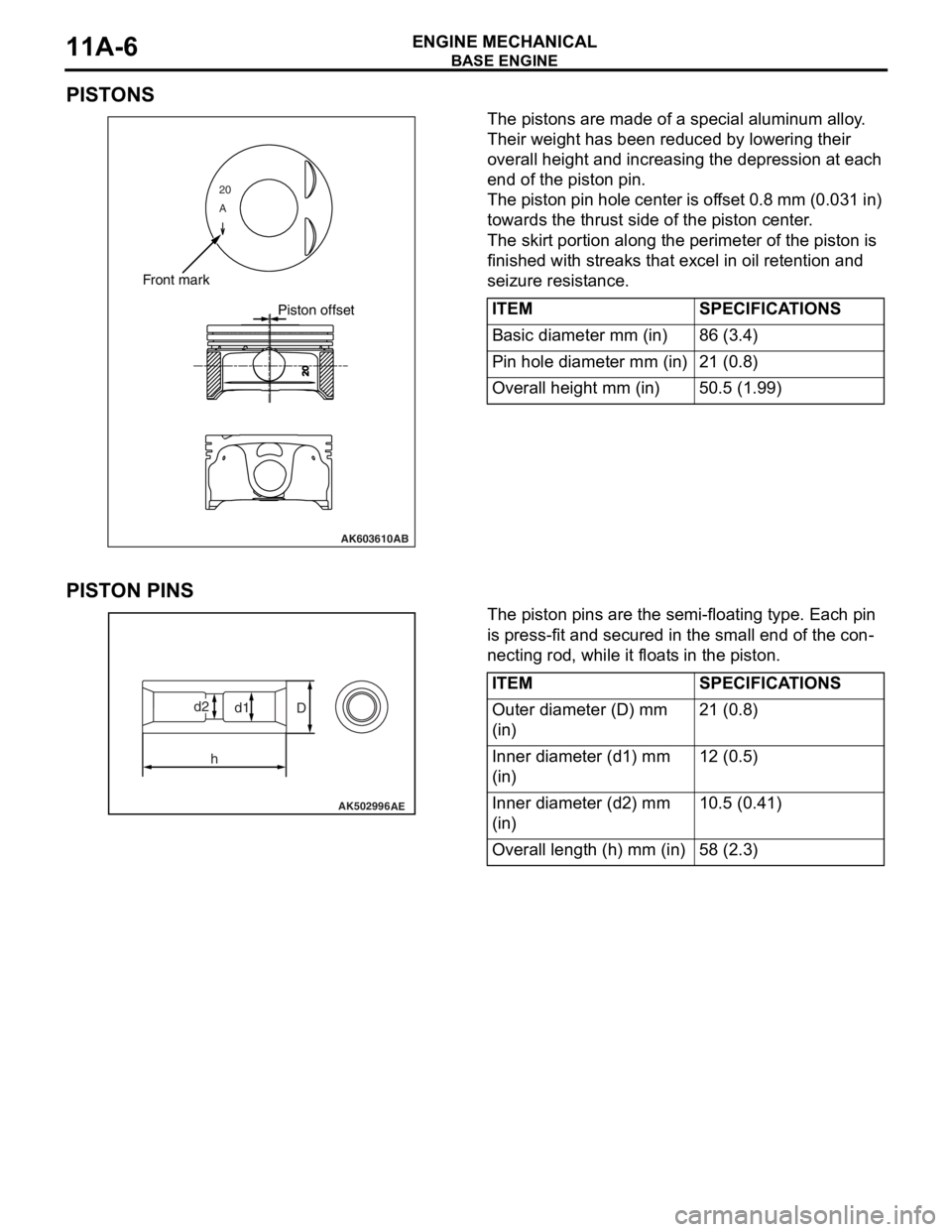

PISTONS

The pistons are made of a special aluminum alloy.

Their weight has been reduced by lowering their

overall height and increasing the depression at each

end of the piston pin.

The piston pin hole center is offset 0.8 mm (0.031 in)

towards the thrust side of the piston center.

The skirt portion along the perimeter of the piston is

finished with streaks that excel in oil retention and

seizure resistance.

PISTON PINS

The piston pins are the semi-floating type. Each pin

is press-fit and secured in the small end of the con

-

necting rod, while it floats in the piston.

20

A

AK603610

Front mark

Piston offset

AB

ITEMSPECIFICATIONS

Basic diameter mm (in)86 (3.4)

Pin hole diameter mm (in)21 (0.8)

Overall height mm (in)50.5 (1.99)

AK502996AE

D

hd1d2

ITEMSPECIFICATIONS

Outer diameter (D) mm

(in)21 (0.8)

Inner diameter (d1) mm

(in)12 (0.5)

Inner diameter (d2) mm

(in)10.5 (0.41)

Overall length (h) mm (in)58 (2.3)

