Turn signal MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 90 of 284

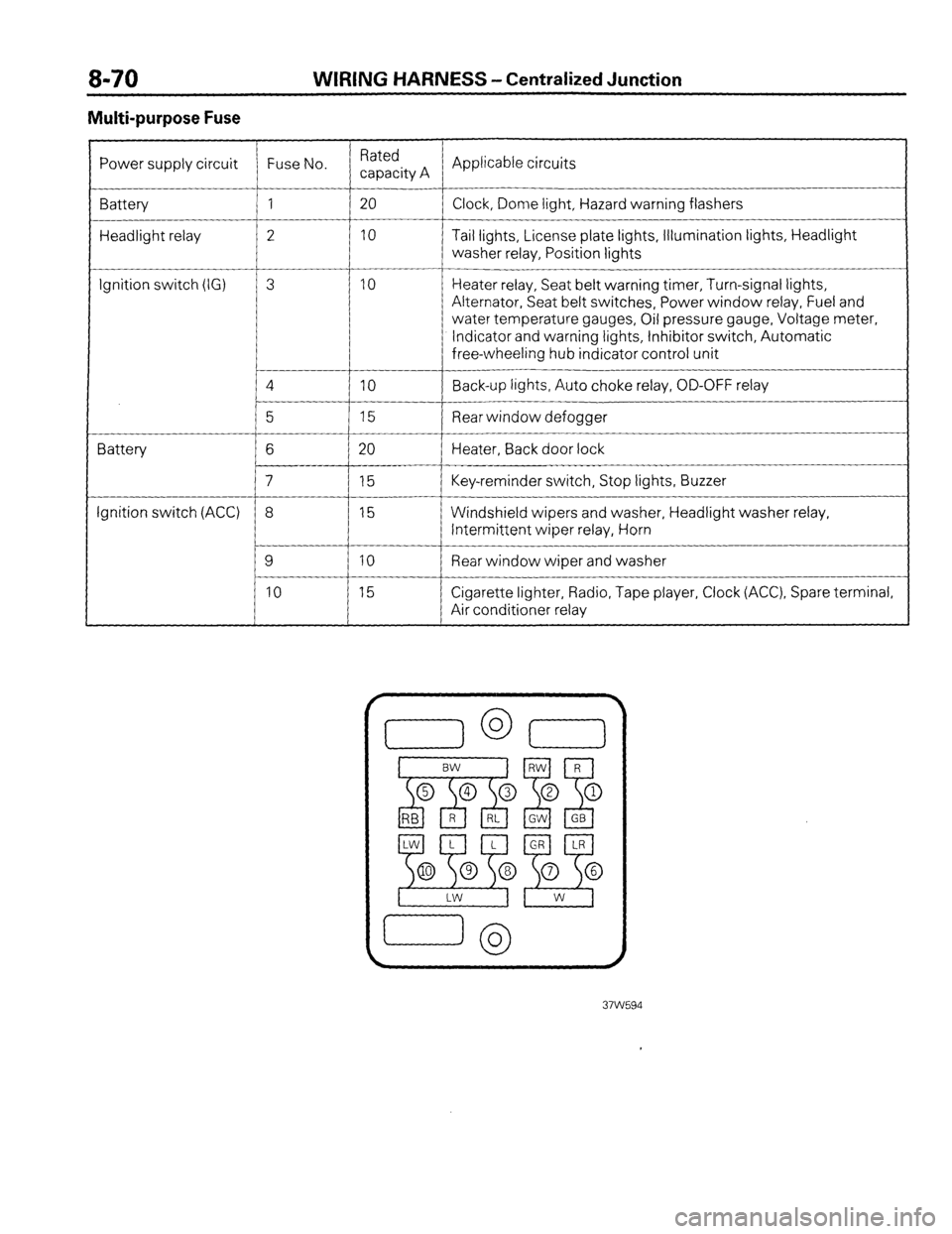

WIRING HARNESS - Centralized Junction

Multi-purpose Fuse

Power supply circuit Fuse No. Rated

capacity A Applicable circuits

Battery 1 20

Clock, Dome light, Hazard warning flashers

Headlight relay 2 10 Tail lights, License plate lights, Illumination lights, Headlight

washer relay, Position lights

__-

Ignition switch (IG) 3 10 Heater relay, Seat belt warning timer, Turn-signal lights,

Alternator, Seat belt switches, Power window relay, Fuel and

water temperature gauges, Oil pressure gauge, Voltage meter,

Indicator and warning lights, Inhibitor switch, Automatic

free-wheeling hub indicator control unit

4

IO Back-up lights, Auto choke relay, OD-OFF relay

__-

5 15 Rear window defogger

Battery 6 20 Heater, Back door lock

7 15 Key-reminder switch, Stop lights, Buzzer

Ignition switch (ACC) 8 15 Windshield wipers and washer, Headlight washer relay,

Intermittent wiper relay, Horn

9 10 Rear window wiper and washer

10 15 Cigarette lighter, Radio, Tape player, Clock (ACC), Spare terminal,

Air conditioner relay

Page 96 of 284

![MITSUBISHI MONTERO 1987 1.G User Guide 8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A MITSUBISHI MONTERO 1987 1.G User Guide 8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A](/img/19/7559/w960_7559-95.png)

8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A m

A

To turn signal flasher

unit [Refer to P.8-49.1 Multi-

n, Irnn4P

ComSeter

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7. 37W605

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White

1 STB Revision

Page 101 of 284

CHARGING SYSTEM - Service Adjustment Procedures 8-81

(2) Upon completion of the test, set the engine speed at idle and

turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Remove the test voltmeter and ammeter and the engine ta-

chometer.

(5) Connect the alternator output wire to the alternator “B” ter-

minal.

(6) Connect the battery ground cable.

ll3Y1848 2. Remove battery from vehicle.

