brake fluid MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 201 of 241

GENERAL

BASIC BRAKE SYSTEM35A-2

GENERALM2350000100956

Brake systems with higher reliability and durability

have achieved distinguished braking performance.

FEATURES

.

IMPROVEMENT OF BRAKING PERFOR-

MANCE

•A 10-inch single brake booster with the variable

boost ratio mechanism has been used to assure

maximum braking force with less pedal pressure

in case of emergency.

•In addition to the 10-inch single brake booster, a

small and long stroke-type master cylinder has

been adopted to achieve downsizing and secure

assist force.

•15-inch or 16-inch ventilated disc brakes have

been adopted for the front.

•8-inch leading trailing-type drum brake, 14-inch

or 16-inch solid disc brake has been adopted for

the rear.

.

IMPROVEMENT IN SAFETY

•The 4-wheel anti-lock brake system (4ABS) has

been installed to prevent slippage resulting from

the wheel lock and assure stable vehicle posture

and driveability.

•A rear wheel early lock-prevention proportioning

valve has been used.

•Electronic control braking force distribution sys-

tem (EBD) has been adopted to assure the maxi-

mum braking force independently of the

passenger's position in the vehicle.

•X-type piping of brake lines have been adopted

for the front and rear wheels.

•Audible wear indicators are used on the front and

rear brake pads to warn the driver of wear limit.

.

SERVICE QUALITY IMPROVEMENTS

•Diagnostic function has been adopted to ABS for

easier inspection.

•Brake fluid reservoir, master cylinder, and brake

booster have been integrated for downsizing and

better serviceability.

