air filter MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 113 of 284

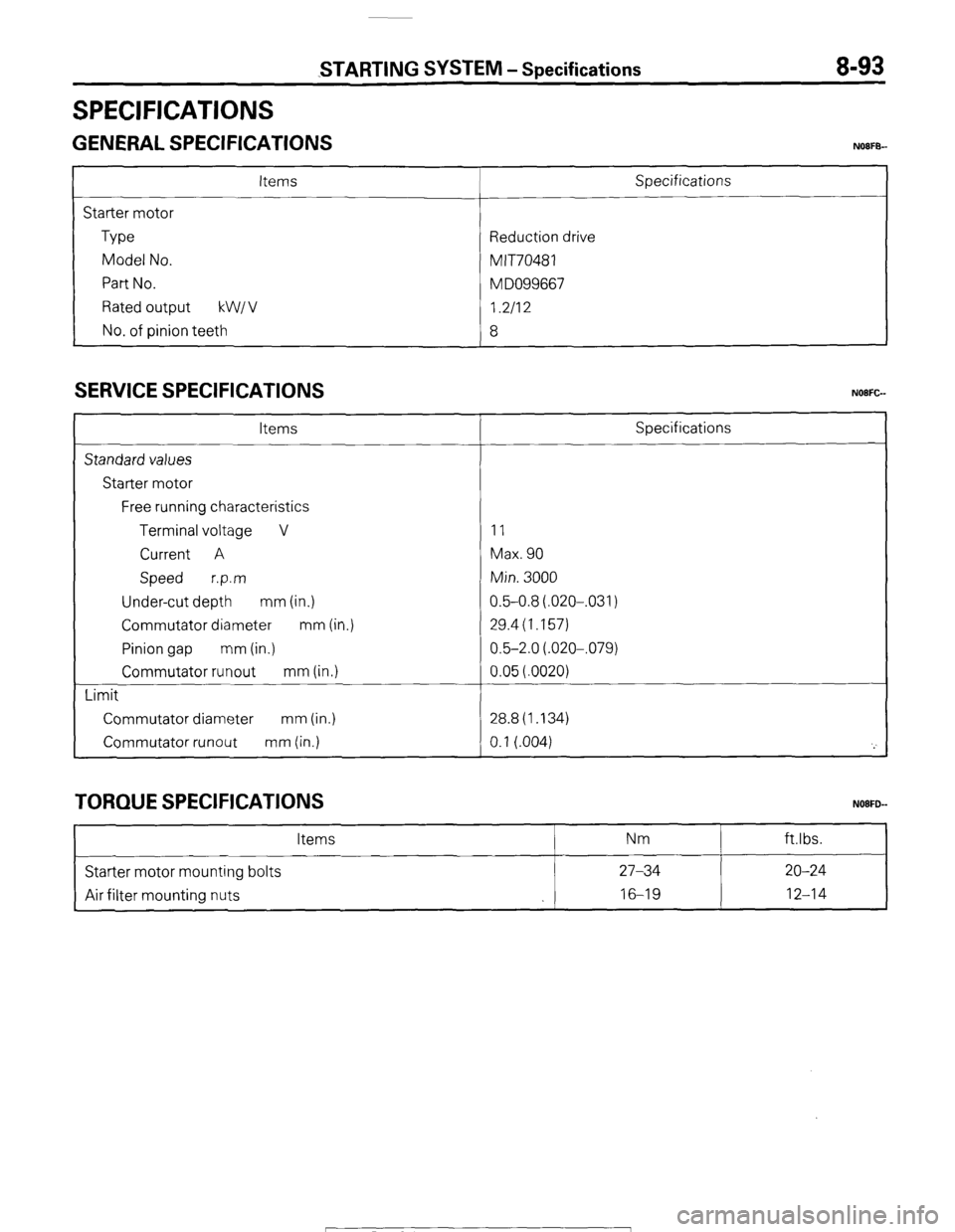

SPECIFICATIONS

STARTING SYSTEM - Specifications 8-93

GENERAL SPECIFICATIONS NOIFB-

Items

Starter motor

Type

Model No.

Part No.

Rated output kW1 v

No. of pinion teeth Specifications

Reduction drive

MIT70481

M DO99667

I.2112

8

SERVICE SPECIFICATIONS

Items

Standard values

Starter motor

Free running characteristics

Terminal voltage V

Current A

Speed r.p.m

Under-cut depth mm (in.)

