warning MITSUBISHI LANCER IX 2006 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 246 of 800

ON-VEHICLE SERVICE

POWER STEERING37-16

WARNING

•If the vehicle continues to be driven after

the collision absorbing mechanism has

operated, the steering column shaft may

be damaged while it is in use.

•If there is a slack in the one-way capsule,

do not attempt to repa ir it but replace the

steering column shaft assembly.

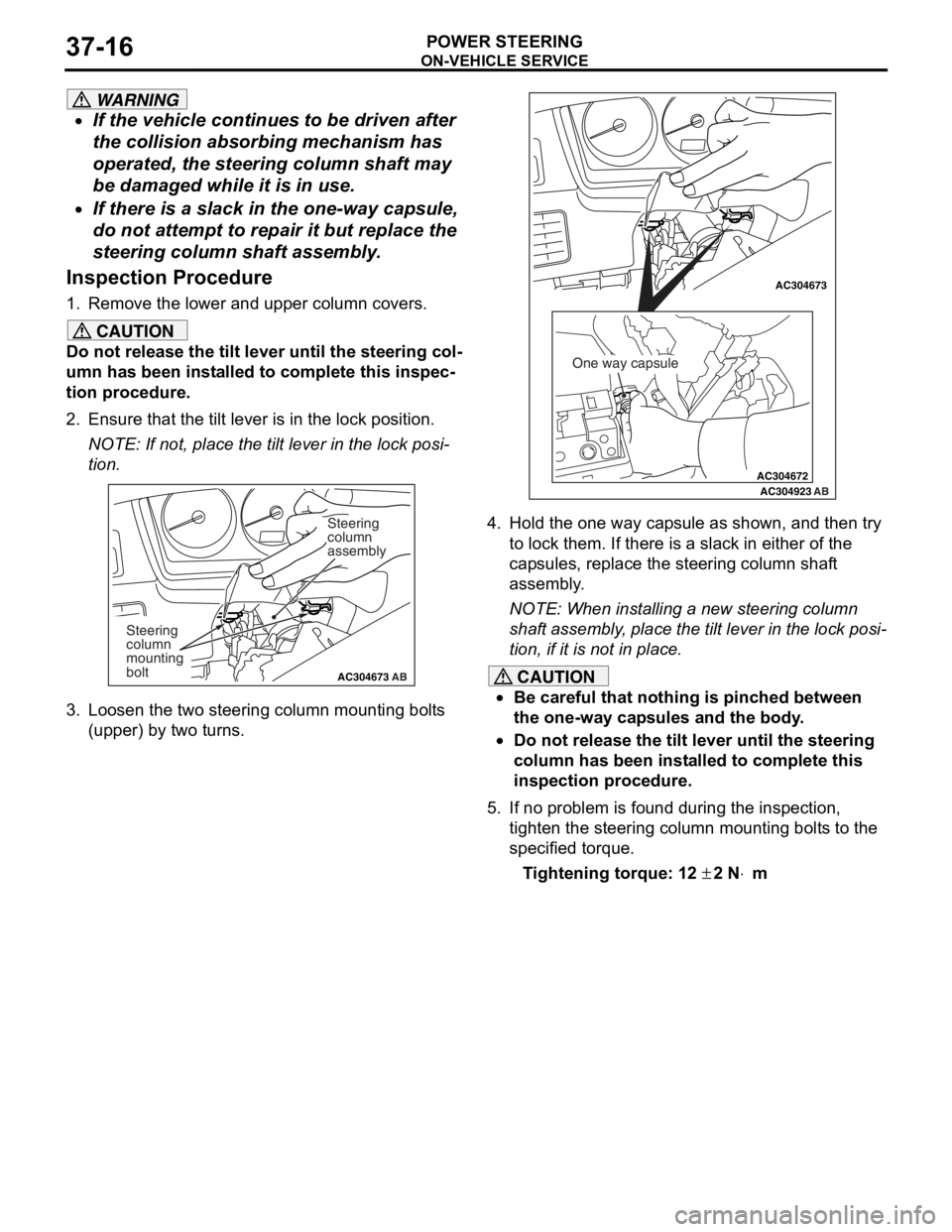

Inspection Procedure

1. Remove the lower and upper column covers.

CAUTION

Do not release the tilt lever until the steering col-

umn has been installed to complete this inspec-

tion procedure.

2. Ensure that the tilt lever is in the lock position.

NOTE: If not, place the tilt lever in the lock posi-

tion.

AC304673AC304673

Steering

column

assembly

AB

Steering

column

mounting

bolt

3. Loosen the two steering column mounting bolts

(upper) by two turns.

AC304672

AC304673AC304673

AC304923 AB

One way capsule

4. Hold the one way capsule as shown, and then try

to lock them. If there is a slack in either of the

capsules, replace the steering column shaft

assembly.

NOTE: When installing a new steering column

shaft assembly, place the tilt lever in the lock posi

-

tion, if it is not in place.

CAUTION

•Be careful that nothing is pinched between

the one-way capsules and the body.

•Do not release the tilt lever until the steering

column has been installed to complete this

inspection procedure.

5. If no problem is found during the inspection, tighten the steering column mounting bolts to the

specified torque.