Page 60 of 241

BASE ENGINE

ENGINE MECHANICAL11A-16

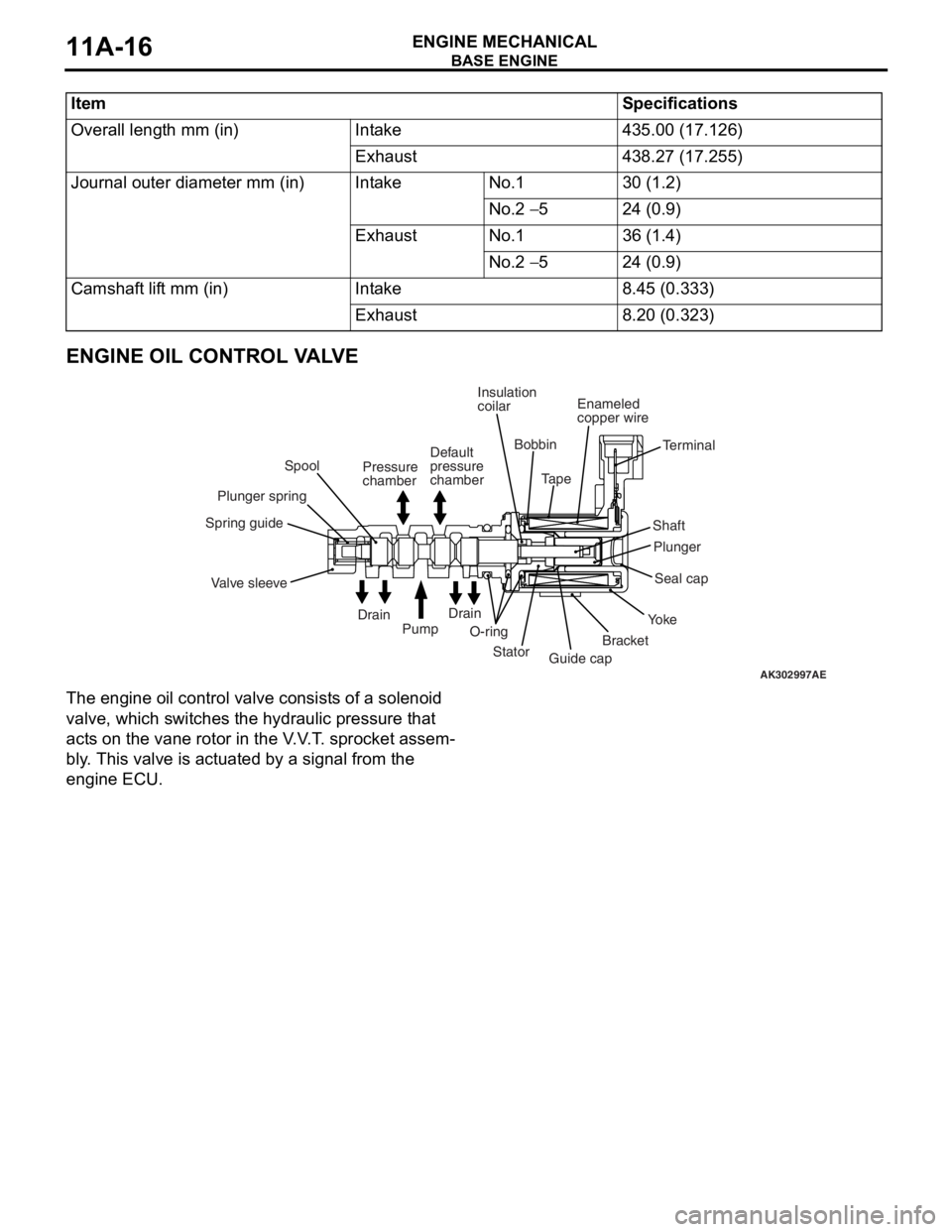

ENGINE OIL CONTROL VALVE

The engine oil control valve consists of a solenoid

valve, which switches the hydraulic pressure that

acts on the vane rotor in the V.V.T. sprocket assem

-

bly. This valve is actuated by a signal from the

engine ECU.

ItemSpecifications

Overall length mm (in)Intake435.00 (17.126)

Exhaust438.27 (17.255)

Journal outer diameter mm (in)IntakeNo.130 (1.2)

No.2 − 524 (0.9)

ExhaustNo.136 (1.4)

No.2 − 524 (0.9)

Camshaft lift mm (in)Intake8.45 (0.333)

Exhaust8.20 (0.323)

