alternator MITSUBISHI MONTERO 1987 1.G Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 106 of 284

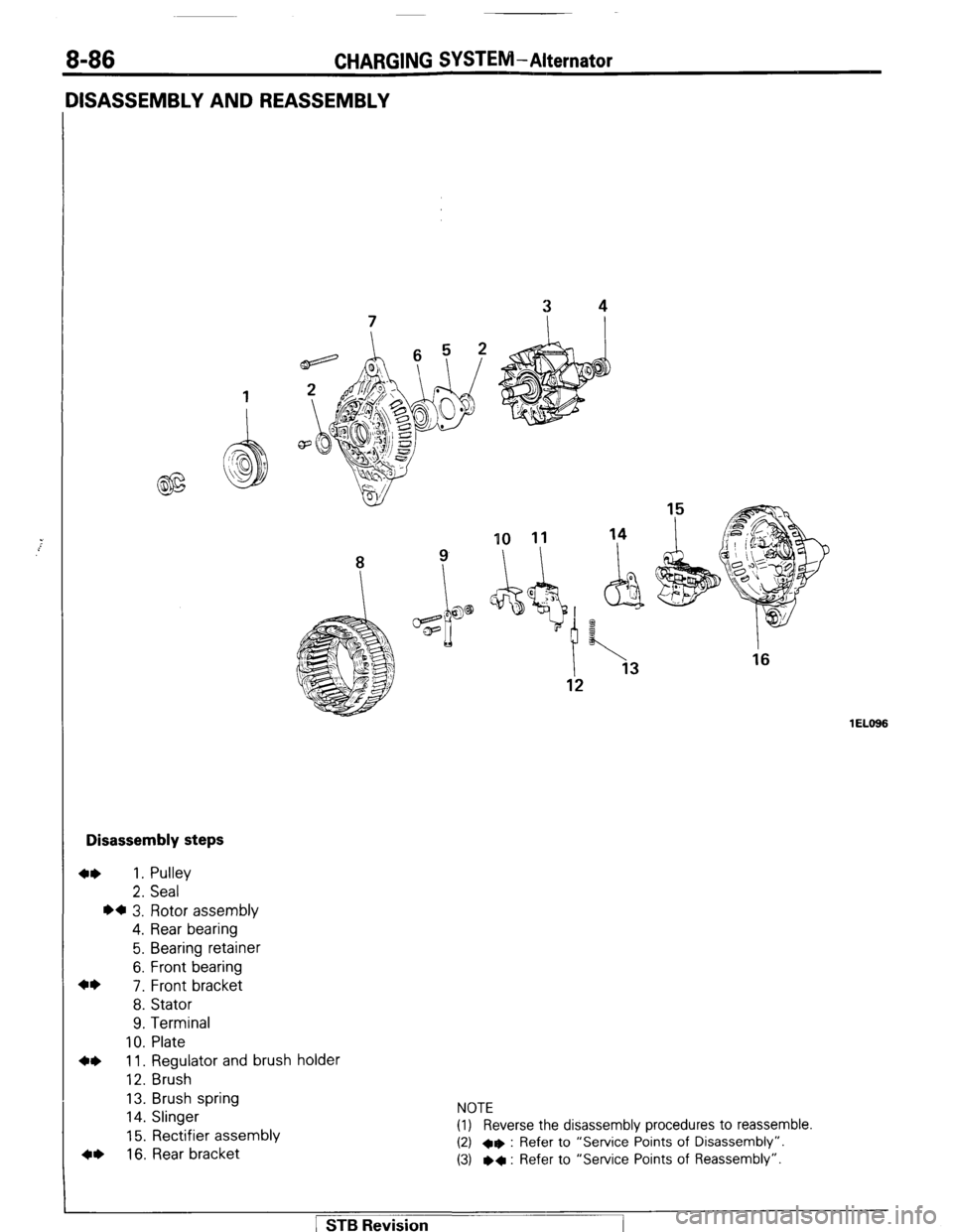

CHARGING SYSTEM-Alternator

10 11 14

8 ? \I I

Disassembly steps

4* 1. Pulley

2. Seal

l a 3. Rotor assembly

4. Rear bearing

5. Bearing retainer

6. Front bearing

4*

7. Front bracket

8. Stator

9. Terminal

10. Plate

4* 11. Regulator and brush holder

12. Brush

13. Brush spring

14. Slinger

15. Rectifier assembly

4, 16. Rear bracket NOTE

(1) Reverse the disassembly procedures to reassemble.