Tightening torque: 12 ± 2 N⋅m

Page 247 of 800

STEERING WHEEL

POWER STEERING37-17

STEERING WHEEL

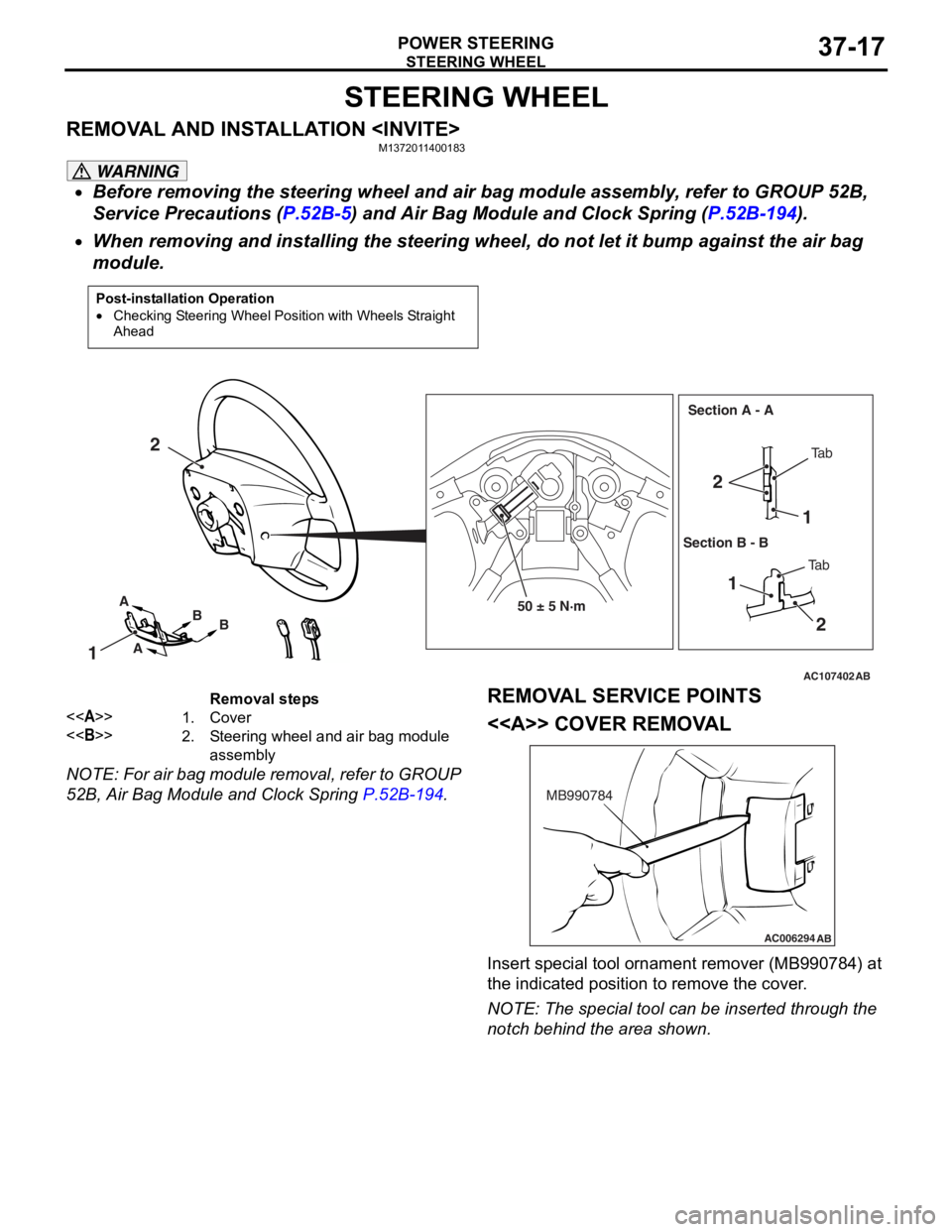

REMOVAL AND INSTALLATION

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (

P.52B-5) and Air Bag Module and Clock Spring (P.52B-194).

•

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC107402AB

50 ± 5 N·m

1

2

21

1 2

A

A B

B Ta b

Ta b

Section A - A

Section B - B

Removal steps

<>1.Cover

<>2.Steering wheel and air bag module

assembly

When removing and installing the steering whee l, do not let it bump against the air bag

module.

NOTE: For air bag module removal, refer to GROUP

52B, Air Bag Module and Clock Spring

P.52B-194.

REMOVAL SERVICE POINTS

<> COVER REMOVAL

AC006294 AB

MB990784

Insert special tool ornament remover (MB990784) at

the indicated position to remove the cover.

NOTE: The special tool can be inserted through the

notch behind the area shown.