AK302997AE

Spring guide

Valve sleevePlunger springSpool

O-ringInsulation

coilar

Stator

Guide capBracketYo k eSeal cap Plunger ShaftTerminal Bobbin

TapeEnameled

copper wire

Drain

Drain

Pump Pressure

chamberDefault

pressure

chamber

Page 116 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-23

ACTUATORM2132002000353

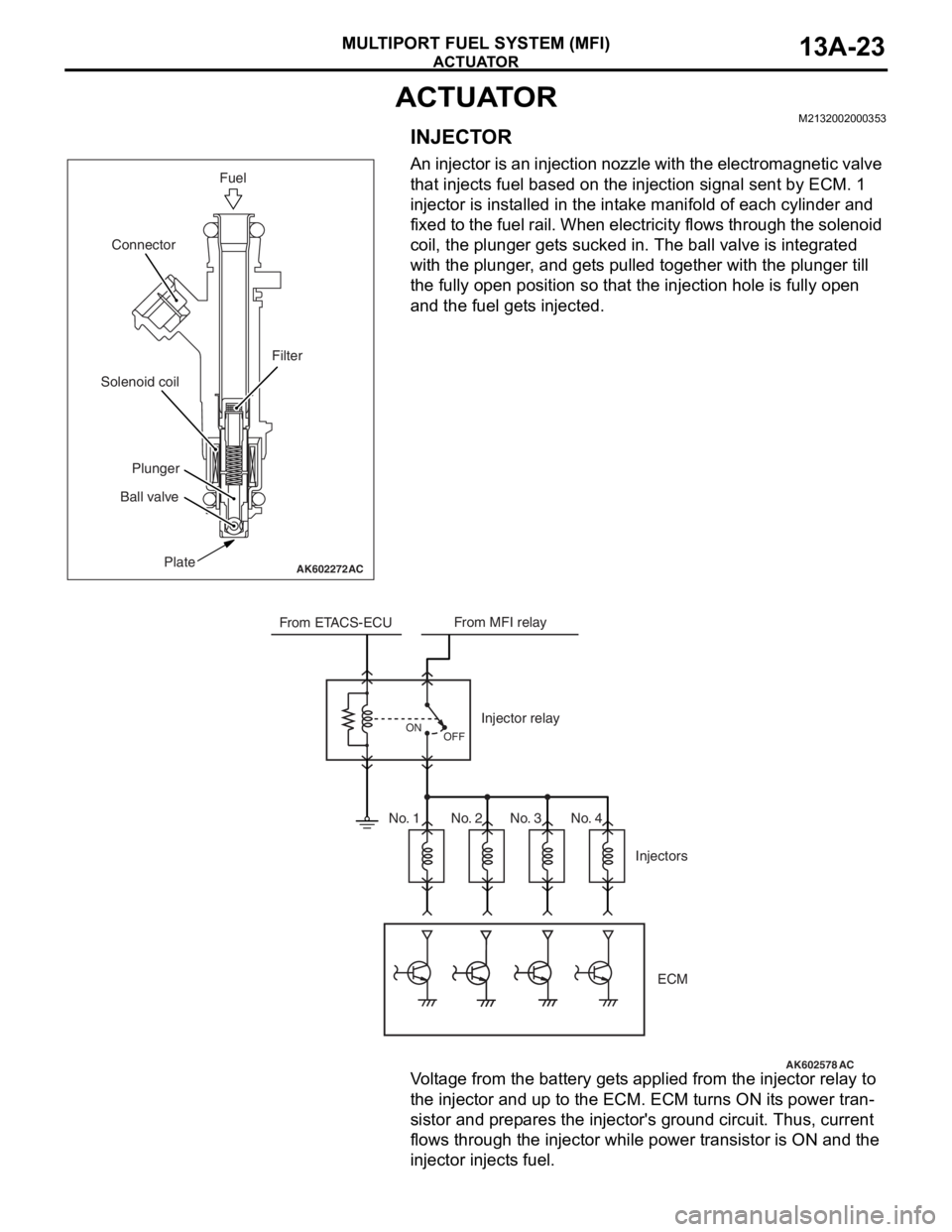

INJECTOR

An injector is an injection nozzle with the electromagnetic valve

that injects fuel based on the injection signal sent by ECM. 1

injector is installed in the intake manifold of each cylinder and

fixed to the fuel rail. When electricity flows through the solenoid

coil, the plunger gets sucked in. The ball valve is integrated

with the plunger, and gets pulled together with the plunger till

the fully open position so that the injection hole is fully open

and the fuel gets injected.

Voltage from the battery gets applied from the injector relay to

the injector and up to the ECM. ECM turns ON its power tran

-

sistor and prepares the injector's ground circuit. Thus, current

flows through the injector while power transistor is ON and the

injector injects fuel.

