heater MITSUBISHI MONTERO 1987 1.G Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 249 of 284

HEATERS - Heater Unit 24-13

2. REMOVAL OF INSTRUMENT PANEL

Refer to GROUP 23 BODY-Instrument Panel.

INSPEGTION N24cAa

l

Check the damper and link mechanism for operation.

l Check the heater core for clogging or water leakage.

l Check the water valve for operation and clogging.

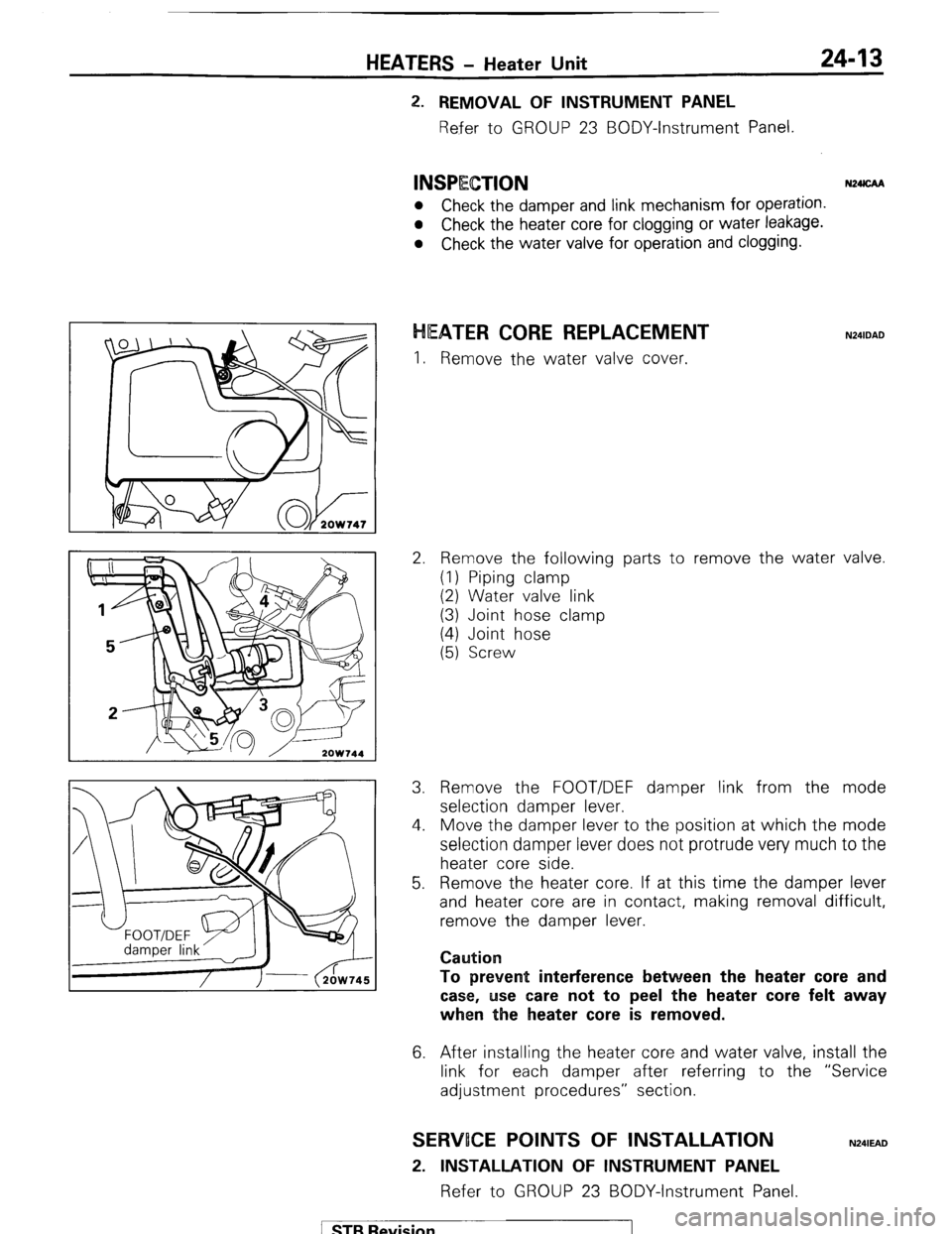

EATER CORE REPLACEMENT

I. Remove the water valve cover.

2. Remove the following parts to remove the water valve.

(1) Piping clamp

(2) Water valve link

(3) Joint hose clamp

(4) Joint hose

(5) Screw

3. Remove the FOOT/DEF damper link from the mode

selection damper lever.

