height MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 50 of 241

BASE ENGINE

ENGINE MECHANICAL11A-6

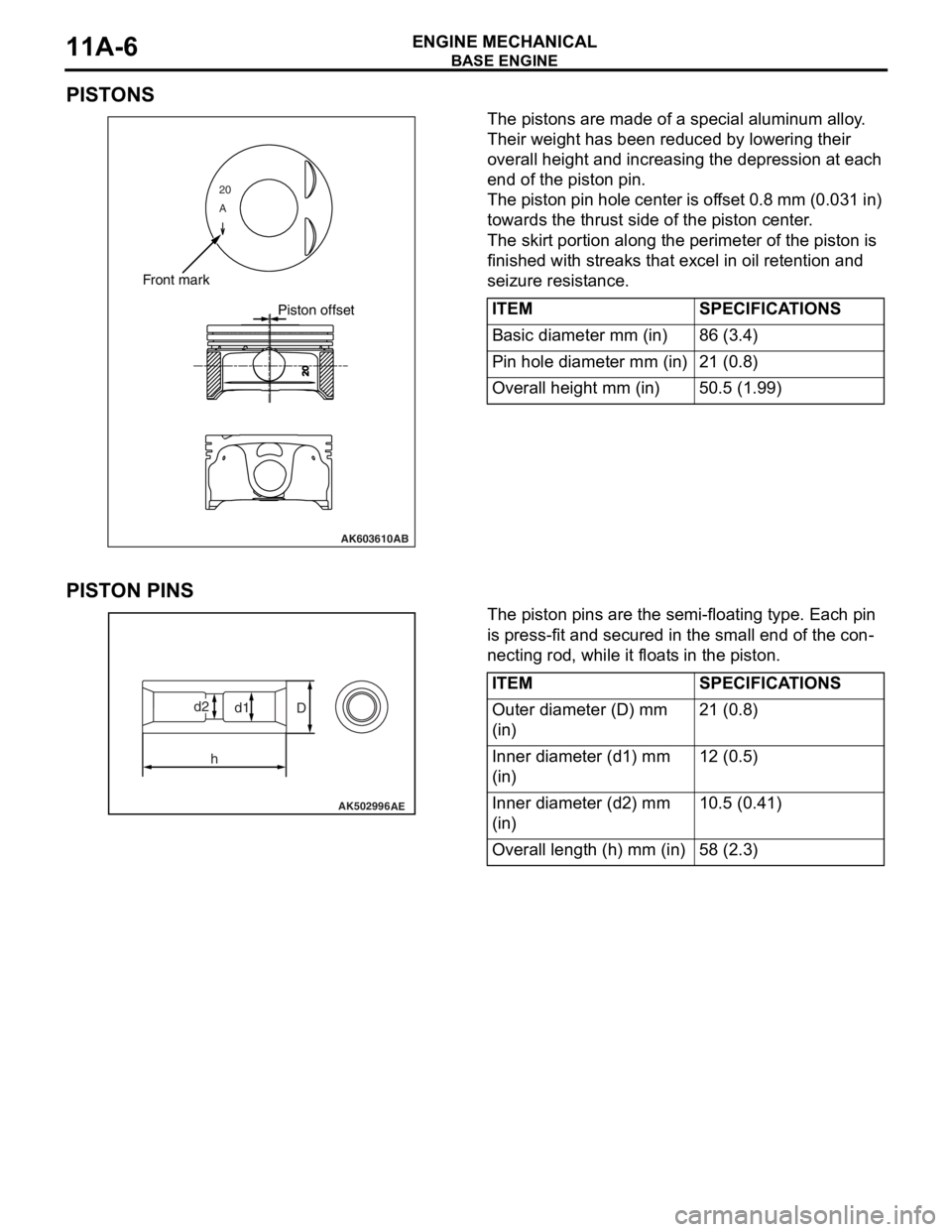

PISTONS

The pistons are made of a special aluminum alloy.

Their weight has been reduced by lowering their

overall height and increasing the depression at each

end of the piston pin.

The piston pin hole center is offset 0.8 mm (0.031 in)

towards the thrust side of the piston center.

The skirt portion along the perimeter of the piston is

finished with streaks that excel in oil retention and

seizure resistance.

PISTON PINS

The piston pins are the semi-floating type. Each pin

is press-fit and secured in the small end of the con

-

necting rod, while it floats in the piston.