AK602272AC

Fuel

Plate Ball valvePlunger Solenoid coilConnector

Filter

AK602578

From ETACS-ECUFrom MFI relay

Injector relay

Injectors

OFF ON

ECM

AC

No. 1 No. 2 No. 3 No. 4

Page 138 of 241

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-45

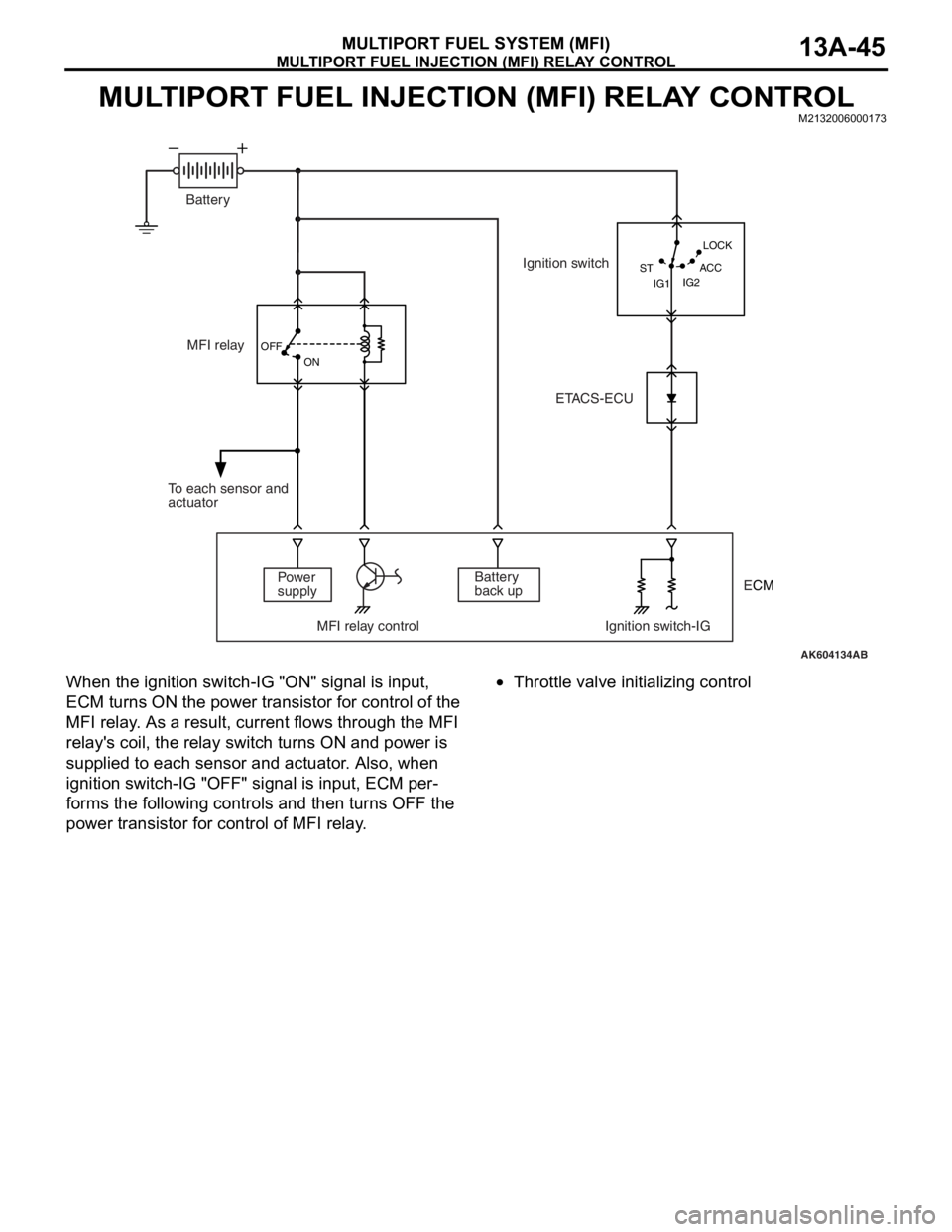

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROLM2132006000173

When the ignition switch-IG "ON" signal is input,

ECM turns ON the power transistor for control of the

MFI relay. As a result, current flows through the MFI

relay's coil, the relay switch turns ON and power is

supplied to each sensor and actuator. Also, when

ignition switch-IG "OFF" signal is input, ECM per

-

forms the following controls and then turns OFF the

power transistor for control of MFI relay.

