Wiring MITSUBISHI MONTERO 1987 1.G Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 217 of 284

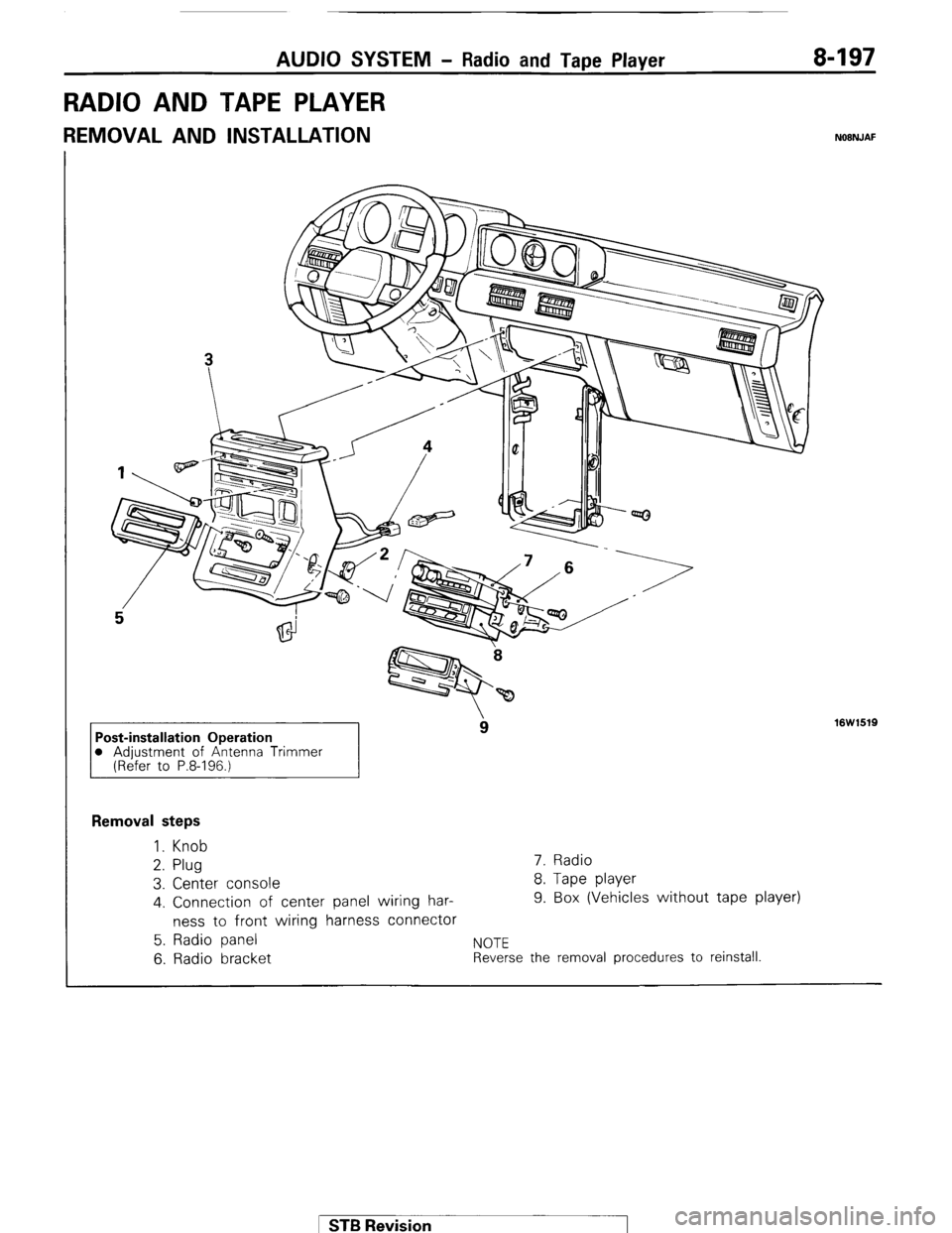

AUDIO SYSTEM - Radio and Tape Player e-197

RADIO AND TAPE PLAYER

REMOVAL AND INSTALLATION NOINJAF

16W1519

Post-installation Operation l Adjustment of Antenna Trimmer

(Refer to P.8-196.) Removal steps

1. Knob

2. Plug

3. Center console

4. Connection of center panel wiring har-

ness to front wiring harness connector 7. Radio

8. Tape player

9. Box (Vehicles without tape player)

5. Radio panel

6. Radio bracket NOTE

Reverse the removal procedures to reinstall. 1 STB Revision

Page 220 of 284

8-200 AUDIO SYSTEM - Antenna/Noise Suppression

3. REMOVAL OF FRONT FENDER PANEL

Refer to GROUP 23 Body-Front Fender

SEFiVlCE ff OINTS OF INSTALLATION

3. IbSTALLATION OF FRONT FENDER PANEL

Refer to GROUP 23 Body-Front Fender.

NOISE SWPRESSION N08NOAA

I. Noise interfering with radio reception may be roughly

classified as follows:

(1) Noise produced by the vehicle itself

Noise from the ignition circuit, alternator circuit, etc

(2) Noise generated in the radio itself

Thermal noise from transistors, IC, resistor, etc.

(3) Atmospheric noise

Noise from other cars, neon signs, etc.

2. The radio has devices to suppress noise of the radio itsel f

3. and atmospheric noise, but it is difficult to eliminate them

completely. Noise produced by the vehicle includes whin-

ing from the alternator system, and a strong, impulsive,

fast popping noise from the ignition system.

Before performing any checking or adjustments, first

confirm the following points.

Adjust the antenna trimmer completely.

Set the push buttons (tuning) properly.