4. Move the damper lever to the position at which the mode

selection damper lever does not protrude very much to the

heater core side.

5. Remove the heater core. If at this time the damper lever

and heater core are in contact, making removal difficult,

remove the damper lever.

Caution

To prevent interference between the heater

core and

case, use care not to peel the heater

core felt away

when the heater core is removed.

6. After installing the heater core and water valve, install the

link for each damper after referring to the “Service

adjustment procedures” section.

SERWOCE POINTS OF INSTALLATION

2. INSTALLATION OF INSTRUMENT PANEL

Refer to GROUP 23 BODY-Instrument Panel.

N241EAD

1 STB Revision

Page 250 of 284

24-14 HEATERS + Blower Assembly

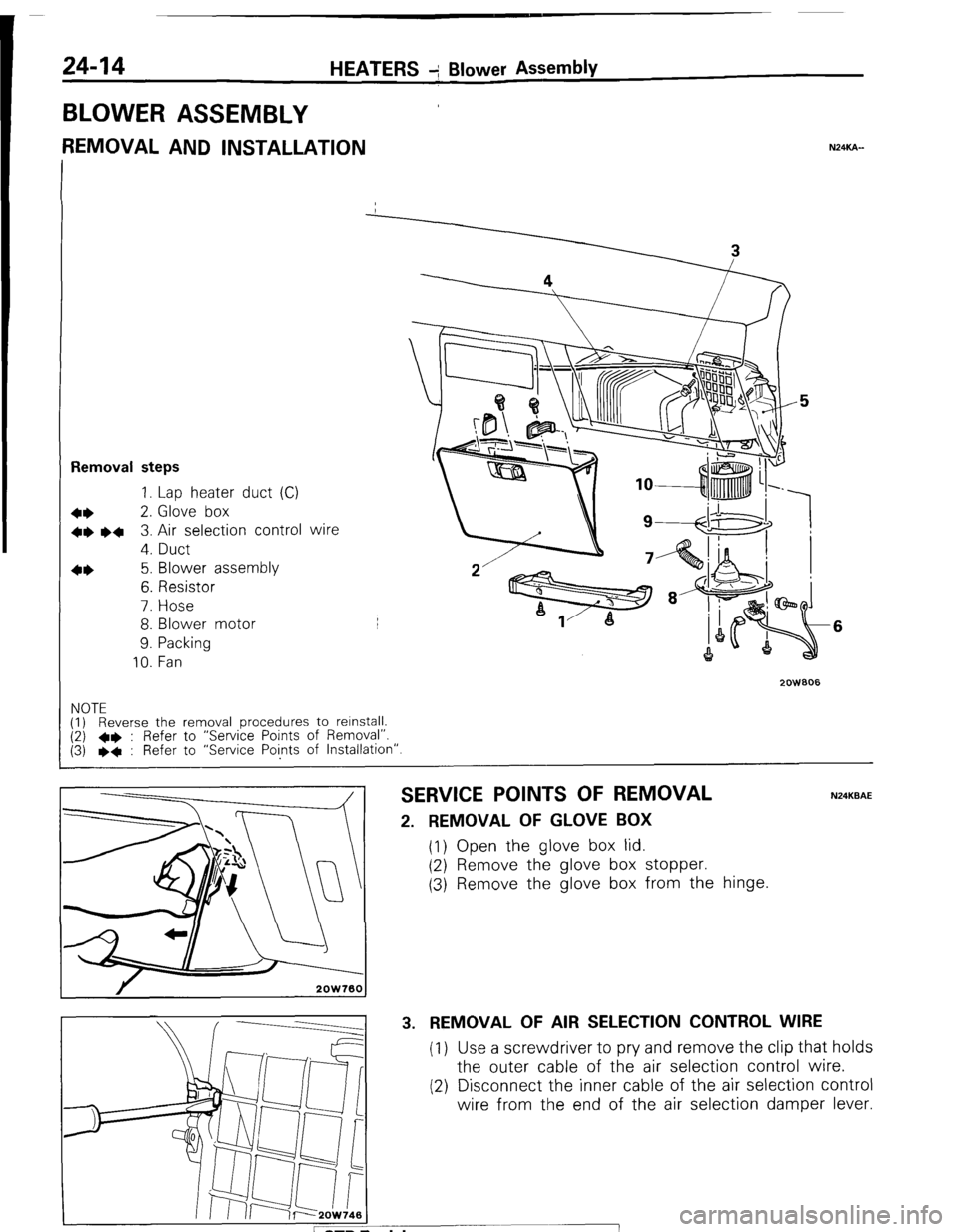

BLOWER ASSEMBLY

REMOVAL AND INSTALLATION NXKA-

Removal steps

1. Lap heater duct (C)

+* 2. Glove box

+e l + 3. Air selection control wire

4. Duct

4* 5. Blower assembly

6. Resistor

7. Hose

8. Blower motor

9. Packing

10. Fan

2oWBO6

6

NOTE

(1) Reverse the removal procedures to relnstall. (2) l * : Refer to “Service Points of Removal”.

(3) l * : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL N24KBAE

2. REMOVAL OF GLOVE BOX

(1) Open the glove box lid.

(2) Remove the glove box stopper.

(3) Remove the glove box from the hinge.

3. REMOVAL OF AIR SELECTION CONTROL WIRE

(1) Use a screwdriver to pry and remove the clip that holds

the outer cable of the air selection control wire.

(2) Disconnect the inner cable of the air selection control

wire from the end of the air selection damper lever.

Page 251 of 284

HEATERS - Blower Assembly 24-15

--I

Front wirina harness

d

!