Caution

White

I Blue

I Care should be taken in the event battery case is cracked

or leaking to protect hands from the electrolyte. A suit-

able pair of rubber gloves (not the household type) should

be worn when removing battery by hand.

3. Inspect battery carrier for damage caused by loss of acid from

battery. If acid damage is present, it will be necessary to clean

area with a solution of clean warm water and baking soda.

Scrub area with a stiff bristle brush and wipe off with a cloth

moistened with ammonia or baking soda in water.

4. Clean top of battery with same solutions as described in Step

(3).

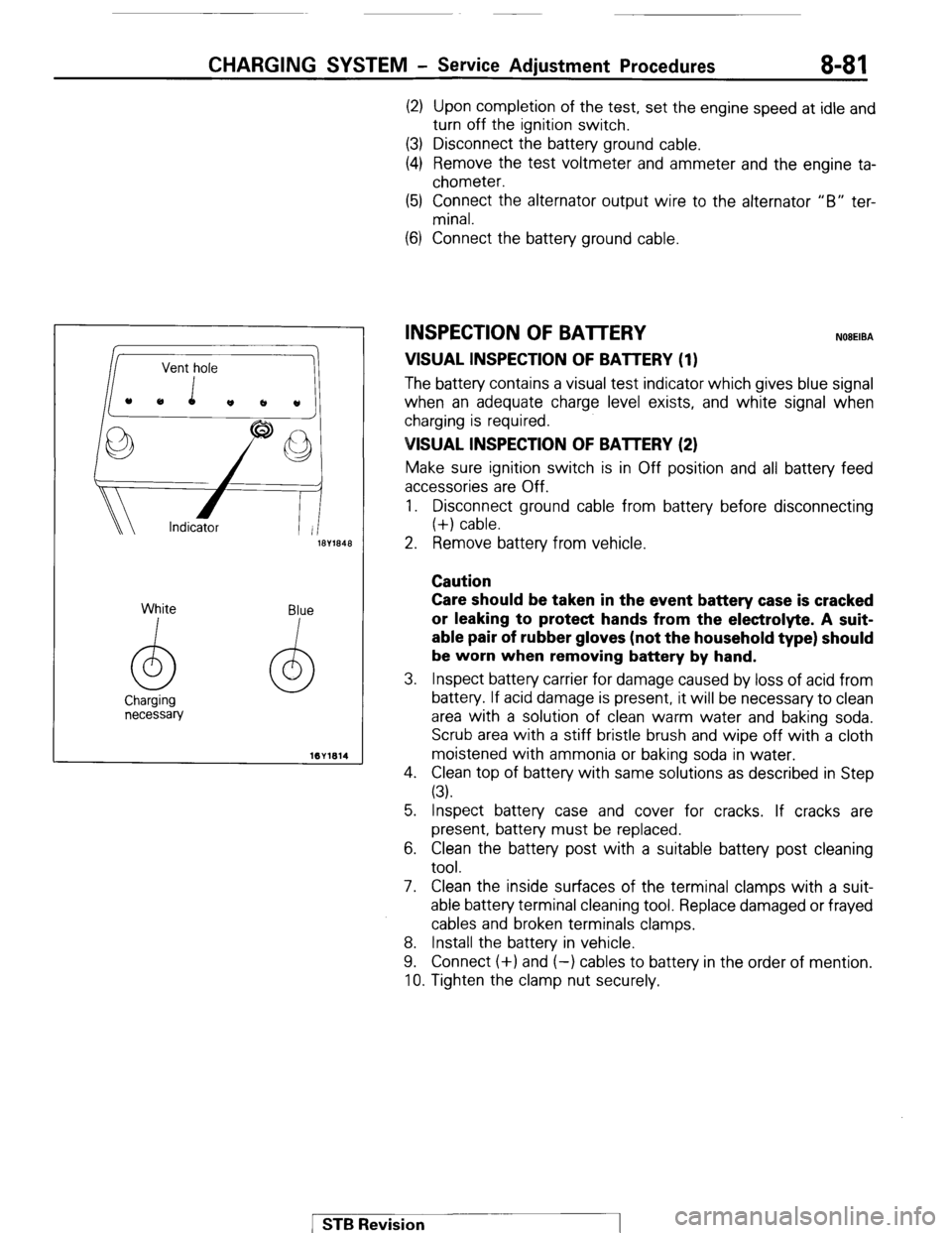

INSPECTION OF BATTERY NOBEIBA

VISUAL INSPECTION OF BATTERY (1)

The batten/ contains a visual test indicator which gives blue signal

when an adequate charge level exists, and white signal when

charging is required.

VISUAL INSPECTION OF BAlTERY (2)

Make sure ignition switch is in Off position and all battery feed

accessories are Off.

1. Disconnect ground cable from battery before disconnecting

(+) cable.

5. Inspect battery case and cover for cracks. If cracks are

present, battery must be replaced.

6. Clean the battery post with a suitable battery post cleaning

tool.

7. Clean the inside surfaces of the terminal clamps with a suit-

able battery terminal cleaning tool. Replace damaged or frayed

cables and broken terminals clamps.