Extend the antenna all the way.

PREVENTION OF IGNITION CIRCUIT NOISE

A resistance-equipped cable is used for the high-tension cable

in order to prevent noise; however, if any noise from the

ignition circuit does occur, check the tightness and ground

connection of the positive (+) terminal of the noise filter, and,

if necessary, check the noise filter.

Caution

Be careful not to connect the noise filter to the hightension

cable; doing so could damage the noise filter.

PREVENTION OF OTHER CIRCUIT NOISE

1. For other noises, take necessary corrective actions in

accordance with the following items and the NOISE

SUPPRESSION CHART.

2. Polish the grounding cable terminal, and connect it proper-

ly.

3. Polish the pillar antenna ground terminal, and connect it

properly.

4. Ground electric parts completely.

5. Keep the antenna cable and speaker lead wire away from

other electric wiring.

STB Revision

Page 225 of 284

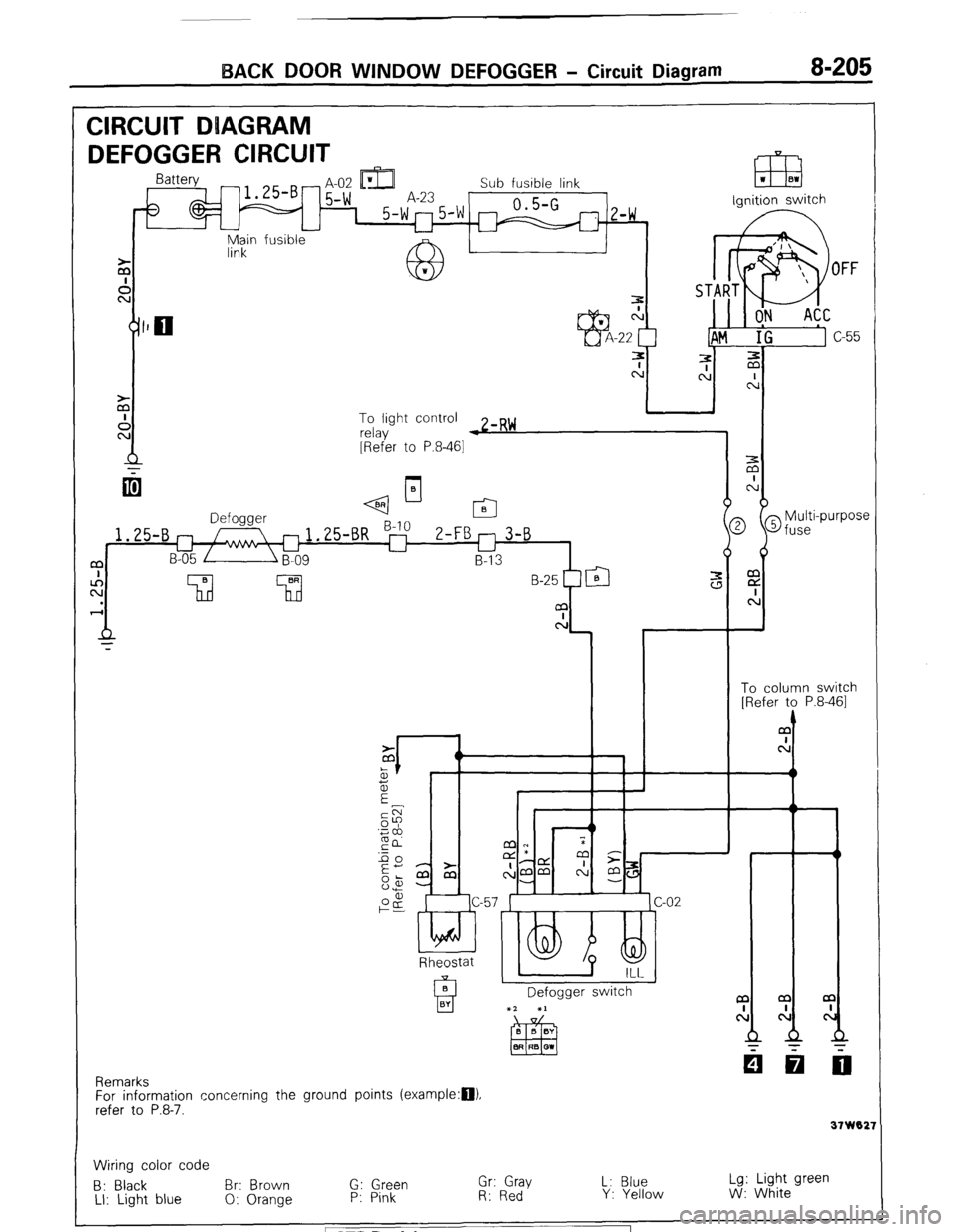

BACK DOOR WINDOW DEFOGGER - Circuit Diagram 8-205

CIRCUIT DUAGRAM

DEFOGGER CIRCUIT -t IDI L

m

- H-UL Ll&J Sub fusible link

5-w A-23 0.5-G 1 5-w"5'w m

z-w ,

u

fusible ignition switch

Main

link

To light control

relay w zmR~

[Refer to P.8-461

q--l-

2 @fuse

i

Multi-purpose m

E

c:

t

To column switch

[Refer to P.8-461

1.25-B

a

c!

Rheostat

Defogger switch a

cl

31 W02:

Remarks

For information concerning the ground points (example:D).

refer to P.8-7.

