window MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 156 of 284

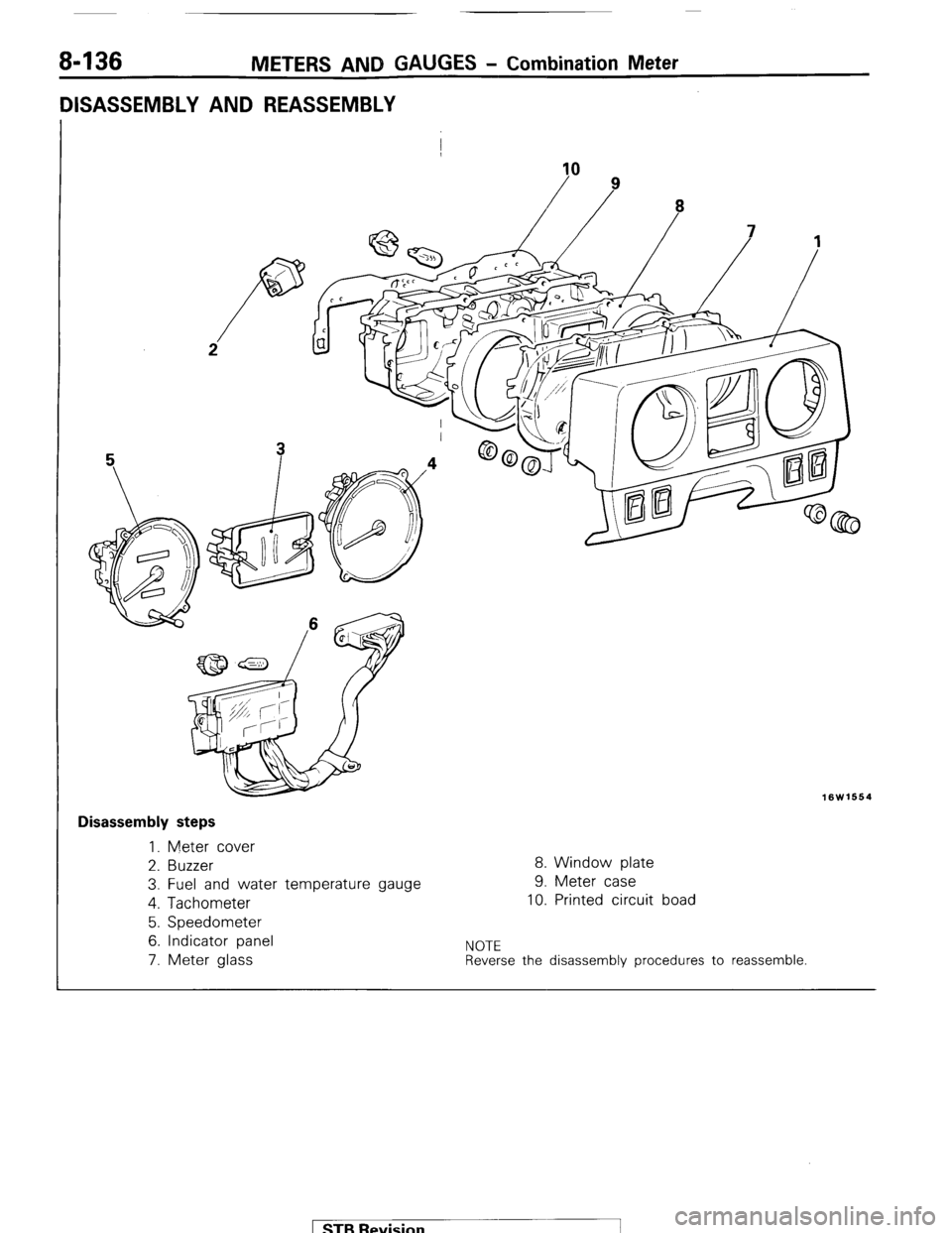

8-136 METERS AND GAUGES - Combination Meter

DISASSEMBLY AND REASSEMBLY

I

10

16W1664

I Disassembly steps

1. Meter cover

2. Buzzer

8. Window plate

3. Fuel and water temperature gauge 9. Meter case

4. Tachometer

10. Printed circuit boad

5. Speedometer

6. Indicator panel

NOTE 7. Meter glass Reverse the disassembly procedures to reassemble. 1 STB Revision -1