20

A

AK603610

Front mark

Piston offset

AB

ITEMSPECIFICATIONS

Basic diameter mm (in)86 (3.4)

Pin hole diameter mm (in)21 (0.8)

Overall height mm (in)50.5 (1.99)

AK502996AE

D

hd1d2

ITEMSPECIFICATIONS

Outer diameter (D) mm

(in)21 (0.8)

Inner diameter (d1) mm

(in)12 (0.5)

Inner diameter (d2) mm

(in)10.5 (0.41)

Overall length (h) mm (in)58 (2.3)

Page 57 of 241

BASE ENGINE

ENGINE MECHANICAL11A-13

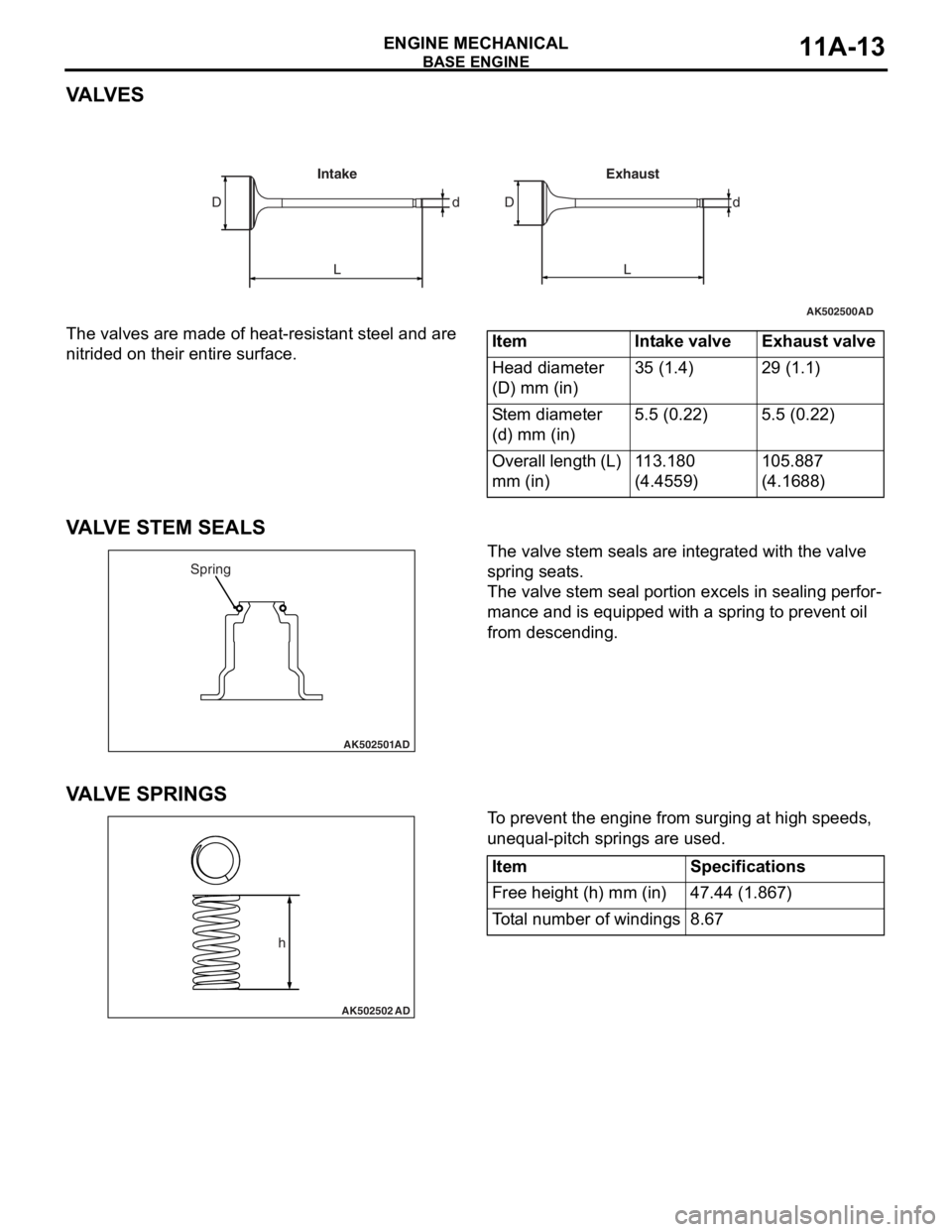

VA LV E S

The valves are made of heat-resistant steel and are

nitrided on their entire surface.

VALVE STEM SEALS

The valve stem seals are integrated with the valve

spring seats.

The valve stem seal portion excels in sealing perfor-

mance and is equipped with a spring to prevent oil

from descending.

VA LV E S P R I N G S

To prevent the engine from surging at high speeds,

unequal-pitch springs are used.

AK502500

LL Dd dD

AD

Intake Exhaust

ItemIntake valveExhaust valve

Head diameter

(D) mm (in)35 (1.4)29 (1.1)

Stem diameter

(d) mm (in)5.5 (0.22)5.5 (0.22)

Overall length (L)

mm (in)113.180

(4.4559)105.887

(4.1688)

AK502501

Spring

AD

AK502502

h

AD

ItemSpecifications

Free height (h) mm (in)47.44 (1.867)

Total number of windings8.67

Page 151 of 241

GENERAL INFORMATION

INTERIOR52A-2

GENERAL INFORMATIONM2520000101013

Functionality, interior comfort, and safety have been

emphasized, giving interior design for elegance and

relaxation space. Various measures have been taken

to protect the environment and recycle resources.