Page 248 of 800

STEERING WHEEL

POWER STEERING37-18

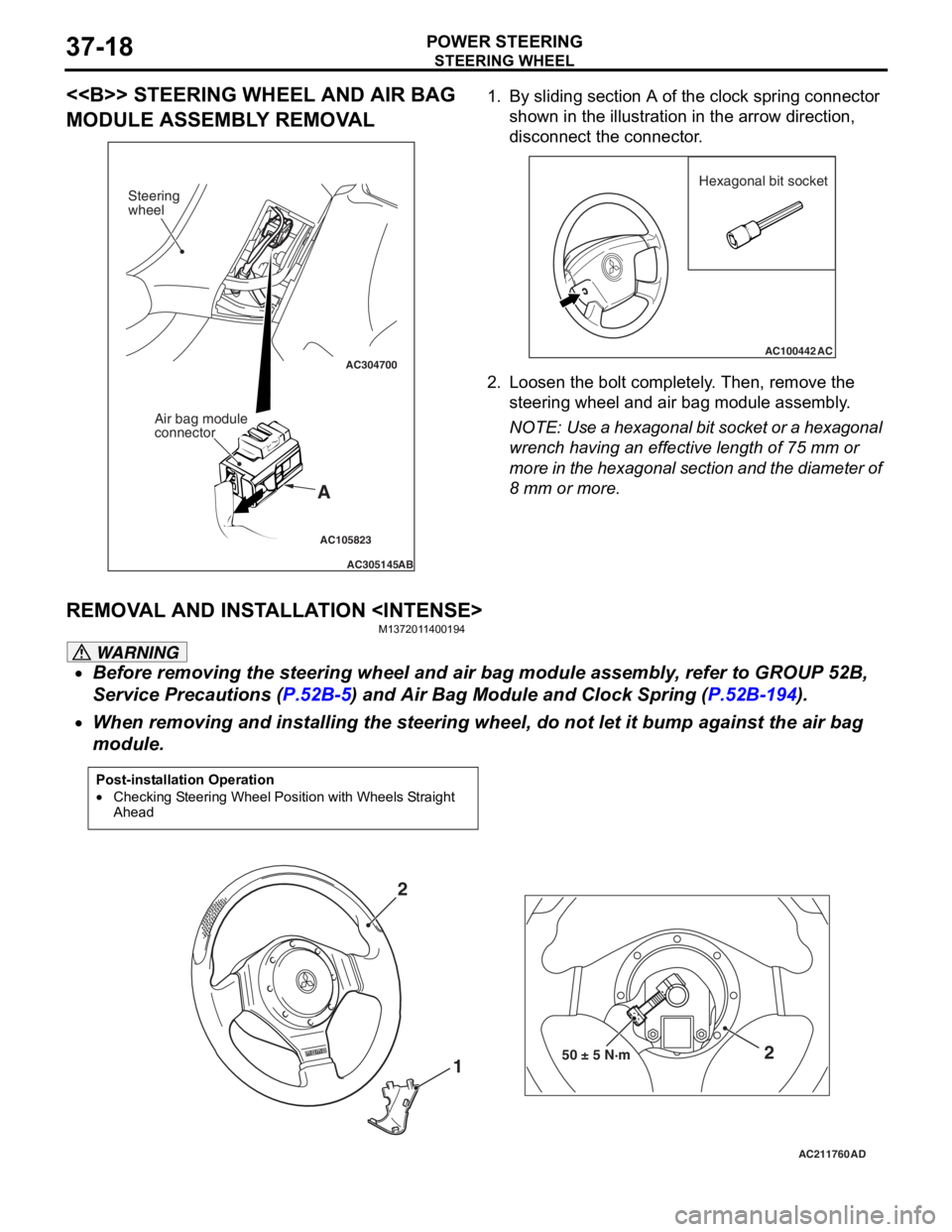

<> STEERING WHEEL AND AIR BAG

MODULE ASSEMBLY REMOVAL

AC105823

AC304700

AC305145AB

A

Steering

wheel

Air bag module

connector

1.By slidin g se ctio n A of the clock spring connector

shown in the illu strat i on in the arrow dire ctio n,

d i sconne ct the con necto r .

AC100442

Hexagonal bit socket

AC

2.L oose n the b o lt comp letely . Then , remo ve th e

steering wheel and air ba g mo dule assembly .

NOTE: Use a hexagon al b i t socket o r a h e xag onal

wren

ch ha vin g an e ffective lengt h of 75 mm or

mo

re in the hexagonal section and t he diameter of

8

mm

or mo re.

REMOV A L AND INST ALLA TION

M137201 14 0019 4

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (

P.52B-5) and Air Bag Module and Clock Spring (P.52B-194).

•

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC211760 AD

50 ± 5 N·m2

1

2

When removing and installing the steering whee

l, do not let it bump against the air bag

module.