Page 158 of 284

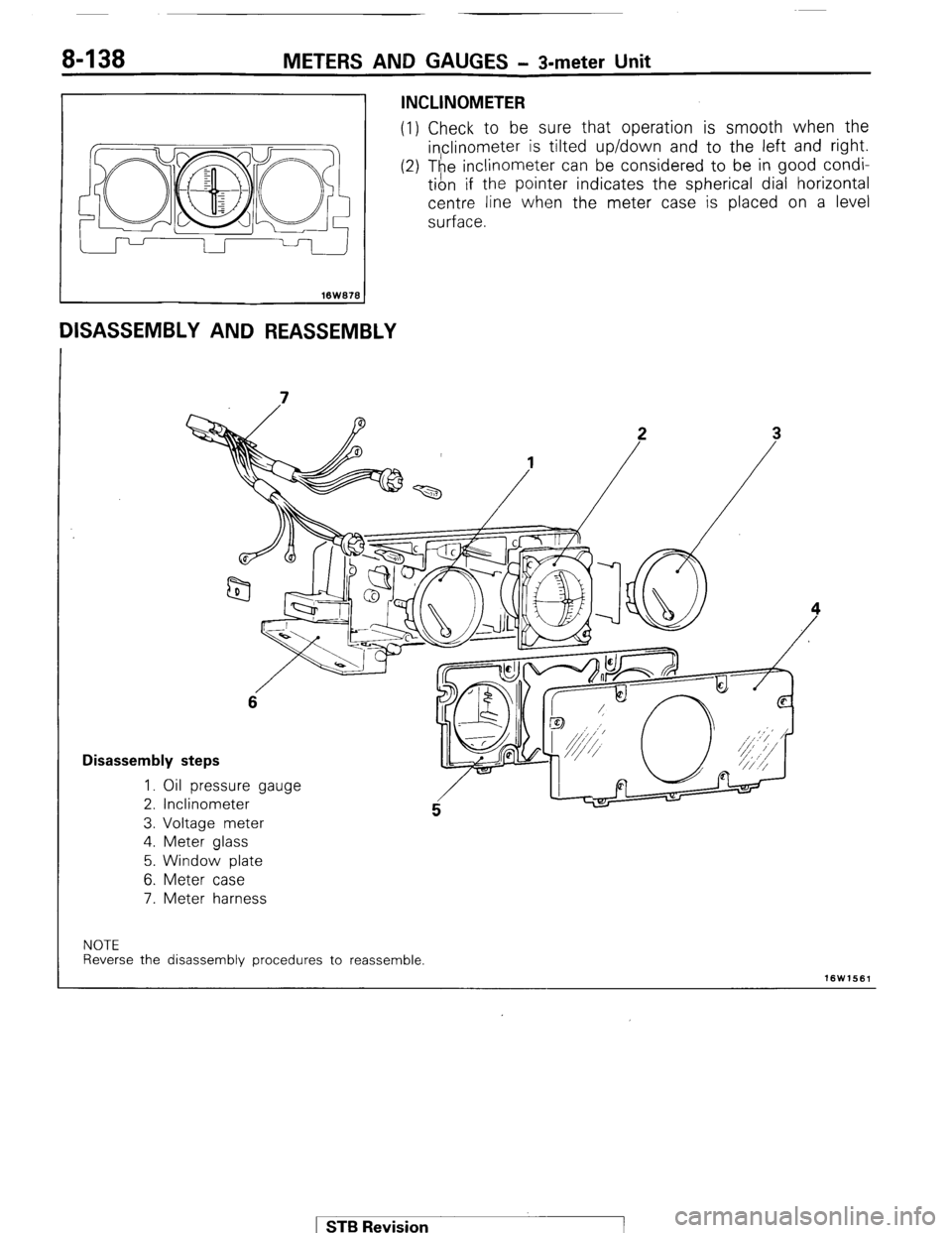

8-138 METERS AND GAUGES - s-meter Unit

16W678

DISASSEMBLY AND REASSEMBLY

INCLINOMETER

(1) Check to be sure that operation is smooth when the

inclinometer is tilted up/down and to the left and right.

(2) The i,nclinometer can be considered to be in good condi-

tion If the pointer indicates the spherical dial horizontal

centre line when the meter case is placed on a level

surface.

6

Disassembly steps

1. Oil pressure gauge

2. Inclinometer

3. Voltage meter

4. Meter glass

5. Window plate

6. Meter case

7. Meter harness

NOTE

Reverse the disassembly procedures to reassemble.