(2) +e : Refer to “Service Points of Disassembly”.

(3) l

+ : Refer to “Service Points of Reassembly”.

1 EL666 1 STB Revision

Page 107 of 284

CHARGING SYSTEM-Alternator 8-87

6ELllt

SERVICE POINTS OF DISASSEMBLY

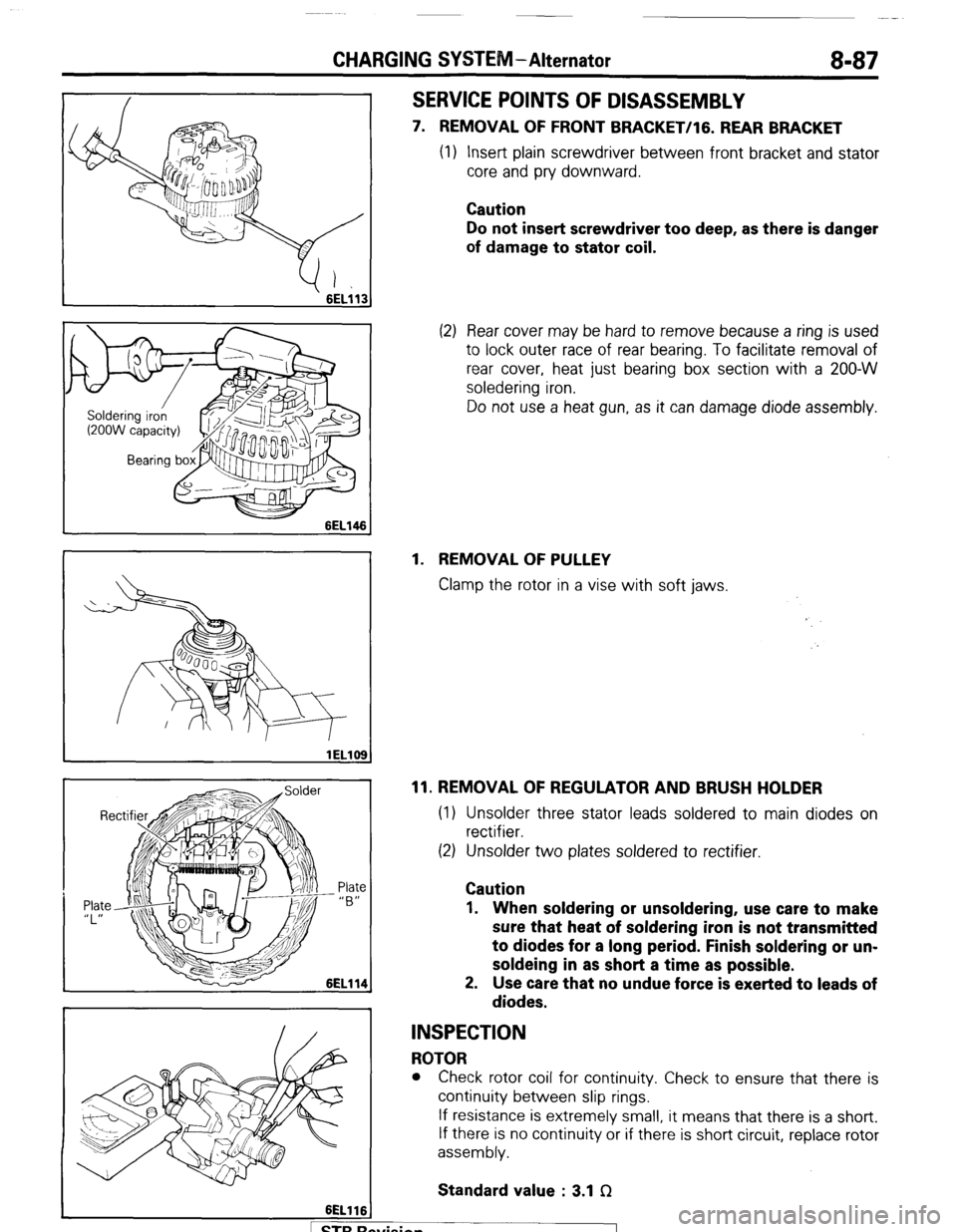

7. REMOVAL OF FRONT BRACKET/lG. REAR BRACKET

(1) Insert plain screwdriver between front bracket and stator

core and pry downward.

Caution

Do not insert screwdriver too deep, as there is danger

of damage to stator coil.

(2) Rear cover may be hard to remove because a ring is used

to lock outer race of rear bearing. To facilitate removal of

rear cover, heat just bearing box section with a 200-W

soledering iron.

Do not use a heat gun, as it can damage diode assembly.

1. REMOVAL OF PULLEY

Clamp the rotor in a vise with soft jaws.

11. REMOVAL OF REGULATOR AND BRUSH HOLDER

(1) Unsolder three stator leads soldered to main diodes on

rectifier.

(2) Unsolder two plates soldered to rectifier.

Caution

1. When soldering or unsoldering, use care to make

sure that heat of soldering iron is not transmitted

to diodes for a long period. Finish soldering or un-

soldeing in as short a time as possible.

2. Use care that no undue force is exerted to leads of

diodes.

INSPECTION

ROTOR

l Check rotor coil for continuity. Check to ensure that there is

continuity between slip rings.

If resistance is extremely small, it means that there is a short.

If there is no continuity or if there is short circuit, replace rotor

assembly.

Standard value : 3.1 f2

. . .

