ESP MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 2 of 284

2 INTRODUCTION - How To Use This Manual

HOW TO USE THIS MANUAL NOOBAAK

CONTENTS

The preceding page contains the GROUP INDEX

which lists the group title and group number.

PAGE NUMBERS

All page numbers consist of two sets of digits

separated by a dash. The digits preceding the dash

identify the number of the group. The digits follow-

ing the dash represent the consecutive page

number within the group. The page numbers can

be found on the top left or right of each page.

TEXT

Unless otherwise specified, each service procedure

covers all models. Procedures covering specific

models are identified by the model codes, or similar

designation (engine type, transmission type, etc.).

A description of these designations is covered in

this unit under “VEHICLE IDENTIFICATION”.

SERVICE PROCEDURES

The service steps are arranged in numerical order

and attentions to be paid in performing vehicle ser-

vice are described in detail in SERVICE POINTS.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a part

or assembly on inspection and means the maximum

or minimum value within which the part or assembly

must be kept functionally or in strength. It is a value

established outside the range of standard value. Installation steps

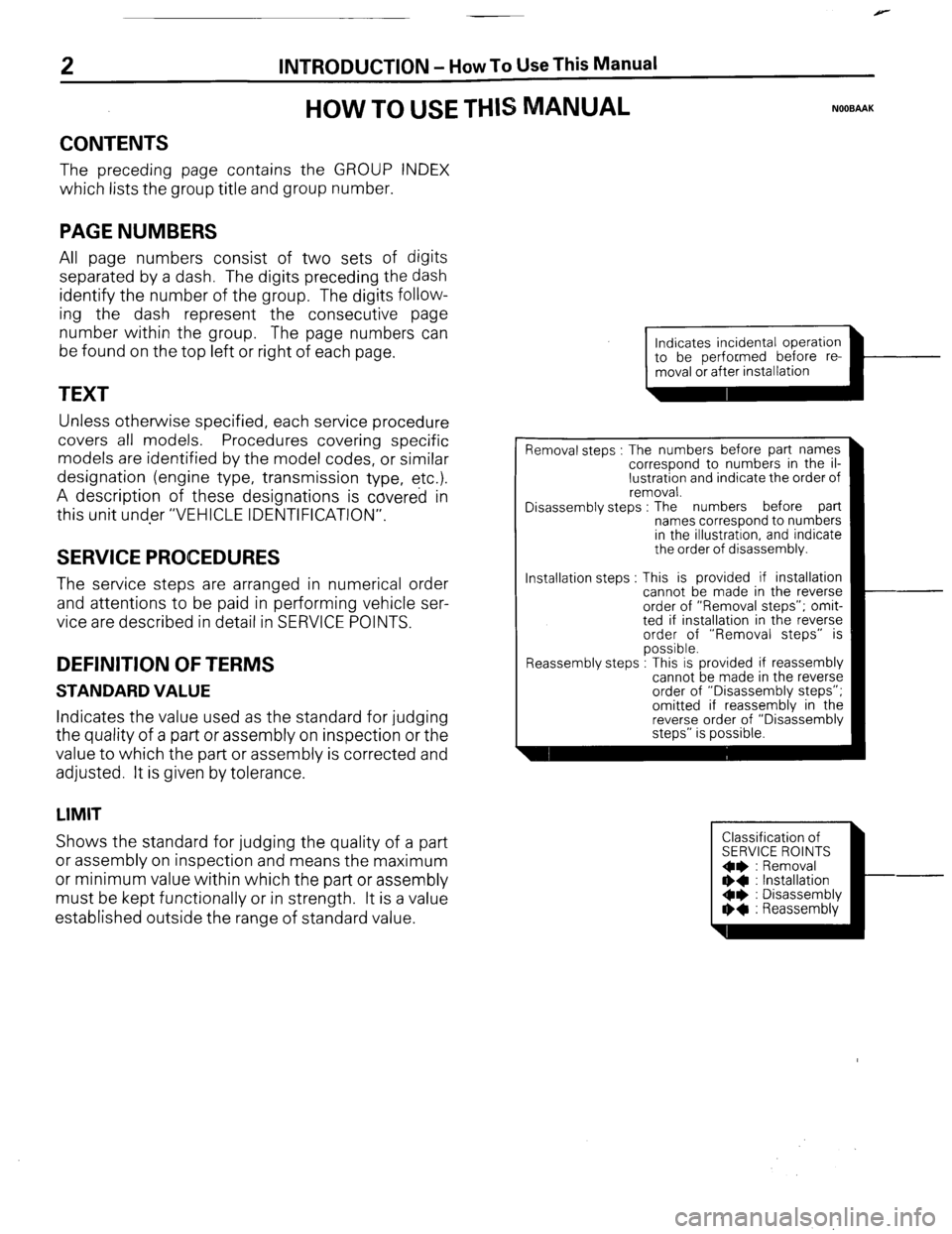

Indicates incidental operation

piiiKL=l-

Removal steps : The numbers before part names

correspond to numbers in the il-

lustration and indicate the order of

removal.

Disassembly steps : The numbers before part

names correspond to numbers

in the illustration, and indicate

the order of disassembly.

This is provided if installation

cannot be made in the reverse

order of “Removal steps”; omit-

ted if installation in the reverse

order of “Removal steps” is

possible.

.

Reassembly steps : I his IS provided It reassembly

cannot be made in the reverse

order of “Disassembly steps”;

omitted if reassembly in the

reverse order of “Disassembly

steps” is possible.

Classification of

SERVICE ROINTS

Oe : Removal

** : Installation

Oe : Disassembly

I)+ : Reassembly

Page 3 of 284

INTRODUCTION - H

ow To Use This Manual 3

-L

!