16W1561

1 ST6 Revision

Page 183 of 284

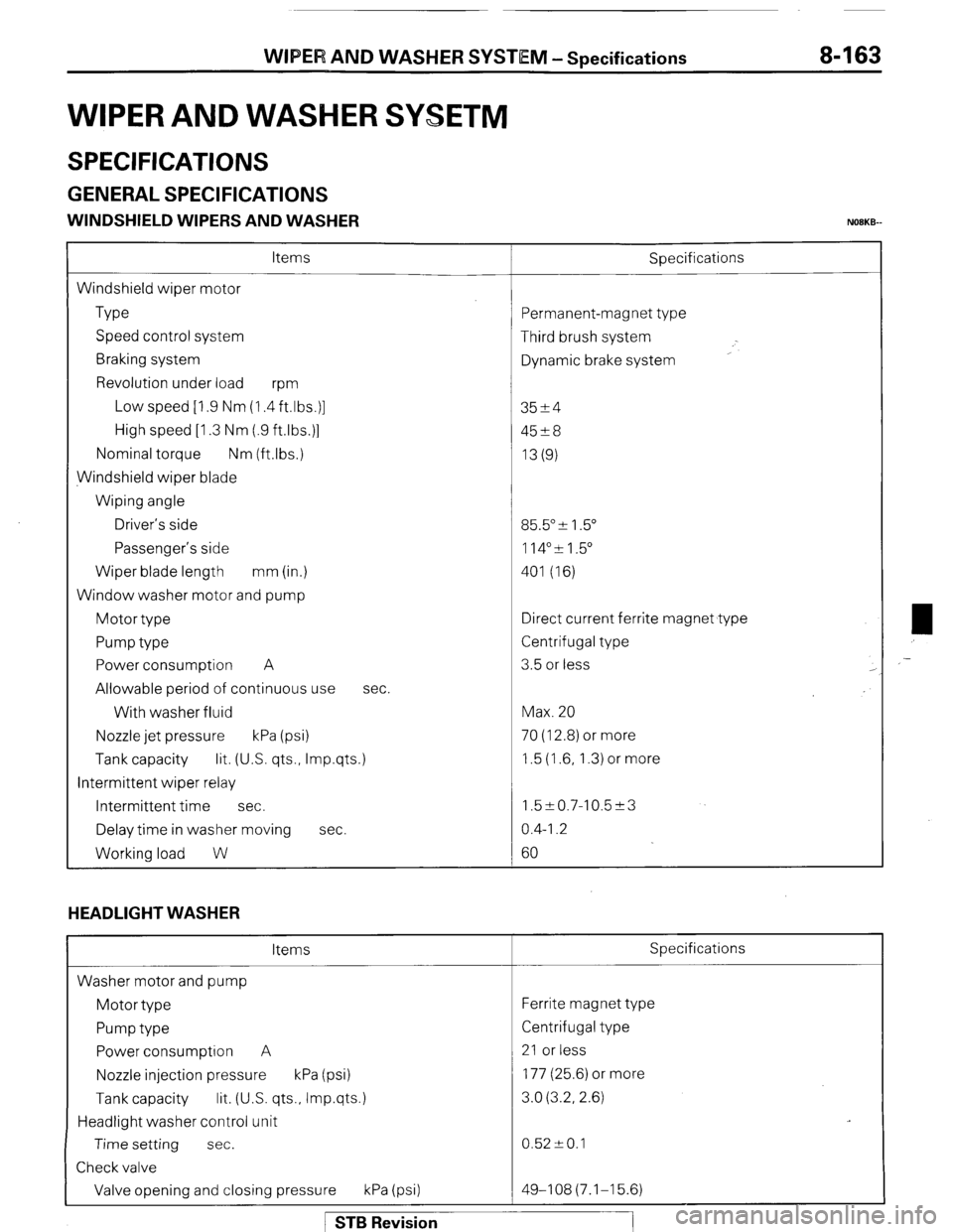

WIPER AND WASHER SYSTEM -Specifications 8-163

WIPER AND WASHER SYSETM

SPECIFICATIONS

GENERAL SPECIFICATIONS

WINDSHIELD WIPERS AND WASHER NOBKB-

Items

Windshield wiper motor

Type

Speed control system

Braking system

Revolution under load

wm

Low speed [I .9 Nm (1.4 ft.lbs.)]

High speed [I .3 Nm (.9 ftlbs.)]

Nominal torque Nm (ftlbs.)

Windshield wiper blade

Wiping angle

Driver’s side

Passenger’s side

Wiper blade length mm (in.)

Window washer motor and pump

Motor type

Pump type

Power consumption A

Allowable period of continuous use

With washer fluid

Nozzle jet pressure kPa (psi) Sbecifications

sec.

Tank capacity lit. (US. qts., Imp.qts.)

Intermittent wiper relay

Intermittent time sec.

Delay time in washer moving sec.

Working load W

HEADLIGHT WASHER

Items

Washer motor and pump

Motor type

Pump type

Power consumption A

Nozzle injection pressure kPa (psi)

Tank capacity lit. (U.S. qts., Imp.qts.)

Headlight washer control unit

Time setting sec.

Check valve

Valve opening and closing pressure kPa (psi) ‘ermanent-magnet type

Third brush system

Dynamic brake system

3524

45?8

13(g)

35.5” & 1.5”

114”51.5”

401 (16)

Iirect current ferrite magnet type

Zentrifugal type

3.5 or less

Max. 20

70 (12.8) or more

1.5 (1.6, 1.3) or more

1.5~0.7-10.5~3

0.4-I .2

60

Specifications

Ferrite magnet type

Centrifugal type

21 or less

177 (25.6) or more

3.0 (3.2, 2.6)

0.52 -+ 0.1

49-108(7.1-15.6) ,-

1 STB Revision

Page 184 of 284

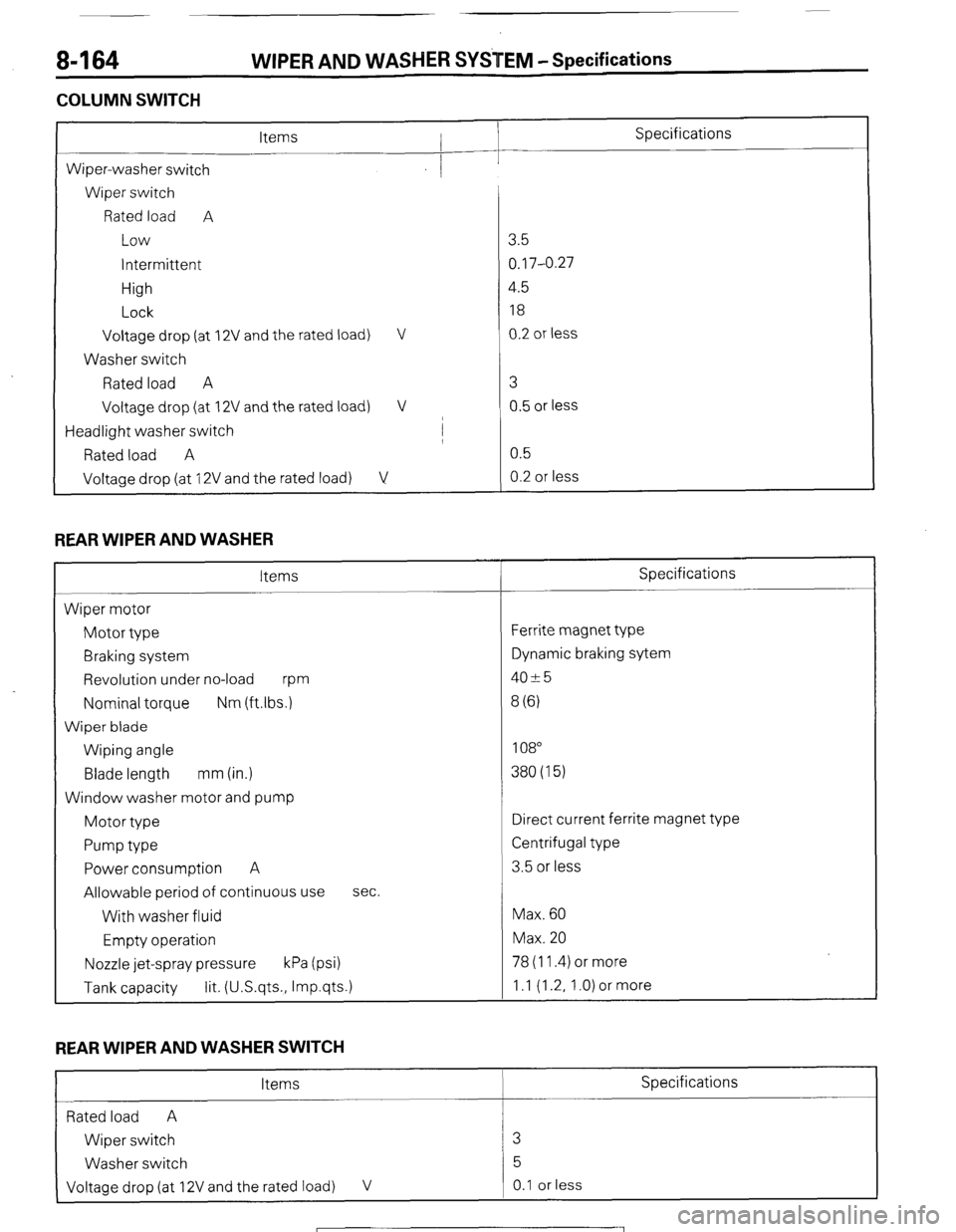

8-164 WIPER AND WASHER SYSTEM -Specifications

COLUMN SWITCH

L

Specifications

Wiper-washer switch

Wiper switch

Rated load A

Low

intermittent

High

Lock

Voltage drop (at

Washer switch

Rated load A

Voltage drop (at 2V and the rated load) V

2V and the rated load) V

/

Headlight washer switch I

Rated load A

Voltage drop (at 12V and the rated load) V

REAR WIPER AND WASHER

Items

Wiper motor

Motor type

Braking system

Revolution under no-load

m

Nominal torque Nm (ftlbs.)

