window MITSUBISHI MONTERO 1987 1.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 270 of 284

24-34 AIR-CONDITIONING-Service Adiustment Procedures

r---- :

:ES

Dry bulb therr&neter

2OW825

PEAFORMANCE TEST

TESI N24FWAB NOTE

Air temperature in test room must be 21°C (70°F) minimum for this

test.

(1) Connect a tachometer and manifold gauge set.

(2) Set air conditioner controls to Max air conditioner, tempera-

ture lever on full cool, and blower on high.

(3) Turn engine on 1000 rpm with air conditioner clutch engaged.

(4) Engine should be warmed up with doors, windows, and hood

open.

(5) Insert a thermometer in the left center air conditioner outlet

and operate the engine for 5 minutes.

(6) Note the discharge air temperature.

NOTE

If the clutch cycles, take the reading before the clutch disen-

gages.

Performance Temperature Chart Garage ambient

temperature

21 “C 26.5 “C 32 “C 37.5 “C 40.6 “C (70 “F) (80 “F) (90 “F) (100 “F) (I 05 “F)

Discharge air

temperature

Compressor

discharge pressure

Evaporator suction

pressure

1.7-4.4 “C 1.7-5.0 “C 1.7-5.6 “C 1.7-6.1 “C 1.7-6.7 “C (35-40 “F) (35-41 “F) (35-42 “F) (35-43 “F) (35-44 “F)

928- 1,322 kPa 1.069-1.547 kPa 1,209-1,772 kPa 1,336-1,969 kPa 1,406-2,109 kPa

(132-188 psi) (152-220 psi) (172-252 psi) (190-280 psi) (200-300 psi)

127-148 kPa

131-162 kPa 134-176 kPa 135- 188 kPa 136-194 kPa

(18-21 psi) (18.6-23 psi) (19-25 psi) (19.2-26.8 psi) (19.4-27.6 psi)

REFRIGERANT LEAK REPAIR PROCEDURE N24FnAB

LOST CHARGE If the system has lost all charge due to a leak:

(1) Evacuate the system. (See the procedure).

(2) Charge the system with approximately one pound of refriger-

ant.

(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Refrigerant

leak tester

Replacement filter-drier units must be sealed while in stor-

age. The drier used in these units will saturate water quickly

upon exposure to the atmosphere. When installing a drier,

have all tools and supplies ready for quick reassembly to

avoid keeping the system open any longer than necessary. (7) Evacuate and charge the system.

LOW CHARGE If the system has not lost all of its refrigerant charge; locate and

tester repair all leaks. If it is necessary to increase the system pressure

up to find the leak (because of an especially low charge) add refrig-

erant. If it is possible to repair the leak without discharging the

refrigerant system, use the procedure for correcting low refriger-

2OUO316 ant level.