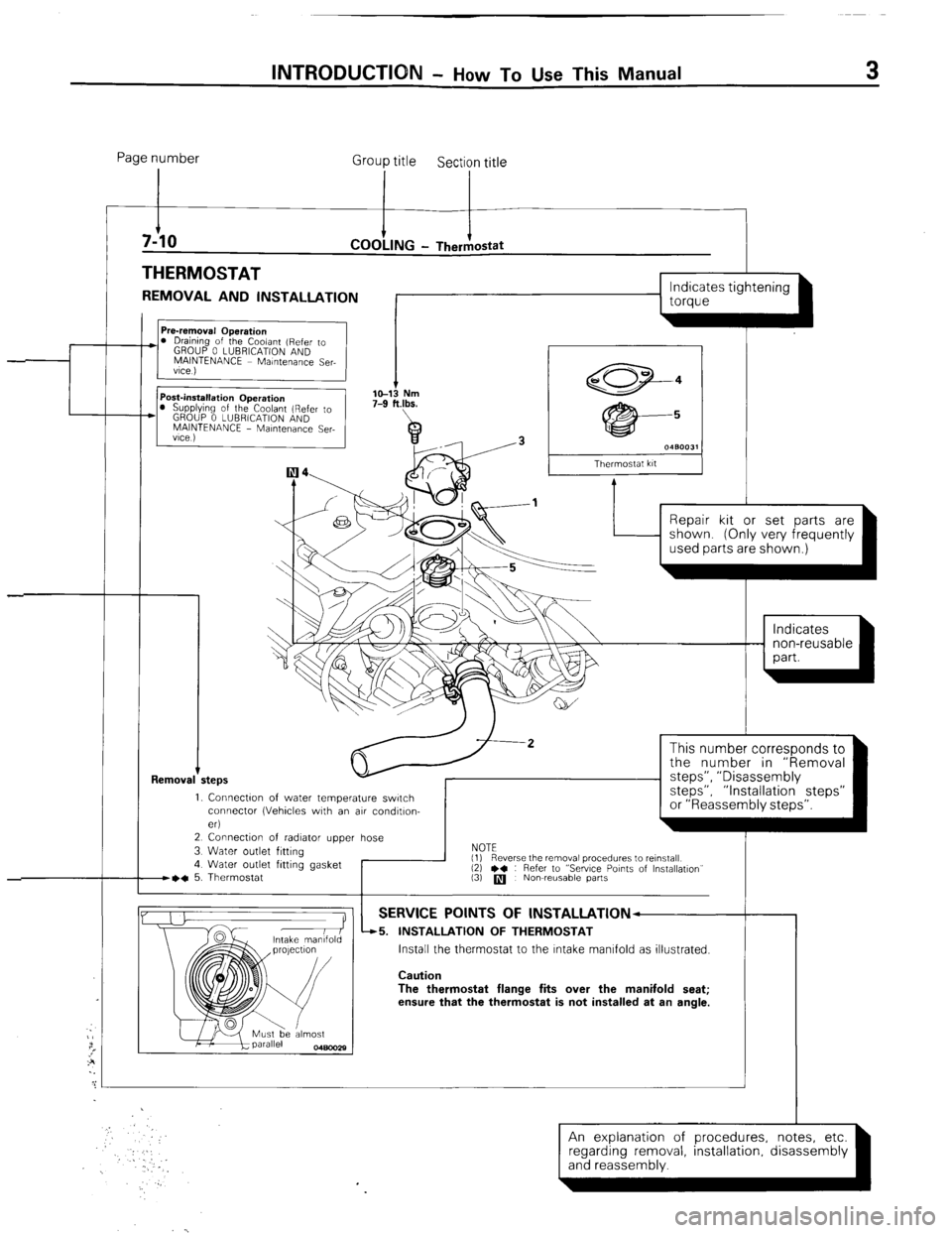

Page number

Group title

Section title

THERMOSTAT

REMOVAL AND INSTALLATION

I

I I

L

1 torque

Removal +

I s 0480031

Thermostat kit

Repair kit or set parts are

1. Connectw of water temperature switch

connector (Vehicles with an air condltlon-

eri

2 Connection of radiator upper hose

3 Water outlet fitting

4 Water outlet fitting gasket

B~C 5. Thermostat I

This number corresponds to

the number in “Removal

steps”, ” Disassembly

steps”, “Installation steps”

or “Reassembly steps”.

NOTE

(1)

(3)

q Nowreusable parts

-r Reverse the removal procedures to reinstall

12) l * : Refer to “Sewce Points of Installation”

SERVICE POINTS OF lNSTALLATlON--

45. INSTALLATION OF THERMOSTAT

Install the thermostat to the Intake manifold as illustrated.

Caution

The thermostat flange fits over the manifold seat;

ensure that the thermostat is not installed at an angle.

An explanation of procedures, notes, etc.