Wiper blade

Wiping angle

Blade length mm (in.)

Window washer motor and pump

Motor type

Pump type

Power consumption A

Allowable period of continuous use

With washer fluid

Empty operation sec.

Nozzle jet-spray pressure kPa (psi) 78 (11.4) or more

Tank capacity lit. (U.S.qts., Imp.qts.) 1 .I (1.2, 1 .O) or more 3.5

0.17-0.27

4.5

18

0.2 or less

3

0.5 or less

0.5

0.2 or less

Specifications

Ferrite magnet type

Dynamic braking sytem

4025

8 (6)

108

380(15)

Direct current ferrite magnet type

Centrifugal type

3.5 or less

Max. 60

Max. 20

REAR WIPER AND WASHER SWITCH

Items Specifications

Rated load A

Wiper switch 3

Washer switch 5

Voltage drop (at 12V and the rated load) V 0.1 or less

1 STB Revision

Page 195 of 284

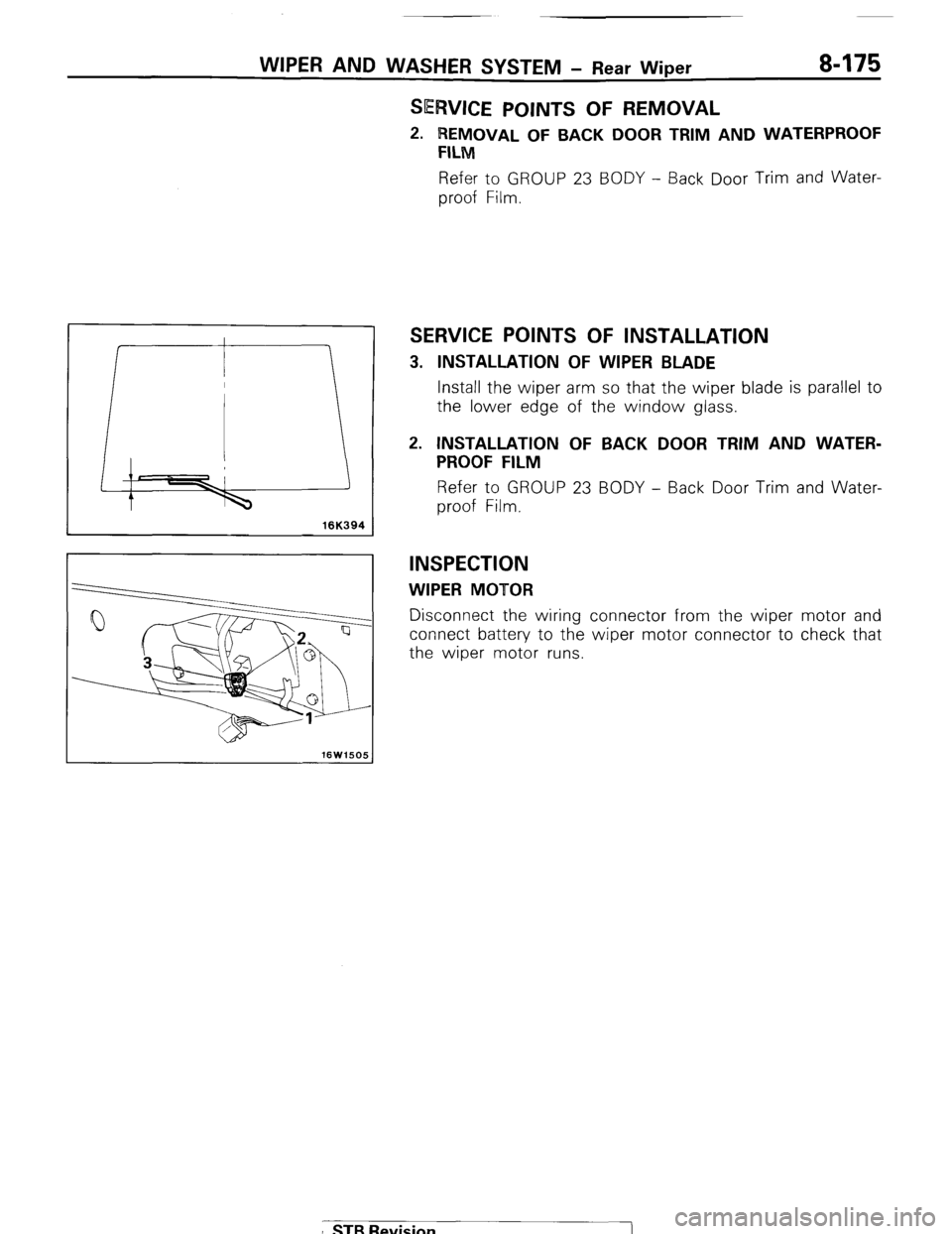

WIPER AND WASHER SYSTEM - Rear Wiper 8-175

SERVICE POINTS OF REMOVAL

2. REMOVAL OF BACK DOOR TRIM AND WATERPROOF

FILM

Refer to GROUP 23 BODY - Back Door Trim and Water-

proof Film.

I 16K394 1

SERVICE POINTS OF INSTALLATION

3. INSTALLATION OF WIPER BLADE

Install the wiper arm so that the wiper blade is parallel to

the lower edge of the window glass.

