belt MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 41 of 241

A/C COMPRESSOR

HEATER, AIR CONDITIONING AND VENTILATION55-9

A/C COMPRESSORM2551001100268

HIGH EFFICIENCY COMPRESSOR WITH

INTEGRATED OIL SEPARATOR

High efficiency compressor with integrated oil sepa-

rator has been adopted to enhance fuel economy by

reducing the A/C operating rate.

MAGNETIC CLUTCH WITH THERMAL

FUSE

At the compressor lock, the thermal fuse integrated

in the magnet clutch is blown due to the frictional

heat against the compressor in order to reduce risk

of the drive belt breakage. The thermal fuse, together

with the coil, is coated with resin to enhance resis

-

tance to corrosion.

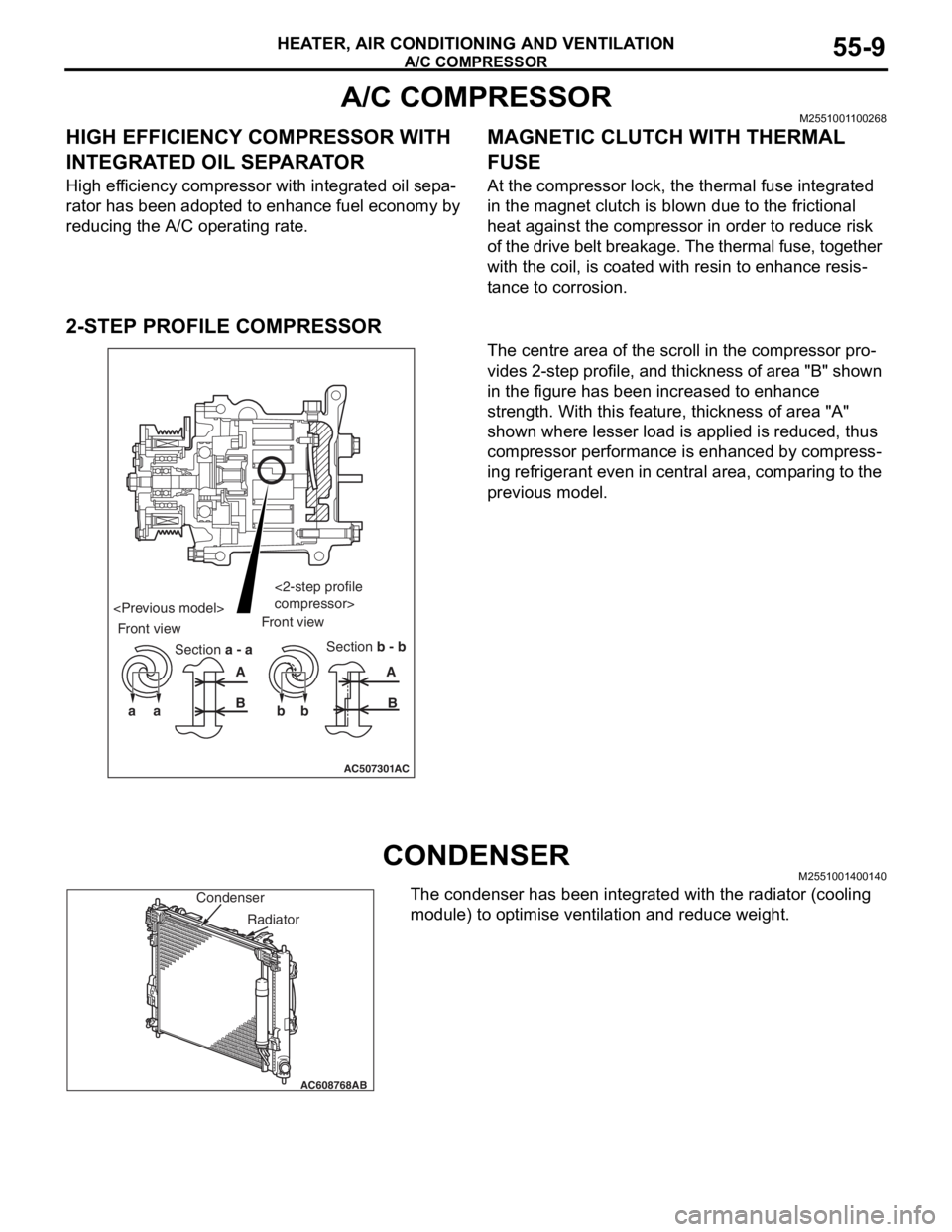

2-STEP PROFILE COMPRESSOR

The centre area of the scroll in the compressor pro-

vides 2-step profile, and thickness of area "B" shown

in the figure has been increased to enhance

strength. With this feature, thickness of area "A"

shown where lesser load is applied is reduced, thus

compressor performance is enhanced by compress

-

ing refrigerant even in central area, comparing to the

previous model.