FEATURES

Quality improvement

1. Two-tone interior

2. Full interior trim

Usability improvement

1. Armrest (floor console, rear seat, front door trim, rear door trim)

2. Cup holder (floor console, rear seat armrest)

3. Bottle holder (front door trim)

Convenient storage

1. Glove box

2. Seatback pocket (driver’s seat)

3. Card holder (glove box)

4. Tissue paper holder (floor console)

5. Floor console box

6. Door pocket (front door trim, rear door trim)

Safety improvement

1. Front and rear collision protection seat mecha-

nism (front seat)

2. ISO-FIX lower anchor (rear seat outside)

3. Upper tether anchor (rear shelf)

4. ELR 3-point seat belt (driver’s seat)

5. ELR/ALR 3-point seat belt (front passenger, rear)

6. Seat belt retractor with a driver's side preten-

sioner and force limiter

7. Seat belt retractor with a passenger’s side pre-

tensioner and force limiter

8. Headliner energy absorption rib

Consideration for the optimum driving position

1. Seat height adjustment (driver’s seat)

2. Head restraint with height adjustment (front, rear)

3. Seat slide adjustment (front)

Measures for resource recycling

1. Aggressively use PP materials that are easy to recycle and easy to stamp material symbols on

the plastic (resin) parts.

2. Reduction of chemical material (formaldehyde*,

organic solvent)

NOTE: *: Clear and colourless, toxic, irritating odour

Page 154 of 241

SEAT

INTERIOR52A-5

SEAT

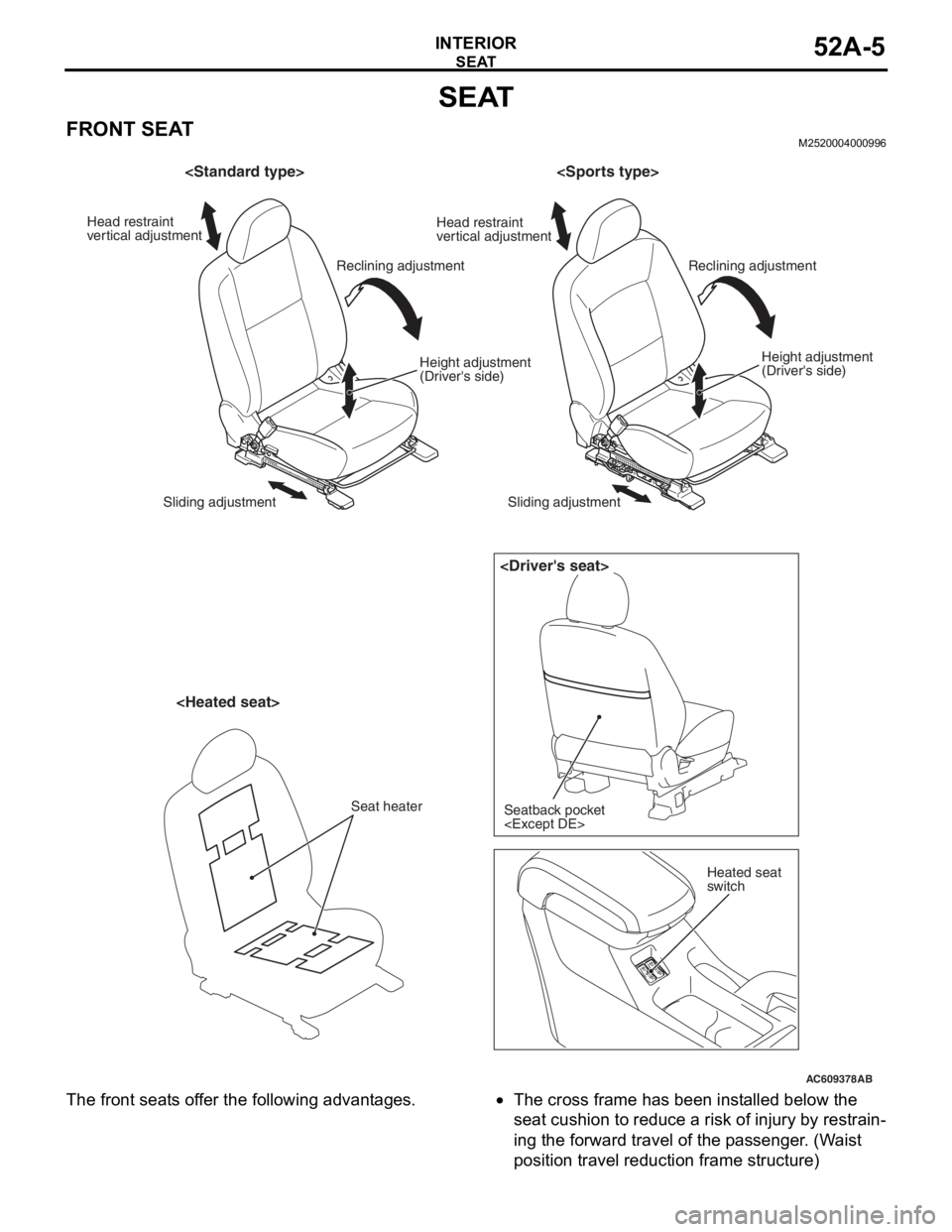

FRONT SEATM2520004000996

The front seats offer the following advantages.•The cross frame has been installed below the

seat cushion to reduce a risk of injury by restrain

-

ing the forward travel of the passenger. (Waist

position travel reduction frame structure)