8. Install the battery in vehicle.

9. Connect (+) and (-) cables to battery in the order of mention.

10. Tighten the clamp nut securely.

1 STB Revision

Page 133 of 284

IGNITION SYSTEM-Service Adjustment Procedures 8-113

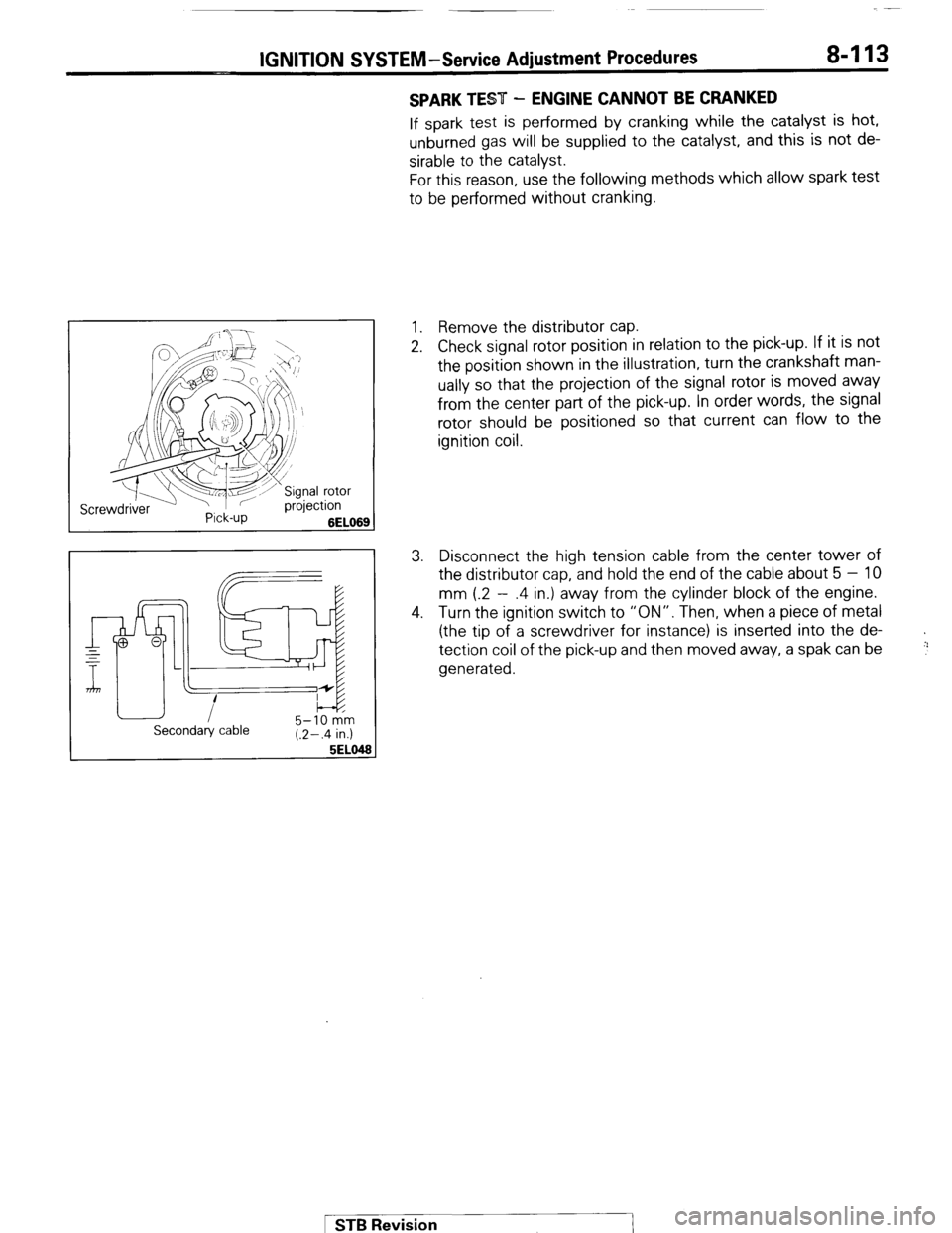

SPARK TEST - ENGINE CANNOT BE CRANKED

If spark test is performed by cranking while the catalyst is hot,

unburned gas will be supplied to the catalyst, and this is not de-

sirable to the catalyst.

For this reason, use the following methods which allow spark test

to be performed without cranking.

1. Remove the distributor cap.

2. Check signal rotor position in relation to the pick-up. If it is not

the position shown in the illustration, turn the crankshaft man-

ually so that the projection of the signal rotor is moved away

from the center part of the pick-up. In order words, the signal

rotor should be positioned so that current can flow to the

ignition coil.

3. Disconnect the high tension cable from the center tower of

the distributor cap, and hold the end of the cable about 5 - 10

mm (.2 - .4 in.) away from the cylinder block of the engine.

4. Turn the ignition switch to “ON”. Then, when a piece of metal

(the tip of a screwdriver for instance) is inserted into the de-

tection coil of the pick-up and then moved away, a spak can be

generated.

+

!:’

Secondary cable 5-10 km

(.2-.4 in.)