Page 204 of 241

CONSTRUCTION DESCRIPTION

BASIC BRAKE SYSTEM35A-5

CONSTRUCTION DESCRIPTION

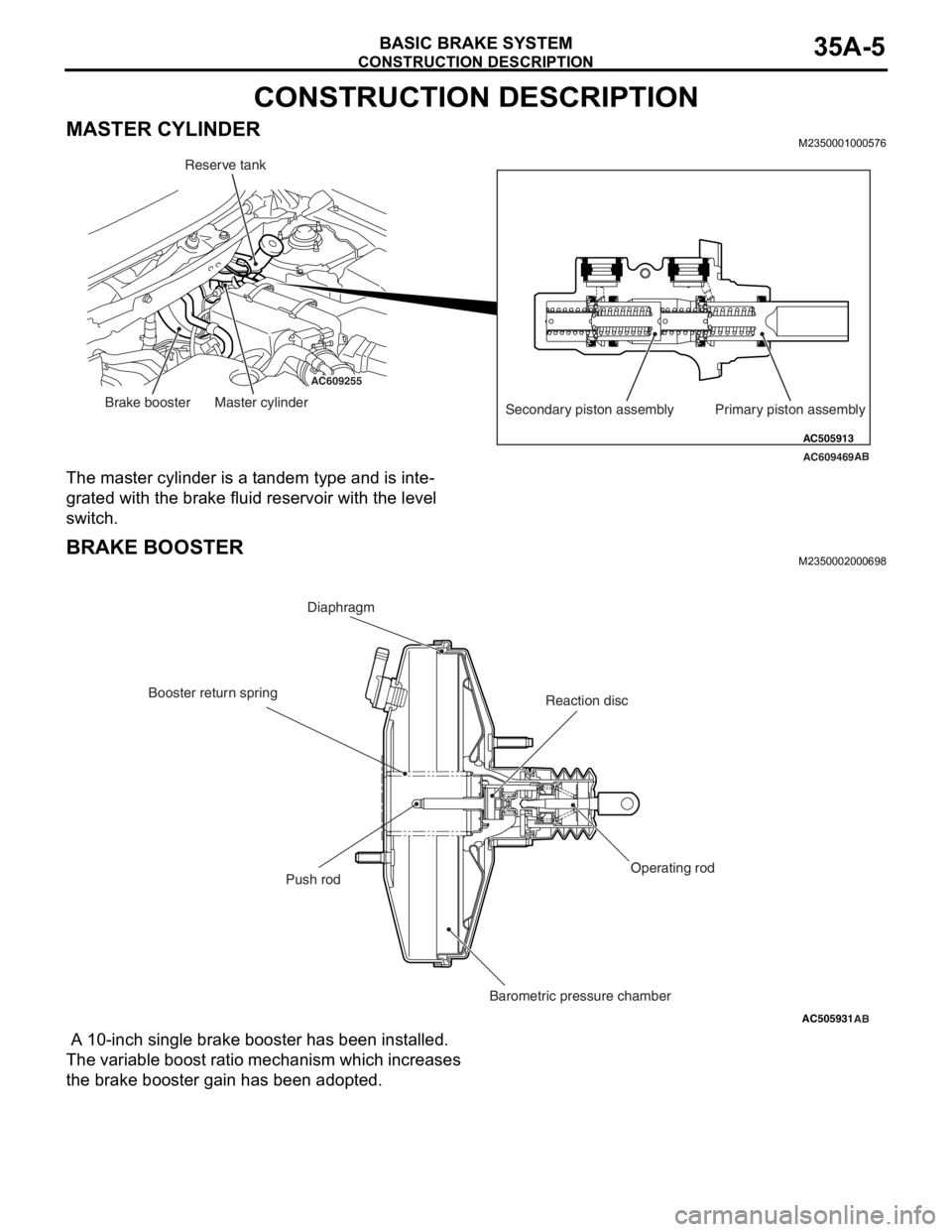

MASTER CYLINDERM2350001000576

The master cylinder is a tandem type and is inte-

grated with the brake fluid reservoir with the level

switch.

BRAKE BOOSTERM2350002000698

A 10-inch single brake booster has been installed.

The variable boost ratio mechanism which increases

the brake booster gain has been adopted.

AC609255

AC609469 AC505913

AB

Primary piston assembly Secondary piston assembly Brake booster Master cylinderReserve tank