I 1 STB hewsion

Page 108 of 284

8-88 CHARGING SYSTEM-Alternator

6EL115

3ELOlO

lELll0

lELll1

A

) STBRc

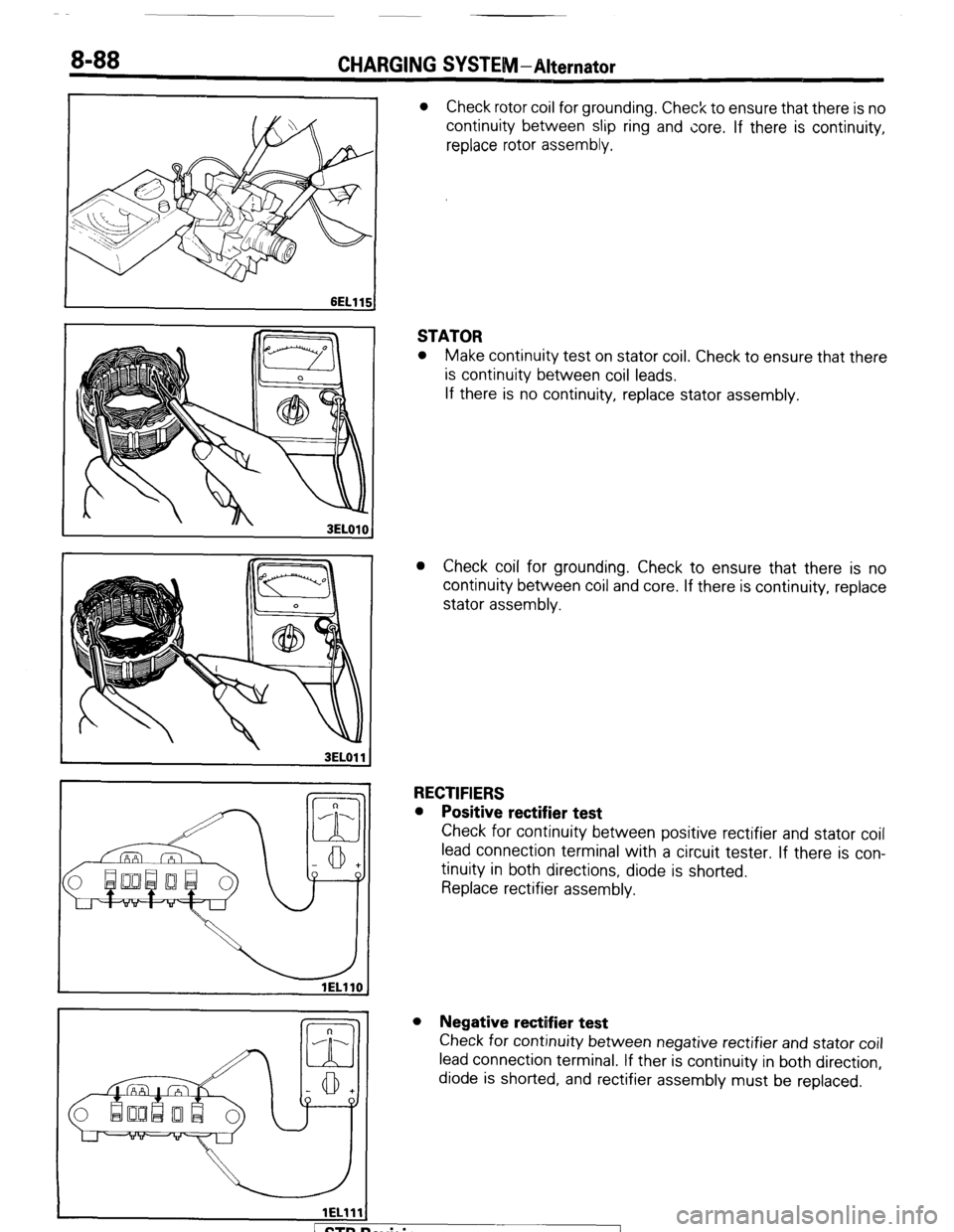

l Check rotor coil for grounding. Check to ensure that there is no

continuity between slip ring and core. If there is continuity,

replace rotor assembly.

STATOR

l Make continuity test on stator coil. Check to ensure that there

is continuity between coil leads.

If there is no continuity, replace stator assembly.

l Check coil for grounding. Check to ensure that there is no

continuity between coil and core. If there is continuity, replace

stator assembly.

RECTIFIERS

l Positive rectifier test

Check for continuity between positive rectifier and stator coil

lead connection terminal with a circuit tester. If there is con-

tinuity in both directions, diode is shorted.

Replace rectifier assembly.

l Negative rectifier test

Check for continuity between negative rectifier and stator coil

lead connection terminal. If ther is continuity in both direction,

diode is shorted, and rectifier assembly must be replaced.