5EL0

1 STB Revision

Page 143 of 284

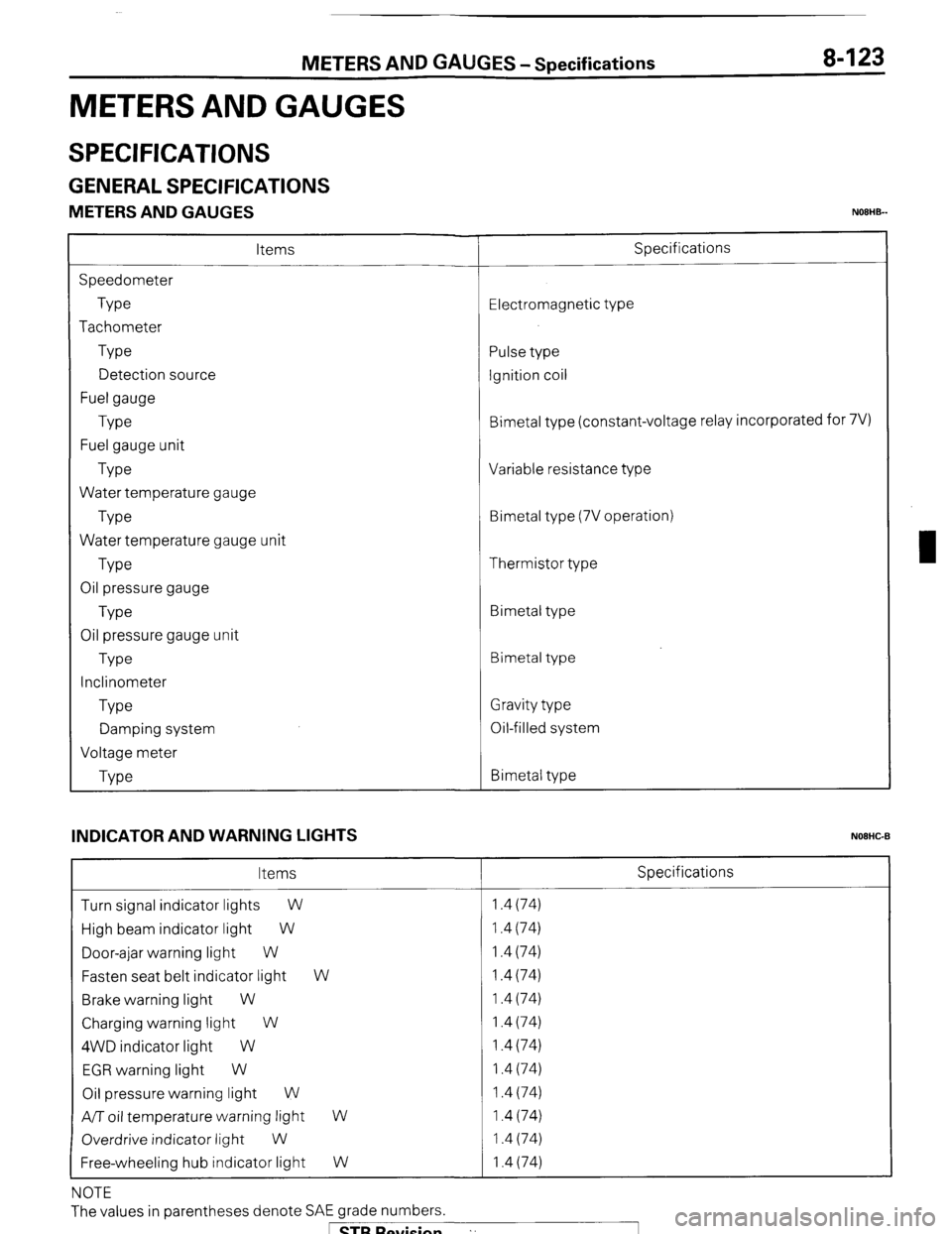

METERS AND GAUGES-Specifications

METERS AND GAUGES

8-123

SPECIFICATIONS

GENERAL SPECIFICATIONS

METERS AND GAUGES NOEHB-

Items

Speedometer

Type

Tachometer

Type

Detection source

Fuel gauge

Type

Fuel gauge unit

Type

Water temperature gauge

Type

Water temperature gauge unit

Type

Oil pressure gauge

Type

Oil pressure gauge unit

Type

Inclinometer

Type

Damping system

Voltage meter

Type Specifications

Electromagnetic type

Pulse type

Ignition coil

Bimetal type (constant-voltage relay incorporated for 7V)

Variable resistance type

Bimetal type (7V operation)

Thermistor type

Bimetal type

Bimetal type

Gravity type

Oil-filled system

Bimetal type

INDICATOR AND WARNING LIGHTS

NOEHC-B

Items Specifications

Turn signal indicator lights

W 1.4 (74)

High beam indicator light W 1.4 (74)

Door-ajar warning light W 1.4 (74)

Fasten seat belt indicator light W 1.4 (74)

Brake warning light W 1.4 (74)

Charging warning light W 1.4 (74)

4WD indicator light W 1.4 (74)

EGR warning light W 1.4 (74)

Oil pressure warning light W 1.4 (74)

A/T oil temperature warning light

W 1.4 (74)

Overdrive indicator light

W 1.4 (74)

Free-wheeling hub indicator light W 1.4 (74)

NOTE

The values in parentheses denote SAE grade numbers.