Page 250 of 800

STEERING COLUMN SHAFT ASSEMBLY

POWER STEERING37-20

STEERING COLUMN SHAFT ASSEMBLY

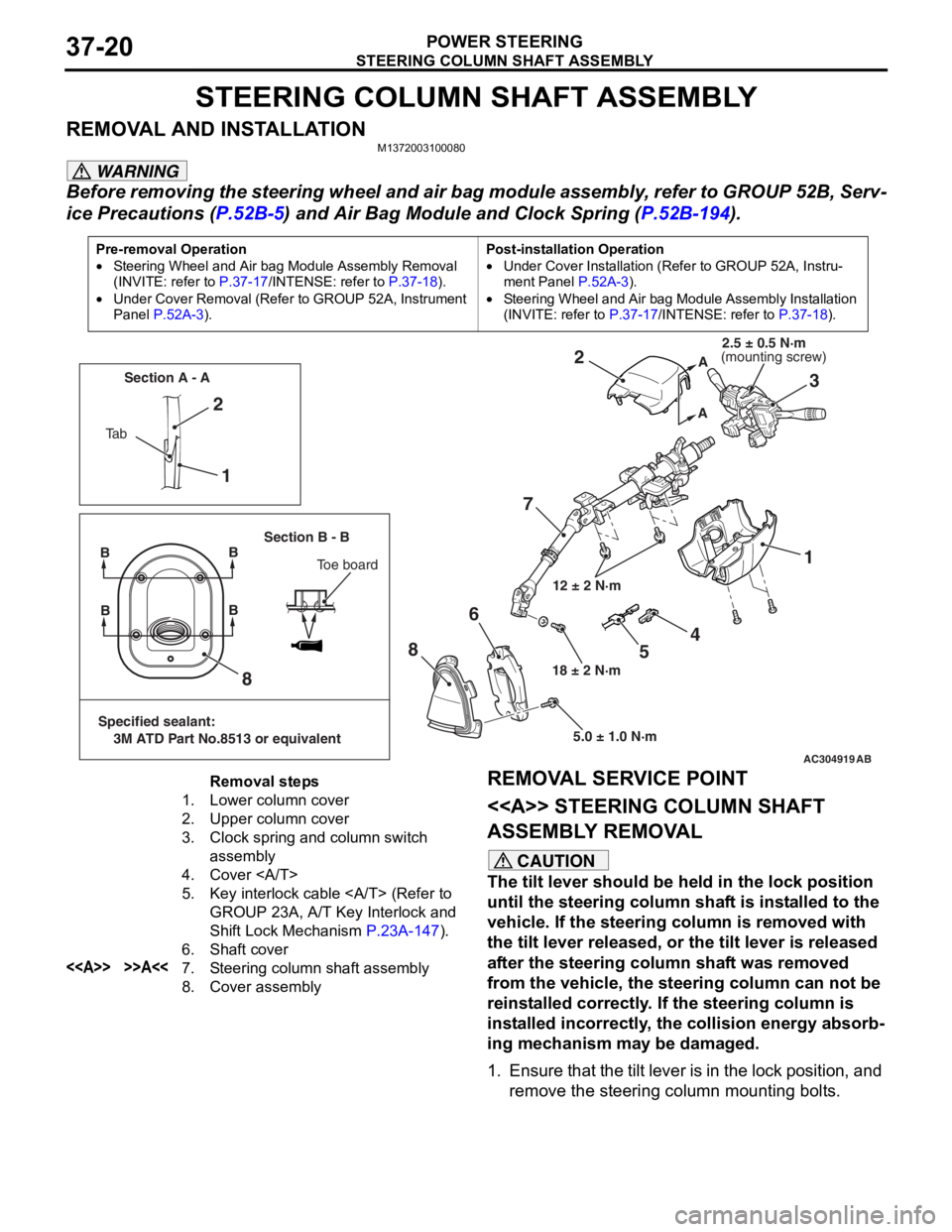

REMOVAL AND INSTALLATIONM1372003100080

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B, Serv-

ice Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-194).

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(INVITE: refer to

P.37-17/INTENSE: refer to P.37-18).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel

P.52A-3).

Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A, Instru-

ment Panel P.52A-3).

•Steering Wheel and Air bag Module Assembly Installation

(INVITE: refer to

P.37-17/INTENSE: refer to P.37-18).

AC304919AB

12 ± 2 N·m

18 ± 2 N·m 5.0 ± 1.0 N·m

1

2

73

2

1

8

8 6

A

A

Ta b Section A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1.Lower column cover

2.Upper column cover

3.Clock spring and column switch

assembly

4.Cover

5.Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism

P.23A-147).

6.Shaft cover

<>>>A<<7.Steering column shaft assembly

8.Cover assembly

REMOVAL SERVICE POINT

<> STEERING

COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed

from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy absorb

-

ing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and remove the steering column mounting bolts.

Page 253 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-23

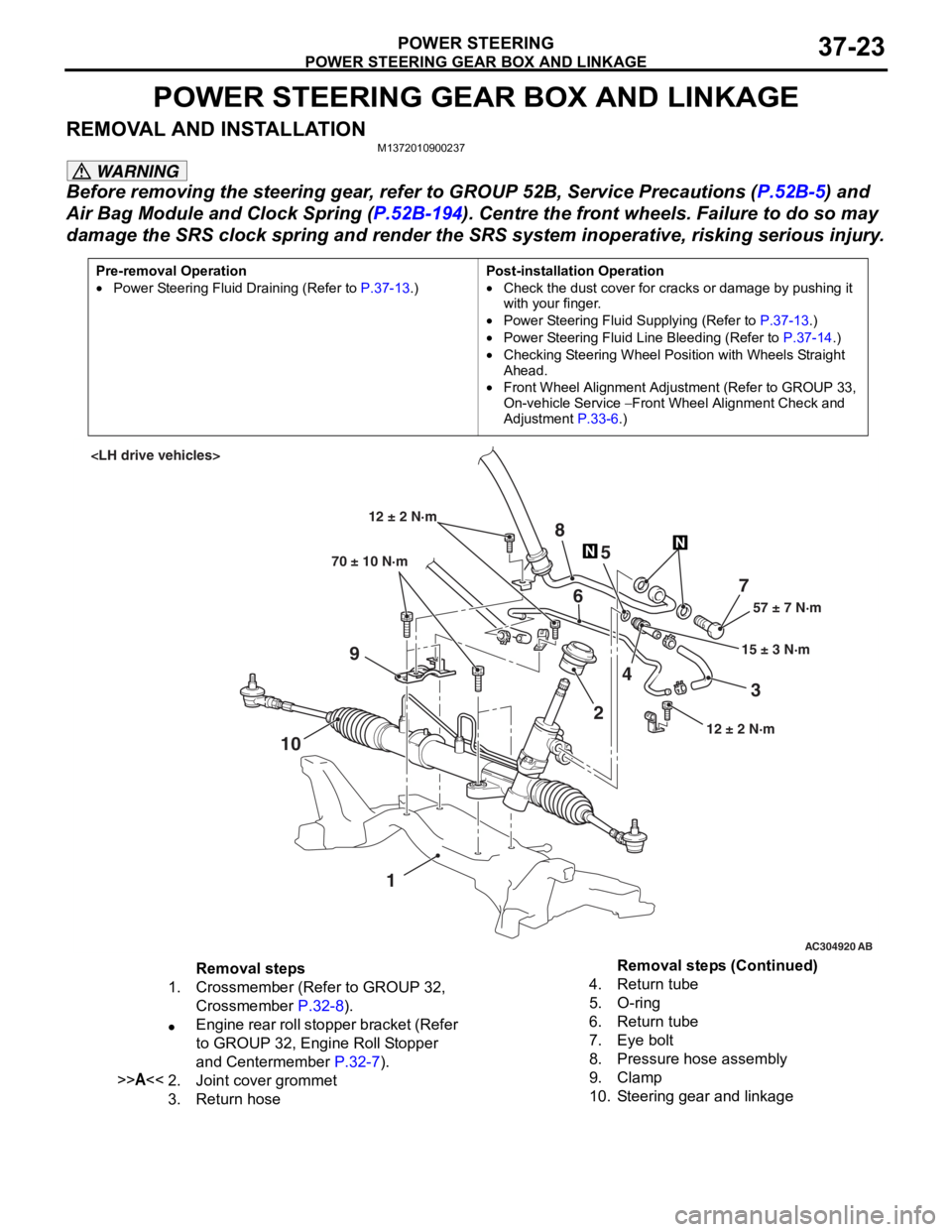

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATIONM1372010900237

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-194). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)

Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-14.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

− Front Wheel Alignment Check and

Adjustment

P.33-6.)