2OW537

2OW768

2OW779

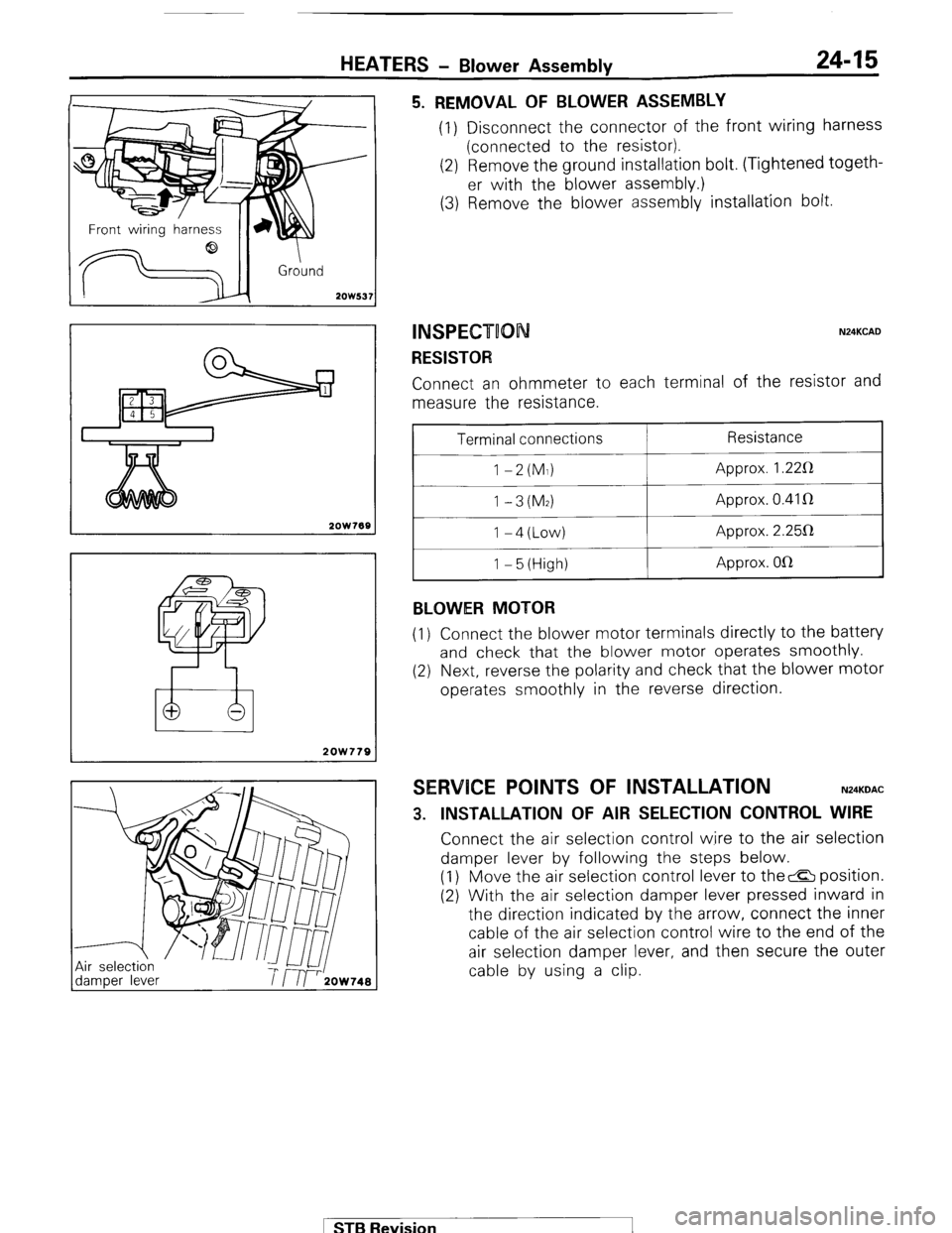

5. REMOVAL OF BLOWER ASSEMBLY (1) Disconnect the connector of the front wiring harness

(connected to the resistor).

(2) Remove the ground installation bolt. (Tightened togeth-

er with the blower assembly.)

(3) Remove the blower assembly installation bolt.

INSPECT00 N24KCAD

RESISTOR Connect an ohmmeter to each terminal of the resistor and

measure the resistance.

Terminal connections

1 -2(M1)

1 -3(M2) I-4(Low)

1 - 5 (High)

BLOWER MOTOR Resistance

Approx. 1.22R

Approx. 0.41 R

Approx. 2.25112

Approx. OlR

(1) Connect the blower motor terminals directly to the battery

and check that the blower motor operates smoothly.

(2) Next, reverse the polarity and check that the blower motor

operates smoothly in the reverse direction.

SERVICE POINTS OF INSTALLATION N24KDAC

3. INSTALLATION OF AIR SELECTION CONTROL WIRE Connect the air selection control wire to the air selection

damper lever by following the steps below.

(1) Move the air selection control lever to the& position.

(2) With the air selection damper lever pressed inward in

the direction indicated by the arrow, connect the inner

cable of the air selection control wire to the end of the

air selection damper lever, and then secure the outer

cable by using a clip.