evision

-7

Page 110 of 284

8-90 CHARGING SYSTEM-Alternator

Rear bracket Wire

6EL122

6EL123 I

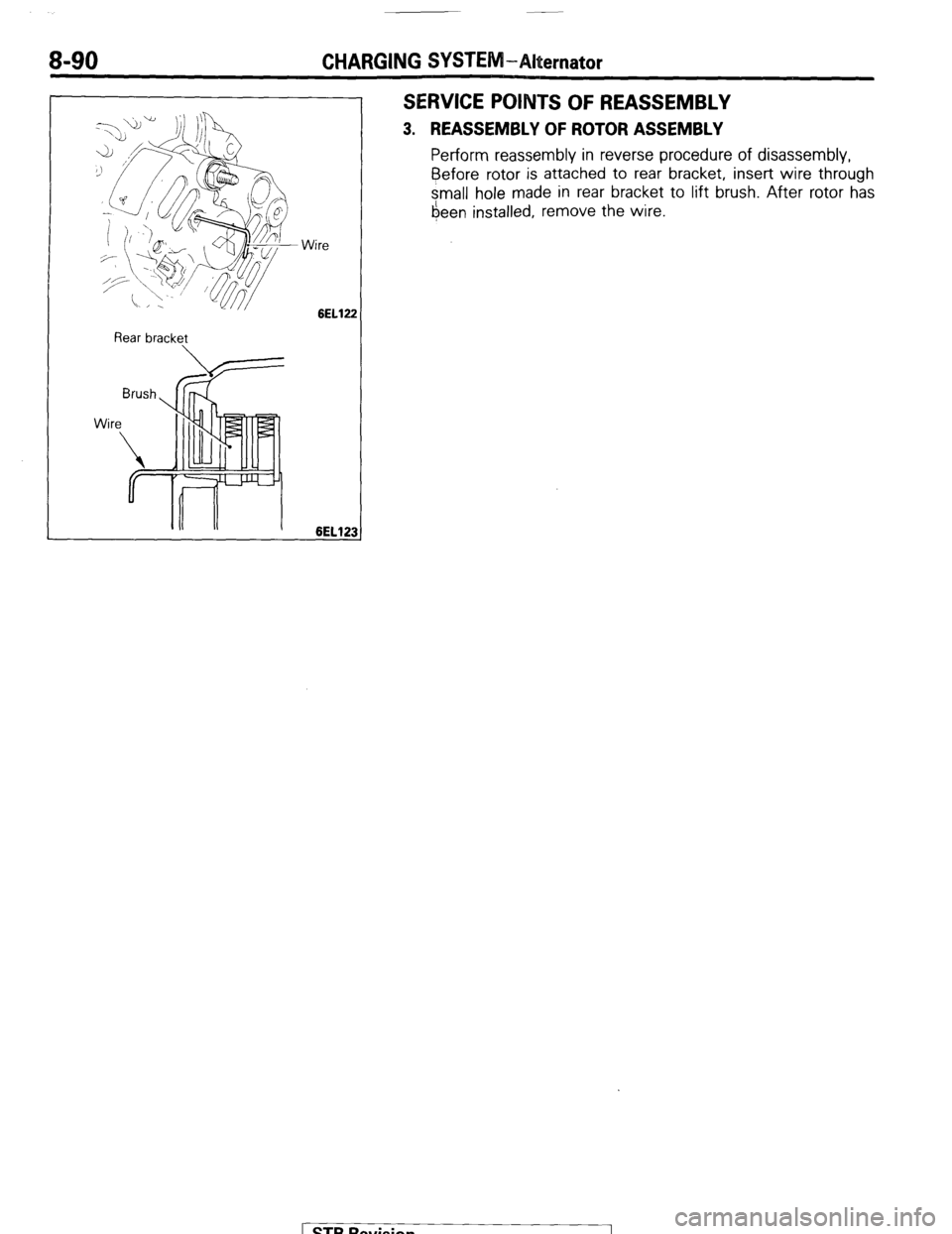

SERVICE POINTS OF REASSEMBLY

3. REASSEMBLY OF ROTOR ASSEMBLY

Perform reassembly in reverse procedure of disassembly,

Before

rotor is attached to rear bracket, insert wire through

small hole made in rear bracket to lift brush. After rotor has

6een installed, remove the wire.