•Throttle valve initializing control

AK604134AB OFF

ON

IG2 STLOCK

ACC

IG1

MFI relay

Power

supply

MFI relay control Ignition switch-IGBattery

back up To each sensor and

actuatorIgnition switch

ETACS-ECU Battery

ECM

Page 139 of 241

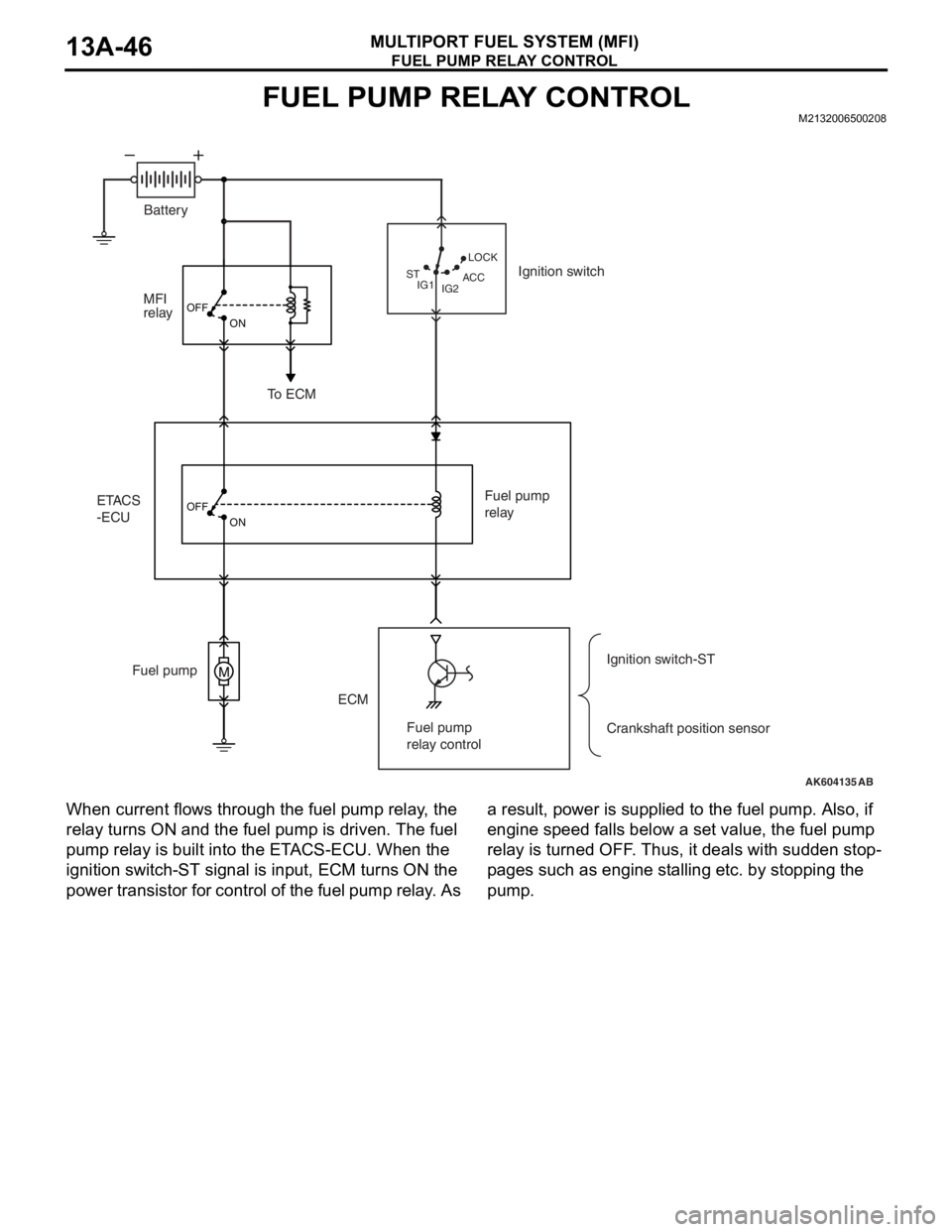

FUEL PUMP RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-46

FUEL PUMP RELAY CONTROLM2132006500208

When current flows through the fuel pump relay, the

relay turns ON and the fuel pump is driven. The fuel

pump relay is built into the ETACS-ECU. When the

ignition switch-ST signal is input, ECM turns ON the

power transistor for control of the fuel pump relay. As a result, power is supplied to the fuel pump. Also, if

engine speed falls below a set value, the fuel pump

relay is turned OFF. Thus, it deals with sudden stop

-

pages such as engine stalling etc. by stopping the

pump.