AC609378

AB

Head restraint

vertical adjustment Head restraint

vertical adjustment

Reclining adjustment Reclining adjustment

Seatback pocket

switch

Height adjustment

(Driver's side)

Sliding adjustment Sliding adjustment

Seat heater

Height adjustment

(Driver's side)

Page 155 of 241

SEAT

INTERIOR52A-6

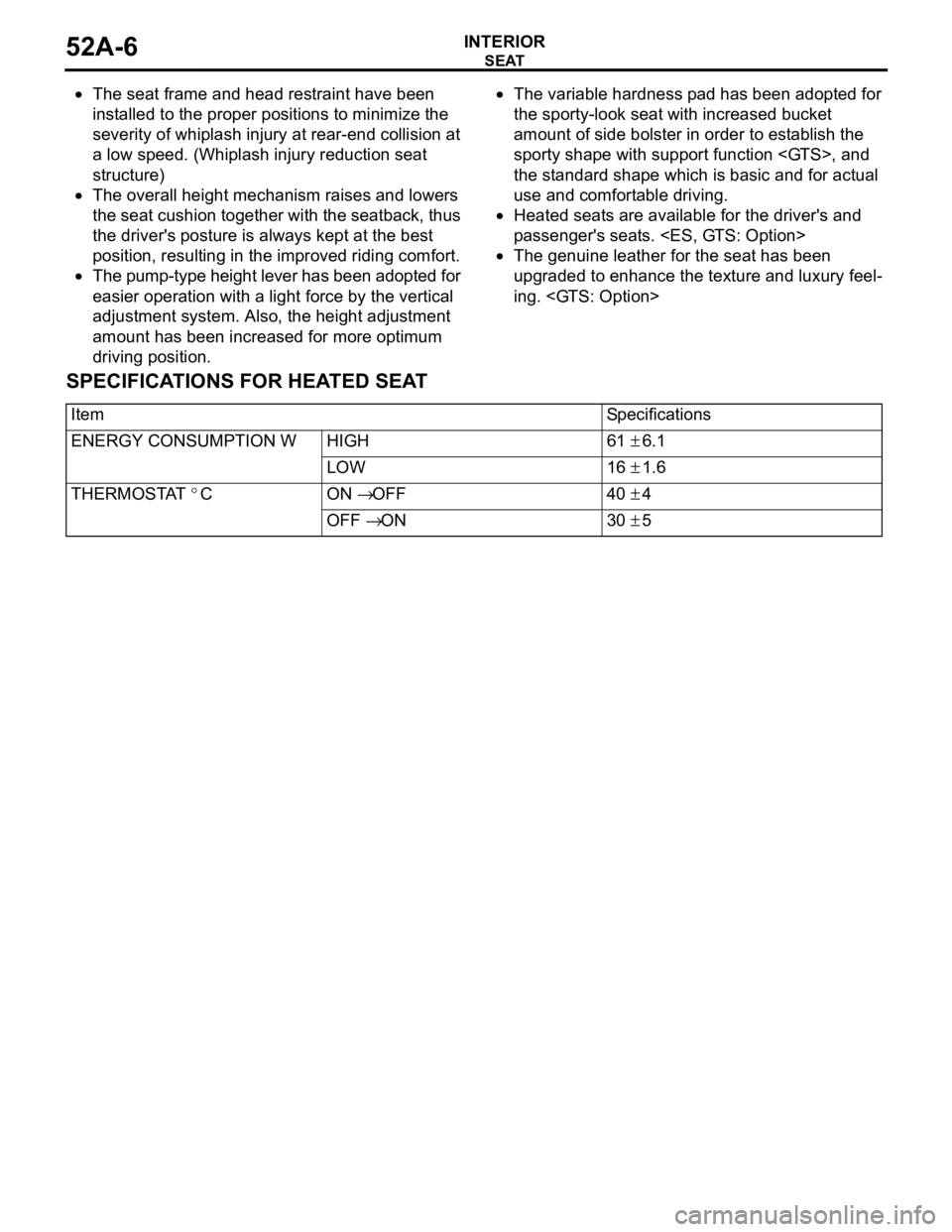

•The seat frame and head restraint have been

installed to the proper positions to minimize the

severity of whiplash injury at rear-end collision at

a low speed. (Whiplash injury reduction seat

structure)

•The overall height mechanism raises and lowers

the seat cushion together with the seatback, thus

the driver's posture is always kept at the best

position, resulting in the improved riding comfort.

•The pump-type height lever has been adopted for

easier operation with a light force by the vertical

adjustment system. Also, the height adjustment

amount has been increased for more optimum

driving position.