AC505931AB

Diaphragm

Reaction disc

Operating rod

Push rod

Barometric pressure chamber Booster return spring

Page 212 of 241

GENERAL INFORMATION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-3

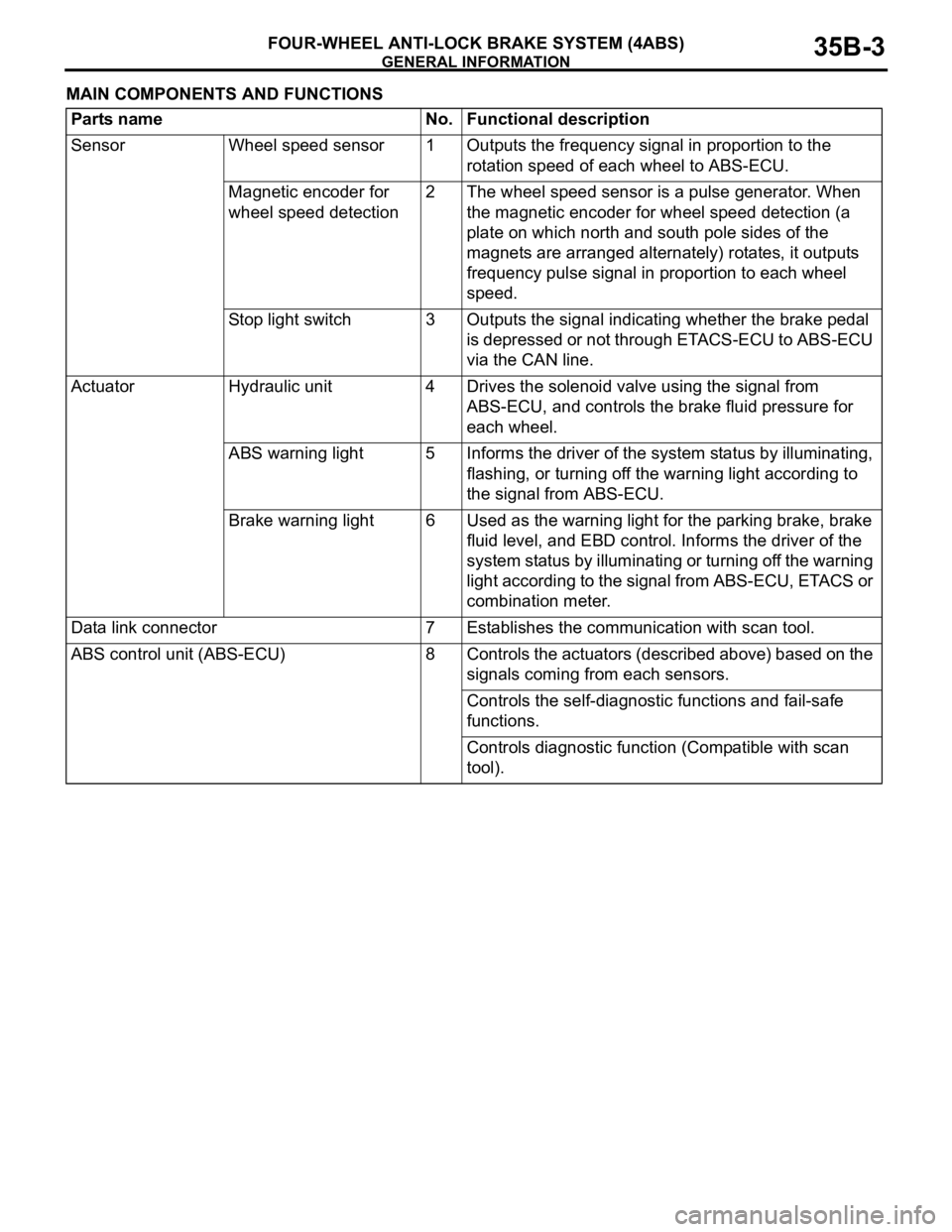

MAIN COMPONENTS AND FUNCTIONS

.

Parts nameNo.Functional description

SensorWheel speed sensor1Outputs the frequency signal in proportion to the

rotation speed of each wheel to ABS-ECU.

Magnetic encoder for

wheel speed detection2The wheel speed sensor is a pulse generator. When

the magnetic encoder for wheel speed detection (a

plate on which north and south pole sides of the

magnets are arranged alternately) rotates, it outputs

frequency pulse signal in proportion to each wheel

speed.

Stop light switch3Outputs the signal indicating whether the brake pedal

is depressed or not through ETACS-ECU to ABS-ECU

via the CAN line.

ActuatorHydraulic unit4Drives the solenoid valve using the signal from

ABS-ECU, and controls the brake fluid pressure for

each wheel.

ABS warning light5Informs the driver of the system status by illuminating,

flashing, or turning off the warning light according to

the signal from ABS-ECU.

Brake warning light6Used as the warning light for the parking brake, brake

fluid level, and EBD control. Informs the driver of the

system status by illuminating or turning off the warning

light according to the signal from ABS-ECU, ETACS or

combination meter.

Data link connector7Establishes the communication with scan tool.

ABS control unit (ABS-ECU)8Controls the actuators (described above) based on the

signals coming from each sensors.

Controls the self-diagnostic functions and fail-safe

functions.

Controls diagnostic function (Compatible with scan

tool).