AK604135

M

OFF

ON

OFF

ON

AB IG2 STLOCK

ACC

IG1

ETACS

-ECUMFI

relay

ECM Fuel pumpFuel pump

relay

Crankshaft position sensor Ignition switch

To ECM

Ignition switch-ST Battery

Fuel pump

relay control

Page 140 of 241

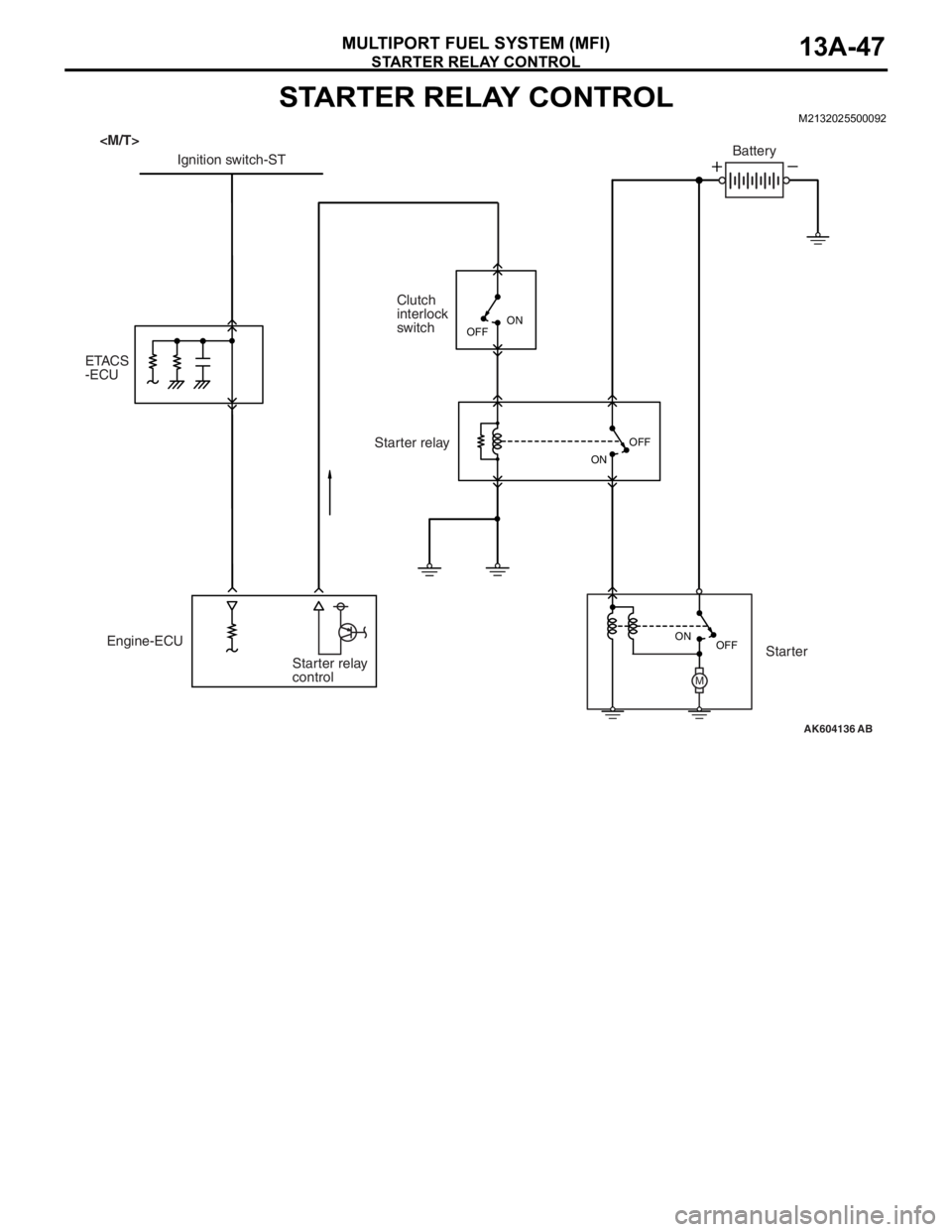

STARTER RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-47

STARTER RELAY CONTROLM2132025500092

AK604136

M

AB OFF ON OFF

ON

Engine-ECU

Starter relay

controlClutch

interlock

switch

ETACS

-ECUIgnition switch-STBattery

Starter relay

Starter

OFFON

Page 141 of 241

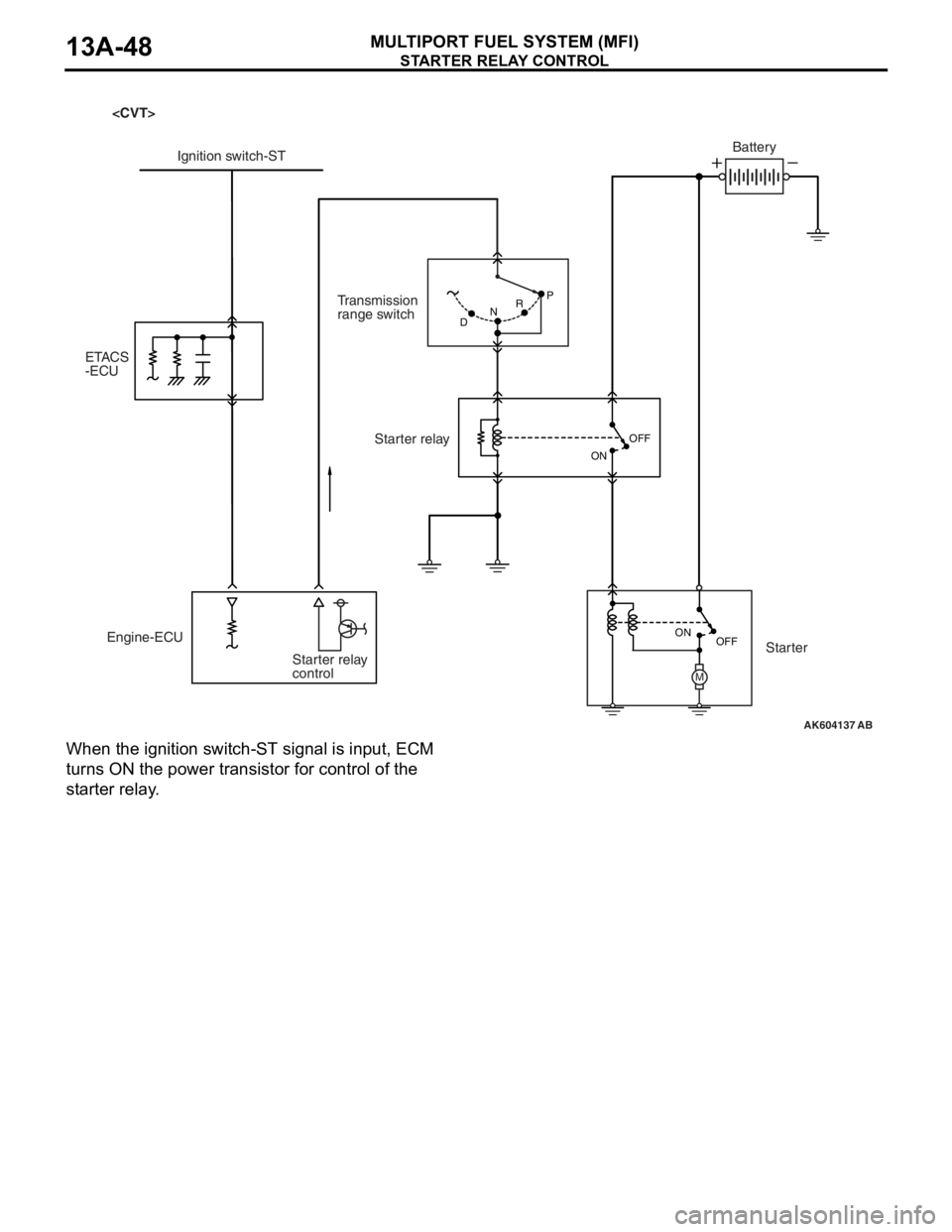

STARTER RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-48

When the ignition switch-ST signal is input, ECM

turns ON the power transistor for control of the

starter relay.