2. INSTALLATION OF BACK DOOR TRIM AND WATER-

PROOF FILM

Refer to GROUP 23 BODY - Back Door Trim and Water-

proof Film.

INSPECTION

WIPER MOTOR

Disconnect the wiring connector from the wiper motor and

connect battery to the wiper motor connector to check that

the wiper motor runs.

I STB Revision

Page 223 of 284

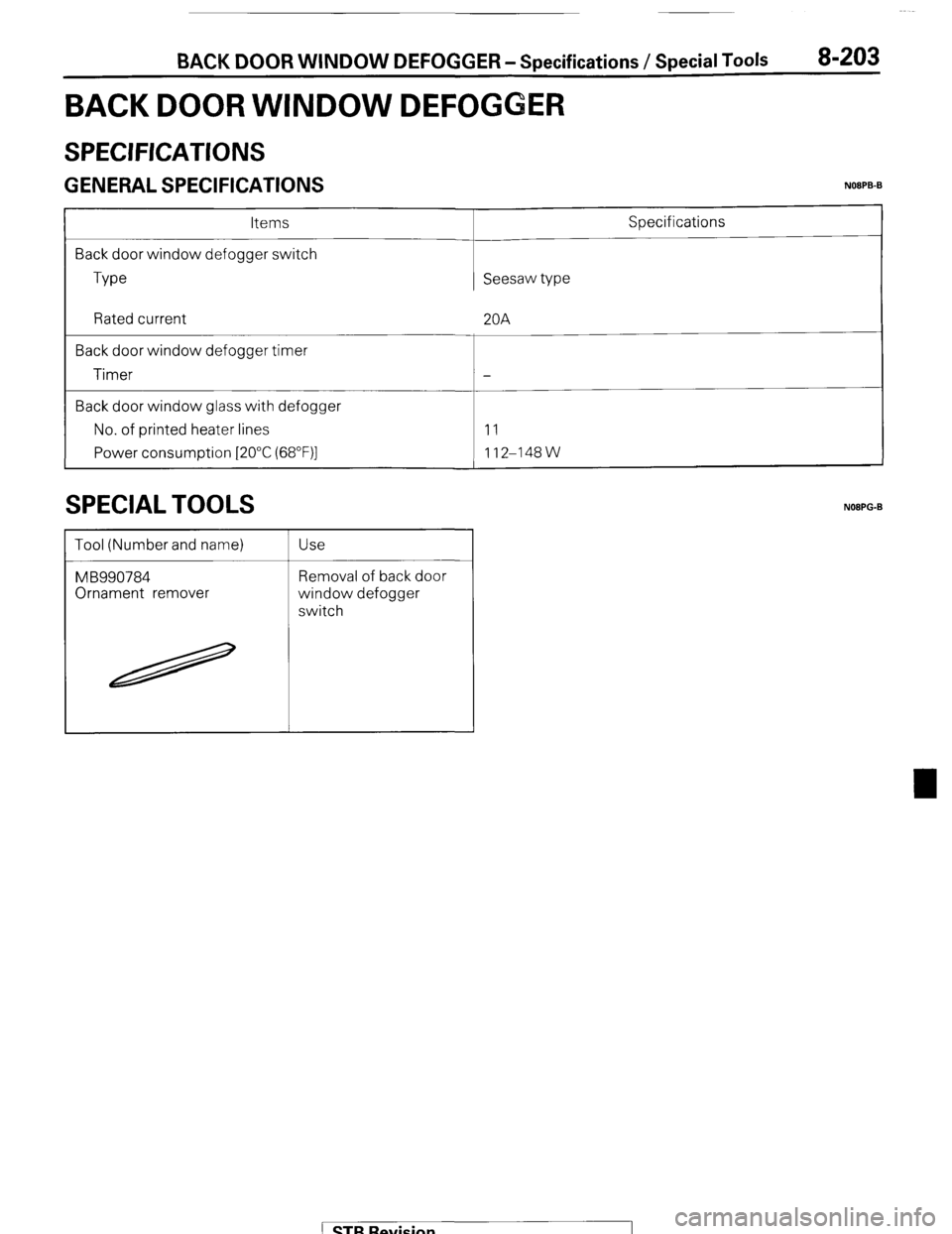

BACK DOOR WINDOW DEFOGGER - Specifications / Special Tools

BACK DOOR WINDOW DEFOGGER

8-203

SPECIFICATIONS

( ;ENERAL SPECIFICATIONS NOOPB-B

Items

Back door window defogger switch

Type Seesaw type Specifications

Rated current

Back door window defogger timer

Timer

Back door window glass with defogger

No. of printed heater lines

Power consumption [2O”C (68”F)] 20A

-

11

112-148W

SPECIAL TOOLS

Tool (Number and name)