CONDENSERM2551001400140

The condenser has been integrated with the radiator (cooling

module) to optimise ventilation and reduce weight.

AC507301

aa bbAA

BB

AC

Section a - aSection b - b Front viewFront view

compressor>

AC608768

Condenser

AB

Radiator

Page 54 of 241

BASE ENGINE

ENGINE MECHANICAL11A-10

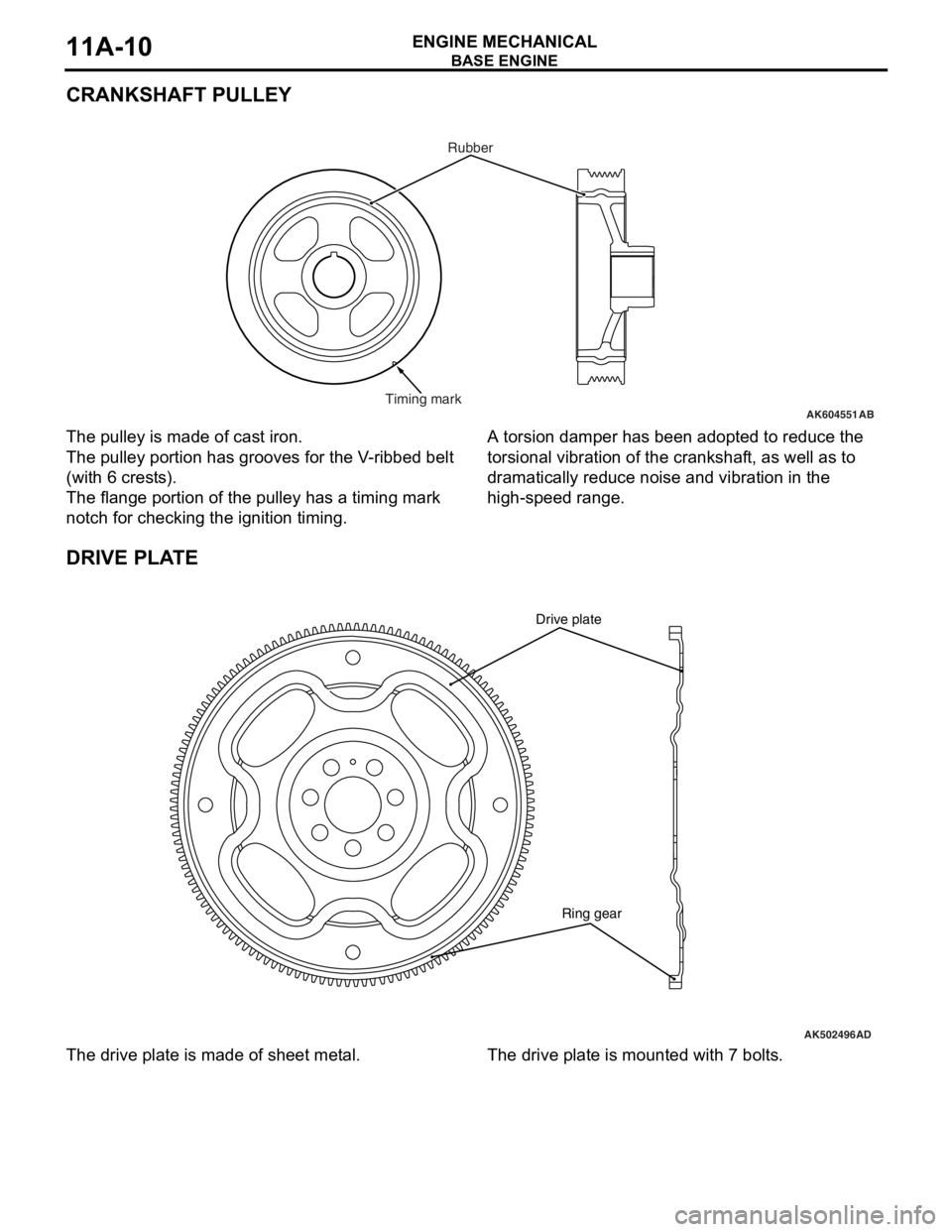

CRANKSHAFT PULLEY

The pulley is made of cast iron.