AC304920 AB

57 ± 7 N·m

15 ± 3 N·m

70 ± 10 N·m

7

3

8

5

6

9

10 24

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1.Crossmember (Refer to GROUP 32,

Crossmember

P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember

P.32-7).

>>A<<2.Joint cover grommet

3.Return hose

4.Return tube

5.O-ring

6.Return tube

7.Eye bolt

8.Pressure hose assembly

9.Clamp

10.Steering gear and linkage

Removal steps (Continued)

Page 325 of 800

KEYLESS ENTRY SYSTEM

BODY42-53

TROUBLESHOOTING

M1428000700287

The keyless entry system is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting

P.54B-15 or GROUP

54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

KEYLESS ENTR Y SYSTEM CHECKM1428001400096

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting

P.54B-15, refer to

GROUP 54C, Troubleshooting P.54C-4.

•Operate the transmitter to check that the doors

and tailgate can be locked and unlocked.

•Operate the transmitter to check that the answer-

back function works in response to door and tail-

gate

NOTE: The adjustment function allows you to

change the answerback setting as follows. Prior

to that check, confirm which setting is activated.

.

•The hazard warning lamps flash twice when

locked and once when unlocked. The room

lamp flashes twice when locked and illumi

-

nates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

locked and flash once when unlocked. The

room lamp flashes twice when locked and illu

-

minates for 15 seconds when unlocked.

•The hazard warning lamps flash twice when

locked and do not flash when unlocked. The

room lamp flashes twice when locked and illu

-

minates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

both locked and unlocked. The room lamp

flashes twice when locked and illuminates for

15 seconds when unlocked.

KEYLESS ENTRY SYS TEM TIMER LOCK

FUNCTION INSPECTION

M1428004000138

Push the transmitter unlock button and check to see

that the doors and tailgate

seconds. If it doesn't, then execute troubleshooting

remedies. Refer to GROUP 54B, Troubleshooting

P.54B-15, refer to GROUP 54C, Troubleshooting

P.54C-4.

ENABLING/DISABLING THE

ANSWERBACK FUNCTION

M1428003200214

If the keyless entry system locks or unlocks the

doors, the room lamp flashes or illuminates, the haz

-

ard warning lamp flashes (hazard answerback func-

tion). The hazard answerback function can be

enabled or disabled according to the following proce

-

dure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

The hazard answerback function can be enabled or

disabled by one of the two following procedures.