(and reassembly. ’ ’ -1 regarding removal installation disassembly

Page 14 of 284

INTRODUCTION - Towing and Hoisting

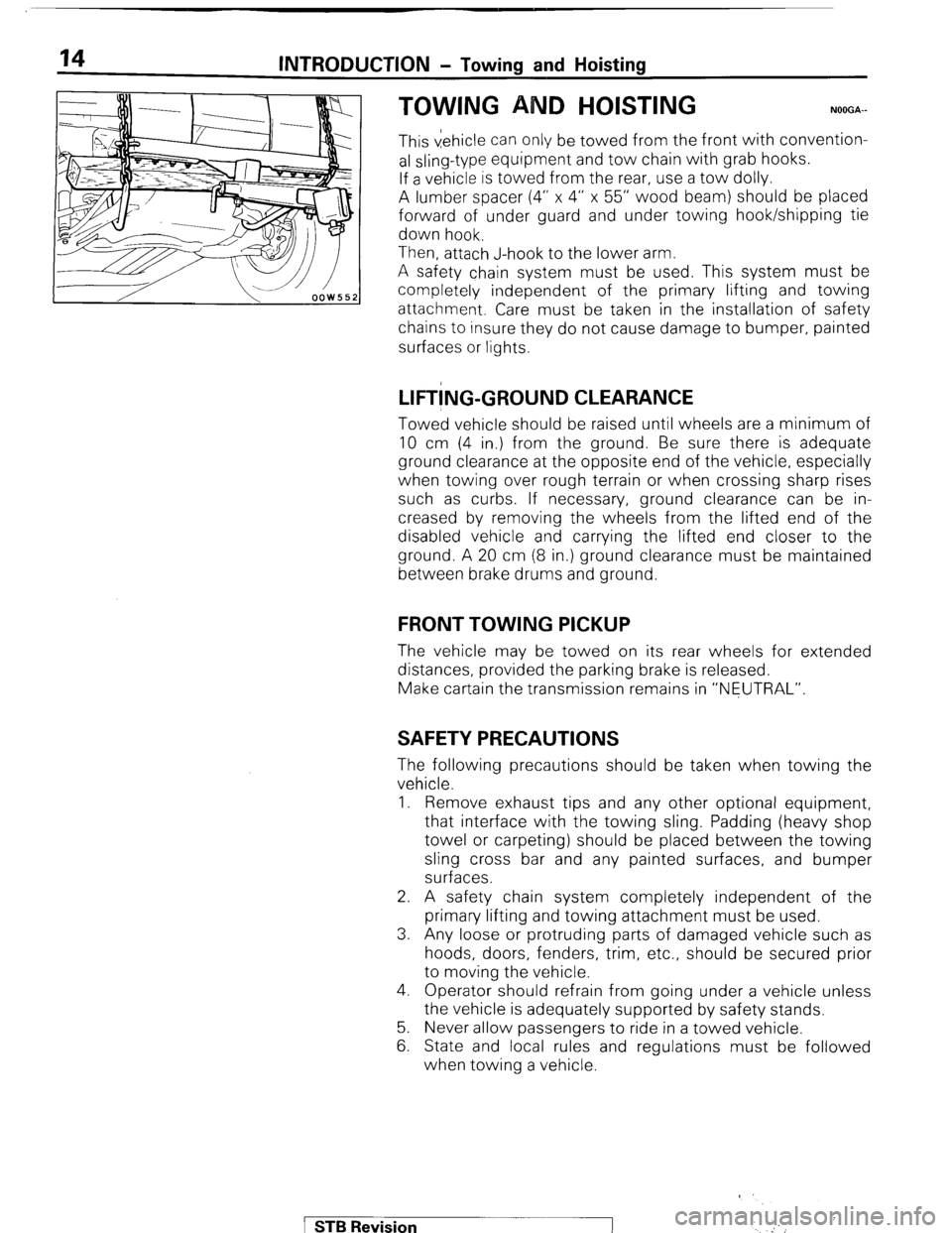

TOWING AND HOISTING NOOGA-

This vehicle can only be towed from the front with convention-

al sling-type equipment and tow chain with grab hooks.

If a vehicle is towed from the rear, use a tow dolly.

A lumber spacer (4” x 4” x 55” wood beam) should be placed

forward of under guard and under towing hook/shipping tie

down hook.

Then, attach J-hook to the lower arm.

A safety chain system must be used. This system must be

completely independent of the primary lifting and towing

attachment. Care must be taken in the installation of safety

chains to insure they do not cause damage to bumper, painted

surfaces or lights.

LIFT!NG-GROUND CLEARANCE

Towed vehicle should be raised until wheels are a minimum of

10 cm (4 in.) from the ground. Be sure there is adequate

ground clearance at the opposite end of the vehicle, especially

when towing over rough terrain or when crossing sharp rises

such as curbs. If necessary, ground clearance can be in-

creased by removing the wheels from the lifted end of the

disabled vehicle and carrying the lifted end closer to the

ground. A 20 cm (8 in.) ground clearance must be maintained

between brake drums and ground.

FRONT TOWING PICKUP

The vehicle may be towed on its rear wheels for extended

distances, provided the parking brake is released.

Make cartain the transmission remains in “NEUTRAL”.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle.

1. Remove exhaust tips and any other optional equipment,

that interface with the towing sling. Padding (heavy shop

towel or carpeting) should be placed between the towing

sling cross bar and any painted surfaces, and bumper

surfaces.

2. A safety chain system completely independent of the

primary lifting and towing attachment must be used.

3. Any loose or protruding parts of damaged vehicle such as

hoods, doors, fenders, trim, etc., should be secured prior

to moving the vehicle.

4. Operator should refrain from going under a vehicle unless

the vehicle is adequately supported by safety stands.

5. Never allow passengers to ride in a towed vehicle.

6. State and local rules and regulations must be followed

when towing a vehicle.