•The variable hardness pad has been adopted for

the sporty-look seat with increased bucket

amount of side bolster in order to establish the

sporty shape with support function

the standard shape which is basic and for actual

use and comfortable driving.

•Heated seats are available for the driver's and

passenger's seats.

•The genuine leather for the seat has been

upgraded to enhance the texture and luxury feel

-

ing.

SPECIFICATIONS FOR HEATED SEAT

ItemSpecifications

ENERGY CONSUMPTION WHIGH61 ± 6.1

LOW16 ± 1.6

THERMOSTAT °CON → OFF40 ± 4

OFF → ON30 ± 5

Page 182 of 241

FRONT SEAT ASSEMBLY

TSB Revision

INTERIOR52A-21

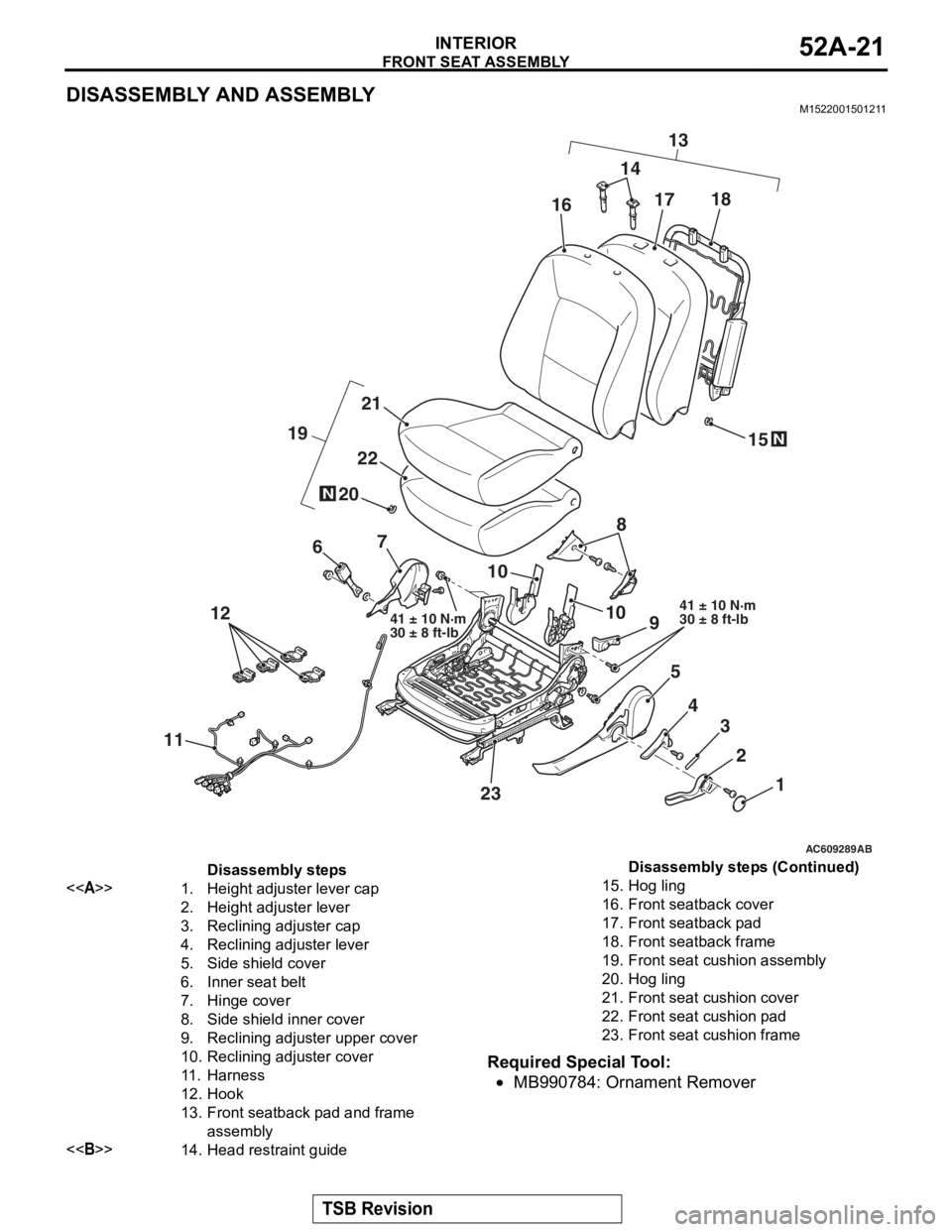

DISASSEMBLY AND ASSEMBLYM1522001501211

Required Special Tool:

•MB990784: Ornament Remover

AC506551

AC609289AB

1

2

3

4

5

9

10

67

12

11

23 14

13

N

10

20

19N

22

21

15

8

161718

41 ± 10 N·m

30 ± 8 ft-lb41 ± 10 N·m

30 ± 8 ft-lb

Disassembly steps

<>1.Height adjuster lever cap

2.Height adjuster lever

3.Reclining adjuster cap

4.Reclining adjuster lever

5.Side shield cover

6.Inner seat belt

7.Hinge cover

8.Side shield inner cover

9.Reclining adjust er upper cover

10.Reclining adjuster cover

11 .Harness

12.Hook

13.Front seatback pad and frame

assembly

<>14.Head restraint guide

15.Hog ling

16.Front seatback cover

17.Front seatback pad

18.Front seatback frame

19.Front seat cushion assembly

20.Hog ling

21.Front seat cushion cover

22.Front seat cushion pad

23.Front seat cushion frame

Disassembly steps (Continued)

Page 183 of 241

FRONT SEAT ASSEMBLY

TSB Revision

INTERIOR52A-22

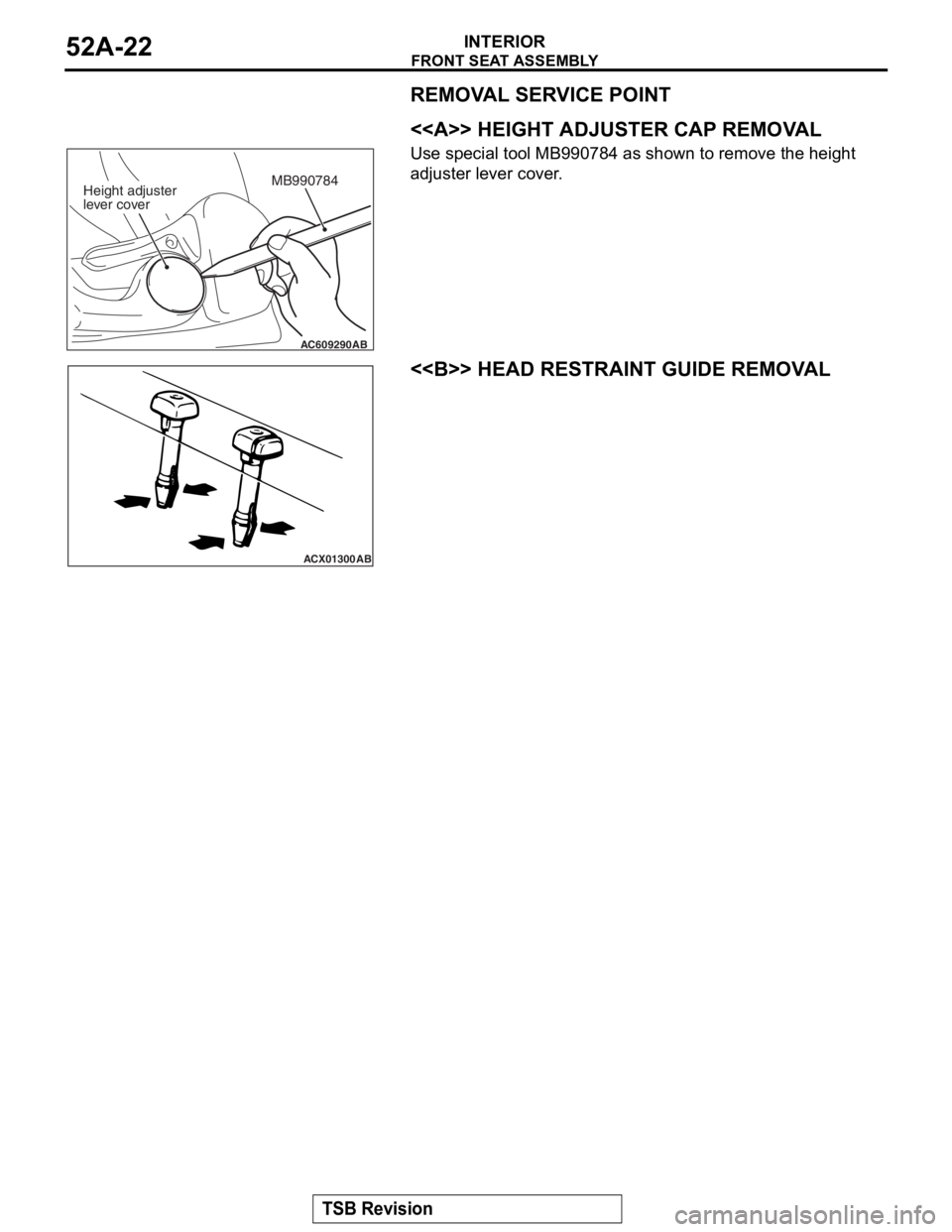

REMOVAL SERVICE POINT

.

<> HEIGHT ADJUSTER CAP REMOVAL

Use special tool MB990784 as shown to remove the height

adjuster lever cover.

.