Commutator diameter mm (in.)

Pinion gap mm (in.)

Commutator runout mm (in.)

Limit

Commutator diameter mm (in.)

Commutator runout mm (in.) Specifications

11

Max. 90

Min. 3000

0.5-0.8(.020-,031)

29.4(1.157)

0.5-2.0(.020-,079)

0.05(.0020)

28.8(1.134)

0.1 (.004)

'_'

TORQUE SPECIFICATIONS

Items Nm ftlbs.

Starter motor mounting bolts 27-34 20-24

Air filter mounting nuts 16-19

12-14

1 STB Revision

Page 117 of 284

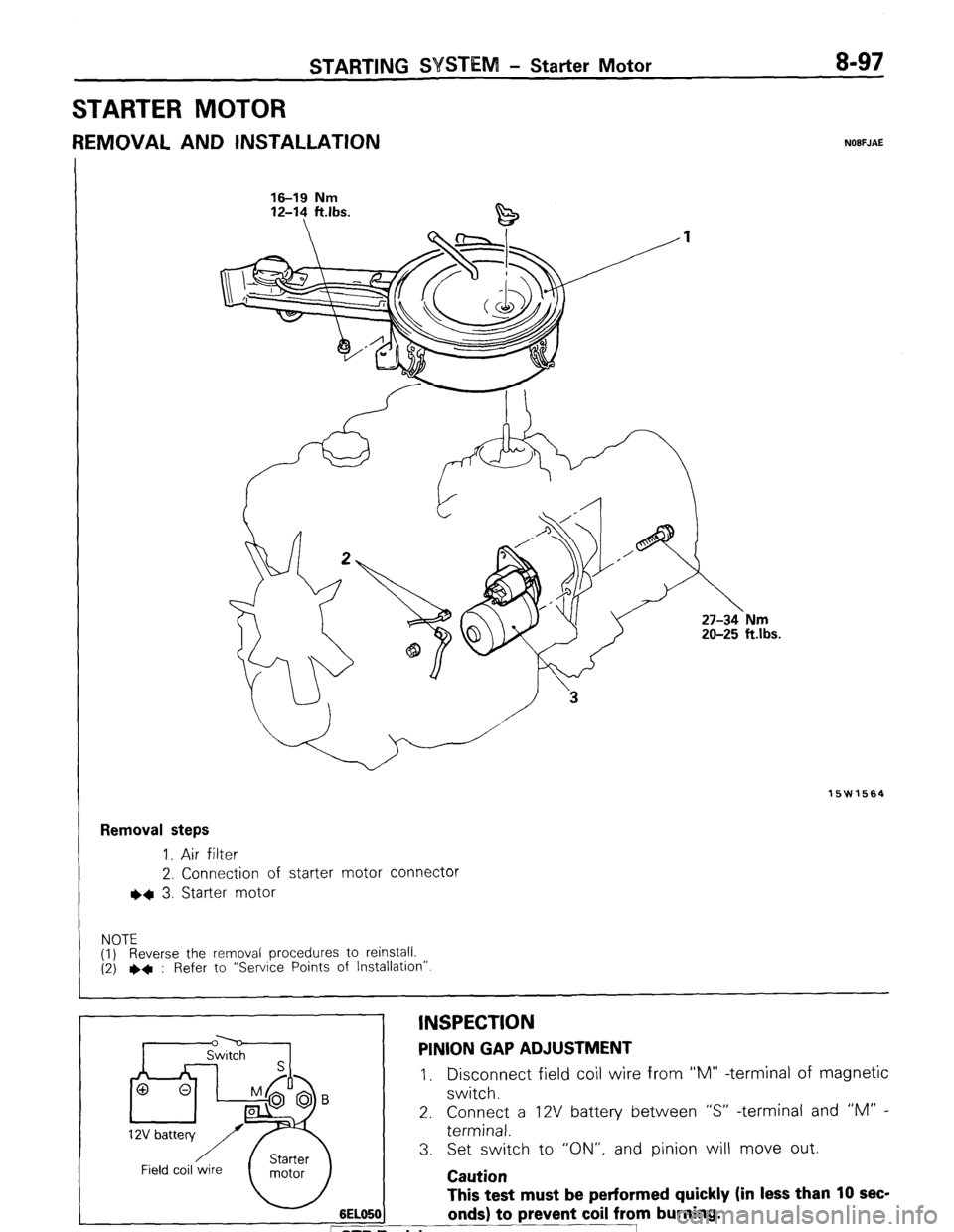

STARTING WSTEM - Starter Motor 8-97

STARTER MOTOR

REMOVAL AND INSTALLATION NOBFJAE

16-19 Nm 16-19 Nm

12-l? ft.lbs. 12-14 ft.lbs.