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White STB Revision

Page 234 of 284

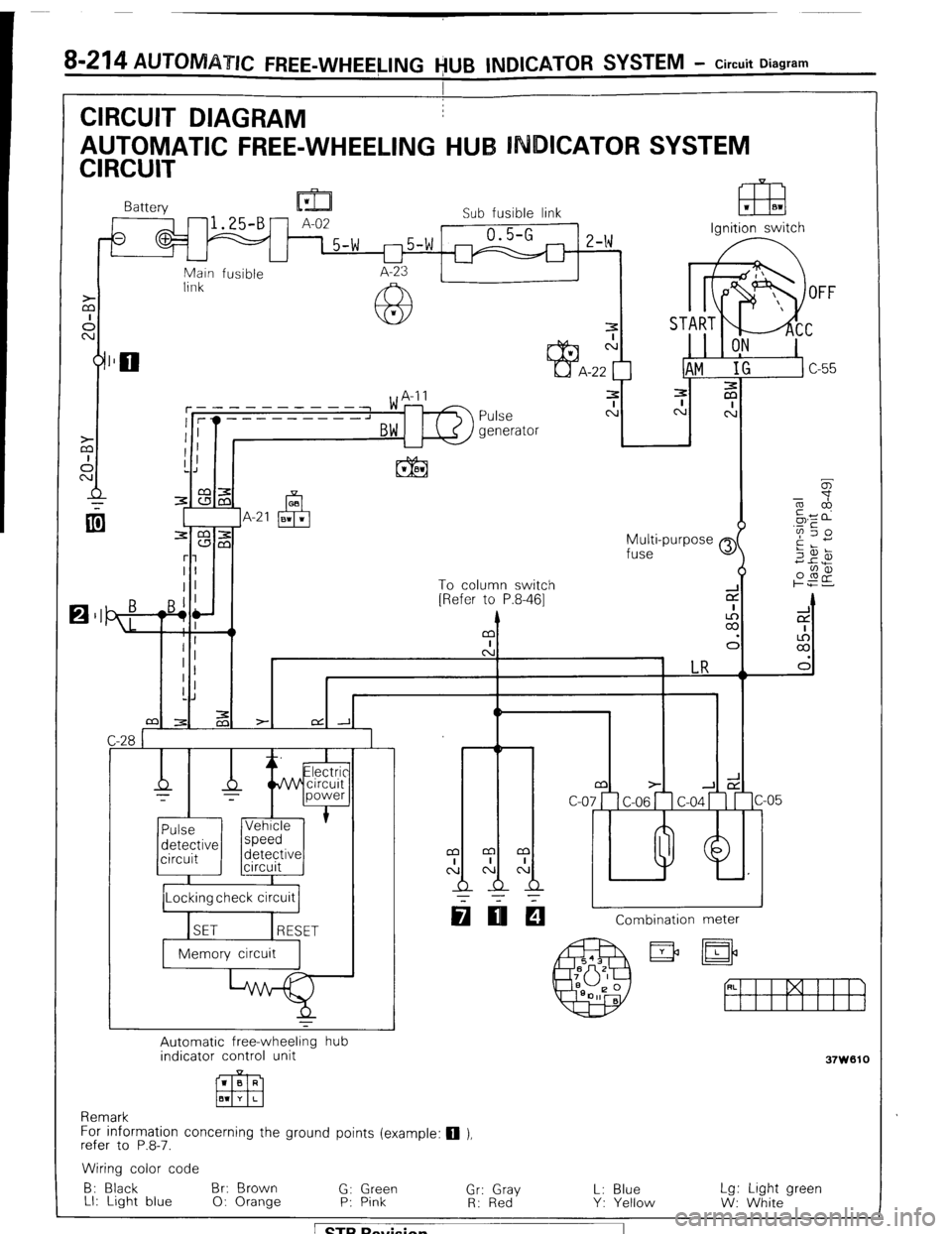

8-214 AUTOM TIC FREE-WHEELING VU6 INDICATOR SYSTEM - Circuit Diagram

I

m I IA-21 m

v?~

r:

BI I To column switch

2

[Refer to P.8-461 CT

= 9’i A I

I

m z

I ’

c: d

I ’

LR

!J

I I 1

CIRCUIT DIAGRAM

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM

CIRCUIT

F==e=%

Battery lu-!

A-02 Sub fusible link

- 15-w r-)5-w 0.5-G

2-w

I I I I

Main fusible

link

7

N

-22

3

Pulse c:

generator

h Ignition switch

I /Locking check circuit 1

q IIEI Combination meter

Automatic free-wheeling hub

indicator control unit

1 B R

Em El1 Y L

Remark

For information concerning the ground points (example: q ),

refer to P.8-7.