The pulley portion has grooves for the V-ribbed belt

(with 6 crests).

The flange portion of the pulley has a timing mark

notch for checking the ignition timing.

A torsion damper has been adopted to reduce the

torsional vibration of the crankshaft, as well as to

dramatically reduce noise and vibration in the

high-speed range.

DRIVE PLATE

The drive plate is made of sheet metal.The drive plate is mounted with 7 bolts.

AK604551Timing markRubberAB

AK502496

Ring gear Drive plate

AD

Page 88 of 241

GENERAL INFORMATION

ENGINE COOLING14-2

GENERAL INFORMATIONM2140000100780

The cooling system is a water-cooled pressurized,

forced circulation type which offers the following fea

-

tures.

•To stabilize engine coolant temperature, the ther-

mostat is located at the coolant inlet port from the

radiator.

•To improve engine cooling performance and save

weight, a plastic tank and aluminum radiator fins

are used.

SPECIFICATIONS

CONSTRUCTION DIAGRAM

ItemSpecification

Cooling methodWater-cooled pressurized, forced

circulation with electrical fan

RadiatorTy p ePressurized corrugate type

Performance kJ/h (kcal/h)222,480 (53,148)

Water pumpTy p eCentrifugal impeller

Drive methodDrive belt

ThermostatTy p eWax pellet with jiggle valve

Valve open temperature °C (°F)82 (180)