1 STB Revision

‘

Page 34 of 284

8-14 WIRING HARNESS - Troubleshooting

1680222

Changeover knob 1680224

1680225 1

1680226

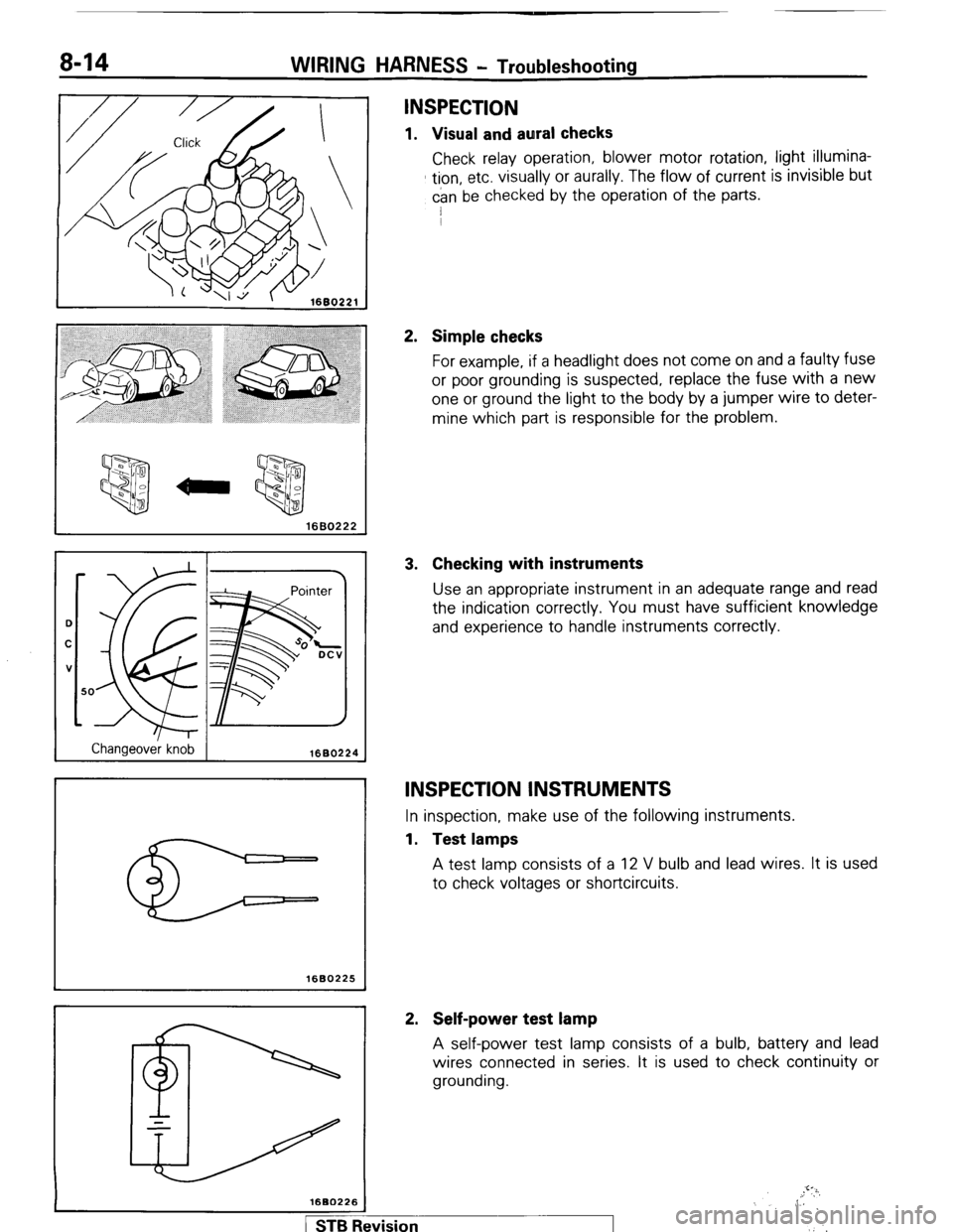

INSPECTION

1. Visual and aural checks

Check relay operation, blower motor rotation, light illumina-

tion, etc. visually or aurally. The flow of current is invisible but

can be checked by the operation of the parts.

I

2. Simple checks

For example, if a headlight does not come on and a faulty fuse

or poor grounding is suspected, replace the fuse with a new

one or ground the light to the body by a jumper wire to deter-

mine which part is responsible for the problem.

3. Checking with instruments

Use an appropriate instrument in an adequate range and read

the indication correctly. You must have sufficient knowledge

and experience to handle instruments correctly.

INSPECTION INSTRUMENTS

In inspection, make use of the following instruments.

1. Test lamps

A test lamp consists of a 12 V bulb and lead wires. It is used

to check voltages or shortcircuits.

2. Self-power test lamp

A self-power test lamp consists of a bulb, battery and lead

wires connected in series. It is used to check continuity or

grounding.

,.!‘?i,

,, 6

,‘.’

1 STB Revision

Page 37 of 284

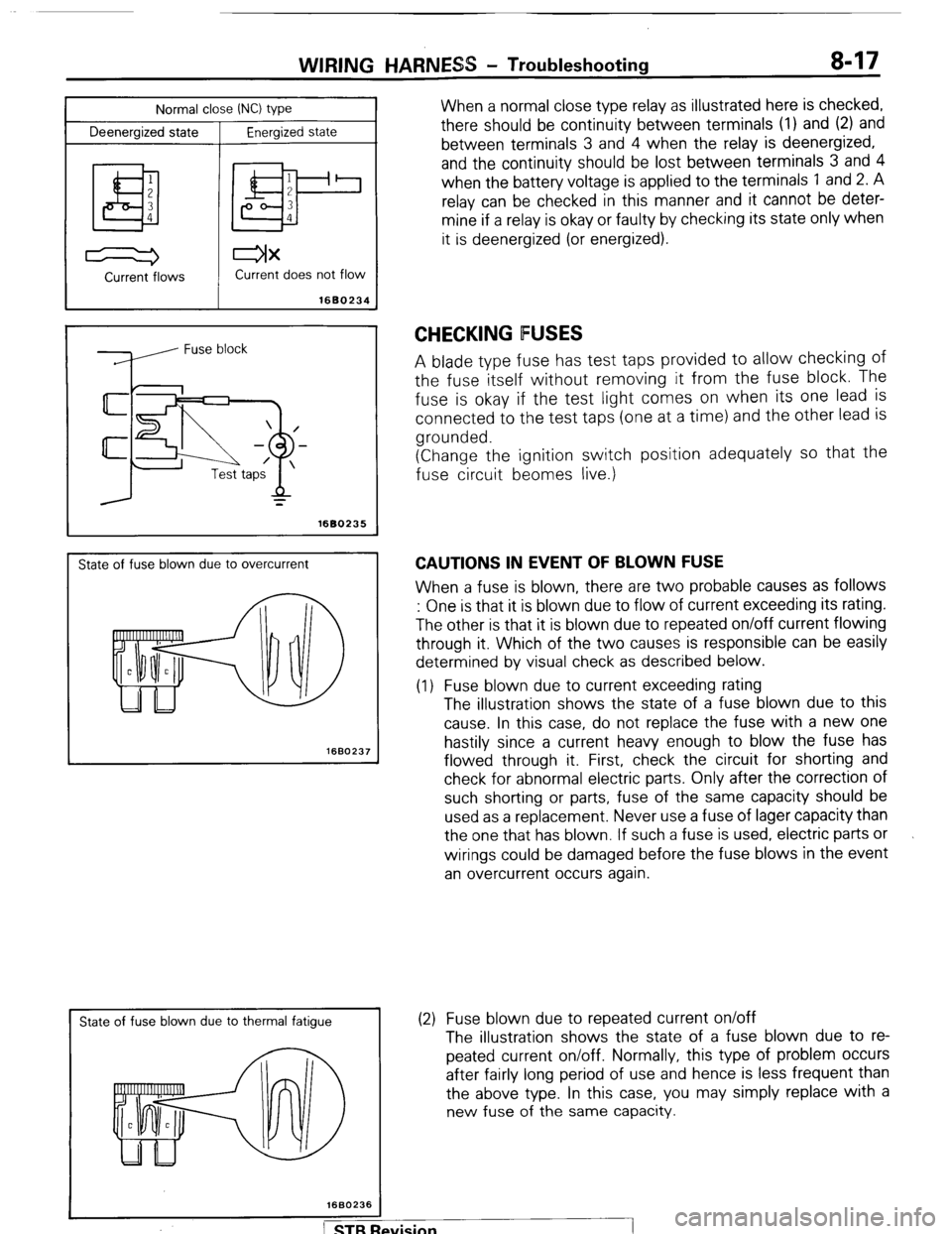

Normal close INC) type

Deenergized state

Energized state

I

WIRING HARNESS - Troubleshooting 8-17

When a normal close type relay as illustrated here is checked,

there should be continuity between terminals (1) and (2) and

between terminals 3 and 4 when the relay is deenergized,

and the continuity should be lost between terminals 3 and 4

when the battery voltage is applied to the terminals 1 and 2. A

relay can be checked in this manner and it cannot be deter-

mine if a relay is okay or faulty by checking its state only when

it is deenergized (or energized).

Current -flows Current does not flow

1680234

=

1680235

State of fuse blown due to overcurrent

1660237

I

State of fuse blown due to thermal fatigue

CHECKING FUSES

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The

fuse is okay if the test light comes on when its one lead is

connected to the test taps (one at a time) and the other lead is

grounded.