37W610

Wiring color code

B: Black Br: Brown

G: Green L: Blue

LI: Light blue Lg: Light green

0: Orange P: Pink “,r: RG,‘d”Y

Y: Yellow

W: White

1 STB Revision

Page 240 of 284

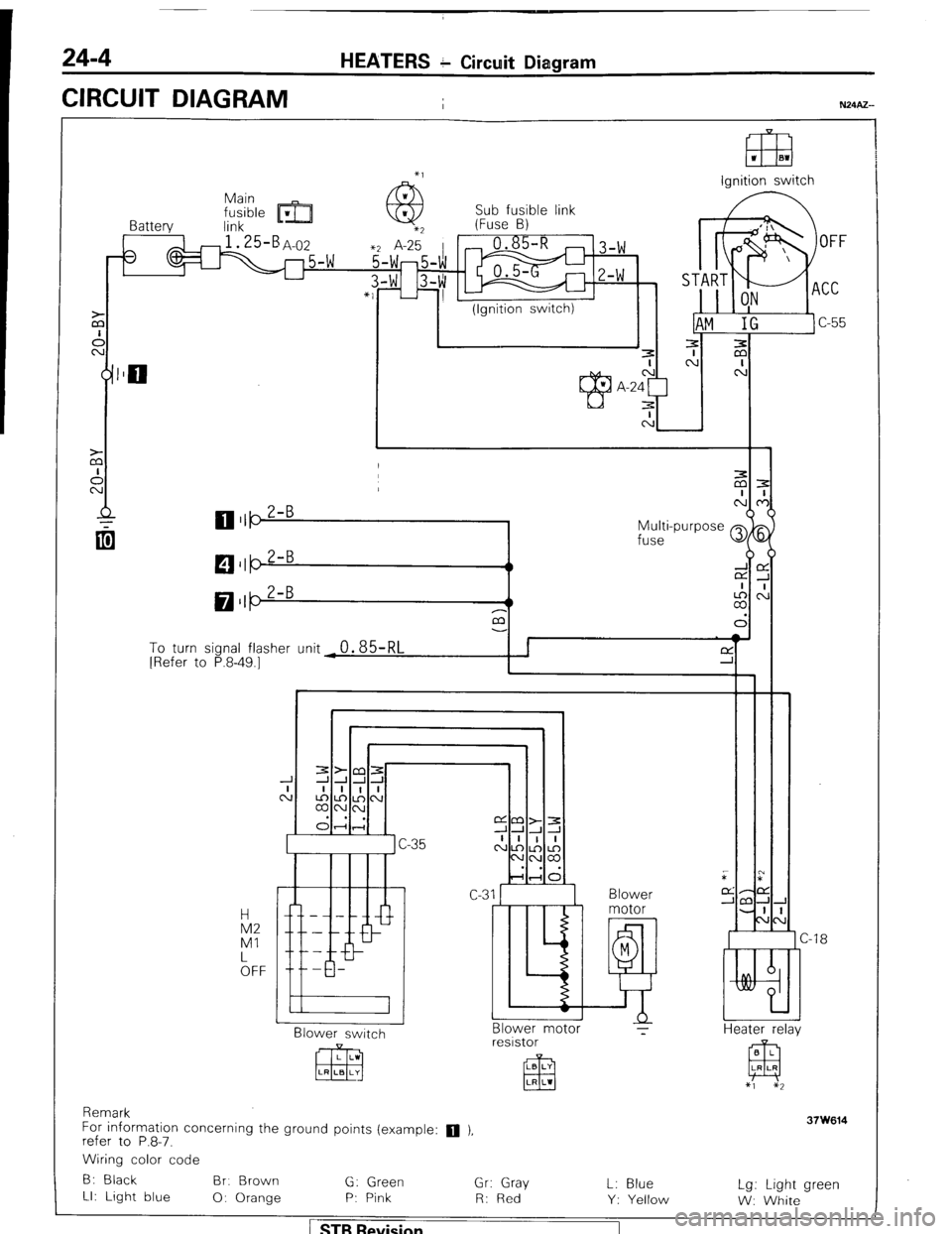

24-4 HEATERS c Circuit Diagram

CIRCUIT DIAGRAM

I

El3 1 El1

lanition switch

Sub fusible link

Battery link m- (Fuse B)

3

1 I (Ignition switch)

Multi-purpose Q

fuse

M $5

LA,:

a3

To turn sional flasher (Init

0.85RI I I f-Y ’ I [Refer to P.8-49.7- - - ‘d -r i

I Blower

Blower switch

CJ -18

Heater r&v Blower motor ?

resistor

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7.