STB Revision

Page 148 of 284

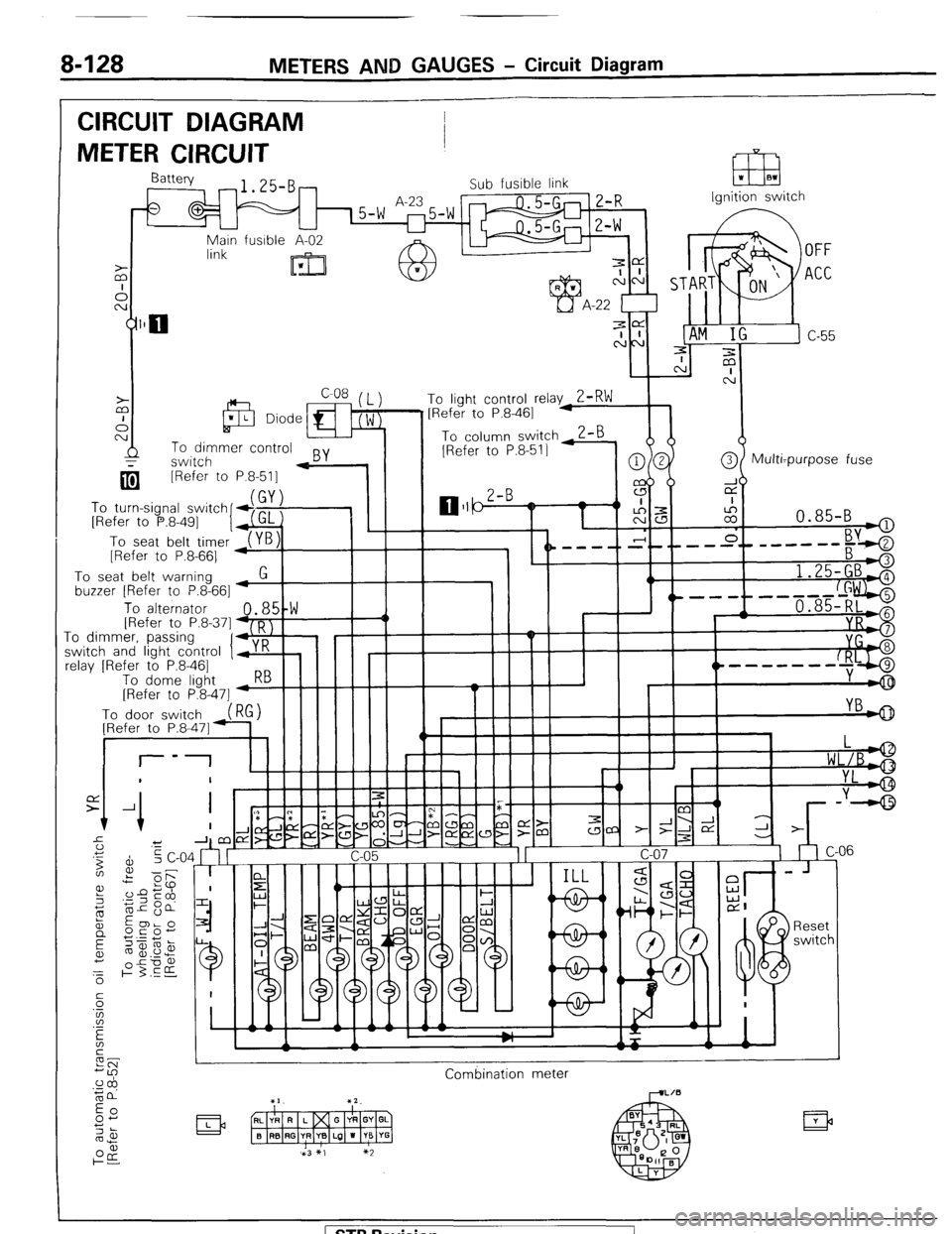

8-128 METERS AND GAUGES - Circuit Diagram

CIRCUIT DIAGRAM

METER CIRCUIT

Ignition switch

q [Refer to

To turn-signal switch

[Refer to P.8-491

I

To seat belt timer

[Refer to P.8-661 P.8-511 -

To seat belt warning

buzzer [Refer to P.8-661

1.25-GBA

, ^.