Page 215 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-6

CONSTRUCTION DESCRIPTION

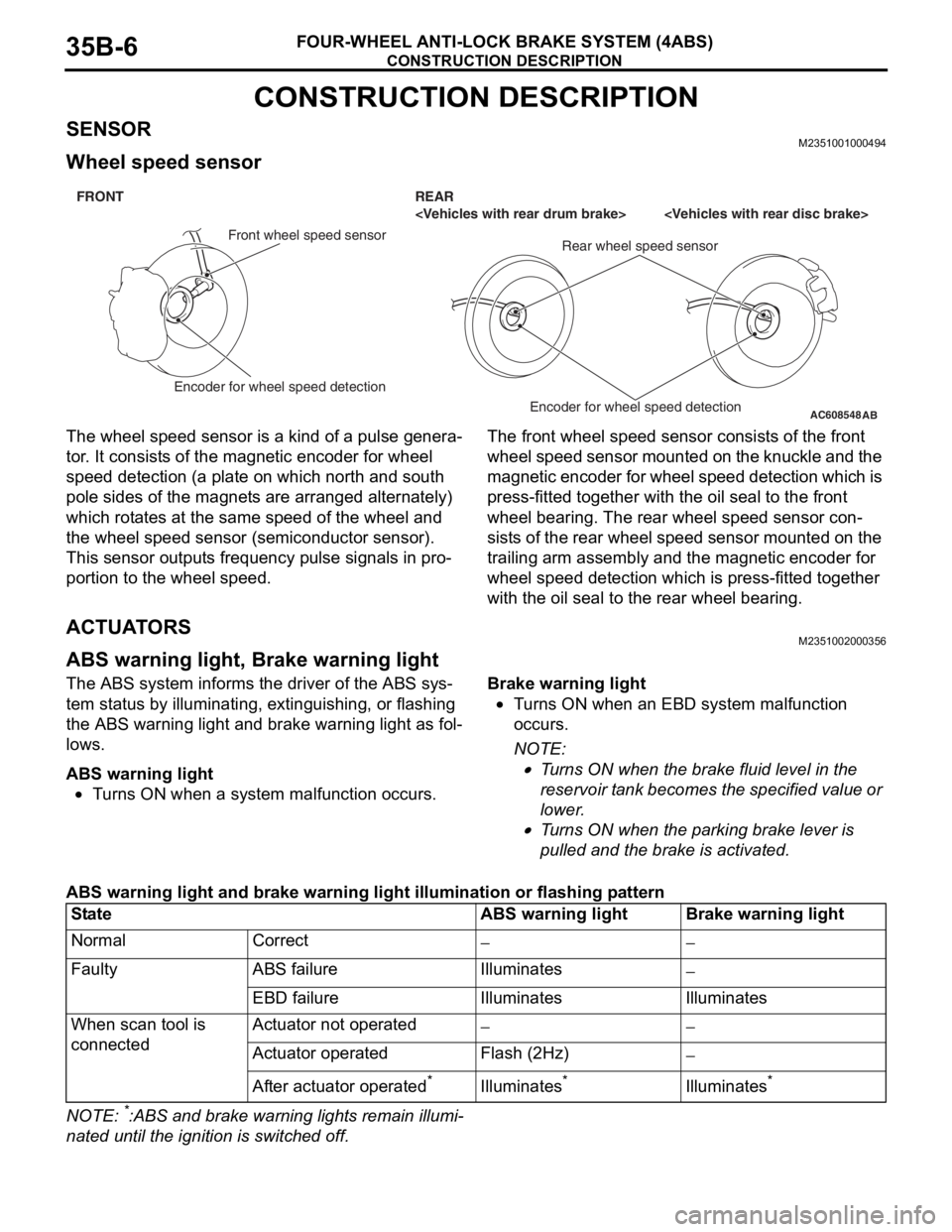

SENSORM2351001000494

Wheel speed sensor

The wheel speed sensor is a kind of a pulse genera-

tor. It consists of the magnetic encoder for wheel

speed detection (a plate on which north and south

pole sides of the magnets are arranged alternately)

which rotates at the same speed of the wheel and

the wheel speed sensor (semiconductor sensor).

This sensor outputs frequency pulse signals in pro

-

portion to the wheel speed.

The front wheel speed sensor consists of the front

wheel speed sensor mounted on the knuckle and the

magnetic encoder for wheel speed detection which is

press-fitted together with the oil seal to the front

wheel bearing. The rear wheel speed sensor con

-

sists of the rear wheel speed sensor mounted on the

trailing arm assembly and the magnetic encoder for

wheel speed detection which is press-fitted together

with the oil seal to the rear wheel bearing.

ACTUATORSM2351002000356

ABS warning light, Brake warning light

The ABS system informs the driver of the ABS sys-

tem status by illuminating, extinguishing, or flashing

the ABS warning light and brake warning light as fol

-

lows.

ABS warning light

•Turns ON when a system malfunction occurs.

Brake warning light

•Turns ON when an EBD system malfunction

occurs.

NOTE: .

•Turns ON when the brake fluid level in the

reservoir tank becomes the specified value or

lower.

•Turns ON when the parking brake lever is

pulled and the brake is activated.

ABS warning light and brake warning light illumination or flashing pattern

NOTE: *:ABS and brake warning lights remain illumi-

nated until the ignition is switched off.

AC608548

AB

FRONT REAR

Front wheel speed sensor

Rear wheel speed sensor

Encoder for wheel speed detection

Encoder for wheel speed detection

StateABS warning lightBrake warning light

NormalCorrect−−

FaultyABS failureIlluminates−

EBD failureIlluminatesIlluminates

When scan tool is

connectedActuator not operated−−

Actuator operatedFlash (2Hz)−

After actuator operated*Illuminates*Illuminates*

Page 216 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-7

ABS-ECUM2351003000520

•By integrating ABS-ECU into the hydraulic unit,

no wiring harness for sending drive signal of the

solenoid valve and pump motor is required,

assuring higher reliability.

•Self-diagnostic and memory functions are inte-

grated into ABS-ECU. If any malfunction is

detected by the self-diagnostic function,

ABS-ECU activates a fail-safe function and illumi

-

nates the ABS warning light and brake warning

light

*.