<> HEAD RESTRAINT GUIDE REMOVAL

AC609290

MB990784

AB

Height adjuster

lever cover

ACX01300AB

Page 223 of 241

GENERAL INFORMATION

REAR SUSPENSION34-2

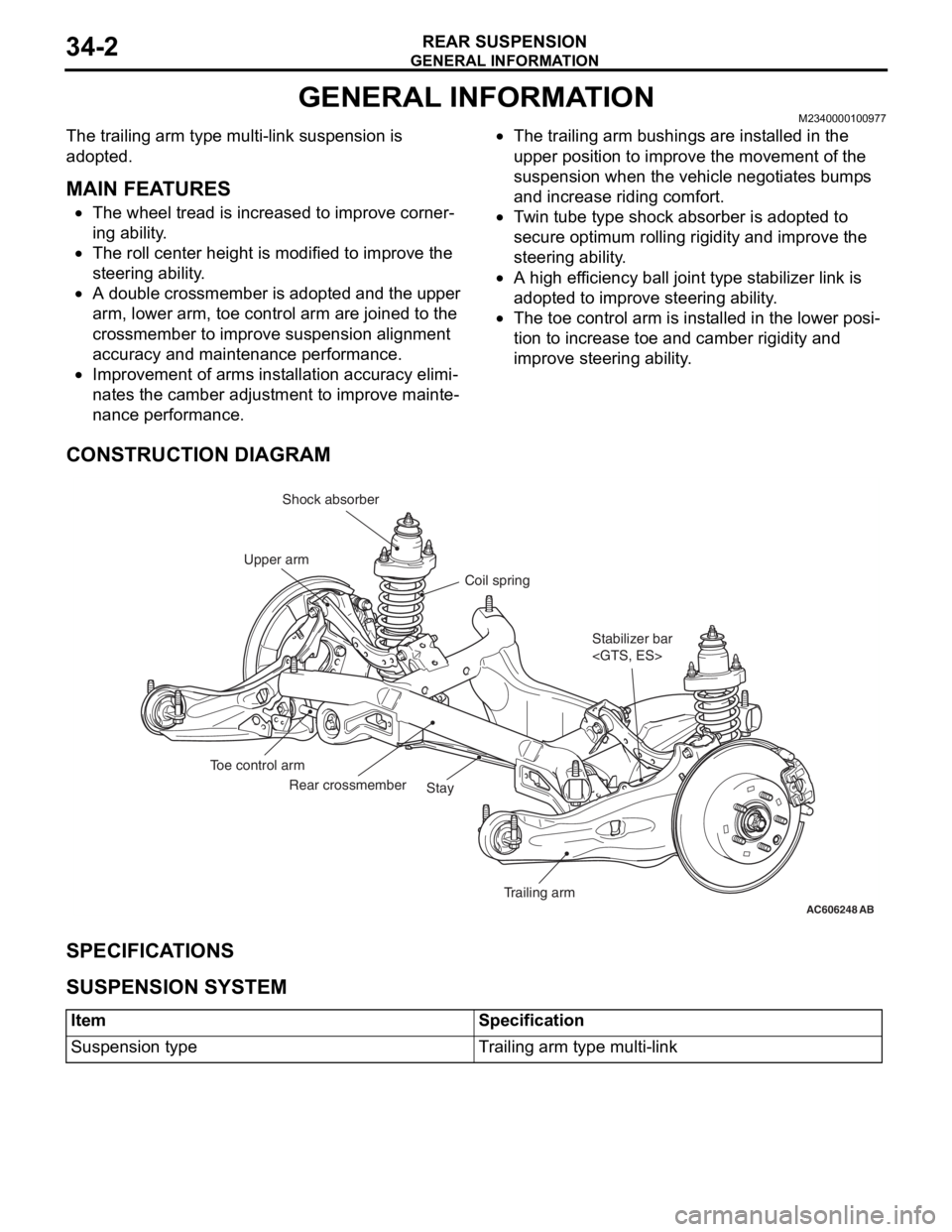

GENERAL INFORMATIONM2340000100977

The trailing arm type multi-link suspension is

adopted.

.

MAIN FEATURES

•The wheel tread is increased to improve corner-

ing ability.

•The roll center height is modified to improve the

steering ability.

•A double crossmember is adopted and the upper

arm, lower arm, toe control arm are joined to the

crossmember to improve suspension alignment

accuracy and maintenance performance.

•Improvement of arms installation accuracy elimi-

nates the camber adjustment to improve mainte-

nance performance.

•The trailing arm bushings are installed in the

upper position to improve the movement of the

suspension when the vehicle negotiates bumps

and increase riding comfort.

•Twin tube type shock absorber is adopted to

secure optimum rolling rigidity and improve the

steering ability.

•A high efficiency ball joint type stabilizer link is

adopted to improve steering ability.

•The toe control arm is installed in the lower posi-

tion to increase toe and camber rigidity and

improve steering ability.

CONSTRUCTION DIAGRAM

SPECIFICATIONS

.

SUSPENSION SYSTEM

.