(Change the ignition switch position adequately so that the

fuse circuit beomes live.)

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes as follows

: One is that it is blown due to flow of current exceeding its rating.

The other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

(1) Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorting and

check for abnormal electric parts. Only after the correction of

such shorting or parts, fuse of the same capacity should be

used as a replacement. Never use a fuse of lager capacity than

the one that has blown. If such a fuse is used, electric parts or

wirings could be damaged before the fuse blows in the event

an overcurrent occurs again.

(2) Fuse blown due to repeated current on/off

The illustration shows the state of a fuse blown due to re-

peated current on/off. Normally, this type of problem occurs

after fairly long period of use and hence is less frequent than

the above type. In this case, you may simply replace with a

new fuse of the same capacity.

Page 42 of 284

8-22 WIRING HARNESS - How to Read Wiring Diagrams

HOW TO READ CIRCUIT DIAGRAMS

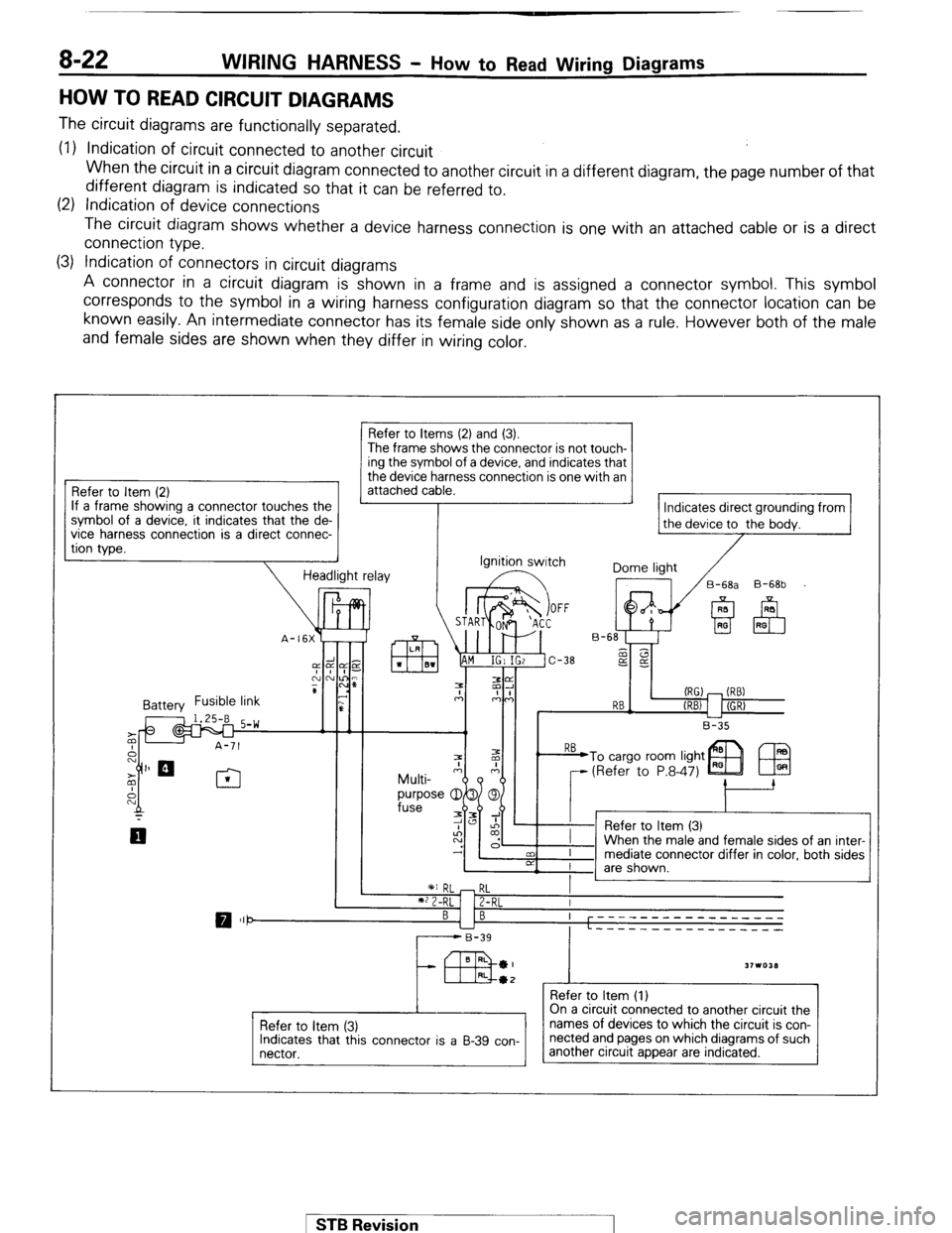

The circuit diagrams are functionally separated.

(1) Indication of circuit connected to another circuit

When the circuit in a circuit diagram connected to another circuit in a different diagram, the page number of that

different diagram is indicated so that it can be referred to.

(2) Indication of device connections

The circuit diagram shows whether a device harness connection is one with an attached cable or is a direct

connection type.

(3) Indication of connectors in circuit diagrams

A connector in a circuit diagram is shown in a frame and is assigned a connector symbol. This symbol

corresponds to the symbol in a wiring harness configuration diagram so that the connector location can be

known easily. An intermediate connector has its female side only shown as a rule. However both of the male

and female sides are shown when they differ in wiring color.

Refer to Item (2)

If a frame showing a connector touches the

?. it indicates that the de-

a direct connec- symbol of a device

vice

harness connectlon IS

tion type.

Refer to Items (2) and (3).

The frame shows the connector is not touch- ing the symbol of a device, and indicates that

the device harness connection is one with an

attached cable.

Indicates direct grounding from

the device to the bodv.

Ignition switch

Dome light

/

17 /B-6& B-68b

(RG) - (RB)

RB-

(REV 1 I (GR)

L-2

B-35

1 *I RL - RL

I

**2-RL 1 Z-RL I

BI B ----- ---- --------

L ----_ __---___----

r------B-39

43 BRL *I

31103LI RL*2 _

Refer to Item (1)

Refer to item (3)

Indicates that this connector is a B-39 con-

nectar. On a circuit connected to another circuit the

names of devices to which the circuit is con-

nected and pages on which diagrams of such

another circuit appear are indicated.