NOTE: *: The brake warning light is used as the

EBD control warning light.

•ABS-ECU detects vehicle speed from the signals

of the wheel speed sensor and its recognizes the

wheel rotation status, estimates the wheel slip

condition based on the preprogrammed algo

-

rithm, and then controls the solenoid valve in the

hydraulic unit so that the wheels do not lock.

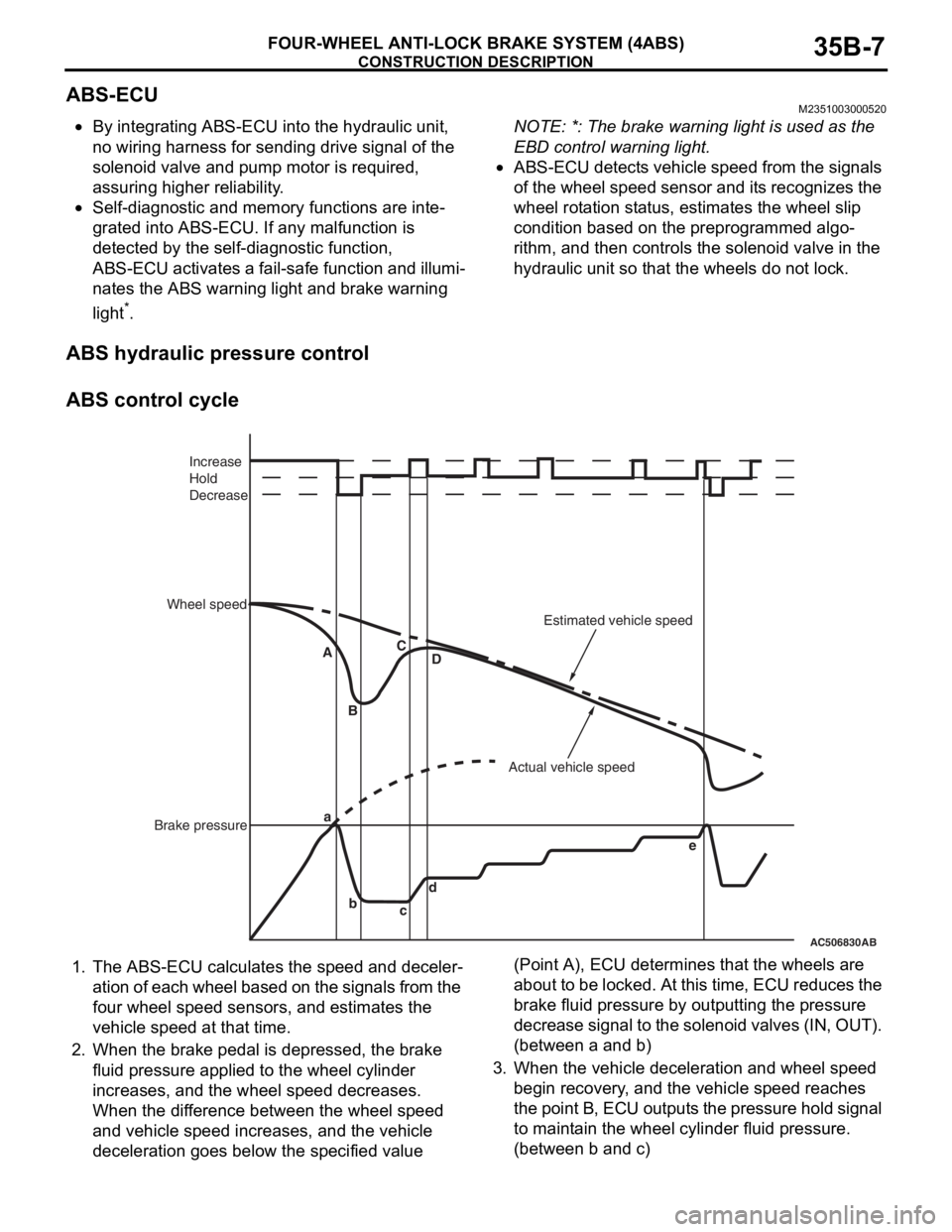

ABS hydraulic pressure control

ABS control cycle

1. The ABS-ECU calculates the speed and deceler-

ation of each wheel based on the signals from the

four wheel speed sensors, and estimates the

vehicle speed at that time.