Wiring color code

B: Black Br. Brown

G: Green

Gr: Gray

LI: Light blue

0: Orange P: Pink

R: Red L: Blue

Y: Yellow Lg: Light green

W: White

1 STB Revision

Page 245 of 284

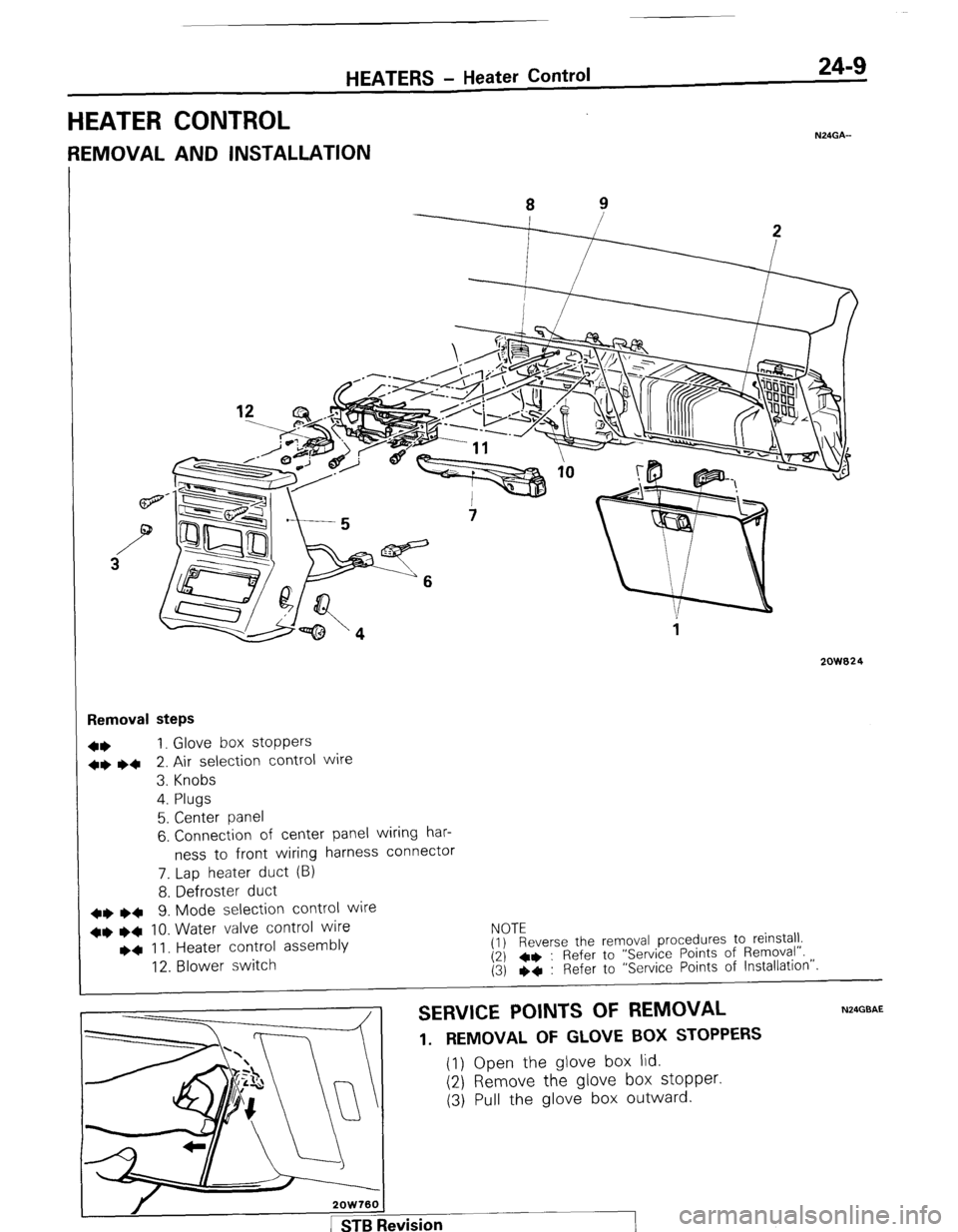

HEATERS - Heater Control 24-9

HEATER CONTROL

N24GA-

REMOVAL AND INSTALLATION

2QW824

Removal steps

4+ 1. Glove box stoppers

++ ~~ 2. Air selection control wire

3. Knobs

4. Plugs

5. Center panel

6. Connection of center panel wiring har-

ness to front wiring harness connector

7. Lap heater duct (B)

8. Defroster duct

++

l + 9. Mode selection control wire

++

l + 10. Water valve control wire

l a II. Heater control assembly

12. Blower switch EyTEeverse the removal procedures to reinstall.

(2) 4+ : Refer to “Service Points of Removal”.

(3) eq : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL N24GBAE

1. REMOVAL OF GLOVE BOX STOPPERS (1) Open the glove box lid.

(2) Remove the glove box stopper. (3) Pull the glove box outward.