MB990784

Ornament remover Use

Removal of back door

window defogger

switch

NOBPG-B

1 STB Revision

Page 224 of 284

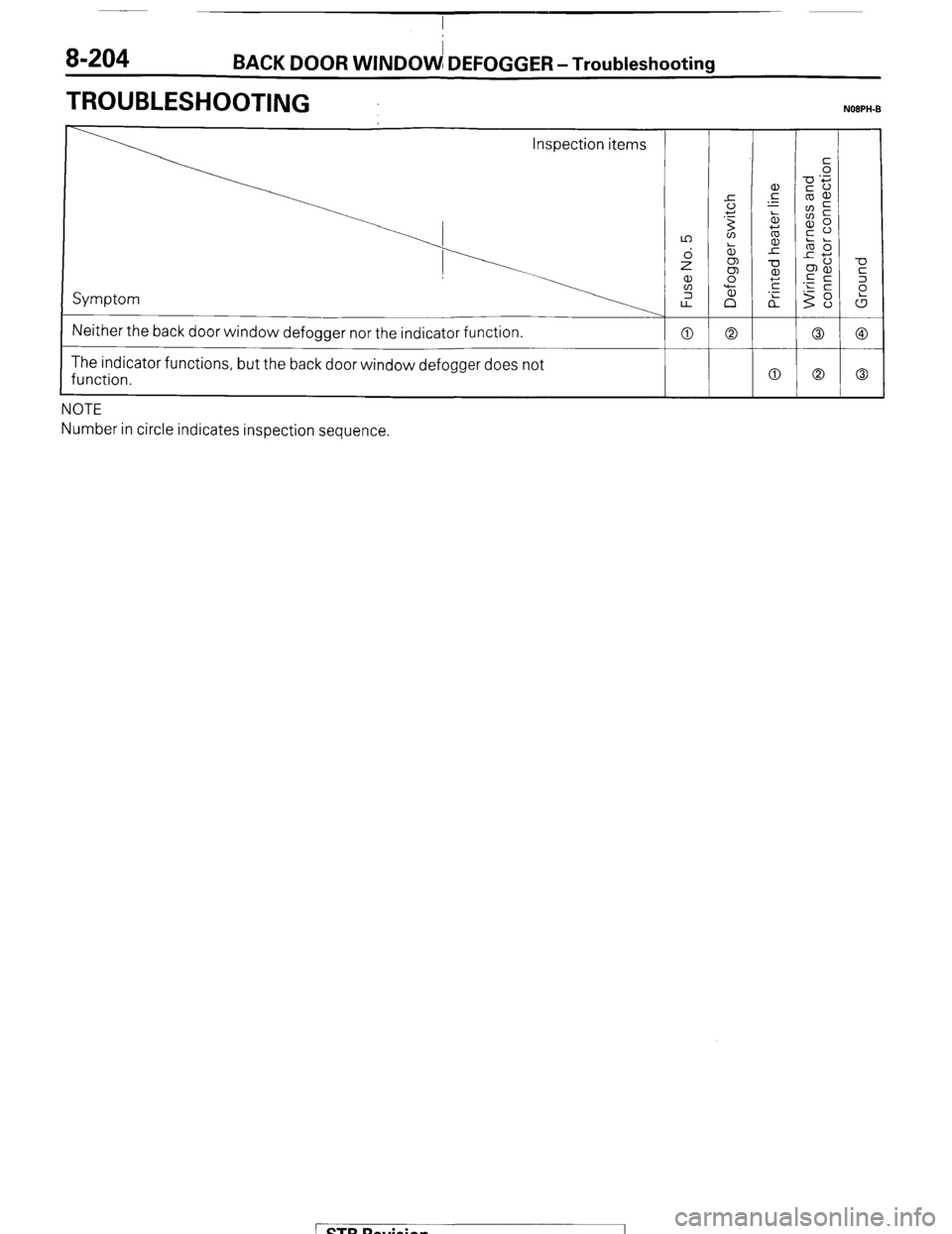

8-204 I BACK DOOR WINDOW DEFOGGER-Troubleshooting

TROUBLESHOOTING NOBPH-B

Neither the back door window defogger nor the indicator function.

0 0 0 @

The indicator functions, but the back door window defogger does not

function.

0 0 0

.---

Number in circle indicates inspection sequence.