To alternator 48,5!W III -1 / 1 , 1 '----f--d+ii$$j IRefer to P.8.371 D I

.I_ -0 dimmkr, passinq

‘I+,:’ ! I I I II -I

I r I I I II YI

;witch and light control y K

clay [Refer to P.8-461

To dome liaht 5--hIIII I

----m-w-

[Refer to P&47] -w

Combination meter

( STB Revision

Page 213 of 284

AUDIO SYSTEM - Specifications 8-193

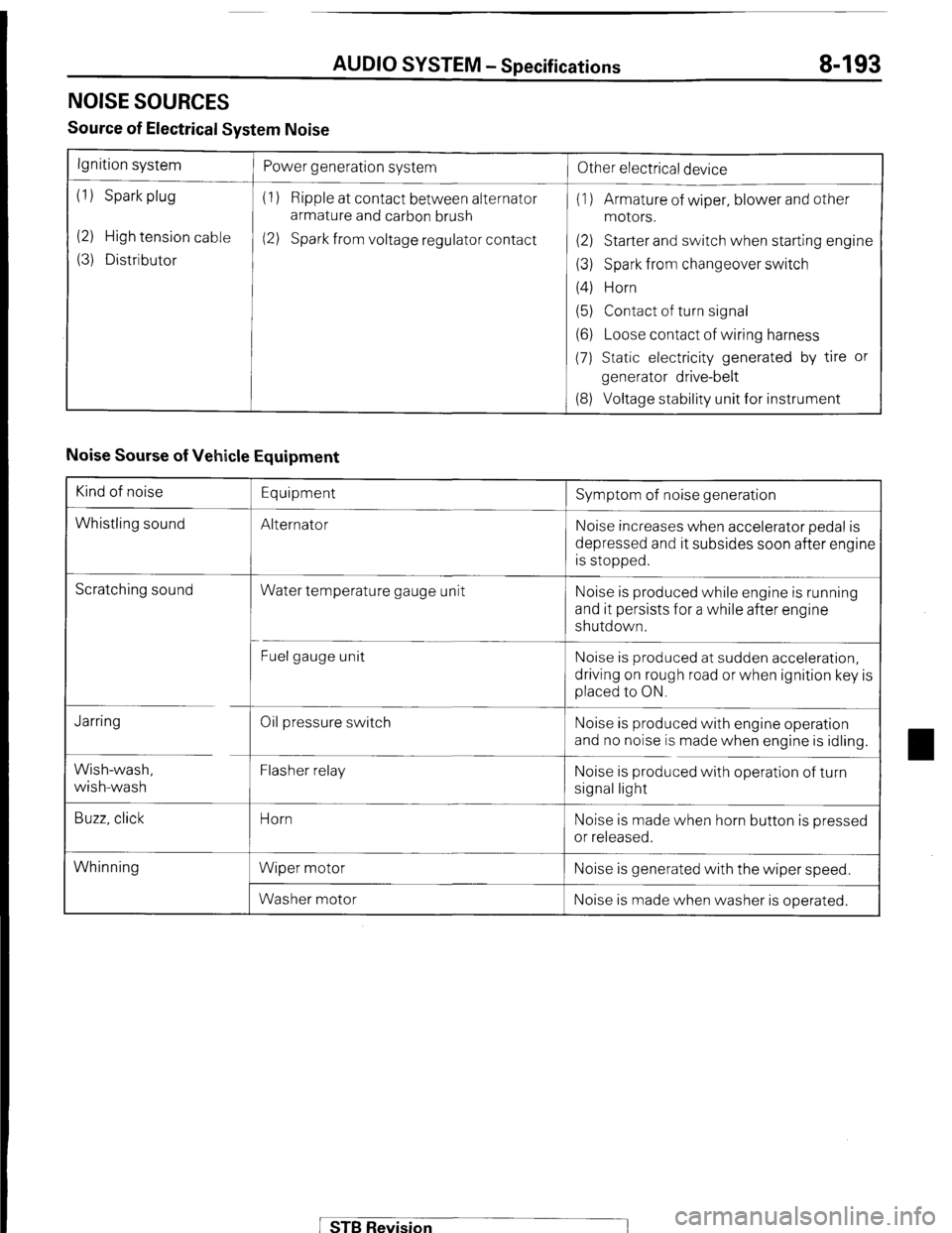

NOISE SOURCES

Source of Electrical System Noise

Ignition system

(1) Spark plug

(2) High tension cable

(3) Distributor Power generation system

(1) Ripple at contact between alternator

armature and carbon brush

(2) Spark from voltage regulator contact

!

Other electrical device

(1) Armature of wiper, blower and other

motors.