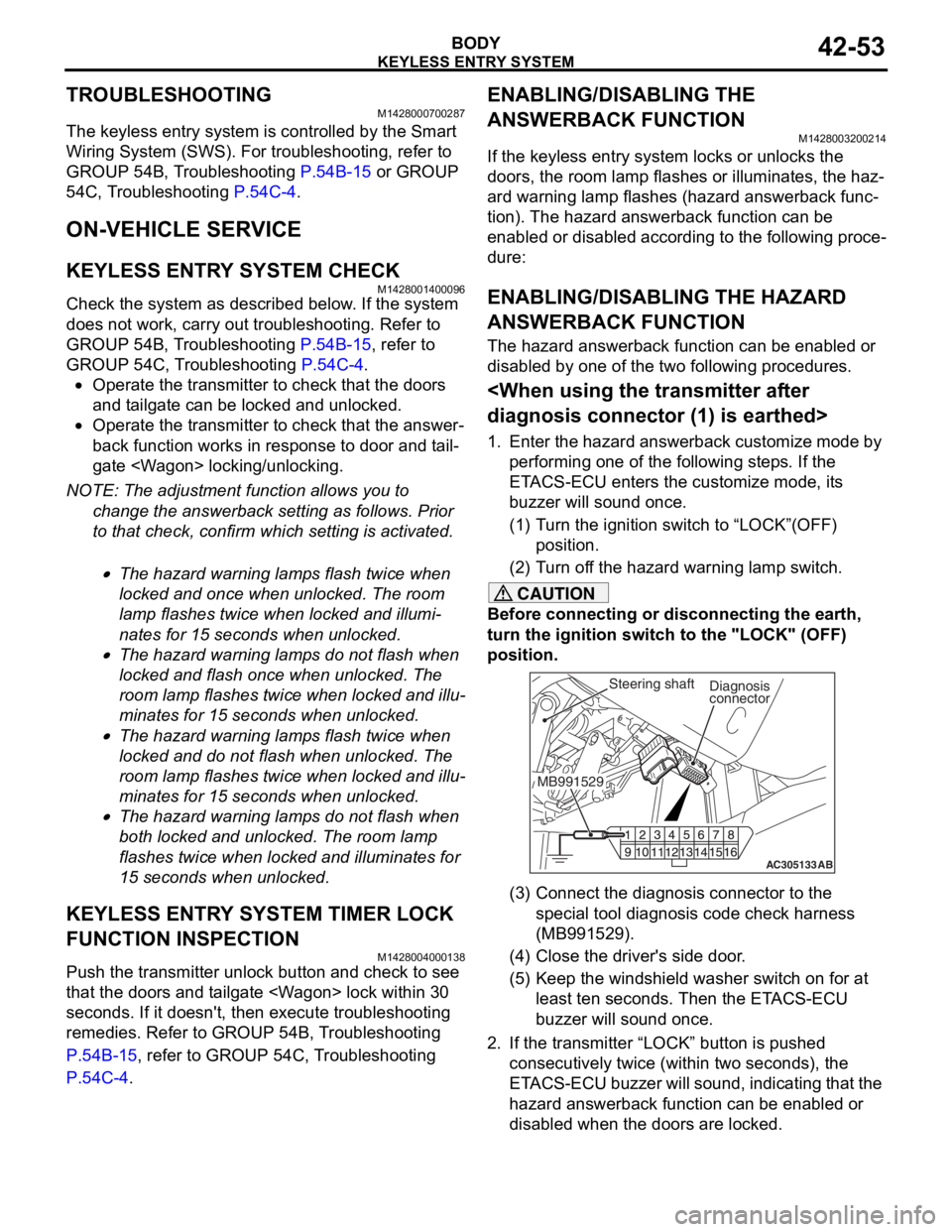

1. Enter the hazard answerback customize mode by performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

(3) Connect the diagnosis connector to the special tool diagnosis code check harness

(MB991529).

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

Page 326 of 800

KEYLESS ENTRY SYSTEM

BODY42-54

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect diagnosis connector terminal (1) form the earth.

(2) Turn the ignition switch to position other then “LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

connector>

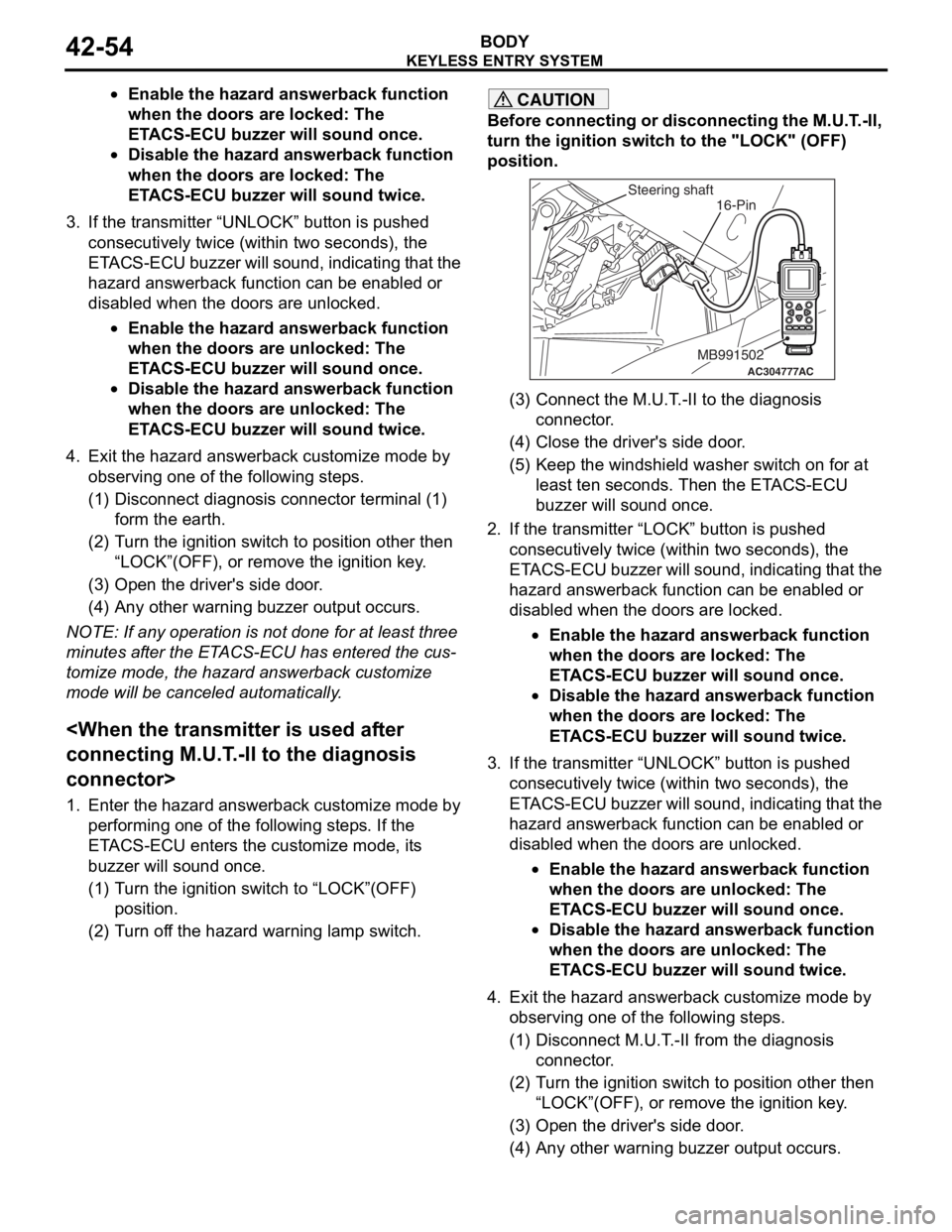

1. Enter the hazard answerback customize mode by performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the M.U.T.-II,

turn the ignition switch to the "LOCK" (OFF)

position.

AC304777

Steering shaft

ACMB991502

16-Pin

(3) Connect the M.U.T.-II to the diagnosis

connector.

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect M.U.T.-II from the diagnosis

connector.

(2) Turn the ignition switch to position other then “LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

Page 327 of 800

KEYLESS ENTRY SYSTEM

BODY42-55

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

(MB991824) to the diagnosis connector>

1. Enter the hazard answerback customize mode by

performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF) position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the V. C. I.,

turn the ignition switch to the "LOCK" (OFF)

position.