AC608448

Condenser fan motor Radiator assemblyRadiator upper hose

assembly

Radiator condenser

tank assembly Radiator fan motor

Cooling fan shroud

Radiator lower hose Transmission oil

cooler line hose

and tube assembly

AB

Page 89 of 241

WATER PASSAGE

ENGINE COOLING14-3

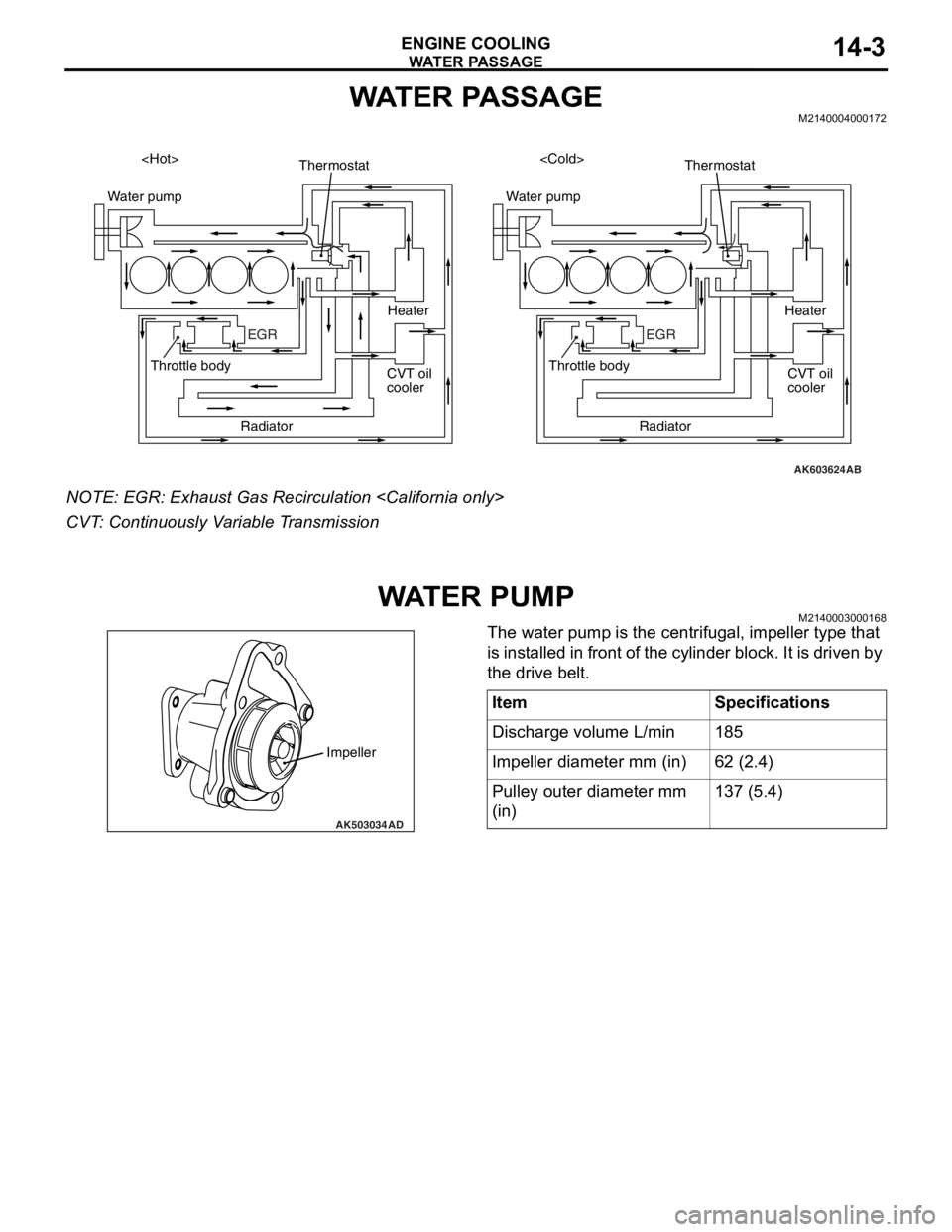

WATER PASSAGEM2140004000172

NOTE: EGR: Exhaust Gas Recirculation

CVT: Continuously Variable Transmission

WAT E R P U M PM2140003000168

The water pump is the centrifugal, impeller type that

is installed in front of the cylinder block. It is driven by

the drive belt.

AK603624

Water pump

EGR

AB

Thermostat

Radiator Throttle body

CVT oil

coolerHeater

Water pump

EGR

Thermostat

Radiator Throttle body

CVT oil

cooler Heater

AK503034

Impeller

AD

ItemSpecifications

Discharge volume L/min185

Impeller diameter mm (in)62 (2.4)

Pulley outer diameter mm

(in)137 (5.4)

Page 150 of 241

52A-1

GROUP 52A

INTERIOR

CONTENTS

GENERAL INFORMATION . . . . . . . .52A-2

INSTRUMENT PANEL AND FLOOR

CONSOLE . . . . . . . . . . . . . . . . . . . . .52A-3

SEAT . . . . . . . . . . . . . . . . . . . . . . . . .52A-5

FRONT SEAT . . . . . . . . . . . . . . . . . . . . . . . 52A-5

REAR SEAT . . . . . . . . . . . . . . . . . . . . . . . . 52A-7

SEAT BELT. . . . . . . . . . . . . . . . . . . . .52A-8

TRIMS . . . . . . . . . . . . . . . . . . . . . . . . .52A-10

INTERIOR TRIMS . . . . . . . . . . . . . . . . . . . . 52A-10

DOOR TRIM . . . . . . . . . . . . . . . . . . . . . . . . 52A-11

HEADLINING . . . . . . . . . . . . . . . . . . .52A-12

Page 151 of 241

GENERAL INFORMATION

INTERIOR52A-2

GENERAL INFORMATIONM2520000101013

Functionality, interior comfort, and safety have been

emphasized, giving interior design for elegance and

relaxation space. Various measures have been taken

to protect the environment and recycle resources.

FEATURES

Quality improvement

1. Two-tone interior

2. Full interior trim

Usability improvement

1. Armrest (floor console, rear seat, front door trim, rear door trim)

2. Cup holder (floor console, rear seat armrest)

3. Bottle holder (front door trim)

Convenient storage

1. Glove box

2. Seatback pocket (driver’s seat)

3. Card holder (glove box)

4. Tissue paper holder (floor console)

5. Floor console box

6. Door pocket (front door trim, rear door trim)

Safety improvement

1. Front and rear collision protection seat mecha-

nism (front seat)

2. ISO-FIX lower anchor (rear seat outside)

3. Upper tether anchor (rear shelf)

4. ELR 3-point seat belt (driver’s seat)

5. ELR/ALR 3-point seat belt (front passenger, rear)

6. Seat belt retractor with a driver's side preten-

sioner and force limiter

7. Seat belt retractor with a passenger’s side pre-

tensioner and force limiter

8. Headliner energy absorption rib

Consideration for the optimum driving position

1. Seat height adjustment (driver’s seat)

2. Head restraint with height adjustment (front, rear)

3. Seat slide adjustment (front)

Measures for resource recycling

1. Aggressively use PP materials that are easy to recycle and easy to stamp material symbols on

the plastic (resin) parts.