/ STB Rqvision

Page 225 of 284

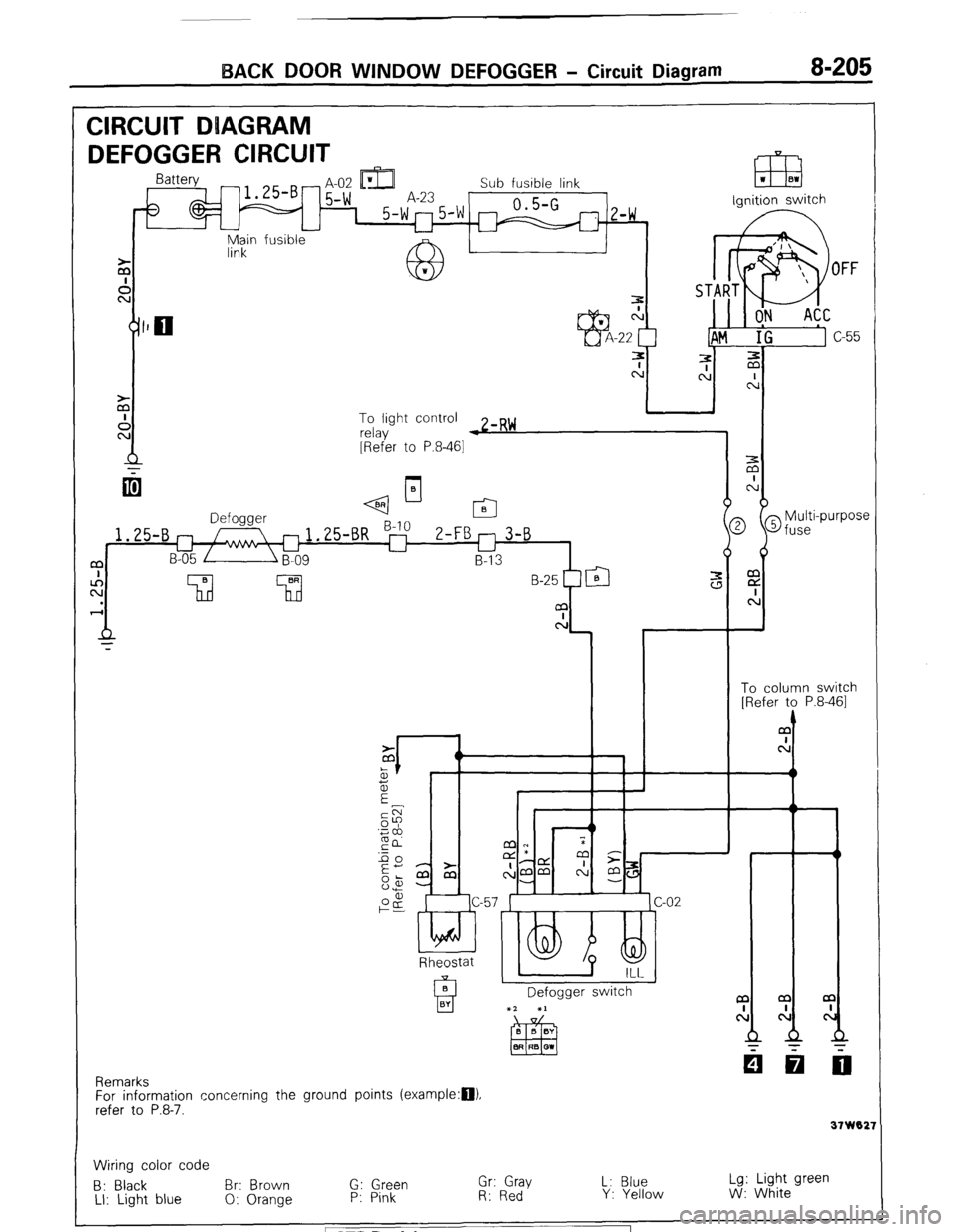

BACK DOOR WINDOW DEFOGGER - Circuit Diagram 8-205

CIRCUIT DUAGRAM

DEFOGGER CIRCUIT -t IDI L

m

- H-UL Ll&J Sub fusible link

5-w A-23 0.5-G 1 5-w"5'w m

z-w ,

u

fusible ignition switch

Main

link

To light control

relay w zmR~

[Refer to P.8-461

q--l-

2 @fuse

i

Multi-purpose m

E

c:

t

To column switch

[Refer to P.8-461

1.25-B

a

c!

Rheostat

Defogger switch a

cl

31 W02:

Remarks

For information concerning the ground points (example:D).

refer to P.8-7.

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White STB Revision

Page 226 of 284

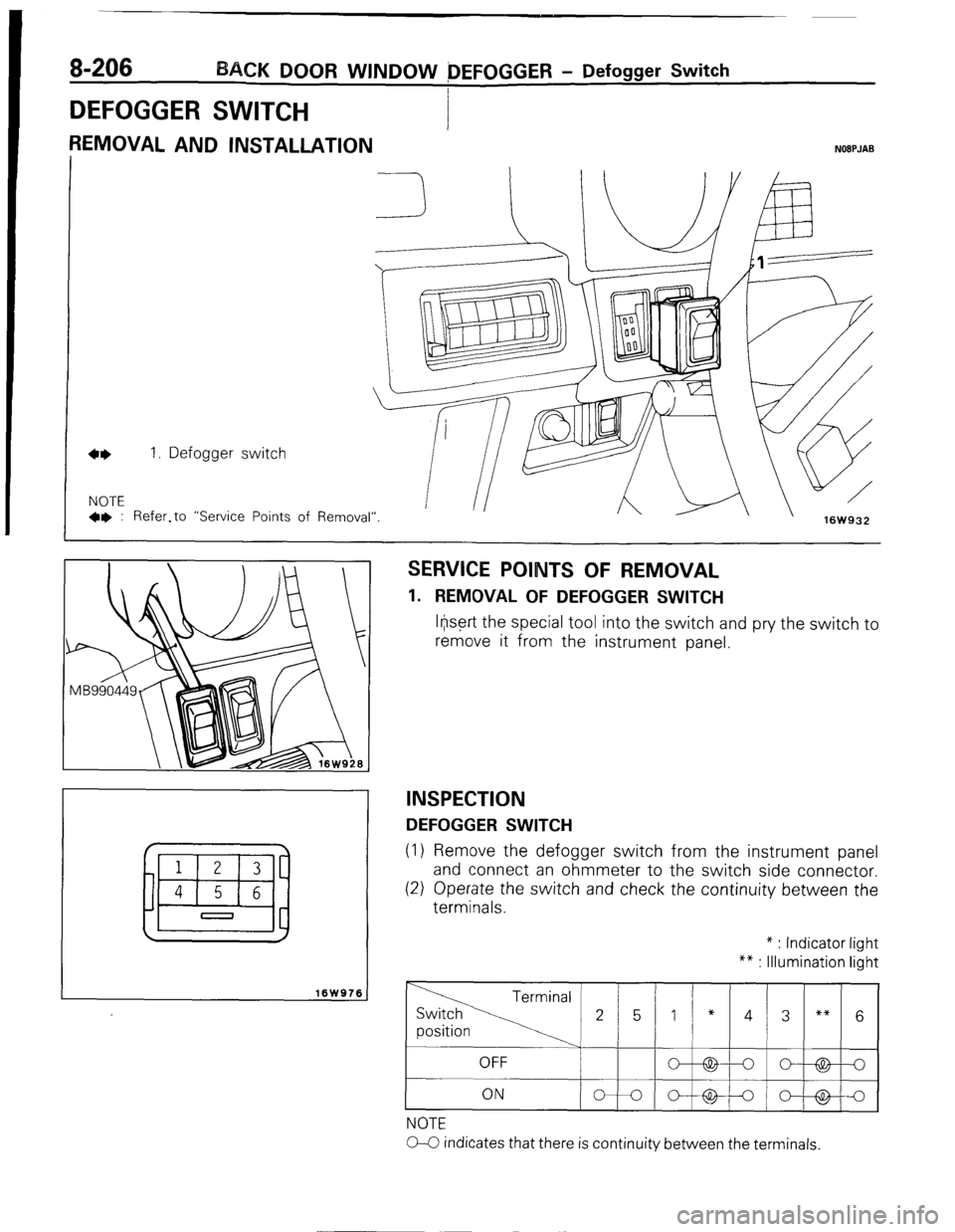

DEFOGGER SWITCH

1

REMOVAL AND INSTALLATION

8-206 BACK DOOR WINDOW OEFOGGER - Defogger Switch

I

NOEPJAB

1. Defogger switch

NOTE

+* : Refer.to “Service Points . ^

I_ A w

ot Kernoval” 16W932

I

16W976 J

SERVICE POINTS OF REMOVAL

1. REMOVAL OF DEFOGGER SWITCH

lr@rt the special tool into the switch and pry the switch to

remove it from the instrument panel.

INSPECTION

DEFOGGER SWITCH

(1) Remove the defogger switch from the instrument panel

and connect an ohmmeter to the switch side connector.