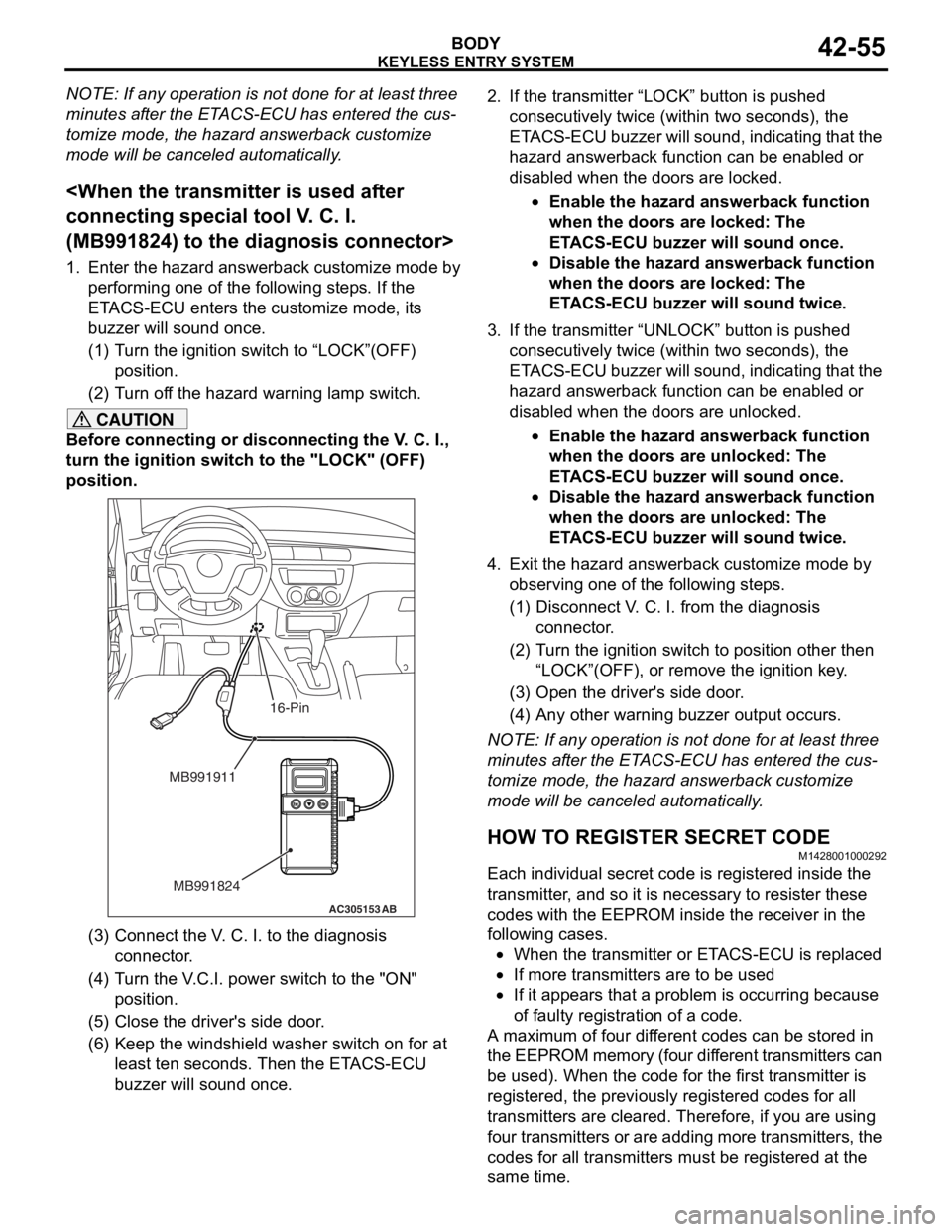

AC305153AB

MB991911

MB991824

16-Pin

(3) Connect the V. C. I. to the diagnosis connector.

(4) Turn the V.C.I. power switch to the "ON" position.

(5) Close the driver's side door.

(6) Keep the windshield washer switch on for at least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed

consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

•Enable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are locked: The

ETACS-ECU buzzer will sound twice.

3. If the transmitter “UNLOCK” button is pushed consecutively twice (wit hin two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are unlocked.

•Enable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound once.

•Disable the hazard answerback function

when the doors are unlocked: The

ETACS-ECU buzzer will sound twice.

4. Exit the hazard answer back customize mode by

observing one of the following steps.

(1) Disconnect V. C. I. from the diagnosis connector.

(2) Turn the ignition switch to position other then

“LOCK”(OFF), or remove the ignition key.

(3) Open the driver's side door.

(4) Any other warning buzzer output occurs.

NOTE: If any operation is not done for at least three

minutes after the ETACS-ECU has entered the cus

-

tomize mode, the hazard answerback customize

mode will be canceled automatically.

HOW TO REGISTER SECRET CODE

M1428001000292

Each individual secret code is registered inside the

transmitter, and so it is necessary to resister these

codes with the EEPROM insi de the receiver in the

following cases.

•When the transmitter or ETACS-ECU is replaced

•If more transmitters are to be used

•If it appears that a probl em is occurring because

of faulty registration of a code.

A maximum of four different codes can be stored in

the EEPROM memory (four different transmitters can

be used). When the code for the first transmitter is

registered, the previously registered codes for all

transmitters are cleared. Therefore, if you are using

four transmitters or are adding more transmitters, the

codes for all transmitters must be registered at the

same time.