2. When the brake pedal is depressed, the brake

fluid pressure applied to the wheel cylinder

increases, and the wheel speed decreases.

When the difference between the wheel speed

and vehicle speed increases, and the vehicle

deceleration goes below the specified value (Point A), ECU determines that the wheels are

about to be locked. At this time, ECU reduces the

brake fluid pressure by outputting the pressure

decrease signal to the solenoid valves (IN, OUT).

(between a and b)

3. When the vehicle deceleration and wheel speed

begin recovery, and the vehicle speed reaches

the point B, ECU outputs the pressure hold signal

to maintain the wheel cylinder fluid pressure.

(between b and c)

AC506830AB

a

b

cd A

BC

D

e Increase

Hold

Decrease

Wheel speed

Brake pressureActual vehicle speedEstimated vehicle speed

Page 217 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-8

4. When the wheel speed deceleration is further

recovered and overpasses the point C, ECU

determines that the wheel lock possibility has

been eliminated and increases the brake fluid

pressure by outputting the pressure increase sig

-

nal again. (between c and d)

5. Brake fluid pressure is controlled by repeating the

increase and hold of the pressure. (between d

and e)

6. When the wheel deceleration goes below the

threshold again, ABS-ECU controls the brake

fluid pressure by repeating the cycle (Step 2 to 5).

Four-wheel control

ABS fluid pressure is controlled independently for

four wheels.