1 STB Revision 1

Page 43 of 284

WIRING HARNESS - HOW BO Read Wiring Diagrams 8-23

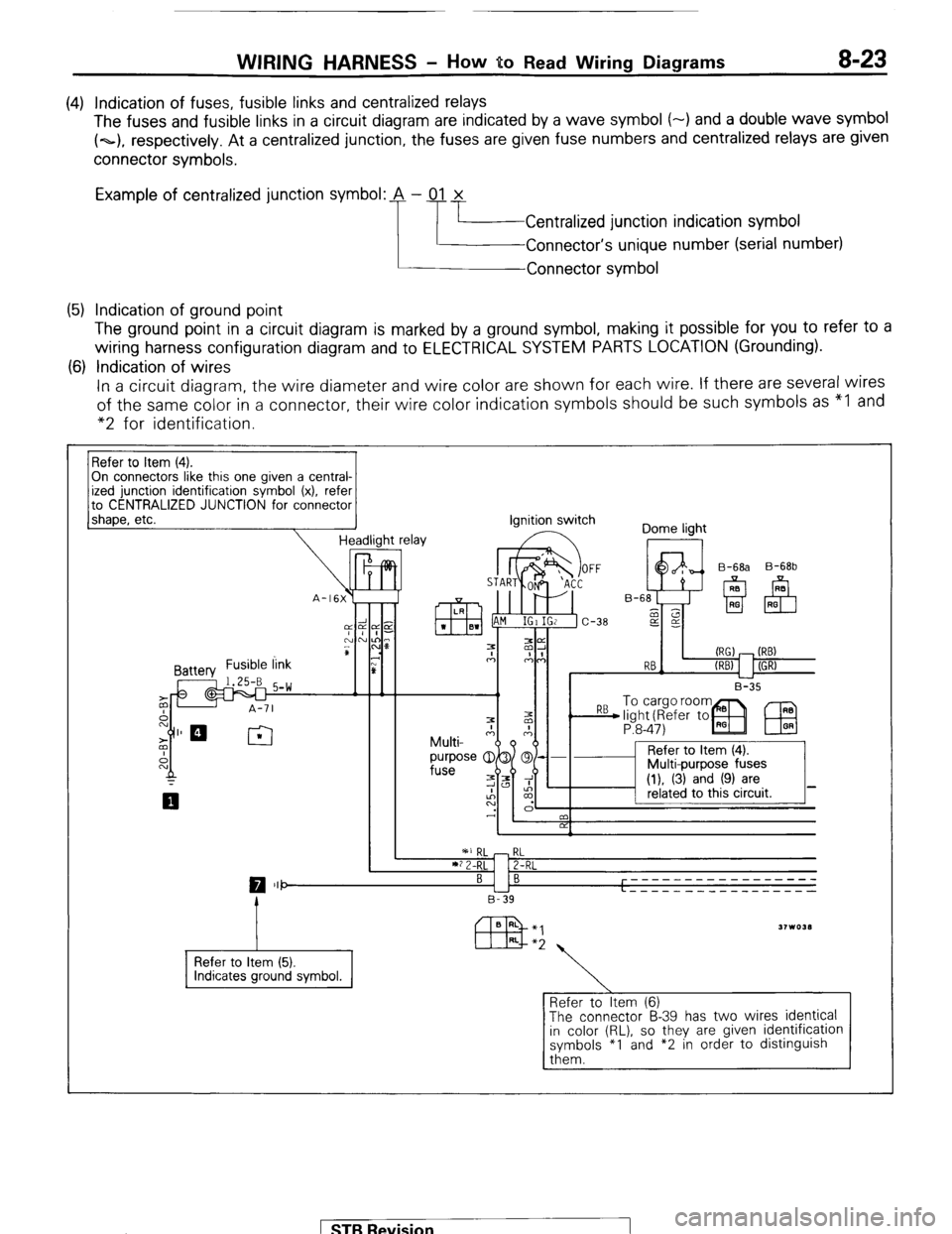

(4) Indication of fuses, fusible links and centralized relays

The fuses and fusible links in a circuit diagram are indicated by a wave symbol (-) and a double wave symbol

(~1, respectively. At a centralized junction, the fuses are given fuse numbers and centralized relays are given

connector symbols.

Example of centralized junction symbol: A - 01 x

Centralized junction indication symbol

Connector’s unique number (serial number)

Connector symbol

(5) Indication of ground point

The ground point in a circuit diagram is marked by a ground symbol, making it possible for you to refer to a

wiring harness configuration diagram and to ELECTRICAL SYSTEM PARTS LOCATION (Grounding).

(6) Indication of wires

In a circuit diagram, the wire diameter and wire color are shown for each wire. If there are several wires

of the same color in a connector, their wire color indication symbols should be such symbols as “I and

“2 for identification.

On connectors like this one given a central-

to CENTRALIZED JUNCTION for connector

1 shaoe. etc.

-I Headlight relay ignition switch

Dome light

I II I B-35 B-68b

P:8-47)

IEU

I ’ 2 I

RL

2-RL

0 III- BI B -----____________

L - - - - - _ _ _ _ _ __ _ _ _ _ _

B-39

Refer to Item (5).

Refer to Item (6)