1 STB Revision

Page 252 of 284

24-16 HEATER? - Ventilators

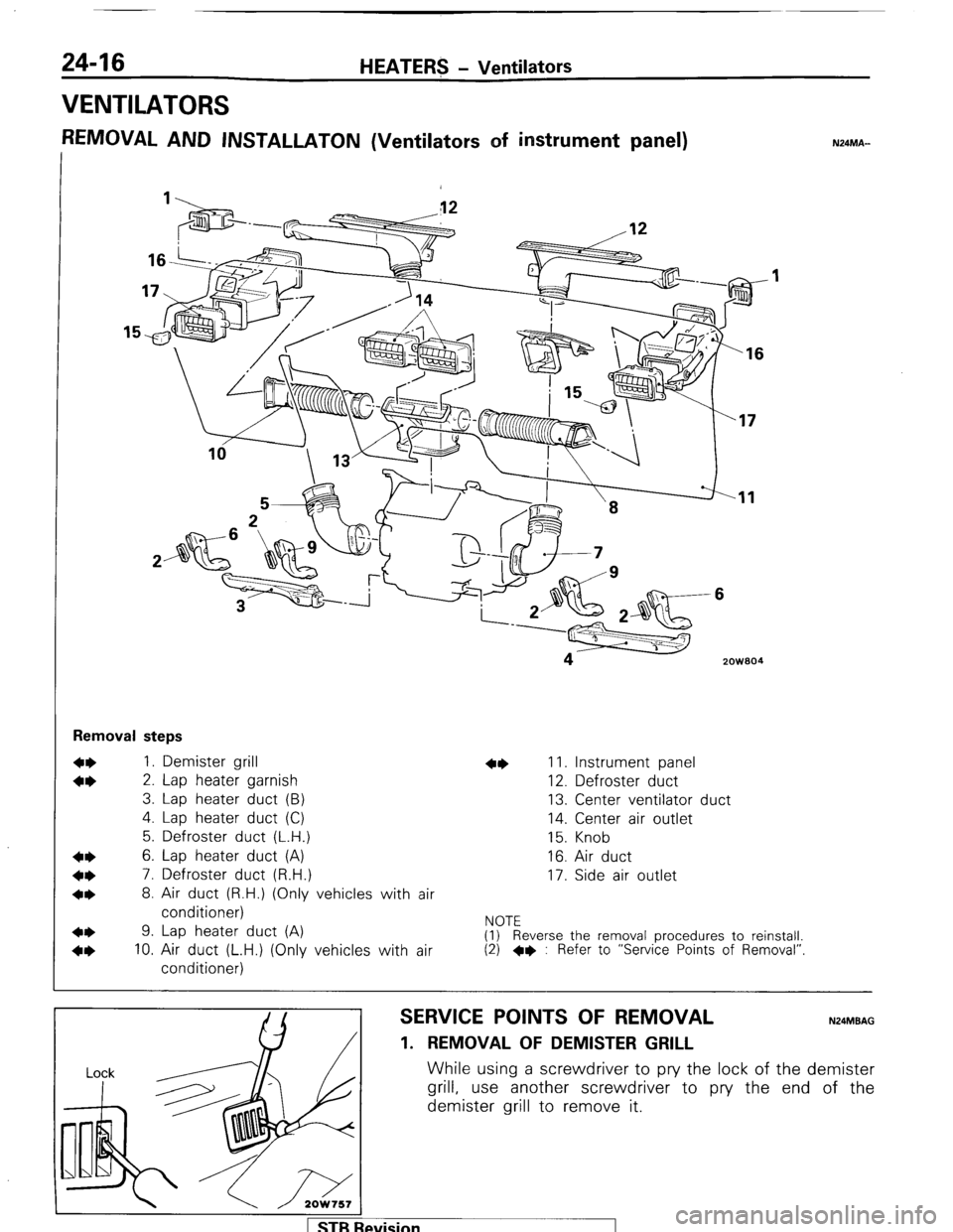

VENTILATORS

REMOVAL AND INSTALLATON (Ventilators of instrument panel) N24MA-

‘16

zowaa I4

Removal steps

1. Demister grill

2. Lap heater garnish

3. Lap heater duct (B)

4. Lap heater duct (C)

5. Defroster duct (L.H.)

6. Lap heater duct (A)

7. Defroster duct (R.H.)

8. Air duct (R.H.) (Only vehicles with air

conditioner)

9. Lap heater duct (A)

10. Air duct (L.H.) (Only vehicles with air

conditioner) 11. Instrument panel

12. Defroster duct

13. Center ventilator duct

14. Center air outlet

15. Knob

16. Air duct

17. Side air outlet

NOTE

(1) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”

SERVICE POINTS OF REMOVAL N24MBAG

1. REMOVAL OF DEMISTER GRILL

While using a screwdriver to pry the lock of the demister

grill, use another screwdriver to pry the end of the

demister grill to remove it.