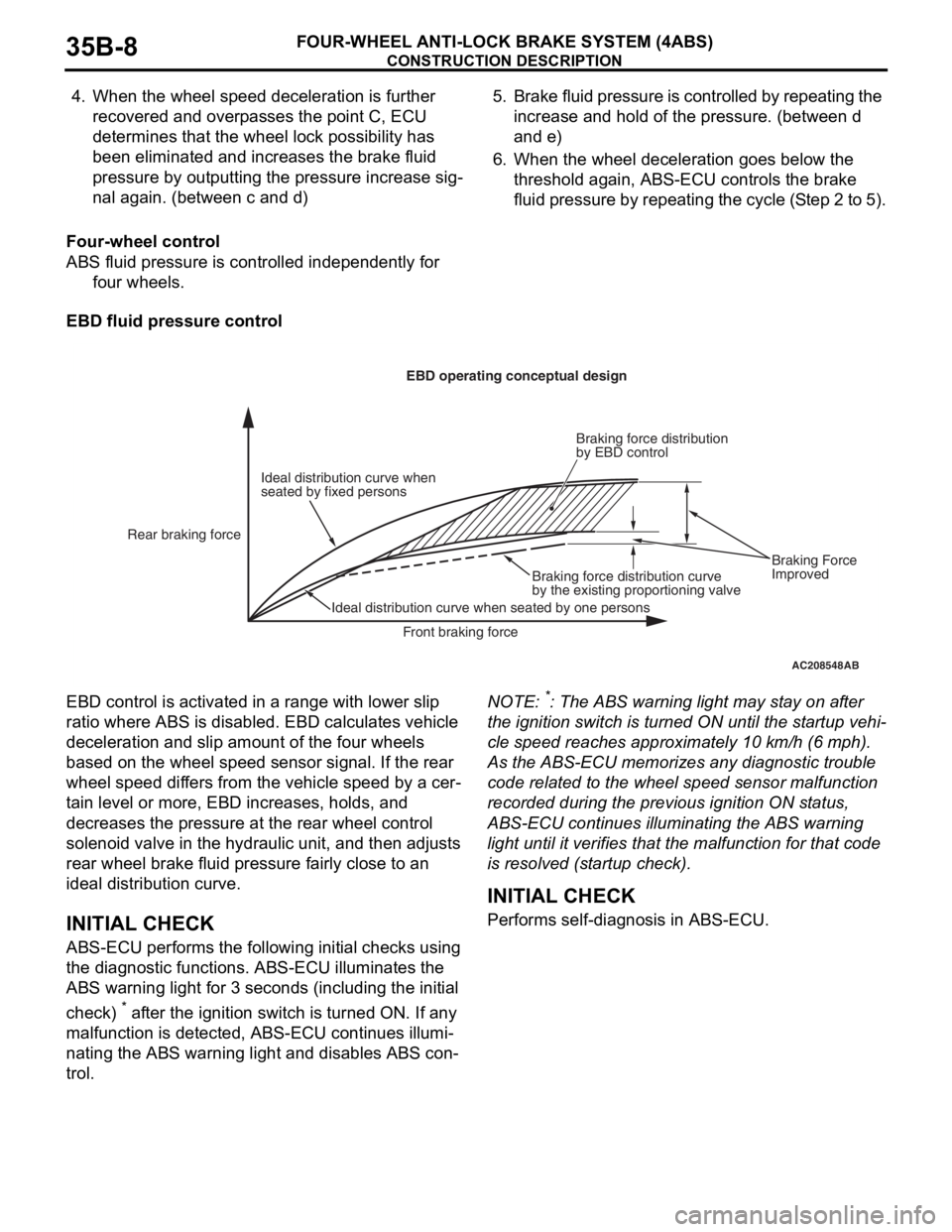

EBD fluid pressure control

EBD control is activated in a range with lower slip

ratio where ABS is disabled. EBD calculates vehicle

deceleration and slip amount of the four wheels

based on the wheel speed sensor signal. If the rear

wheel speed differs from the vehicle speed by a cer

-

tain level or more, EBD increases, holds, and

decreases the pressure at the rear wheel control

solenoid valve in the hydraulic unit, and then adjusts

rear wheel brake fluid pressure fairly close to an

ideal distribution curve.

INITIAL CHECK

ABS-ECU performs the following initial checks using

the diagnostic functions. ABS-ECU illuminates the

ABS warning light for 3 seconds (including the initial

check)

* after the ignition switch is turned ON. If any

malfunction is detected, ABS-ECU continues illumi

-

nating the ABS warning light and disables ABS con-

trol.

NOTE: *: The ABS warning light may stay on after

the ignition switch is turned ON until the startup vehi

-

cle speed reaches approximately 10 km/h (6 mph).

As the ABS-ECU memorizes any diagnostic trouble

code related to the wheel speed sensor malfunction

recorded during the previous ignition ON status,

ABS-ECU continues illuminating the ABS warning

light until it verifies that the malfunction for that code

is resolved (startup check).

.

INITIAL CHECK

Performs self-diagnosis in ABS-ECU.

AC208548AB

Ideal distribution curve when

seated by fixed personsEBD operating conceptual design

Rear braking force

Ideal distribution curve when seated by one personsBraking force distribution curve