15W1564

Removal steps

1. Air filter

2. Connection of starter motor connector

l * 3. Starter motor

NOTE

(1) Reverse the removal procedures to reinstall.

(2) ++ : Refer to “Service Points of Installation”

6EL05( This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning. D Revision

INSPECTION PINION GAP ADJUSTMENT

I, Disconnect field coil wire from “M” -terminal of magnetic

switch.

2. Connect a 12V battery between “S” -terminal and “M” -

terminal.

3. Set switch to “ON”, and pinion will move out.

Caution

Page 244 of 284

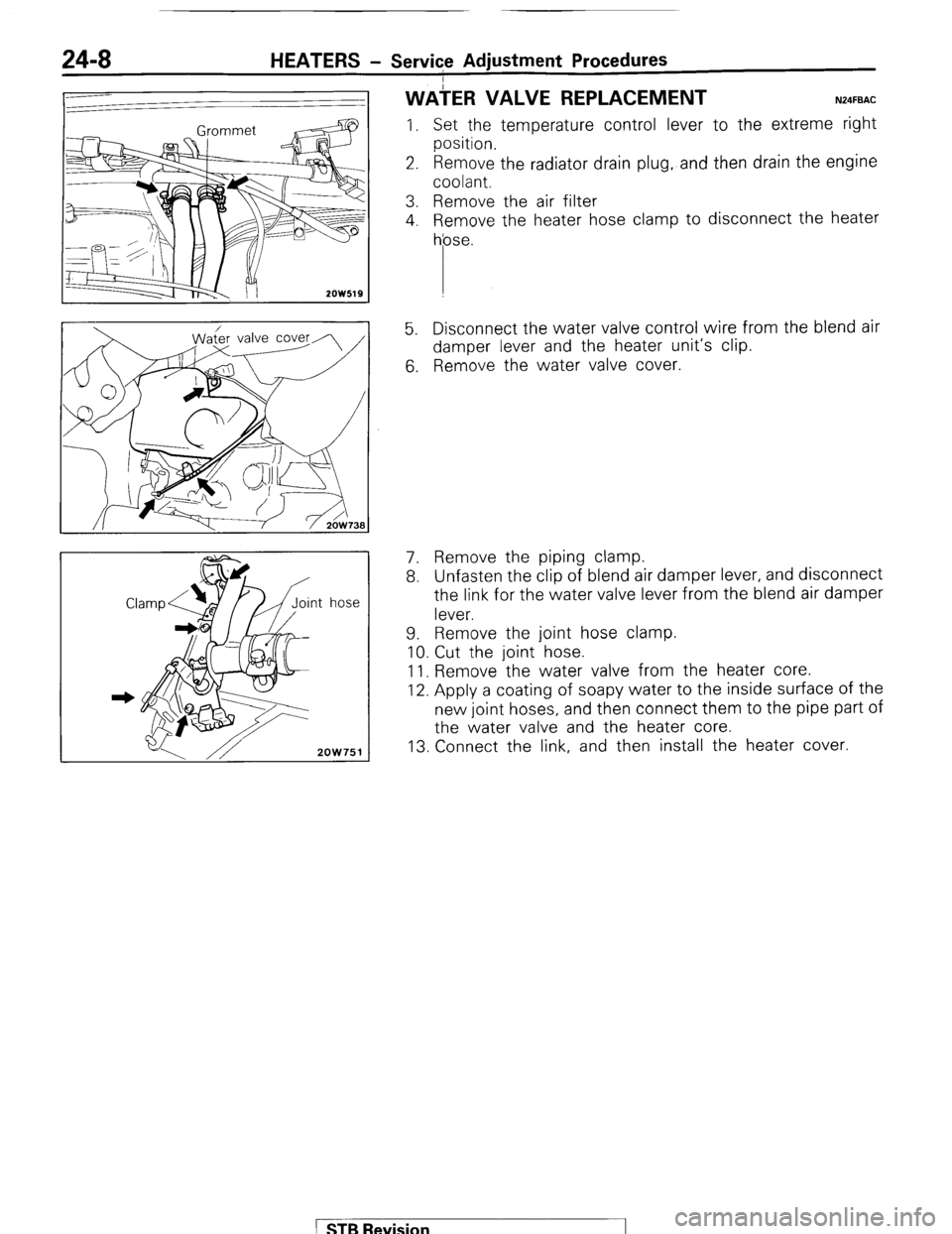

24-8 HEATERS - Service Adjustment Procedures

ater valve cover

2OW751

WAiER VALVE REPLACEMENT N24FBAC

I. Set the temperature control lever to the extreme right

position.

2. Remove the radiator drain plug, and then drain the engine

coolant.

3. Remove the air filter

4. Remove the heater hose clamp to disconnect the heater

hose.

5. Disconnect the water valve control wire from the blend air

damper lever and the heater unit’s clip.

6. Remove the water valve cover.

7. Remove the piping clamp.

8. Unfasten the clip of blend air damper lever, and disconnect

the link for the water valve lever from the blend air damper

lever.

9. Remove the joint hose clamp.

10. Cut the joint hose.

11. Remove the water valve from the heater core.

12. Apply a coating of soapy water to the inside surface of the

new joint hoses, and then connect them to the pipe part of

the water valve and the heater core.