AC606248AB

Stabilizer bar

Trailing arm Stay Rear crossmember Toe control armCoil spring Shock absorber

Upper arm

ItemSpecification

Suspension typeTrailing arm type multi-link

Page 227 of 241

GENERAL INFORMATION

FRONT SUSPENSION33-2

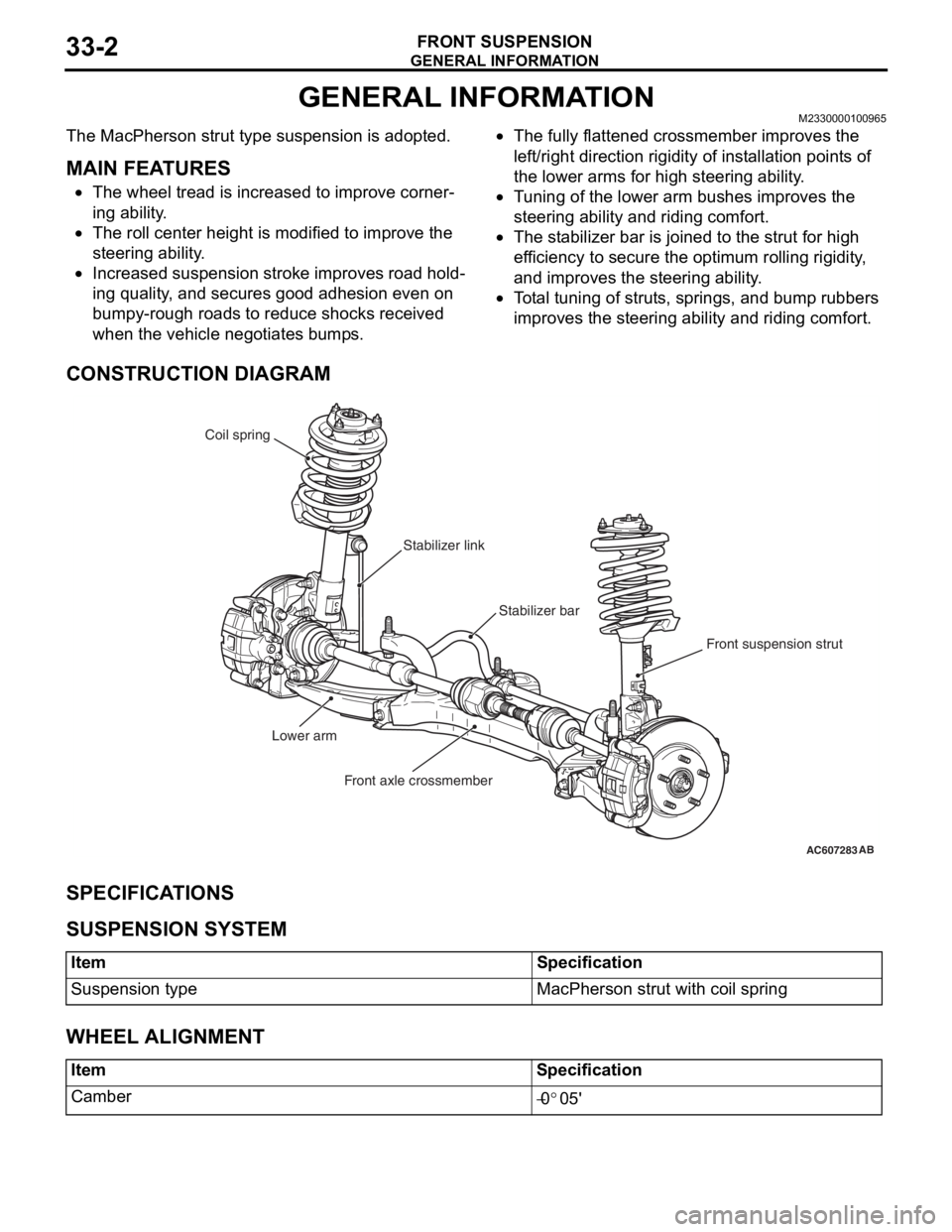

GENERAL INFORMATIONM2330000100965

The MacPherson strut type suspension is adopted..

MAIN FEATURES

•The wheel tread is increased to improve corner-

ing ability.

•The roll center height is modified to improve the

steering ability.

•Increased suspension stroke improves road hold-

ing quality, and secures good adhesion even on

bumpy-rough roads to reduce shocks received

when the vehicle negotiates bumps.

•The fully flattened crossmember improves the

left/right direction rigidity of installation points of

the lower arms for high steering ability.

•Tuning of the lower arm bushes improves the

steering ability and riding comfort.

•The stabilizer bar is joined to the strut for high

efficiency to secure the optimum rolling rigidity,

and improves the steering ability.

•Total tuning of struts, springs, and bump rubbers

improves the steering ability and riding comfort.

CONSTRUCTION DIAGRAM

SPECIFICATIONS

.

SUSPENSION SYSTEM

.

WHEEL ALIGNMENT

AC607283AB

Stabilizer bar Coil spring

Front suspension strut Stabilizer link

Lower arm

Front axle crossmember

ItemSpecification

Suspension typeMacPherson strut with coil spring

ItemSpecification

Camber−0°05'