by the existing proportioning valveBraking force distribution

by EBD control

Front braking forceBraking Force

Improved

Page 220 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-11

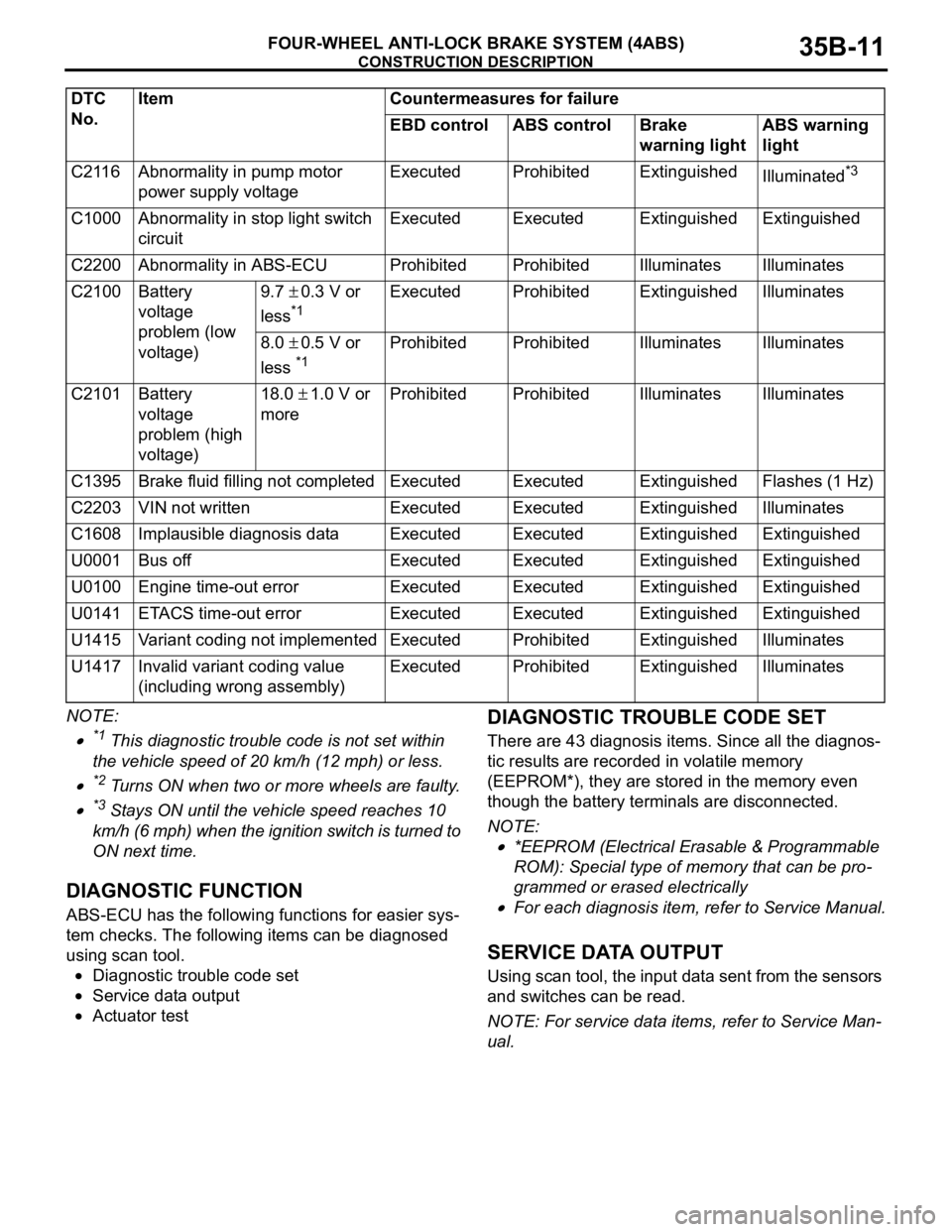

NOTE: .

•*1 This diagnostic trouble code is not set within

the vehicle speed of 20 km/h (12 mph) or less.

•*2 Turns ON when two or more wheels are faulty.

•*3 Stays ON until the vehicle speed reaches 10

km/h (6 mph) when the ignition switch is turned to

ON next time.

DIAGNOSTIC FUNCTION

ABS-ECU has the following functions for easier sys-

tem checks. The following items can be diagnosed

using scan tool.

•Diagnostic trouble code set

•Service data output

•Actuator test.

DIAGNOSTIC TROUBLE CODE SET

There are 43 diagnosis items. Since all the diagnos-

tic results are recorded in volatile memory

(EEPROM*), they are stored in the memory even

though the battery terminals are disconnected.

NOTE: .

•*EEPROM (Electrical Erasable & Programmable

ROM): Special type of memory that can be pro

-

grammed or erased electrically

•For each diagnosis item, refer to Service Manual.

.

SERVICE DATA OUTPUT

Using scan tool, the input data sent from the sensors

and switches can be read.

NOTE: For service data items, refer to Service Man-

ual.

.

C2116Abnormality in pump motor

power supply voltageExecutedProhibitedExtinguishedIlluminated*3

C1000Abnormality in stop light switch

circuitExecutedExecutedExtinguishedExtinguished

C2200Abnormality in ABS-ECUProhibitedProhibitedIlluminatesIlluminates

C2100Battery

voltage

problem (low

voltage)9.7 ± 0.3 V or

less

*1

ExecutedProhibitedExtinguishedIlluminates

8.0 ± 0.5 V or

less

*1

ProhibitedProhibitedIlluminatesIlluminates

C2101Battery

voltage

problem (high

voltage)18.0 ± 1.0 V or

moreProhibitedProhibitedIlluminatesIlluminates

C1395Brake fluid filling not completedExecutedExecutedExtinguishedFlashes (1 Hz)

C2203VIN not writtenExecutedExecutedExtinguishedIlluminates

C1608Implausible diagnosis dataExecutedExecutedExtinguishedExtinguished

U0001Bus offExecutedExecutedExtinguishedExtinguished

U0100Engine time-out errorExecutedExecutedExtinguishedExtinguished

U0141ETACS time-out errorExecutedExecutedExtinguishedExtinguished

U1415Variant coding not implementedExecutedProhibitedExtinguishedIlluminates

U1417Invalid variant coding value

(including wrong assembly)ExecutedProhibitedExtinguishedIlluminates

DTC

No.Item Countermeasures for failure

EBD control ABS control Brake

warning lightABS warning

light