1 STB Revision ”

Page 148 of 284

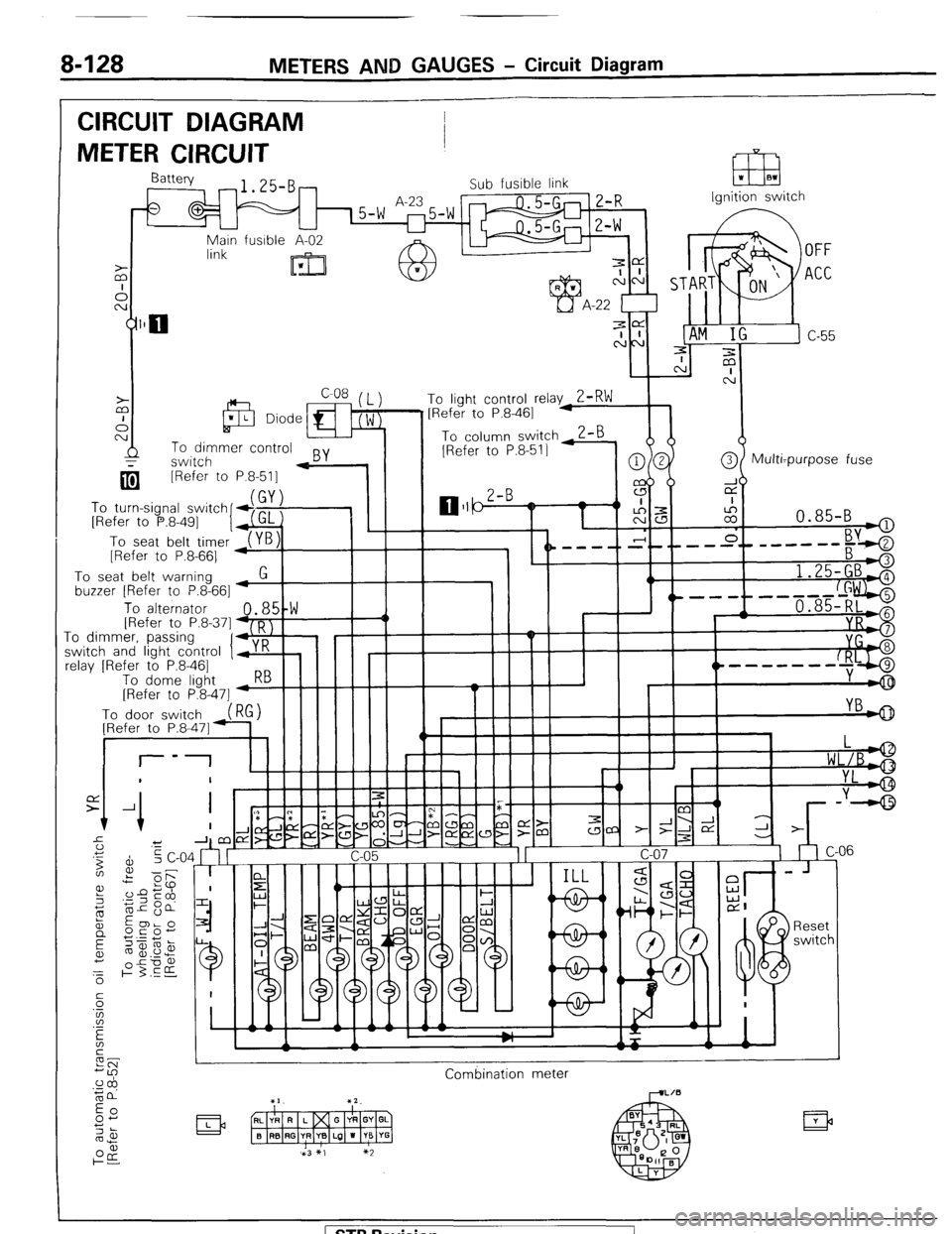

8-128 METERS AND GAUGES - Circuit Diagram

CIRCUIT DIAGRAM

METER CIRCUIT

Ignition switch

q [Refer to

To turn-signal switch

[Refer to P.8-491

I

To seat belt timer

[Refer to P.8-661 P.8-511 -

To seat belt warning

buzzer [Refer to P.8-661

1.25-GBA

, ^.

To alternator 48,5!W III -1 / 1 , 1 '----f--d+ii$$j IRefer to P.8.371 D I

.I_ -0 dimmkr, passinq

‘I+,:’ ! I I I II -I

I r I I I II YI

;witch and light control y K

clay [Refer to P.8-461

To dome liaht 5--hIIII I

----m-w-

[Refer to P&47] -w

Combination meter

( STB Revision

Page 161 of 284

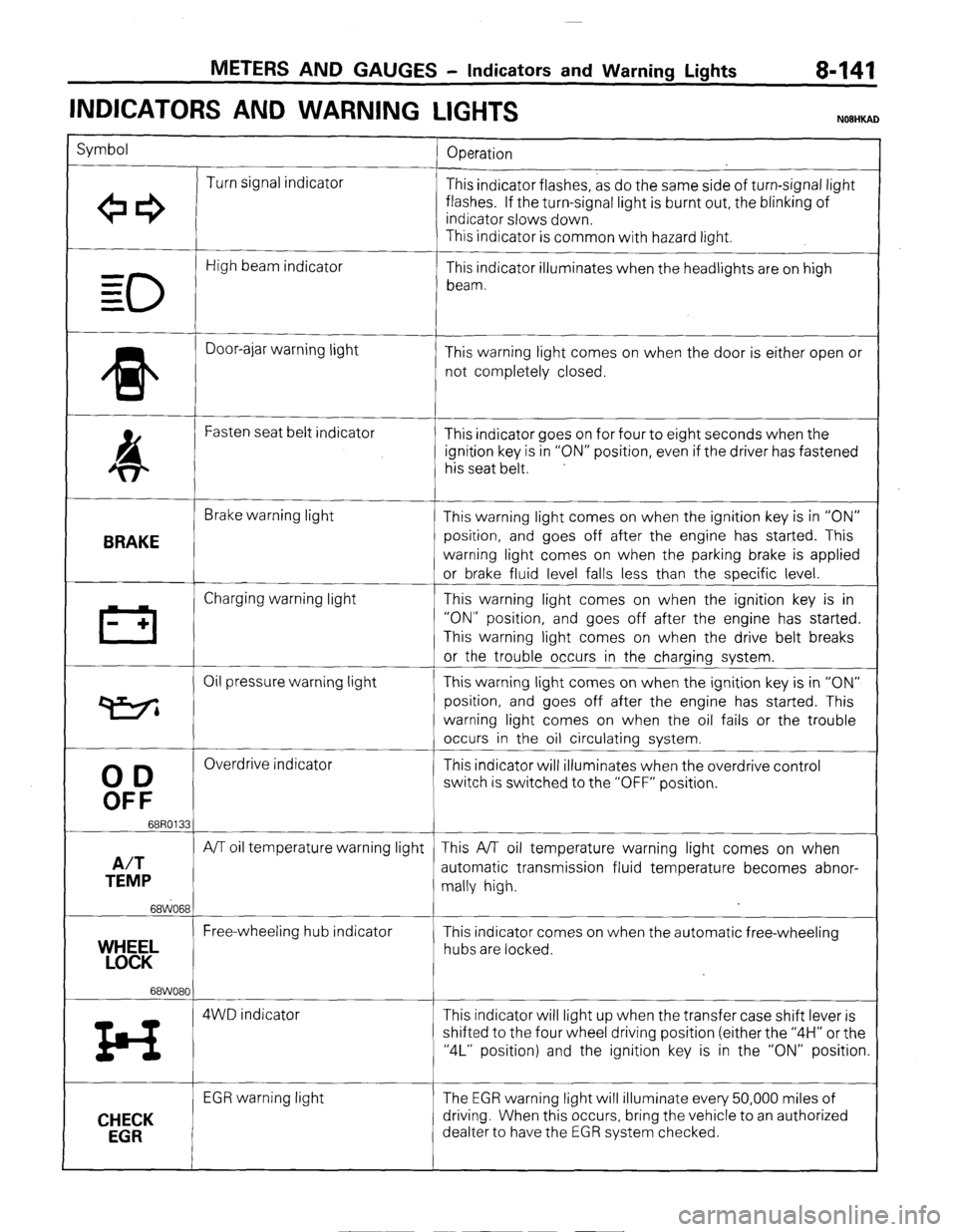

METERS AND GAUGES - Indicators and Warning Lights 8-141

INDICATORS AND WARNING

LIGHTS

Symbol

Operation

Turn signal indicator

+e3 This indicator flashes, as do the same side of turn-signal light

flashes. If the turn-signal light is burnt out, the blinking of

indicator slows down.