(2) Operate the switch and check the continuity between the

terminals. * : Indicator light

** : Illumination light

NOTE

0-C indicates that there is continuity between the terminals.

1 STB Revision

~-E

Page 227 of 284

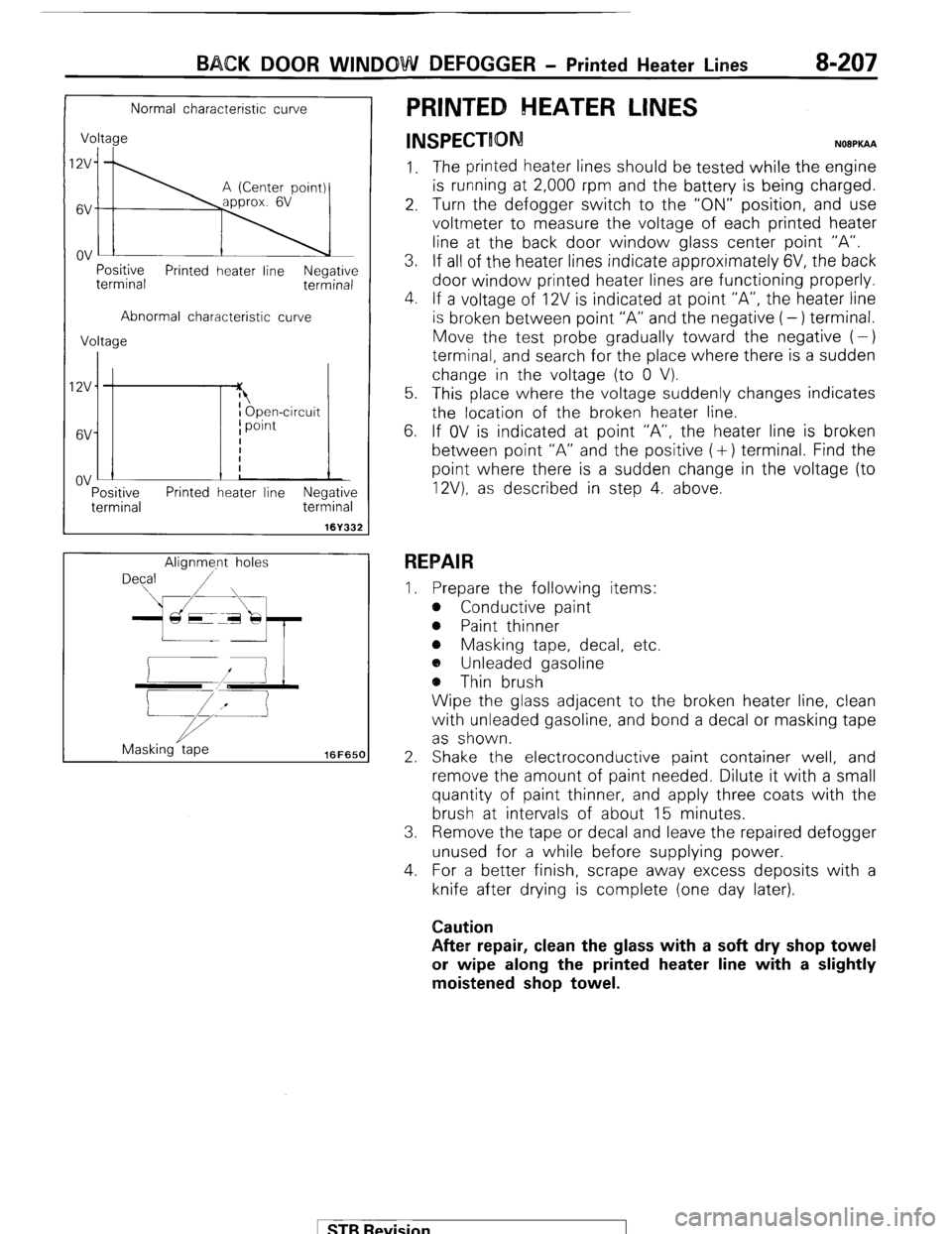

BACK DOOR WINDOW DEFOGGER - Printed Heater Lines B-207

Normal characteristic curve

Voltage

I;\

Positive

terminal Printed heater line Negative

terminal

Abnormal characteristic curve

Voltage

IZV

6V

ov :-

Tf I Open-circuit

I point

I

i

!

Positive Printed heater line Negative

terminal terminal

161332

Alignme.nt holes

Masking tape

16FfiSCl

PRINTED HEATER LINES

INSPECTION N08PKAA

1. The printed heater lines should be tested while the engine

is running at 2,000 rpm and the battery is being charged.

2. Turn the defogger switch to the “ON” position, and use

voltmeter to measure the voltage of each printed heater

line at the back door window glass center point “A”.

3. If all of the heater lines indicate approximately 6V, the back

door window printed heater lines are functioning properly.

4. If a voltage of 12V is indicated at point “A”, the heater line

is broken between point “A” and the negative (-) terminal.

Move the test probe gradually toward the negative (-)

terminal, and search for the place where there is a sudden

change in the voltage (to 0 V).

5. This place where the voltage suddenly changes indicates

the location of the broken heater line.

6. If OV is indicated at point “A”, the heater line is broken

between point “A” and the positive (+) terminal. Find the

point where there is a sudden change in the voltage (to

12V). as described in step 4. above.

REPAIR

I. Prepare the following items:

e Conductive paint

@ Paint thinner

e Masking tape, decal, etc.

a, Unleaded gasoline

@ Thin brush

Wipe the glass adjacent to the broken heater line, clean

with unleaded gasoline, and bond a decal or masking tape

as shown.

2. Shake the electroconductive paint container well, and

remove the amount of paint needed. Dilute it with a small

quantity of paint thinner, and apply three coats with the

brush at intervals of about 15 minutes.

3. Remove the tape or decal and leave the repaired defogger

unused for a while before supplying power.

4. For a better finish, scrape away excess deposits with a

knife after drying is complete (one day later).

Caution

After repair, clean the glass with a soft dry shop towel

or wipe along the printed heater line with a slightly

moistened shop towel.

1 STB Revision