Page 251 of 284

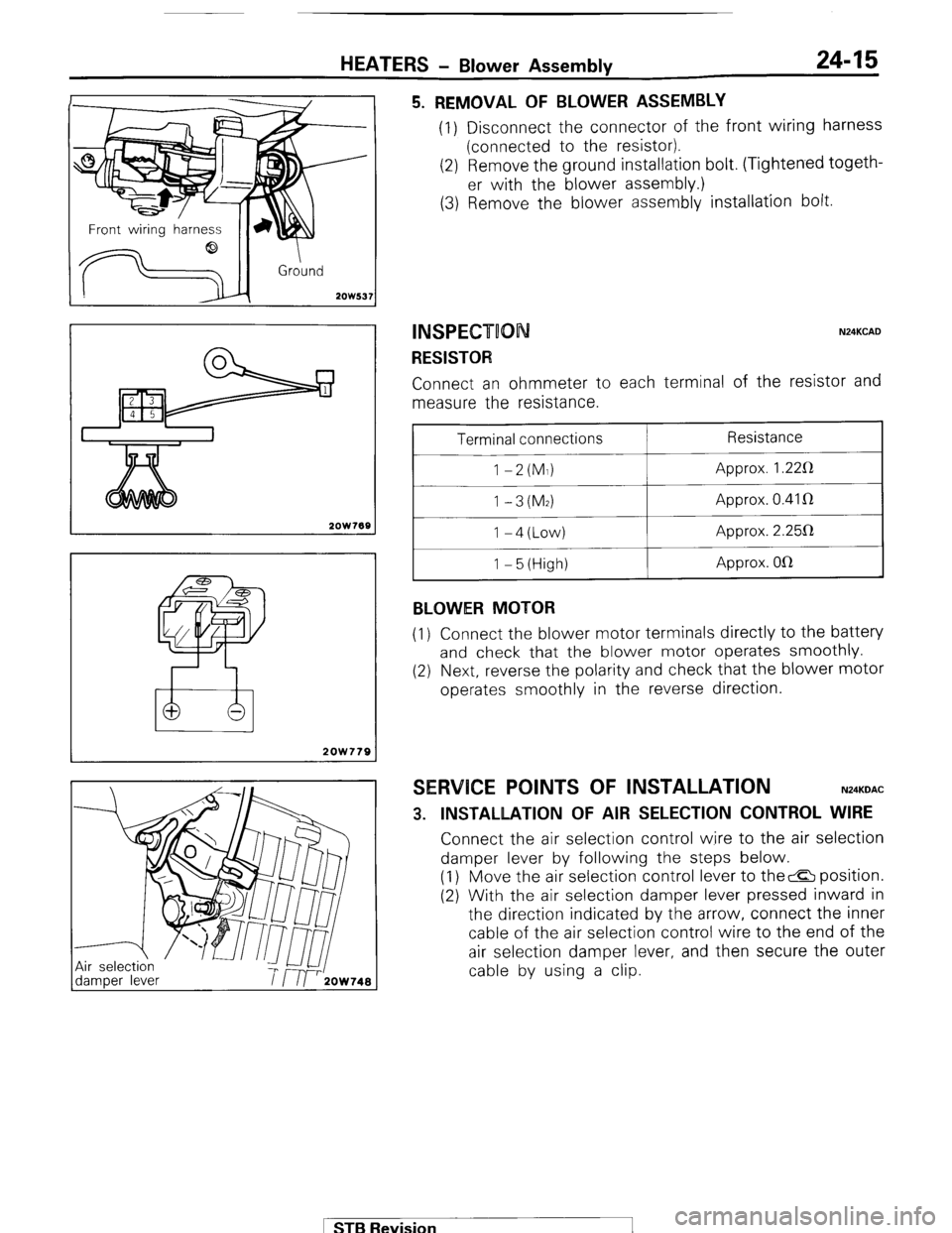

HEATERS - Blower Assembly 24-15

--I

Front wirina harness

d

!

2OW537

2OW768

2OW779

5. REMOVAL OF BLOWER ASSEMBLY (1) Disconnect the connector of the front wiring harness

(connected to the resistor).

(2) Remove the ground installation bolt. (Tightened togeth-

er with the blower assembly.)

(3) Remove the blower assembly installation bolt.

INSPECT00 N24KCAD

RESISTOR Connect an ohmmeter to each terminal of the resistor and

measure the resistance.

Terminal connections

1 -2(M1)

1 -3(M2) I-4(Low)

1 - 5 (High)

BLOWER MOTOR Resistance

Approx. 1.22R

Approx. 0.41 R

Approx. 2.25112

Approx. OlR

(1) Connect the blower motor terminals directly to the battery

and check that the blower motor operates smoothly.

(2) Next, reverse the polarity and check that the blower motor

operates smoothly in the reverse direction.

SERVICE POINTS OF INSTALLATION N24KDAC

3. INSTALLATION OF AIR SELECTION CONTROL WIRE Connect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the& position.

(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection damper lever, and then secure the outer

cable by using a clip.