This indicator is common with hazard light.

0

High beam indicator

- This indicator illuminates when the headlights are on high

= beam.

=

* Door-ajar warning light

This warning light comes on when the door is either open or

not completely closed.

4 Fasten seat belt indicator

This indicator goes on for four to eight seconds when the

ignition key is in “ON” position, even if the driver has fastened

his seat belt.

BRAKE

Brake warning light

This warning light comes on when the ignition key is in “ON”

position, and goes off after the engine has started. This

warning light comes on when the parking brake is applied

or brake fluid level falls less than the specific level.

III Charging warning light This warning light comes on when the ignition key is in

- + “ON” position, and goes off after the engine has started.

This warning light comes on when the drive belt breaks

or the trouble occurs in the charging system.

Oil pressure warning light This warning light comes on when the ignition key is in “ON”

P position, and goes off after the engine has started. This

warning light comes on when the oil fails or the trouble

occurs in the oil circulating system.

00

Overdrive indicator

This indicator will illuminates when the overdrive control

OFF

switch is switched to the “OFF” position.

68R0133

A/T

A/T oil temperature warning light This A/T oil temperature warning light comes on when

TEMP automatic transmission fluid temperature becomes abnor-

mally high.

68WO68

Free-wheeling hub indicator

YEL This indicator comes on when the automatic free-wheeling

hubs are locked.

68WO80

z4 4WD indicator This indicator will light up when the transfer case shift lever is

shifted to the four wheel driving position (either the “4H” or the

“4L” position) and the ignition key is in the “ON” position.

CHECK

EGR

EGR warning light The EGR warning light will illuminate every 50,000 miles of

driving. When this occurs, bring the vehicle to an authorized

dealter to have the EGR system checked.