AK604137

M

AB P

DNR

OFF ON OFF

ON

Engine-ECU

Starter relay

controlTransmission

range switch Ignition switch-STBattery

Starter relay

Starter ETACS

-ECU

Page 143 of 241

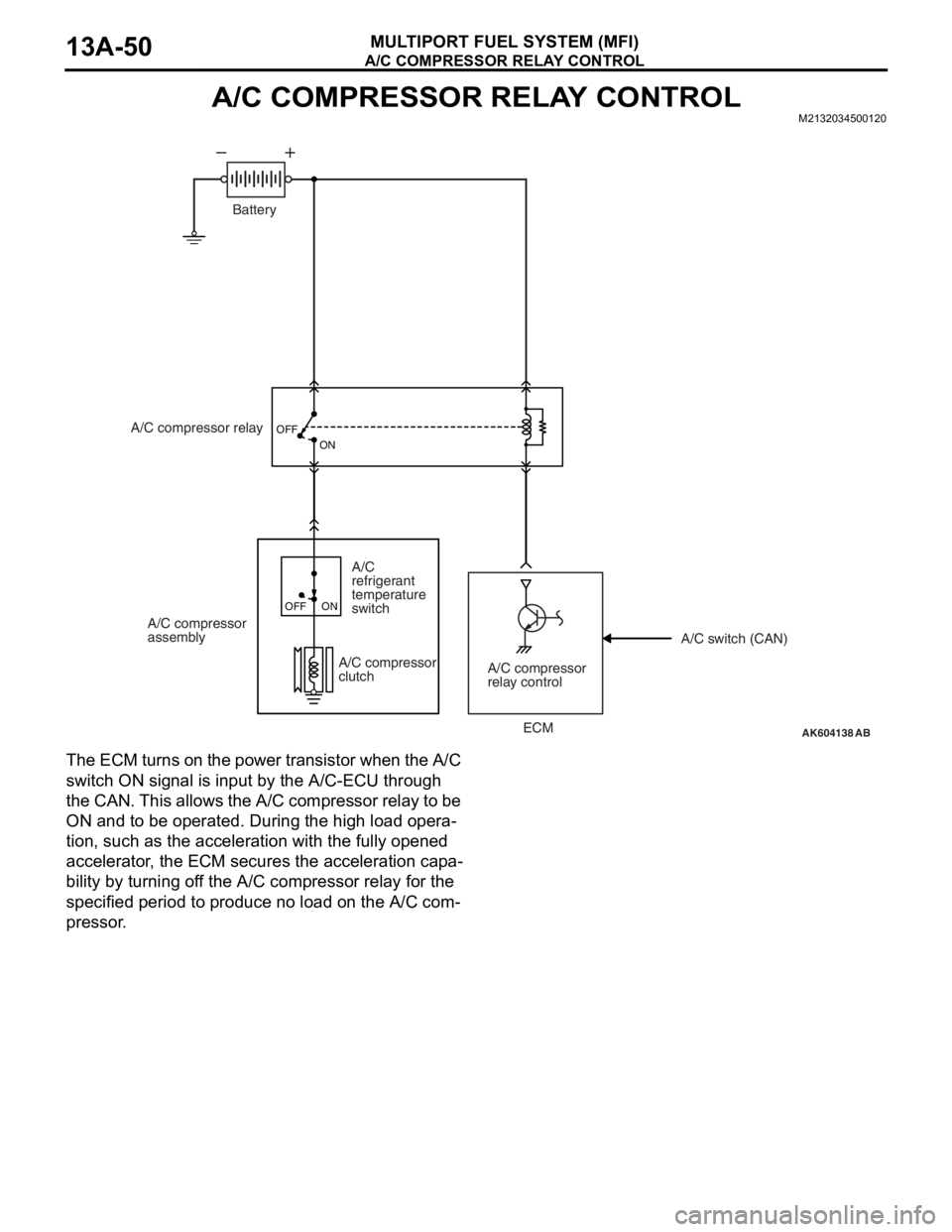

A/C COMPRESSOR RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-50

A/C COMPRESSOR RELAY CONTROLM2132034500120

The ECM turns on the power transistor when the A/C

switch ON signal is input by the A/C-ECU through

the CAN. This allows the A/C compressor relay to be

ON and to be operated. During the high load opera

-

tion, such as the acceleration with the fully opened

accelerator, the ECM secures the acceleration capa

-

bility by turning off the A/C compressor relay for the

specified period to produce no load on the A/C com

-

pressor.

AK604138

OFF

ON

AB

Battery

A/C compressor relay

A/C compressor

assembly

A/C compressor

relay control A/C compressor

clutch

A/C

refrigerant

temperature

switch

OFF ON

A/C switch (CAN)

ECM

Page 164 of 241

INSTRUMENT PANEL ASSEMBLY

TSB Revision

INTERIOR52A-3

CAUTION

•Refer to GROUP 52B-SRS Service Precautions P.52B-24 and Air bag Module and Clock Spring

P.52B-367 before removing the passenger side air bag module.

•Do not subject the SRS-ECU to any shocks when removing or installing the instrument panel.

Pre-removal and Post-installation Operation

•Removal and Installation of Front Pillar Trim (Refer to P.52A-10).

•Removal and Installation of Instrument Under Cover

(Refer to P.52A-10).

•Removal and Installation of Glove Box (Refer to P.52A-10).

•Removal and Installation of Instrument Cover Lower, Air

Outlet Garnish (Refer to P.52A-10).

•Removal and Installation of Audio Unit (Refer to GROUP

54A, Radio with CD Player P.54A-307).

•Removal and Installation of Audio Visual Navigation Unit,

GPS antenna (Refer to GROUP 54A, MMCS P.54A-391).