2. Reduction of chemical material (formaldehyde*,

organic solvent)

NOTE: *: Clear and colourless, toxic, irritating odour

Page 157 of 241

SEAT BELT

INTERIOR52A-8

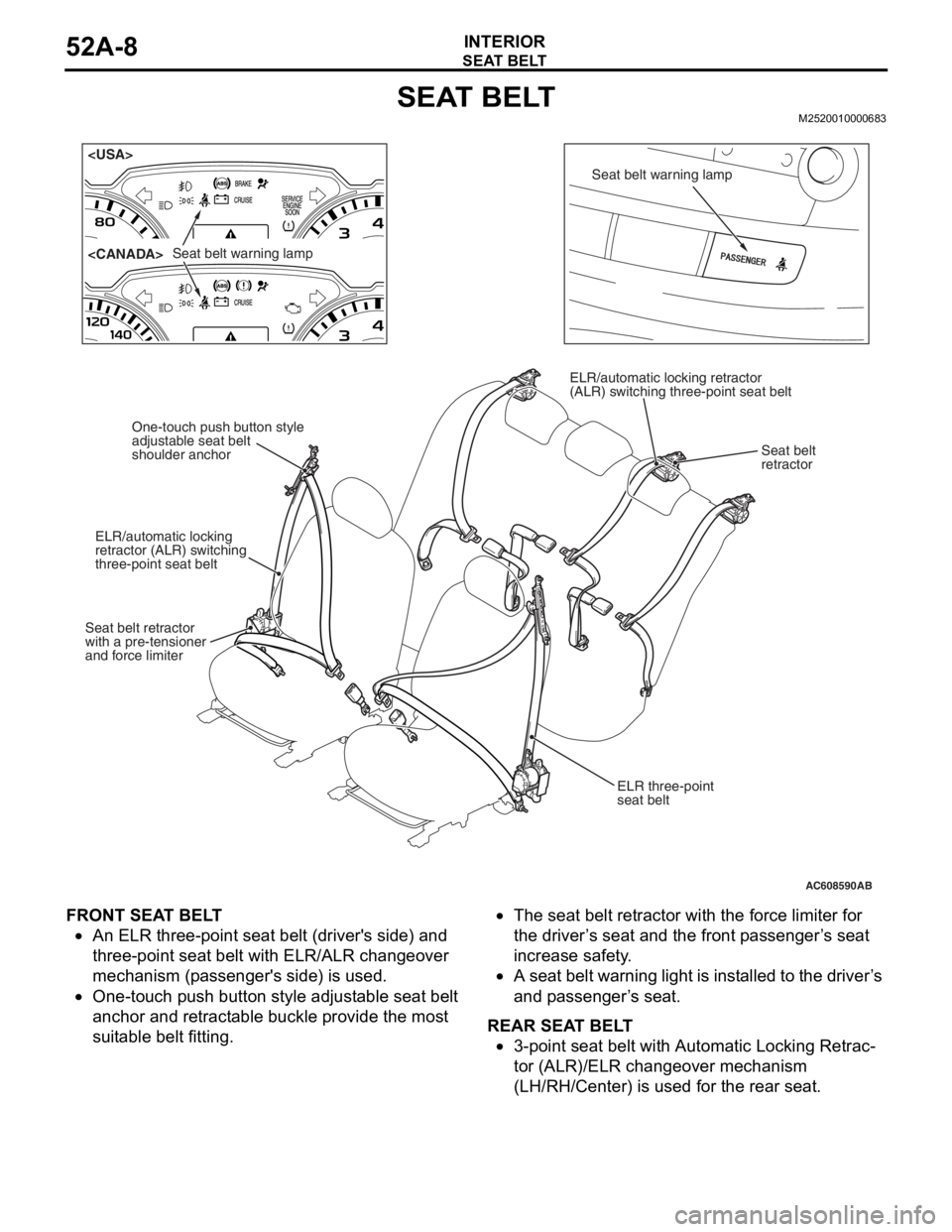

SEAT BELTM2520010000683

FRONT SEAT BELT

•An ELR three-point seat belt (driver's side) and

three-point seat belt with ELR/ALR changeover

mechanism (passenger's side) is used.