13. Connect the link, and then install the heater cover.

1 STB Revision

Page 248 of 284

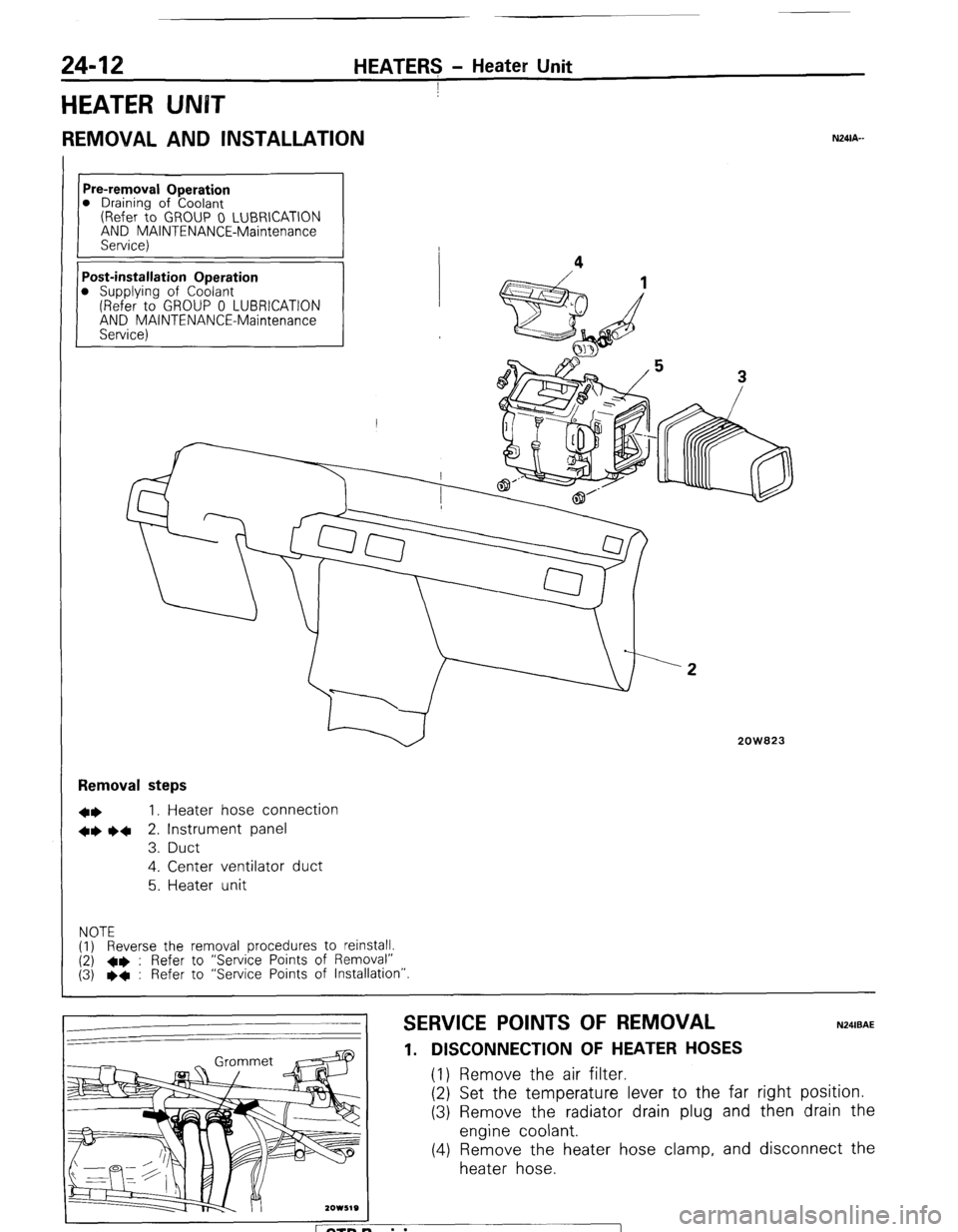

24-12 HEATERS - Heater Unit

I

HEATER UNBT

REMOVAL AND INSTALLATION

Pre-removal Operation

0 Draining of Coolant

(Refer to GROUP 0 LUBRICATION

AND MAINTENANCE-Maintenance

Service)

Post-installation Operation

0 Supplying of Coolant

(Refer to GROUP 0 LUBRICATION

AND MAINTENANCE-Maintenance

Service) Removal steps

l *

I, Heater hose connection

+* l 4

2. Instrument panel

3. Duct

4. Center ventilator duct

5. Heater unit

NOTE

(1) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”

(3) l

+ : Refer to “Service Points of Installation”

2OW823

SERVICE POINTS OF REMOVAL

1. DISCONNECTION OF HEATER HOSES (1) Remove the air filter.

(2) Set the temperature lever to the far

(3) Remove the radiator drain plug and

engine coolant.

(4) Remove the heater hose clamp, and

heater hose.

N24lBAE right position.