) STB Revision

Page 163 of 284

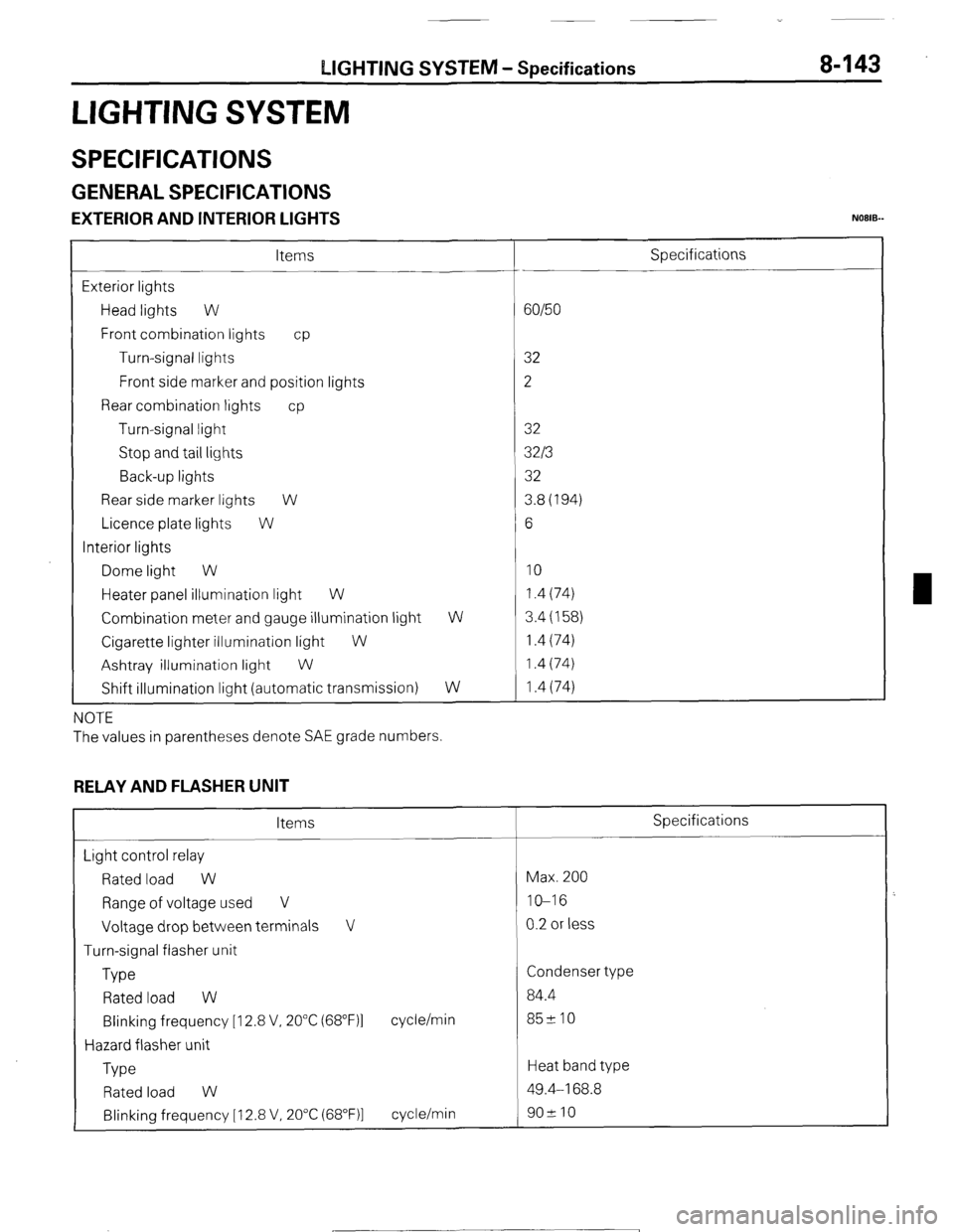

LIGHTING SYSTEM - Specifications 8-143

LIGHTING SYSTEM

SPECIFICATIONS

GENERAL SPECIFICATIONS

EXTERIOR AND INTERIOR LIGHTS NOEIB-

Items

Exterior lights

Head lights W

Front combination lights cp

Turn-signal lights

Front side marker and position lights

Rear combination lights cp

Turn-signal light

Stop and tail lights

Back-up lights

Rear side marker lights W

Licence plate lights W

Interior lights

Dome light W

Heater panel illumination light W

Combination meter and gauge illumination light

Cigarette lighter illumination light

W

Ashtray illumination light

W

Shift illumination light (automatic transmission) W

W

NOTE

The values in parentheses denote SAE grade numbers.

RELAY AND FLASHER UNIT

Items

Light control relay

Rated load W

Range of voltage used V

Voltage drop between terminals V

Turn-signal flasher unit

Type

Rated load W

Blinking frequency [I 2.8 V, 20°C (68”F)l

Hazard flasher unit

Type cycle/min

Rated load W

Blinking frequency [ 12.8 V, 20°C (68”F)l cycle/min Specifications

60/50

32

2

32

32/3

32

3.8(194)

6

10 1.4 (74)

3.4 (158)

1.4 (74)

1.4 (74)

1.4 (74)

Specifications

Max. 200

IO-16

0.2 or less

Condenser type

84.4

85210

Heat band type

49.4-168.8

902 10

1 STB Revision

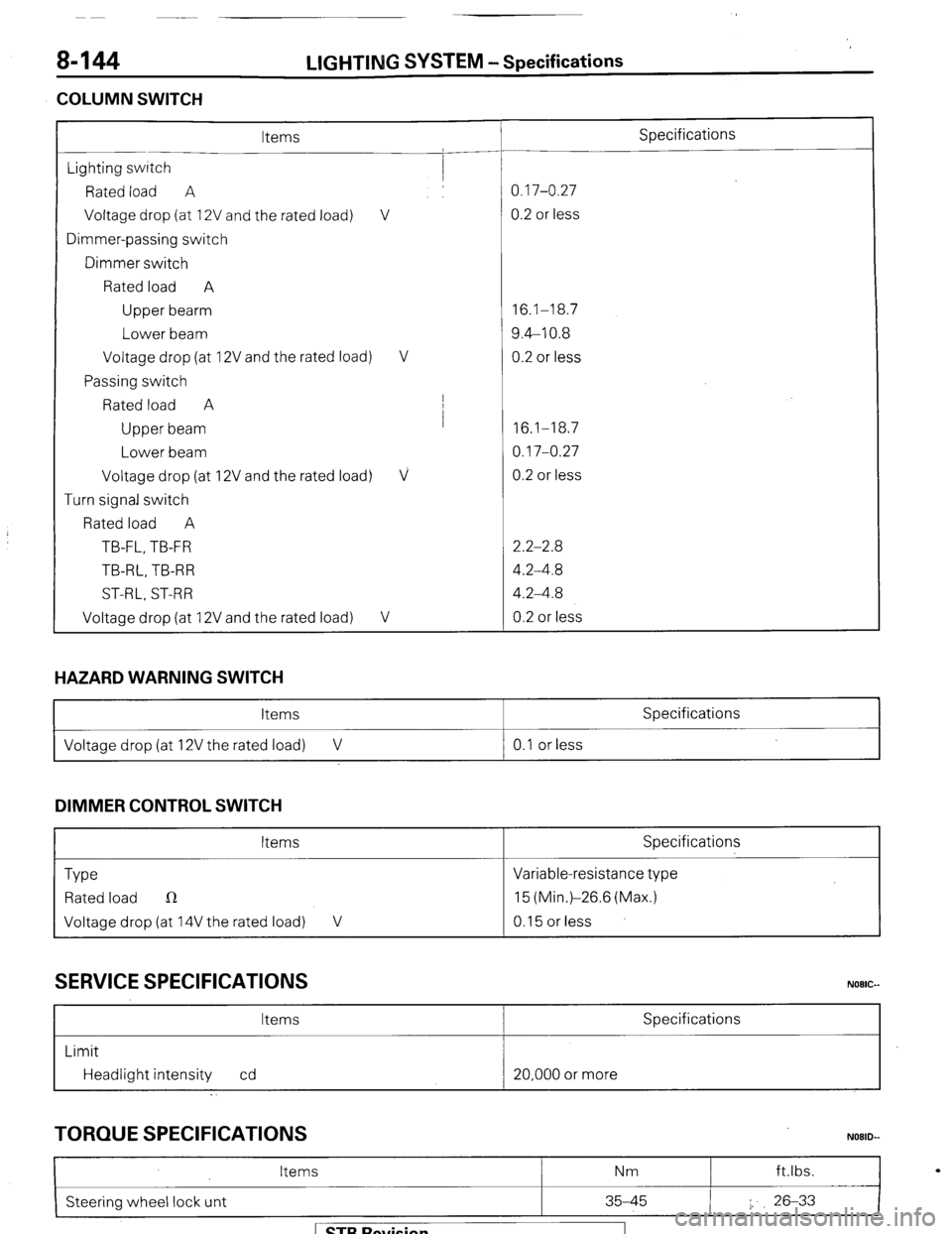

Page 164 of 284

8-144

COLUMN SWITCH LIGHTING

SYSTEM -Specifications

Items Specifications

Lighting switch

Rated load A 0.17-0.27

Voltage drop (at 12V and the rated load) V 0.2 or less

Dimmer-passing switch

Dimmer switch

Rated load A

Upper bearm 16.1-18.7

Lower beam 9.4-10.8

Voltage drop (at 12V and the rated load) V 0.2 or less

Passing switch

Rated load A I

Upper beam I

16.1-18.7

Lower beam 0.17-0.27

Voltage drop (at 12V and the rated load)