•One-touch push button style adjustable seat belt

anchor and retractable buckle provide the most

suitable belt fitting.

•The seat belt retractor with the force limiter for

the driver’s seat and the front passenger’s seat

increase safety.

•A seat belt warning light is installed to the driver’s

and passenger’s seat.

REAR SEAT BELT

•3-point seat belt with Automatic Locking Retrac-

tor (ALR)/ELR changeover mechanism

(LH/RH/Center) is used for the rear seat.

AC608590

Seat belt warning lamp

Seat belt warning lamp

ELR three-point

seat belt

One-touch push button style

adjustable seat belt

shoulder anchor

ELR/automatic locking

retractor (ALR) switching

three-point seat belt

Seat belt retractor

with a pre-tensioner

and force limiter ELR/automatic locking retractor

(ALR) switching three-point seat belt

Seat belt

retractor

AB

Page 158 of 241

SEAT BELT

INTERIOR52A-9

SEAT BELT RETRACTOR WITH FORCE LIMITER

.The driver’s/front passenger’s seat belt retractor has been

equipped with a force limiter. The force limiter is a device which

operates when a predetermined force is applied, and limits the

force.

.

OPERATION

1. If a collision energy is transmi tted to the seat belt, the ELR

mechanism will operate to lock the seat belt.

2. If the energy increases to a predetermined value, the torsion bar will be distorted. As the spindle rotates together with the

torsion bar, the seat belt w ebbing is pulled out, reducing the

impact to the occupants.