1 STB Revision

Page 262 of 284

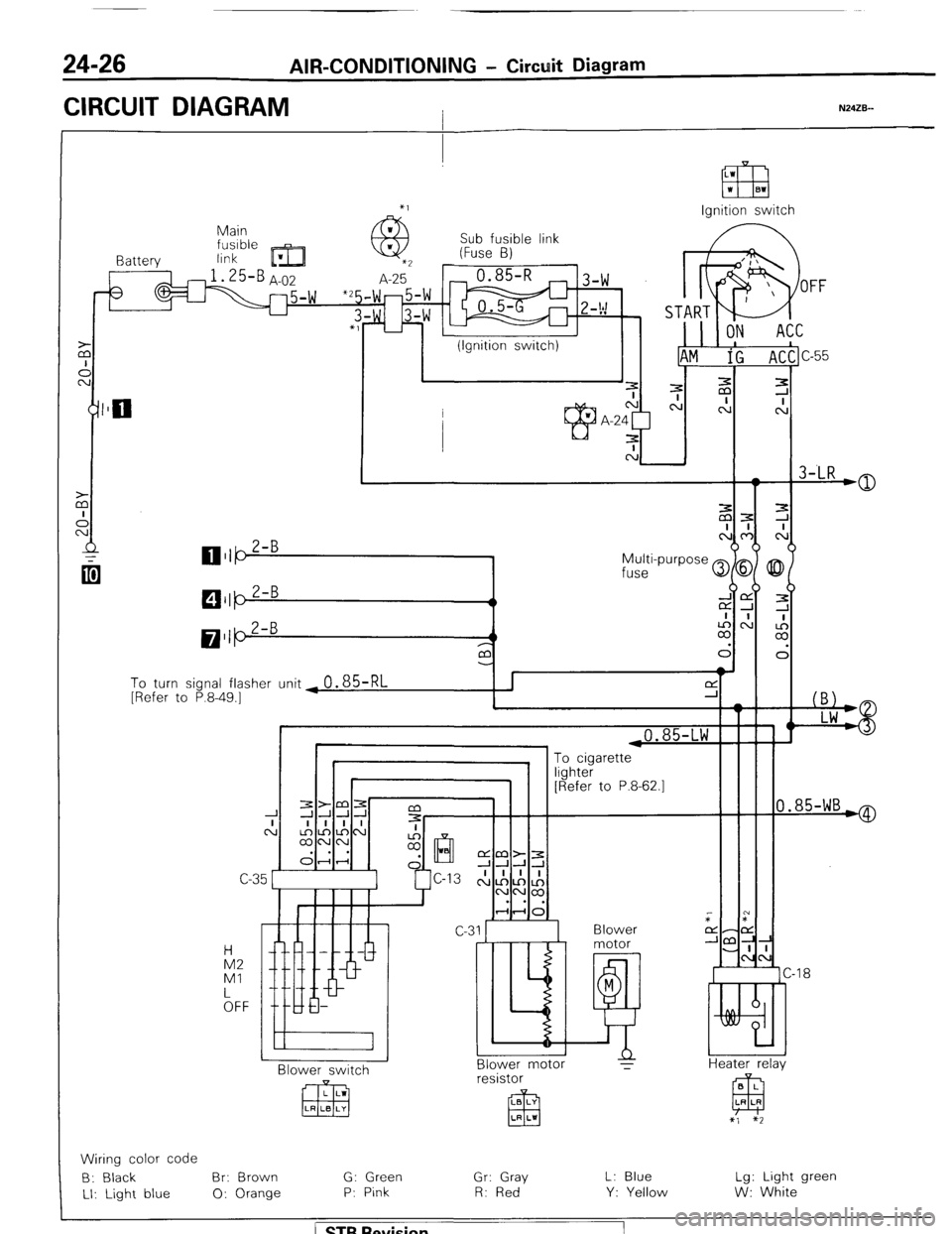

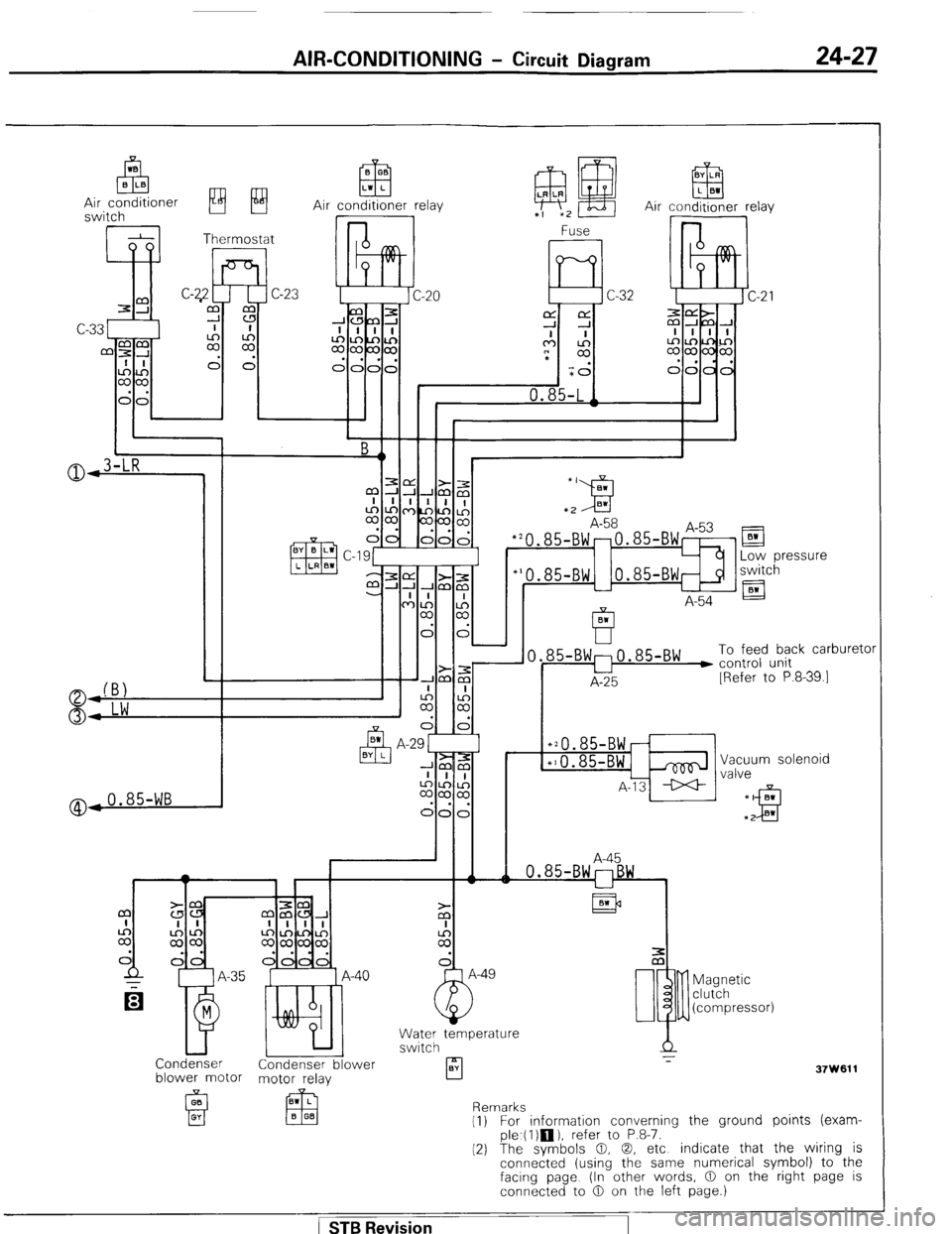

24-26 AIR-CONDITIONING - Circuit Diagram

CIRCUIT DIAGRAM I N24ZB--

Ignition switch

Main

link Sub fusible link

(Fuse B)

I Battery

3

To turn signal flasher unit ~

0.85-RL [Refer to P.8-49.1

i

I 1 ,0.85-LW F

0.85-WB*

“yl lLG1 [Refer to P.8-62.1

C-C

Blower

motor

M

E!! Blower motor

T IA2

Ml

kFF -18

Heater relav N BI ower switch B L

EEJ LR LR resistor

LB LY

El3 LR LI

x’, $2

Wiring color code

B: Black Br: Brown G: Green

Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red

Y: Yellow W: White

/ ST6 Revision

Page 263 of 284

AIR-CONDITIONING - Circuit Diagram 24-27

Air conditioner relay

@,0.85-WB

El

Low pressure

switch

A-54 El

85-BW:0.85-BW ) To feed back carburetc

u control unit

A-25 [Refer to P.8-39.1

*20.85-BWr

*10.85-BWi& Vacuum solenoid

A-13 ++ valve

A-45

Condenser Condenser blower

blower motor motor relay

A

rl z-

BY

37W611 Magnetic

clutch

(compressor)

Remarks

(1) For information converning the ground points (exam-

ple.(l)m), refer to P.8-7.

(2) The symbols 0, 0, etc indicate that the wiring is

connected (using the same numerical symbol) to the

facing page (In other words, 0 on the right page is

connected to 0 on the left page.)