•Removal and Installation of Steering shaft (Refer to

GROUP 37, Steering Column Shaft P.37-25).

•Removal and Installation of Hands-free Cellular Phone

System (Refer to GROUP 54A, Hands-free Module

P.54A-435).

•Removal and Installation of Sensors (Refer to GROUP

55B, Interior Temperature Sensor

P.55B-25).

Page 186 of 241

REAR SEAT ASSEMBLY

TSB Revision

INTERIOR52A-25

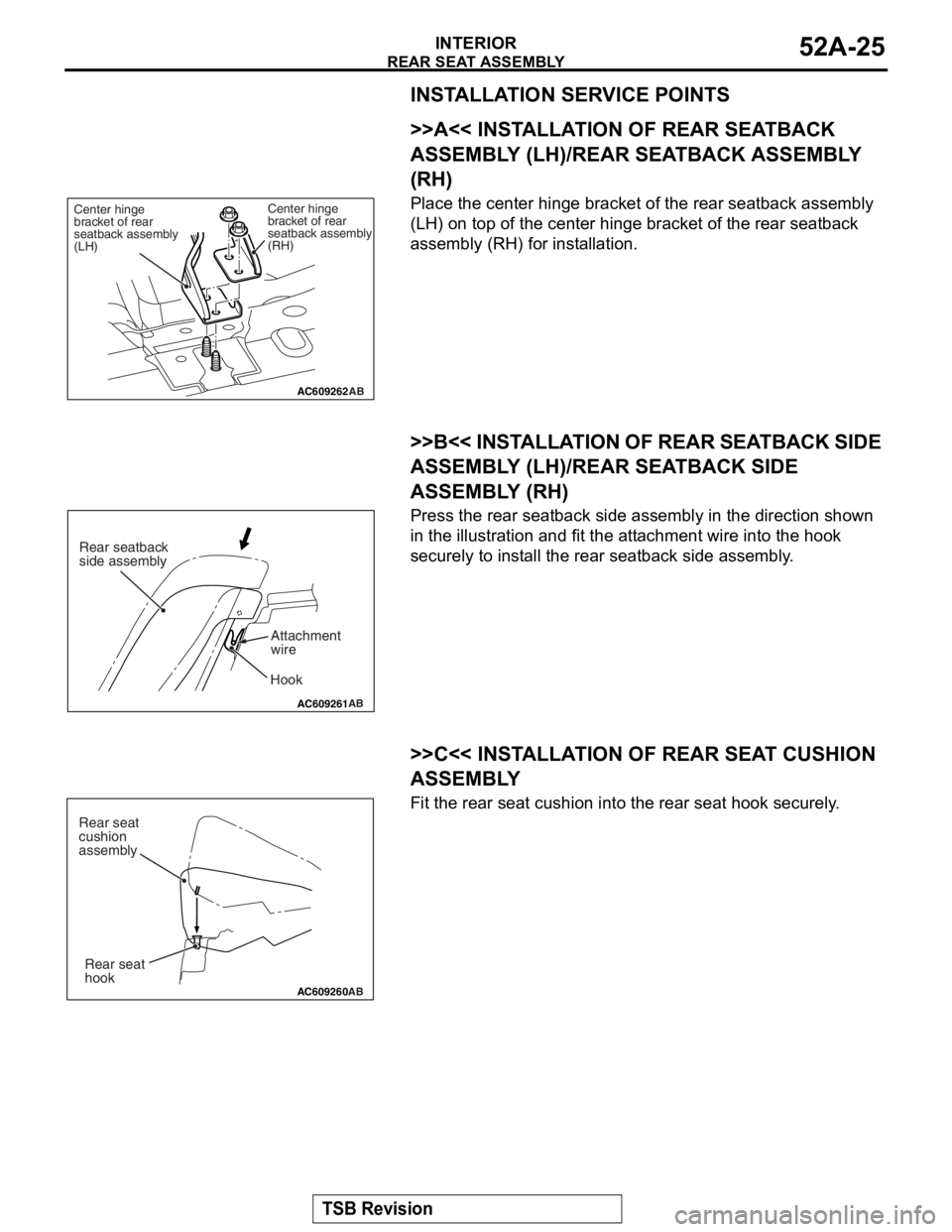

INSTALLATION SERVICE POINTS

.

>>A<< INSTALLATION OF REAR SEATBACK

ASSEMBLY (LH)/REAR SEATBACK ASSEMBLY

(RH)

Place the center hinge bracket of the rear seatback assembly

(LH) on top of the center hinge bracket of the rear seatback

assembly (RH) for installation.

.

>>B<< INSTALLATION OF REAR SEATBACK SIDE

ASSEMBLY (LH)/RE AR SEATBACK SIDE

ASSEMBLY (RH)

Press the rear seatback side as sembly in the direction shown

in the illustration and fit the attachment wire into the hook

securely to install the rear seatback side assembly.

.

>>C<< INSTALLATION OF REAR SEAT CUSHION

ASSEMBLY

Fit the rear seat cushion into the rear seat hook securely.

AC609262

Center hinge

bracket of rear

seatback assembly

(RH)

Center hinge

bracket of rear

seatback assembly

(LH)

AB

AC609261

AB

Hook

Rear seatback

side assembly

Attachment

wire

AC609260AB

Rear seat

hook

Rear seat

cushion

assembly