(2) Starter and switch when starting engine

(3) Spark from changeover switch

(4) Horn

(5) Contact of turn signal

(6) Loose contact of wiring harness

(7) Static electricity generated by tire or

generator drive-belt

(8) Voltage stability unit for instrument

Noise Sourse of Vehicle Equipment

Kind of noise

Whistling sound Equipment

Alternator Symptom of noise generation

Noise increases when accelerator pedal is

depressed and it subsides soon after engine

is stopped.

Scratching sound

Water temperature gauge unit Noise is produced while engine is running

and it persists for a while after engine

shutdown.

Fuel gauge unit Noise is produced at sudden acceleration,

driving on rough road or when ignition key is

placed to ON.

Jarring

Wish-wash,

wish-wash

Buzz, click Oil pressure switch

Flasher relay

Horn

Wiper motor

Washer motor Noise is produced with engine operation

and no noise is made when engine is idling.

Noise is produced with operation of turn

signal light

Noise is made when horn button is pressed

or released.

Whinning Noise is generated with the wiper speed.

Noise is made when washer is operated.

STB Revision

Page 220 of 284

8-200 AUDIO SYSTEM - Antenna/Noise Suppression

3. REMOVAL OF FRONT FENDER PANEL

Refer to GROUP 23 Body-Front Fender

SEFiVlCE ff OINTS OF INSTALLATION

3. IbSTALLATION OF FRONT FENDER PANEL

Refer to GROUP 23 Body-Front Fender.

NOISE SWPRESSION N08NOAA

I. Noise interfering with radio reception may be roughly

classified as follows:

(1) Noise produced by the vehicle itself

Noise from the ignition circuit, alternator circuit, etc

(2) Noise generated in the radio itself

Thermal noise from transistors, IC, resistor, etc.

(3) Atmospheric noise

Noise from other cars, neon signs, etc.

2. The radio has devices to suppress noise of the radio itsel f

3. and atmospheric noise, but it is difficult to eliminate them

completely. Noise produced by the vehicle includes whin-

ing from the alternator system, and a strong, impulsive,

fast popping noise from the ignition system.

Before performing any checking or adjustments, first

confirm the following points.

Adjust the antenna trimmer completely.

Set the push buttons (tuning) properly.

Extend the antenna all the way.

PREVENTION OF IGNITION CIRCUIT NOISE

A resistance-equipped cable is used for the high-tension cable

in order to prevent noise; however, if any noise from the

ignition circuit does occur, check the tightness and ground

connection of the positive (+) terminal of the noise filter, and,

if necessary, check the noise filter.

Caution

Be careful not to connect the noise filter to the hightension

cable; doing so could damage the noise filter.

PREVENTION OF OTHER CIRCUIT NOISE

1. For other noises, take necessary corrective actions in

accordance with the following items and the NOISE

SUPPRESSION CHART.

2. Polish the grounding cable terminal, and connect it proper-

ly.

3. Polish the pillar antenna ground terminal, and connect it

properly.

4. Ground electric parts completely.

5. Keep the antenna cable and speaker lead wire away from

other electric wiring.

STB Revision

Page 277 of 284

AIR-CONDITIONING -Service Adjustment Procedures 24-41

COMPRESSOR NOISE NWLM

When investigating an air conditioning related noise, you must first know the conditions when the noise occurs.

These conditions are: weather, vehicle speed, in gear or neutral, engine temperature or any other special

conditions.

Noises that develop during air- conditioning operation can often be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be caused by loose bolts, nuts, mounting brackets, or a loose clutch

assembly. Verify accessory drive belt tension (power

steering, alternator or air pump). Improper accessory drive belt

tension can cause a misleading noise when the compressor is engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed sensitive. That is, at different engine speeds, and depending upon belt tension, belts can

develop unusual noises that are often mistaken for mechanical problems within the compressor.

Adjustment Procedures

(1) Select a quiet area for testing. Duplicate conditions as much as possible. Switch compressor on and off several

times to clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure), restrict air-flow through

condenser. Install

manifold gauge set to make sure discharge pressure does not exceed 2,070 kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting bolt, and compressor drive belt. Check to assure clutch

coil is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can cause unusual noises.

(4) Check refrigerant charge (See “Charging the System”).

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

1 STB Revision