( STB Revision

Page 267 of 284

AIR-CONDITIONING-Service Adiustment Procedures 24-31

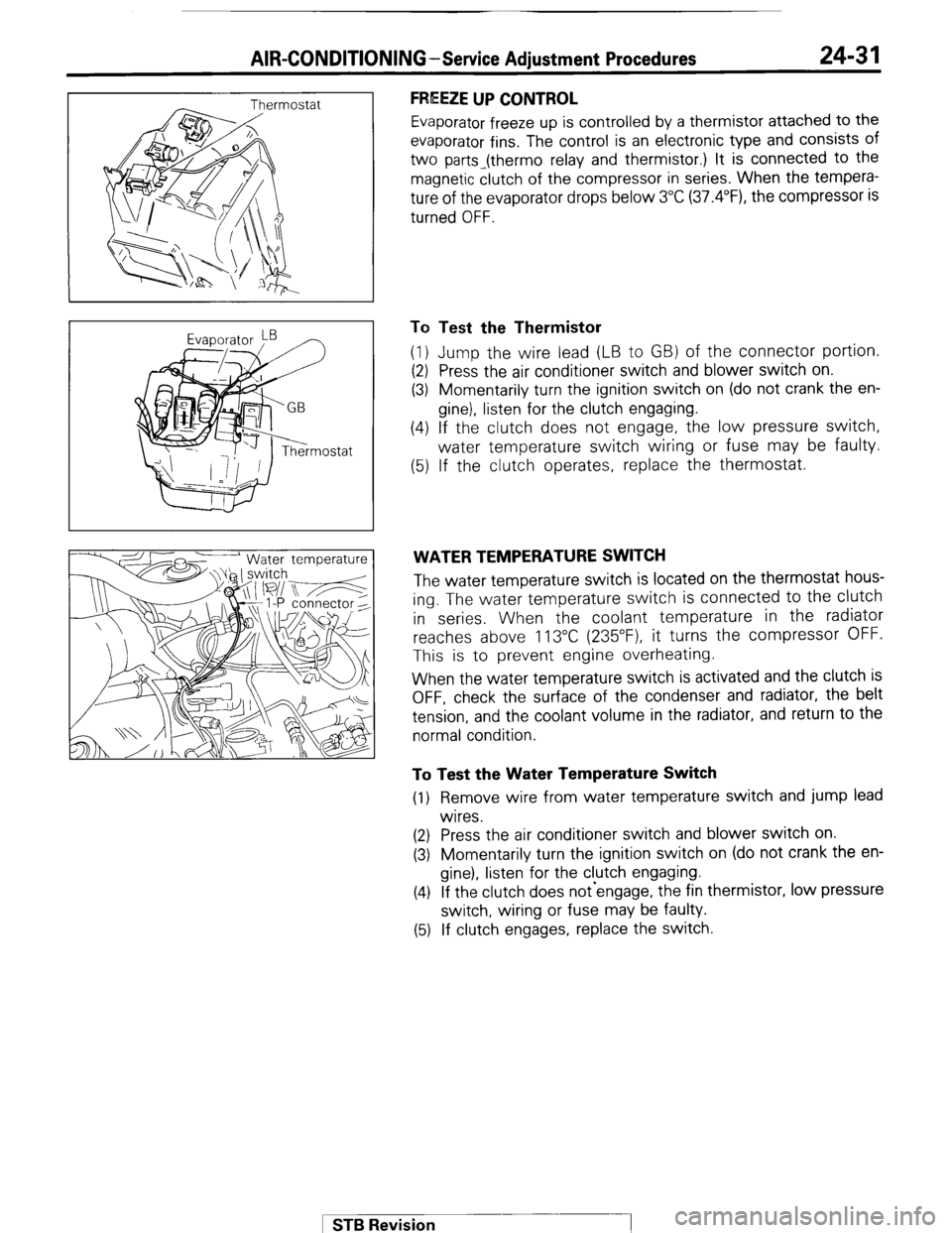

FREEZE UP CONTROL

Evaporator freeze up is controlled by a thermistor attached to the

evaporator fins. The control is an electronic type and consists of

two parts_(thermo relay and thermistor.) It is connected to the

magnetic clutch of the compressor in series. When the tempera-

ture of the evaporator drops below 3°C (37.4”F), the compressor is

turned OFF.

To Test the Thermistor

(1) Jump the wire lead (LB to GB) of the connector portion.

(2) Press the air conditioner switch and blower switch on.

(3) Momentarily turn the ignition switch on (do not crank the en-

gine), listen for the clutch engaging.

(4) If the clutch does not engage, the low pressure switch,

water temperature switch wiring or fuse may be faulty.

(5) If the clutch operates, replace the thermostat.

WATER TEMPERATURE SWITCH

The water temperature switch is located on the thermostat hous-

ing. The water temperature switch is connected to the clutch

in series. When the coolant temperature in the radiator

reaches above 113°C (235”F), it turns the compressor OFF.

This is to prevent engine overheating.

When the water temperature switch is activated and the clutch is

OFF, check the surface of the condenser and radiator, the belt

tension, and the coolant volume in the radiator, and return to the

normal condition.

To Test the Water Temperature Switch

(1) Remove wire from water temperature switch and jump lead

wires.

(2) Press the air conditioner switch and blower switch on.

(3) Momentarily turn the ignition switch on (do not crank the en-

gine), listen for the clutch engaging.

(4) If the clutch does not-engage, the fin thermistor, low pressure

switch, wiring or fuse may be faulty.

(5) If clutch engages, replace the switch.

1 STB Revision