AC100083

TORSION BAR

SPINDLE

BELT

AB

Page 162 of 241

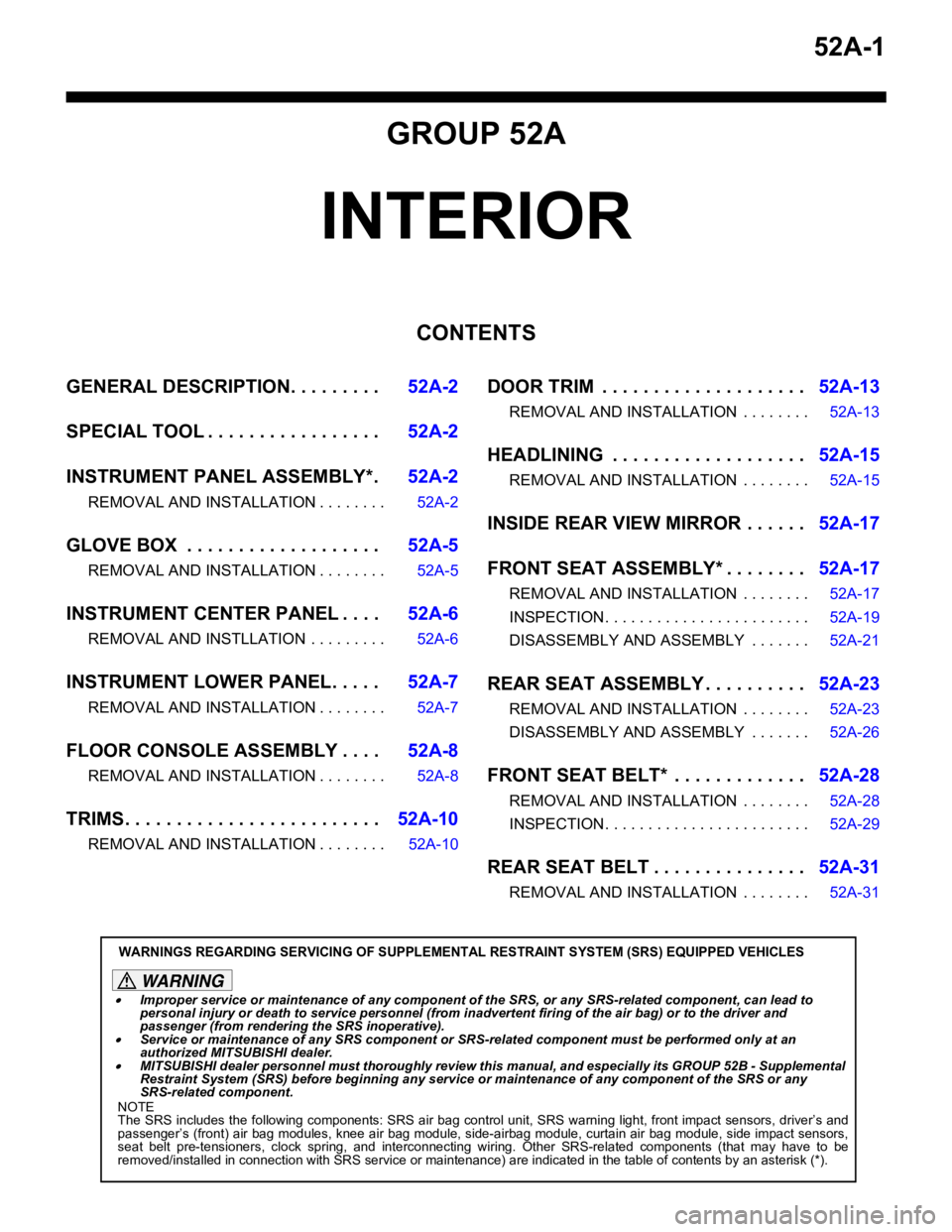

52A-1

GROUP 52A

INTERIOR

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .52A-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .52A-2

INSTRUMENT PANEL ASSEMBLY*.52A-2

REMOVAL AND INSTALLATION . . . . . . . . 52A-2

GLOVE BOX . . . . . . . . . . . . . . . . . . .52A-5

REMOVAL AND INSTALLATION . . . . . . . . 52A-5

INSTRUMENT CENTER PANEL . . . .52A-6

REMOVAL AND INSTLLATION . . . . . . . . . 52A-6

INSTRUMENT LOWER PANEL. . . . .52A-7

REMOVAL AND INSTALLATION . . . . . . . . 52A-7

FLOOR CONSOLE ASSEMBLY . . . .52A-8

REMOVAL AND INSTALLATION . . . . . . . . 52A-8

TRIMS. . . . . . . . . . . . . . . . . . . . . . . . .52A-10

REMOVAL AND INSTALLATION . . . . . . . . 52A-10

DOOR TRIM . . . . . . . . . . . . . . . . . . . .52A-13

REMOVAL AND INSTALLATION . . . . . . . . 52A-13

HEADLINING . . . . . . . . . . . . . . . . . . .52A-15

REMOVAL AND INSTALLATION . . . . . . . . 52A-15

INSIDE REAR VIEW MIRROR . . . . . .52A-17

FRONT SEAT ASSEMBLY* . . . . . . . .52A-17

REMOVAL AND INSTALLATION . . . . . . . . 52A-17

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-19

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-21

REAR SEAT ASSEMBLY . . . . . . . . . .52A-23

REMOVAL AND INSTALLATION . . . . . . . . 52A-23

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-26

FRONT SEAT BELT* . . . . . . . . . . . . .52A-28

REMOVAL AND INSTALLATION . . . . . . . . 52A-28

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-29

REAR SEAT BELT . . . . . . . . . . . . . . .52A-31

REMOVAL AND INSTALLATION . . . . . . . . 52A-31

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of an y component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

passenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, driver’s and

passenger’s (front) air bag modules, knee air bag module, side-airbag module, curtain air bag module, side impact sensors,

seat belt pre-tensioners, clock spring, and interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 163 of 241