The connector B-39 has two wires identical

in color (RL), so they are given identification

symbols *I and *2 in order to distinguish

them. 1 ST6 Revision

Page 238 of 284

24-2 HEATERS - General Information

GENERAL INFORMATION 24BAAD

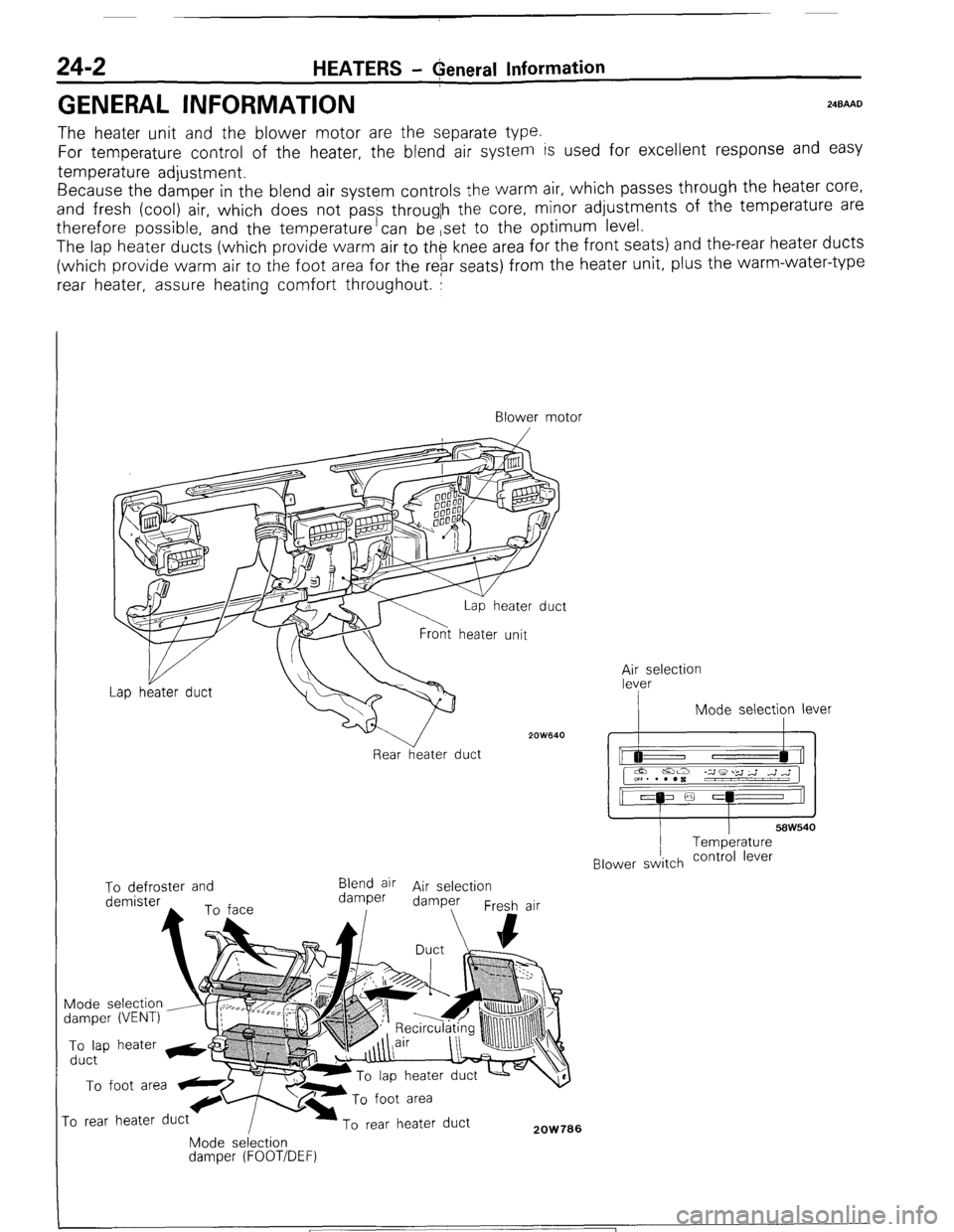

The heater unit and the blower motor are the separate type.

For temperature control of the heater, the blend air system is used for excellent response and easy

temperature adjustment.

Because the damper in the blend air system controls the warm air, which passes through the heater core,

and fresh (cool) air, which does not pass througlh the core, minor adjustments of the temperature are

therefore possible, and the temperature’can be ,set to the optimum level.

The lap heater ducts (which provide warm air to th$ knee area for the front seats) and the-rear heater ducts

(which provide warm air to the foot area for the rebr seats) from the heater unit, plus the warm-water-type

rear heater, assure heating comfort throughout. :

Blower motor

/

2OW640

Rear heater duct ;;eselection

I Mode selection lever

I I

58W540 Temperature

Blower switch contra’ lever To defroster and

Blend air Air selection

demister damper damper

Fresh air

Mode selection

damper (VENT) To lap heater &@

duct To foot area

ro rear heater duct To rear heater duct 2OW706 Mode selection damper (FOOT/DEF)

1 ST6 Revision

Page 264 of 284

24-28 AIR-CONDITIONING-Safety Precautions

SAFETY PRECAUTIONS N24PAAB

SAFETY PRECAUTIONS

I

The refrigerant used in all air-conditioning installations is R-12. It is transparent and colorless in both the liquid and

vapor state. Since it has a boiling point of -29.8T (-21.7”F). at atmospheric pressure, it will be a vapor at all normal

temperatures and pressures. The vapor is heavier than air, non- flammable, and nonexplosive. It is nonpoisonous

except when it is in direct contact with open flame. It is noncorrosive except when combined with water. The

following precautions must be observed when handling R-12.

Caution

Wear

safety goggles when servicing the refrigeration system.

R-12 evaporates so rapidly at normal atmospheric pressures and temperatures that it tends to freeze anything it

contacts. For this reason, extreme care must be taken to prevent any liquid refrigerant from contacting the skin and

especially the eyes.

Always wear safety goggles when servicing the refrigeration part of the air- conditioning system. Keep a bottle of

sterile mineral oil handy when working on the refrigeration system. Should any liquid refrigerant get into the eyes,

use a few drops of mineral oil to wash them out. RI12 is rapidly absorbed by the oil. Next, splash the eyes with

plenty of cold water. Call your doctor immediately even though irritation has ceased after treatment.

Caution

Do not heat R-12 above 52°C (125°F).

In most instances, moderate heat is required to bring the pressure of the refrigerant in its container above the

pressure of the system when charging or adding refrigerant. A bucket or large pan of hot water not over 52°C

(125°F) is all the heat required for this purpose. Do not heat the refrigerant container with a blow torch or any other

means that would raise temperature and pressure above this temperature. Do not weld or steam clean on or near

the system components or refrigerant lines.

Caution

Keep R-12 containers upright when charging the system.

When metering R-12 into the refrigeration system, keep the supply tank or cans in an upright position. If the

refrigerant container is on its side or upside down, liquid refrigerant will enter the system and damage the

compressor.

Caution

Always work in a well-ventilated room.

Good ventilation is vital in the working area. Always discharge the refrigerant into the service bay exhaust system

or outside the building. Large quantities of refrigerant vapor in a small, poorly ventilated room can displace the air

and cause suffocation.

Although R-12 vapor is normally nonpoisonous, contact with an open flame can cause the vapor to become very

poisonous. Do not discharge large quantities of refrigerant in an area having an open flame. A poisonous gas is

producted when using the flame-type leak detector. Avoid inhaling the fumes from the leak detector.

Caution

Do not allow liquid refrigerant to touch bright metal.

Refrigerant will tarnish bright metal and chrome surfaces, and in combination with moisture’can severely corrode

all metal surfaces.