Page 328 of 800

KEYLESS ENTRY SYSTEM

BODY42-56

WHEN THE SPECIAL TOOL DIAGNOSIS

CODE CHECK HARNESS (MB991529) IS

USED

1. Check that the doors lock normally when the key is used.

2. Insert the ignition key.

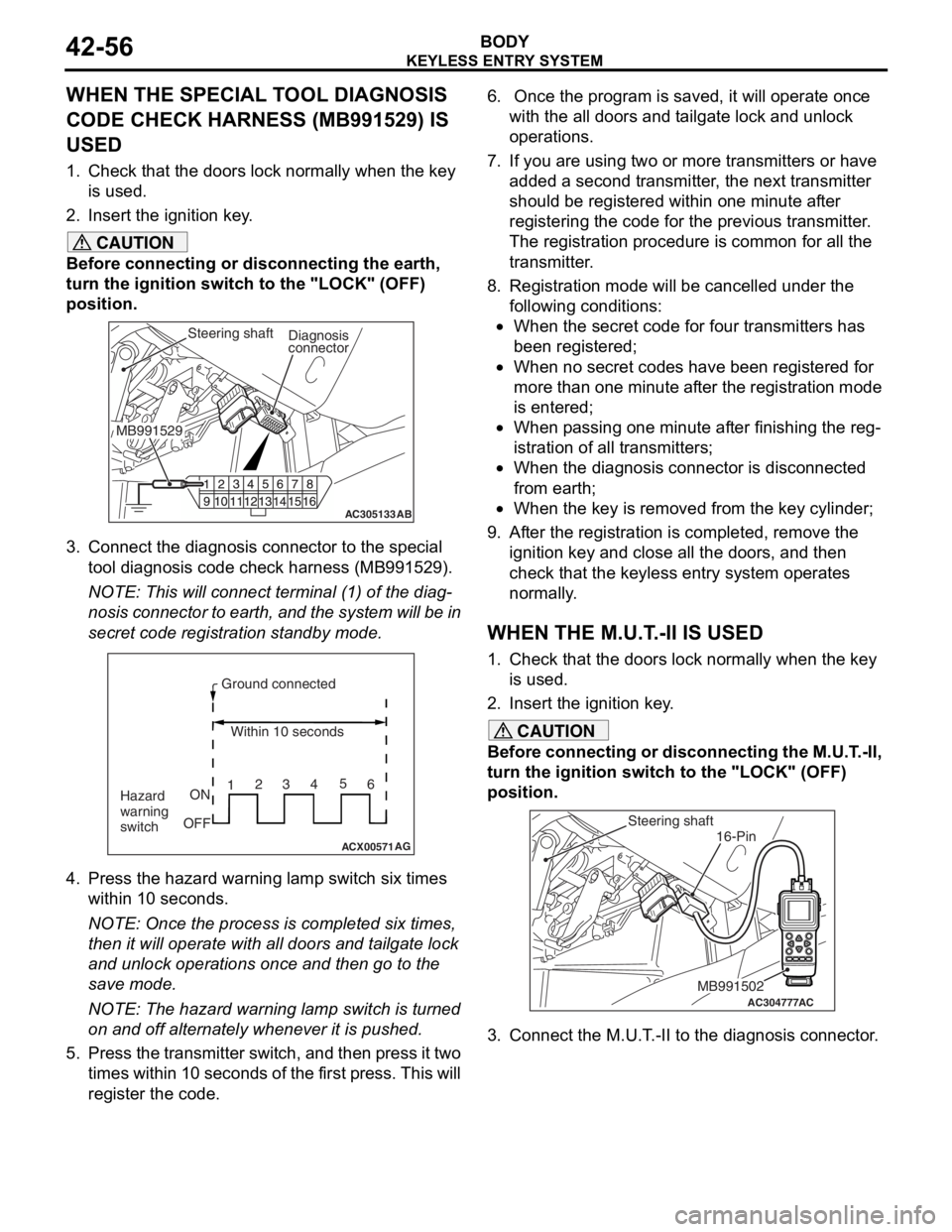

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

AC305133AB

Diagnosis

connector

MB991529Steering shaft

3. Connect the diagnosis connector to the special tool diagnosis code check harness (MB991529).

NOTE: This will connect terminal (1) of the diag-

nosis connector to earth, and the system will be in

secret code registration standby mode.

ACX00571

Ground connected

Within 10 seconds

Hazard

warning

switch ON

OFF 1

23

45

6

AG

4. Press the hazard warning lamp switch six times

within 10 seconds.

NOTE: Once the process is completed six times,

then it will operate with al l doors and tailgate lock

and unlock operations once and then go to the

save mode.

NOTE: The hazard warning lamp switch is turned

on and off alternately whenever it is pushed.

5. Press the transmitter switch, and then press it two times within 10 seconds of the first press. This will

register the code.

6. Once the program is saved, it will operate once

with the all doors and tailgate lock and unlock

operations.

7. If you are using two or more transmitters or have

added a second transmitter, the next transmitter

should be registered within one minute after

registering the code for the previous transmitter.

The registration procedure is common for all the

transmitter.

8. Registration mode will be cancelled under the following conditions:

•When the secret code for four transmitters has

been registered;

•When no secret codes have been registered for

more than one minute after the registration mode

is entered;

•When passing one minute after finishing the reg-

istration of all transmitters;

•When the diagnosis connector is disconnected

from earth;

•When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key and close all the doors, and then

check that the keyless entry system operates

normally.

WHEN THE M.U.T.-II IS USED

1. Check that the doors lock normally when the key

is used.

2. Insert the ignition key.

CAUTION

Before connecting or disconnecting the M.U.T.-II,

turn the ignition switch to the "LOCK" (OFF)

position.

AC304777

Steering shaft

ACMB991502

16-Pin

3. Connect the M.U.T.-II to the diagnosis connector.