GENERAL DESCRIPTION

TSB Revision

INTERIOR52A-2

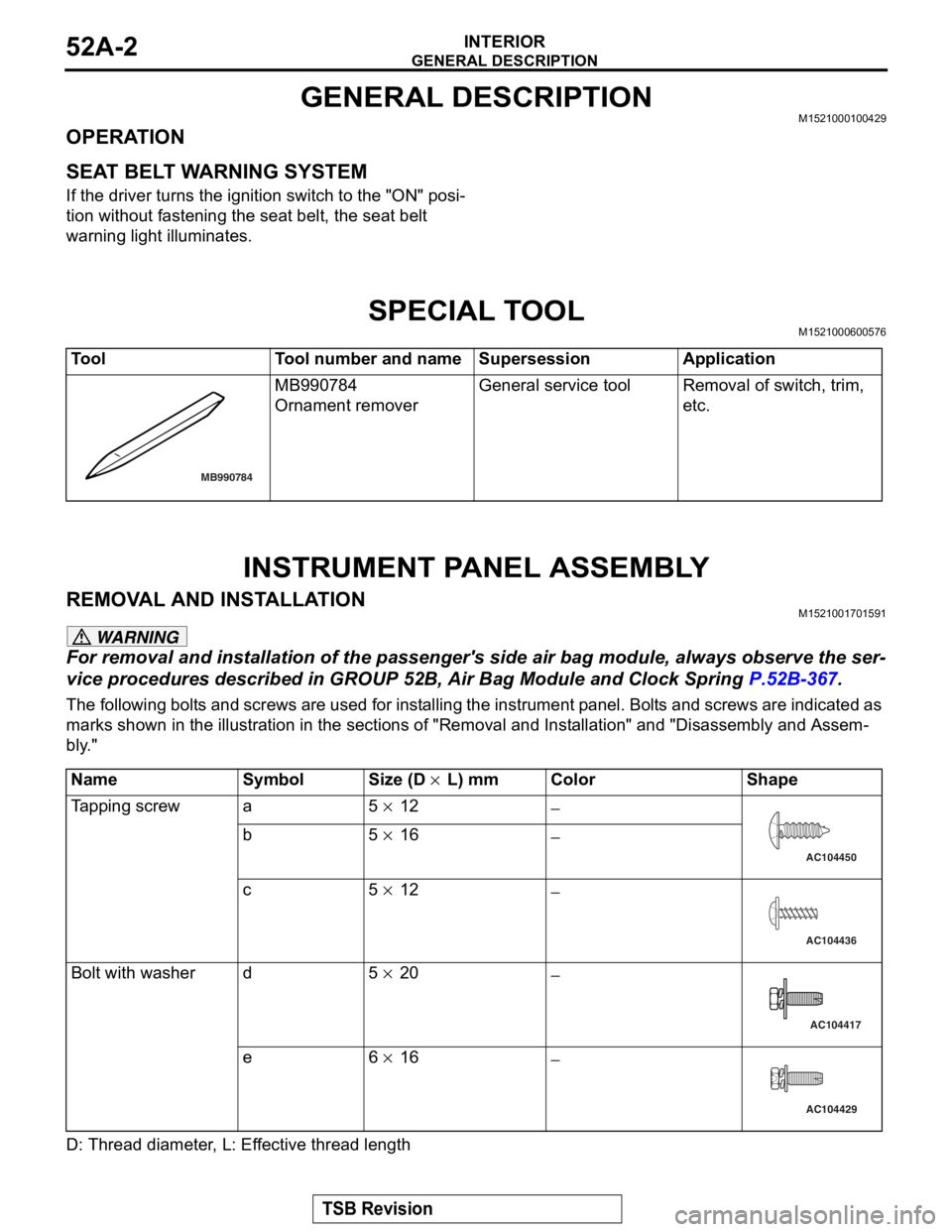

GENERAL DESCRIPTIONM1521000100429

OPERATION

.

SEAT BELT WARNING SYSTEM

If the driver turns the ignition switch to the "ON" posi-

tion without fastening the seat belt, the seat belt

warning light illuminates.

SPECIAL TOOLM1521000600576

INSTRUMENT PANEL ASSEMBLY

REMOVAL AND INSTALLATIONM1521001701591

WARNING

For removal and installation of the passenger's side air bag module, always observe the ser-

vice procedures described in GROUP 52B, Air Bag Module and Clock Spring P.52B-367.

The following bolts and screws are used for installing the in strument panel. Bolts and screws are indicated as

marks shown in the illustration in the sections of "R emoval and Installation" and "Disassembly and Assem

-

bly."

D: Thread diameter, L: Effective thread length

ToolTool number and nameSupersessionApplication

MB990784

Ornament remover

General service toolRemoval of switch, trim,

etc.

MB990784

NameSymbolSize (D × L) mmColorShape

Tapping screwa5 × 12−

b5 × 16−

c5 × 12−

Bolt with washerd5 × 20−

e6 × 16−

AC104450

AC104436

AC104417

AC104429