V 0.2 or less

Turn signal switch

Rated load A

TB-FL, TB-FR 2.2-2.8

TB-RL, TB-R R 4.2-4.8

ST-RL, ST-RR 4.2-4.8

Voltage drop (at 12V and the rated load)

V 0.2 or less

HAZARD WARNING SWITCH

Items Specifications

I Voltage drop (at 12V the rated load) V 0.1 or less

I

DIMMER CONTROL SWITCH

Items Specifications

Type Variable-resistance type

Rated load n 15 (Min.)-26.6 (Max.)

Voltage drop (at 14V the rated load) V 0.15 or less

SERVICE SPECIFICATIONS

Items Specifications

Limit

Headlight intensity cd 20,000 or more

TORQUE SPECIFICATIONS

I

Items Nm ft.lbs.

N08lb

Steering wheel lock unt 35-45 I. 26-33

I

1 STB Revision

Page 167 of 284

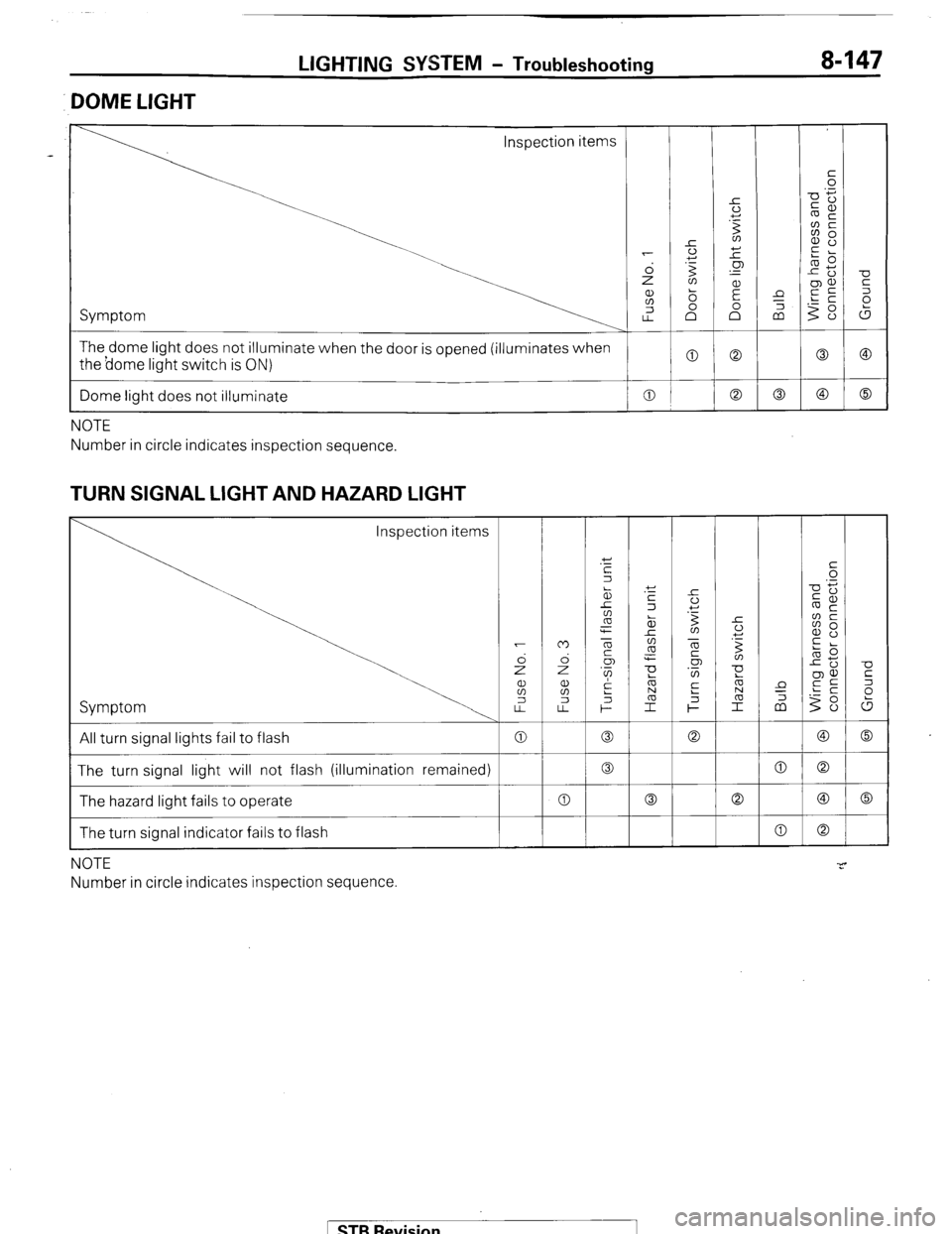

LIGHTING SYSTEM - Troubleshooting 8-147

DOME LIGHT

Inspection items

The dome light does not illuminate when the door is opened (illuminates when

the borne light switch is ON)

I

Dome light does not illuminate 0

I

NOTE

Number in circle indicates inspection sequence.

TURN SIGNAL LIGHT AND HAZARD LIGHT

Inspection items

Symptom

All turn signal lights fail to flash

The turn signal light will not flash (illumination remained)

The hazard light fails to operate

The turn signal indicator fails to flash

NOTE

Number in circle indicates inspection sequence

1 STB Revision