then drain the

disconnect the

ETB Revision

Page 270 of 284

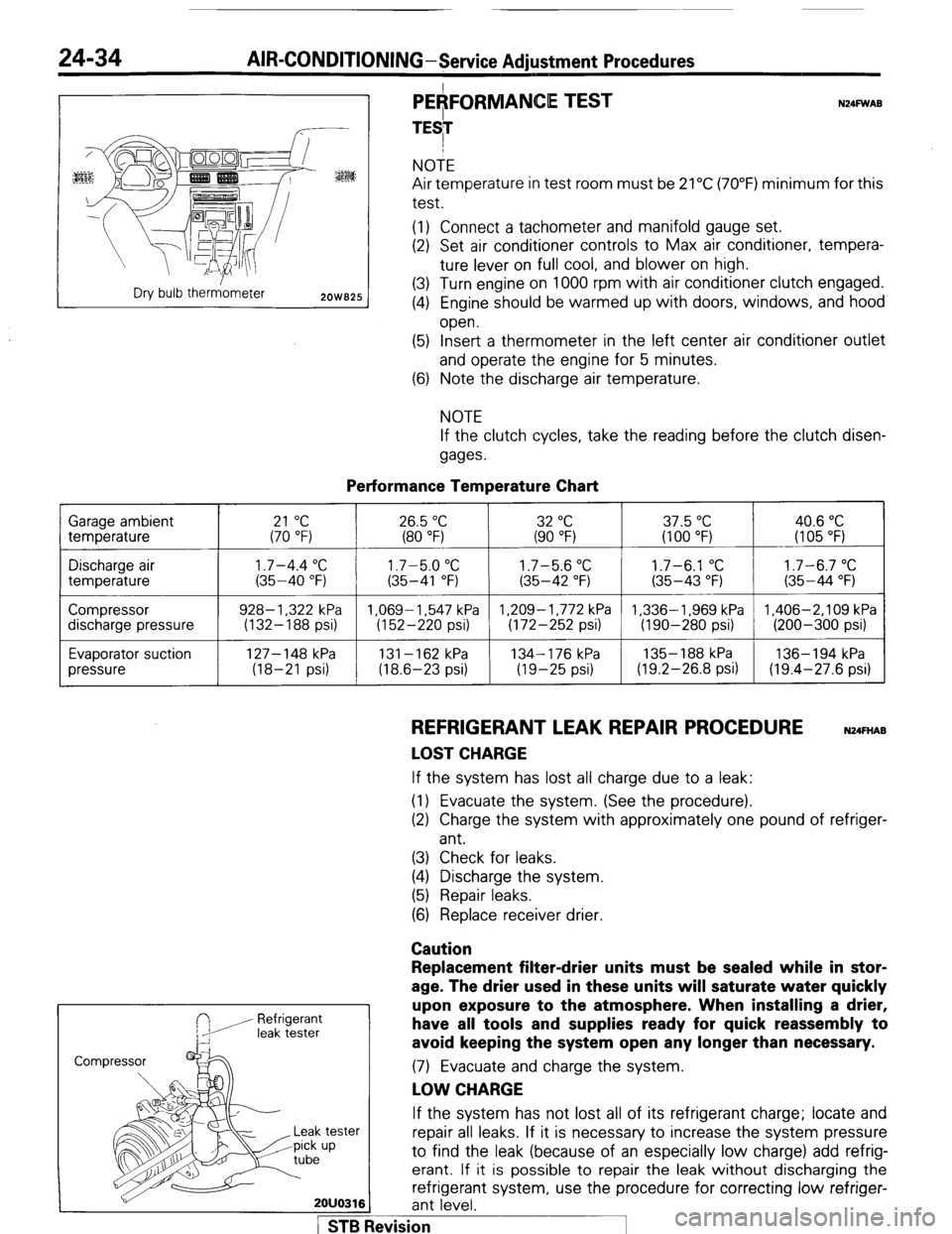

24-34 AIR-CONDITIONING-Service Adiustment Procedures

r---- :

:ES

Dry bulb therr&neter

2OW825

PEAFORMANCE TEST

TESI N24FWAB NOTE

Air temperature in test room must be 21°C (70°F) minimum for this

test.

(1) Connect a tachometer and manifold gauge set.

(2) Set air conditioner controls to Max air conditioner, tempera-

ture lever on full cool, and blower on high.

(3) Turn engine on 1000 rpm with air conditioner clutch engaged.

(4) Engine should be warmed up with doors, windows, and hood

open.

(5) Insert a thermometer in the left center air conditioner outlet

and operate the engine for 5 minutes.

(6) Note the discharge air temperature.

NOTE

If the clutch cycles, take the reading before the clutch disen-

gages.

Performance Temperature Chart Garage ambient

temperature

21 “C 26.5 “C 32 “C 37.5 “C 40.6 “C (70 “F) (80 “F) (90 “F) (100 “F) (I 05 “F)

Discharge air

temperature

Compressor

discharge pressure

Evaporator suction

pressure

1.7-4.4 “C 1.7-5.0 “C 1.7-5.6 “C 1.7-6.1 “C 1.7-6.7 “C (35-40 “F) (35-41 “F) (35-42 “F) (35-43 “F) (35-44 “F)

928- 1,322 kPa 1.069-1.547 kPa 1,209-1,772 kPa 1,336-1,969 kPa 1,406-2,109 kPa

(132-188 psi) (152-220 psi) (172-252 psi) (190-280 psi) (200-300 psi)

127-148 kPa

131-162 kPa 134-176 kPa 135- 188 kPa 136-194 kPa

(18-21 psi) (18.6-23 psi) (19-25 psi) (19.2-26.8 psi) (19.4-27.6 psi)

REFRIGERANT LEAK REPAIR PROCEDURE N24FnAB

LOST CHARGE If the system has lost all charge due to a leak:

(1) Evacuate the system. (See the procedure).

(2) Charge the system with approximately one pound of refriger-

ant.

(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Refrigerant

leak tester

Replacement filter-drier units must be sealed while in stor-

age. The drier used in these units will saturate water quickly

upon exposure to the atmosphere. When installing a drier,

have all tools and supplies ready for quick reassembly to

avoid keeping the system open any longer than necessary. (7) Evacuate and charge the system.

LOW CHARGE If the system has not lost all of its refrigerant charge; locate and

tester repair all leaks. If it is necessary to increase the system pressure

up to find the leak (because of an especially low charge) add refrig-

erant. If it is possible to repair the leak without discharging the

refrigerant system, use the procedure for correcting low refriger-

2OUO316 ant level.

1 STB Revision