1 STB Revision

Page 271 of 284

AIR-CONDITIONING-Service Adiustment Procedures 24-35

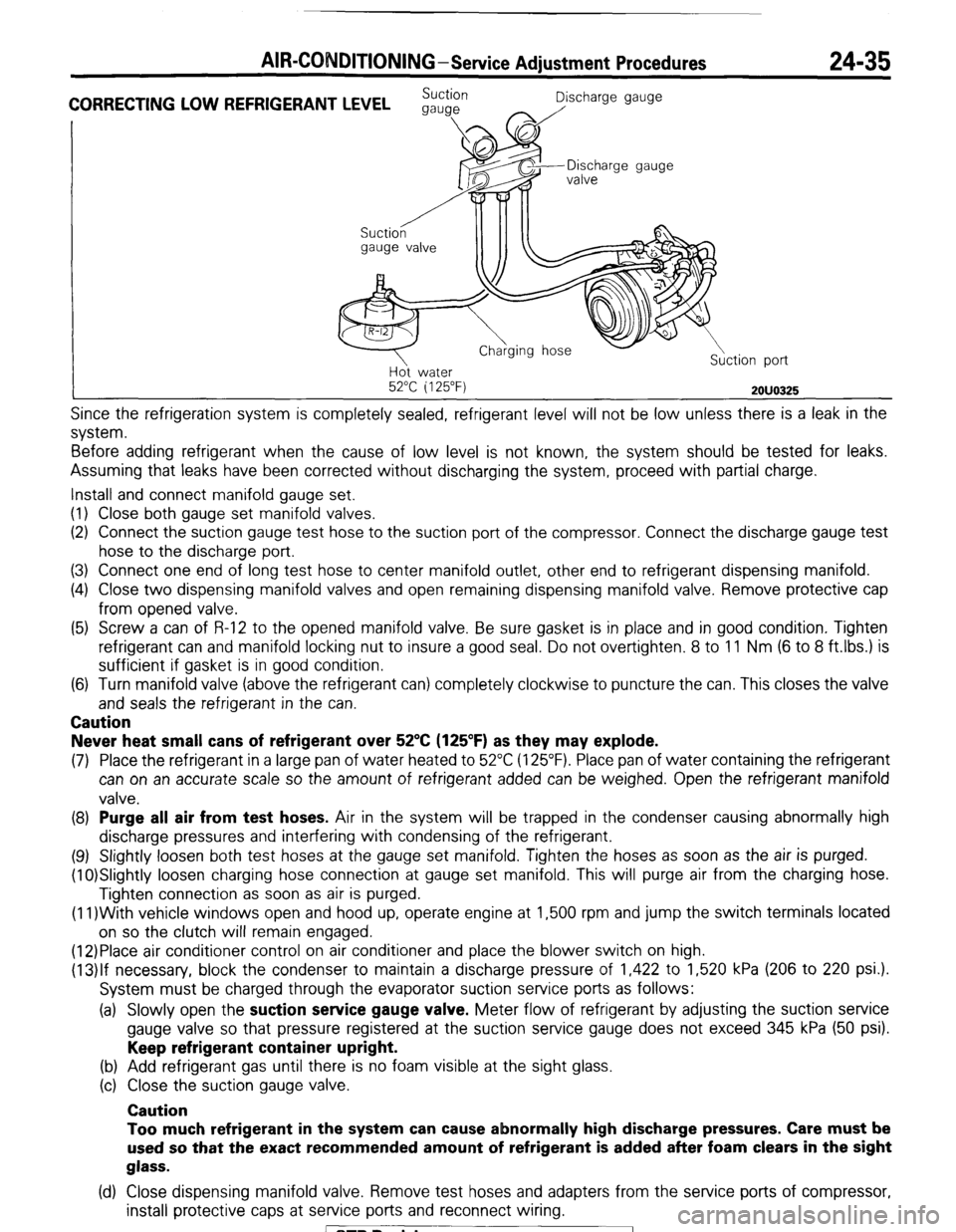

CORRECTING LOW REFRIGERANT LEVEL Suction

Discharge gauge

gauge

I \- a/

gauge valve

II II Discharge gauge

Ho water

52°C i 125°F)

2OUO325

Since the refrigeration system is completely sealed, refrigerant level will not be low unless there is a leak in the

system.

Before adding refrigerant when the cause of low level is not known, the system should be tested for leaks.

Assuming that leaks have been corrected without discharging the system, proceed with partial charge.

Install and connect manifold gauge set.

(I) Close both gauge set manifold valves.

(2) Connect the suction gauge test hose to the suction port of the compressor. Connect the discharge gauge test

hose to the discharge port.

(3) Connect one end of long test hose to center manifold outlet, other end to refrigerant dispensing manifold.

(4) Close two dispensing manifold valves and open remaining dispensing manifold valve. Remove protective cap

from opened valve.

(5) Screw a can of R-12 to the opened manifold valve. Be sure gasket is in place and in good condition. Tighten

refrigerant can and manifold locking nut to insure a good seal. Do not overtighten. 8 to 11 Nm (6 to 8 ft.lbs.) is

sufficient if gasket is in good condition.

(6) Turn manifold valve (above the refrigerant can) completely clockwise to puncture the can. This closes the valve

and seals the refrigerant in the can. Caution

Never heat small cans of refrigerant over 52°C (125’F) as they may explode.

(7) Place the refrigerant in a large pan of water heated to 52°C (125°F). Place pan of water containing the refrigerant

can on an accurate scale so the amount of refrigerant added can be weighed. Open the refrigerant manifold

valve. (8) Purge all air from test hoses.

Air in the system will be trapped in the condenser causing abnormally high

discharge pressures and interfering with condensing of the refrigerant.

(9) Slightly loosen both test hoses at the gauge set manifold. Tighten the hoses as soon as the air is purged.

(10)Slightly loosen charging hose connection at gauge set manifold. This will purge air from the charging hose.

Tighten connection as soon as air is purged.

(1l)With vehicle windows open and hood up, operate engine at 1,500 rpm and jump the switch terminals located

on so the clutch will remain engaged.

(12)Place air conditioner control on air conditioner and place the blower switch on high.

(13)lf necessary, block the condenser to maintain a discharge pressure of 1,422 to 1,520 kPa (206 to 220 psi.).

System must be charged through the evaporator suction service ports as follows:

(a) Slowly open the suction service gauge valve.

Meter flow of refrigerant by adjusting the suction service

gauge valve so that pressure registered at the suction service gauge does not exceed 345 kPa (50 psi). Keep refrigerant container upright.

(b) Add refrigerant gas until there is no foam visible at the sight glass.

(c) Close the suction gauge valve. Caution

Too much refrigerant in the system can cause abnormally high discharge pressures. Care must be

used so that the exact recommended amount of refrigerant is added after foam clears in the sight

glass.

(d) Close dispensing manifold valve. Remove test hoses and adapters from the service ports of compressor,

install protective caps at service ports and reconnect wiring. / STB Revision