/ STB Revision

-I

Page 270 of 284

24-34 AIR-CONDITIONING-Service Adiustment Procedures

r---- :

:ES

Dry bulb therr&neter

2OW825

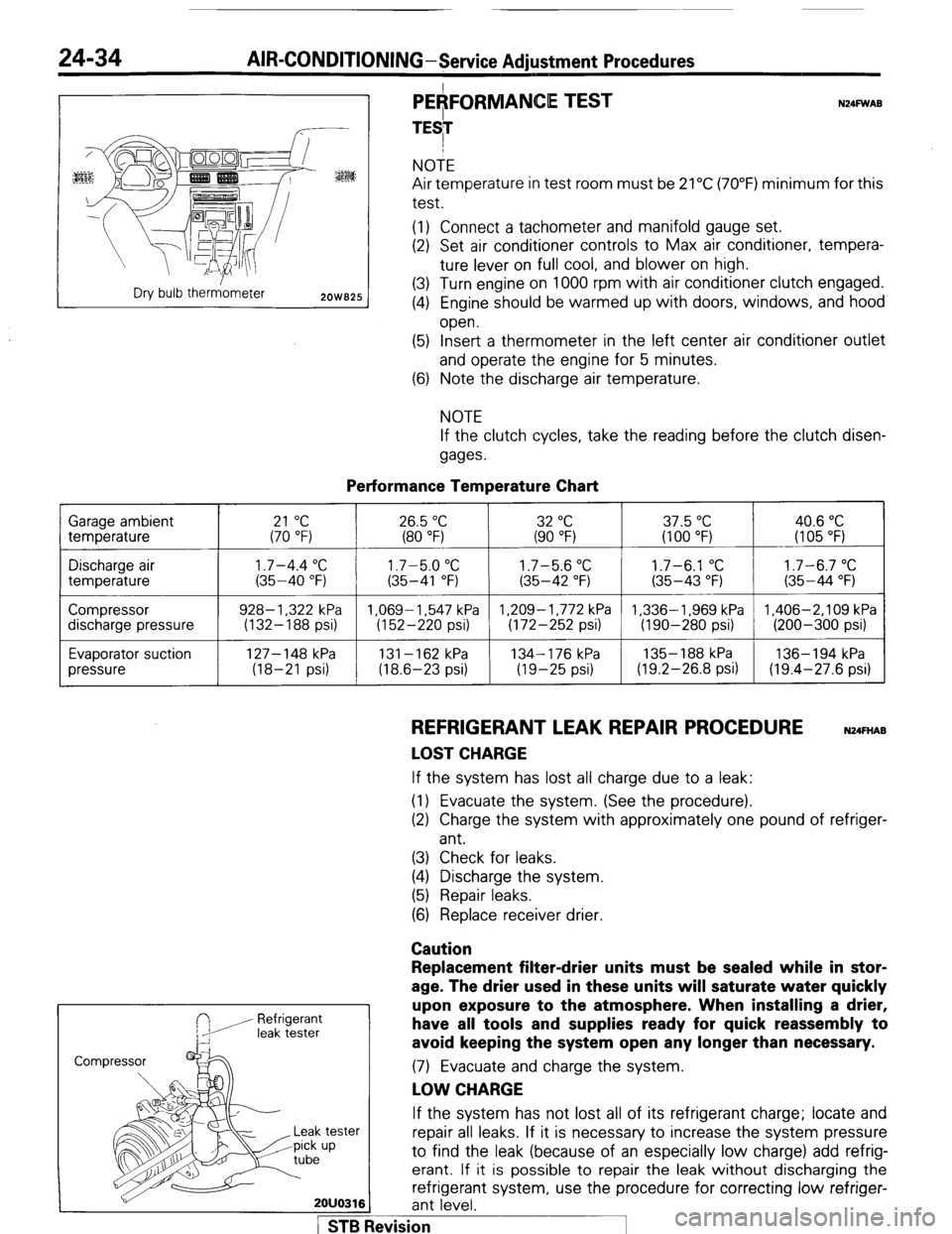

PEAFORMANCE TEST

TESI N24FWAB NOTE

Air temperature in test room must be 21°C (70°F) minimum for this

test.

(1) Connect a tachometer and manifold gauge set.

(2) Set air conditioner controls to Max air conditioner, tempera-

ture lever on full cool, and blower on high.

(3) Turn engine on 1000 rpm with air conditioner clutch engaged.

(4) Engine should be warmed up with doors, windows, and hood

open.

(5) Insert a thermometer in the left center air conditioner outlet

and operate the engine for 5 minutes.

(6) Note the discharge air temperature.

NOTE

If the clutch cycles, take the reading before the clutch disen-

gages.

Performance Temperature Chart Garage ambient

temperature

21 “C 26.5 “C 32 “C 37.5 “C 40.6 “C (70 “F) (80 “F) (90 “F) (100 “F) (I 05 “F)

Discharge air

temperature

Compressor

discharge pressure

Evaporator suction

pressure

1.7-4.4 “C 1.7-5.0 “C 1.7-5.6 “C 1.7-6.1 “C 1.7-6.7 “C (35-40 “F) (35-41 “F) (35-42 “F) (35-43 “F) (35-44 “F)

928- 1,322 kPa 1.069-1.547 kPa 1,209-1,772 kPa 1,336-1,969 kPa 1,406-2,109 kPa

(132-188 psi) (152-220 psi) (172-252 psi) (190-280 psi) (200-300 psi)

127-148 kPa

131-162 kPa 134-176 kPa 135- 188 kPa 136-194 kPa

(18-21 psi) (18.6-23 psi) (19-25 psi) (19.2-26.8 psi) (19.4-27.6 psi)

REFRIGERANT LEAK REPAIR PROCEDURE N24FnAB

LOST CHARGE If the system has lost all charge due to a leak:

(1) Evacuate the system. (See the procedure).

(2) Charge the system with approximately one pound of refriger-

ant.

(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Refrigerant

leak tester

Replacement filter-drier units must be sealed while in stor-

age. The drier used in these units will saturate water quickly

upon exposure to the atmosphere. When installing a drier,

have all tools and supplies ready for quick reassembly to

avoid keeping the system open any longer than necessary. (7) Evacuate and charge the system.

LOW CHARGE If the system has not lost all of its refrigerant charge; locate and

tester repair all leaks. If it is necessary to increase the system pressure

up to find the leak (because of an especially low charge) add refrig-

erant. If it is possible to repair the leak without discharging the

refrigerant system, use the procedure for correcting low refriger-

2OUO316 ant level.

1 STB Revision