levision

Page 253 of 284

HEATERS - Ventilators 24-17

2OW75l

2OW759

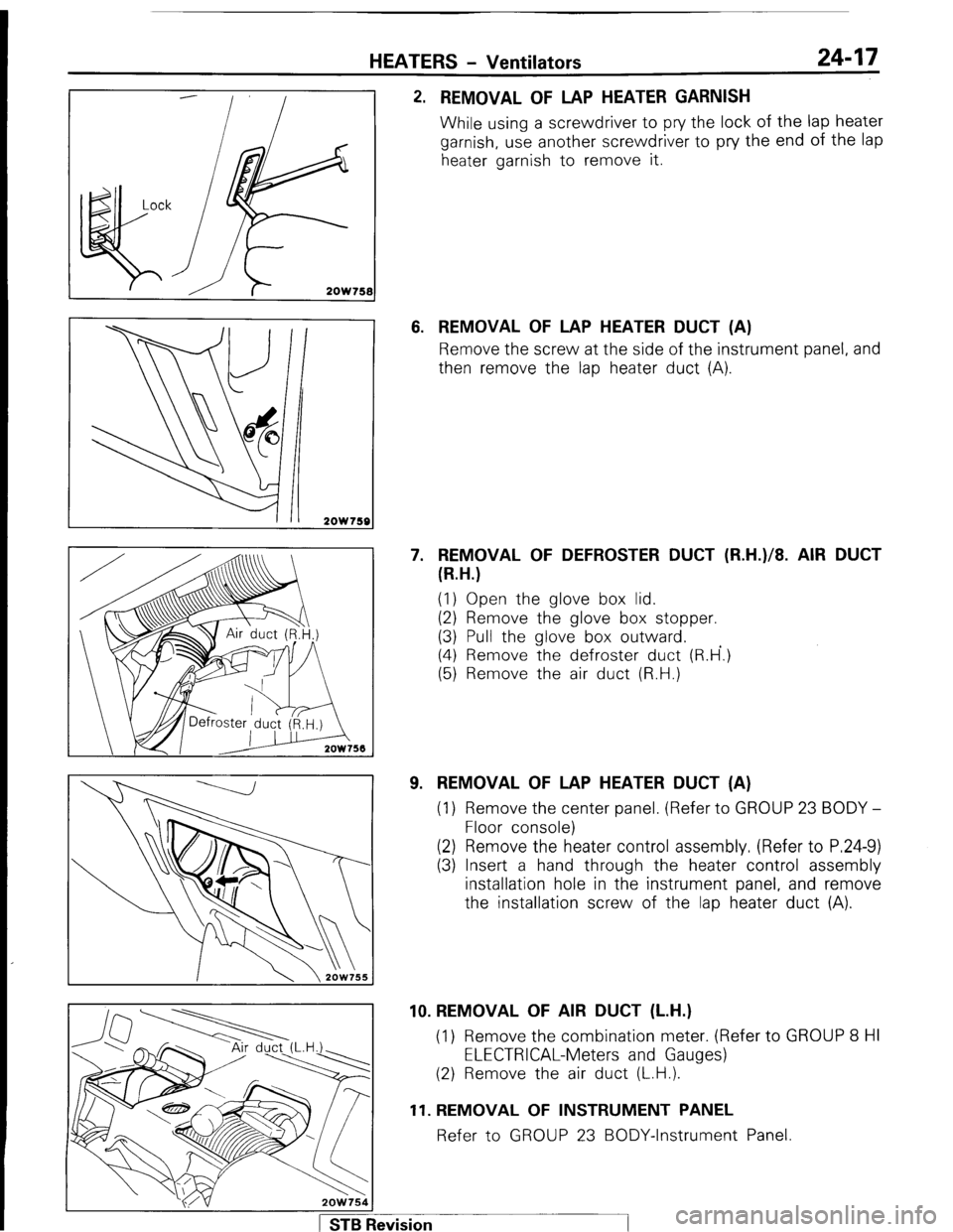

2. REMOVAL OF LAP HEATER GARNISH

While using a screwdriver to pry the lock of the lap heater

garnish, use another screwdriver to pry the end of the lap

heater garnish to remove it.

6. REMOVAL OF LAP HEATER DUCT (A)

Remove the screw at the side of the instrument panel, and

then remove the lap heater duct (A).

7. REMOVAL OF DEFROSTER DUCT (R.H.)/8. AIR DUCT

(R.H.)

(1) Open the glove box lid.

(2) Remove the glove box stopper.

(3) Pull the glove box outward.

(4) Remove the defroster duct (R.H’.)

(5) Remove the air duct (R.H.)

9. REMOVAL OF LAP HEATER DUCT (A)

(1) Remove the center panel. (Refer to GROUP 23 BODY -

Floor console)

(2) Remove the heater control assembly. (Refer to P.24-9)

(3) Insert a hand through the heater control assembly

installation hole in the instrument panel, and remove

the installation screw of the lap heater duct (A).

1 STB Revision 10. REMOVAL OF AIR DUCT (L.H.)

(1) Remove the combination meter. (Refer to GROUP 8 HI

ELECTRICAL-Meters and Gauges)

(2) Remove the air duct (L.H.).

11. REMOVAL OF INSTRUMENT PANEL

Refer to GROUP 23 BODY-Instrument Panel.

Page 254 of 284

24-18 HEATERS - Ventilators

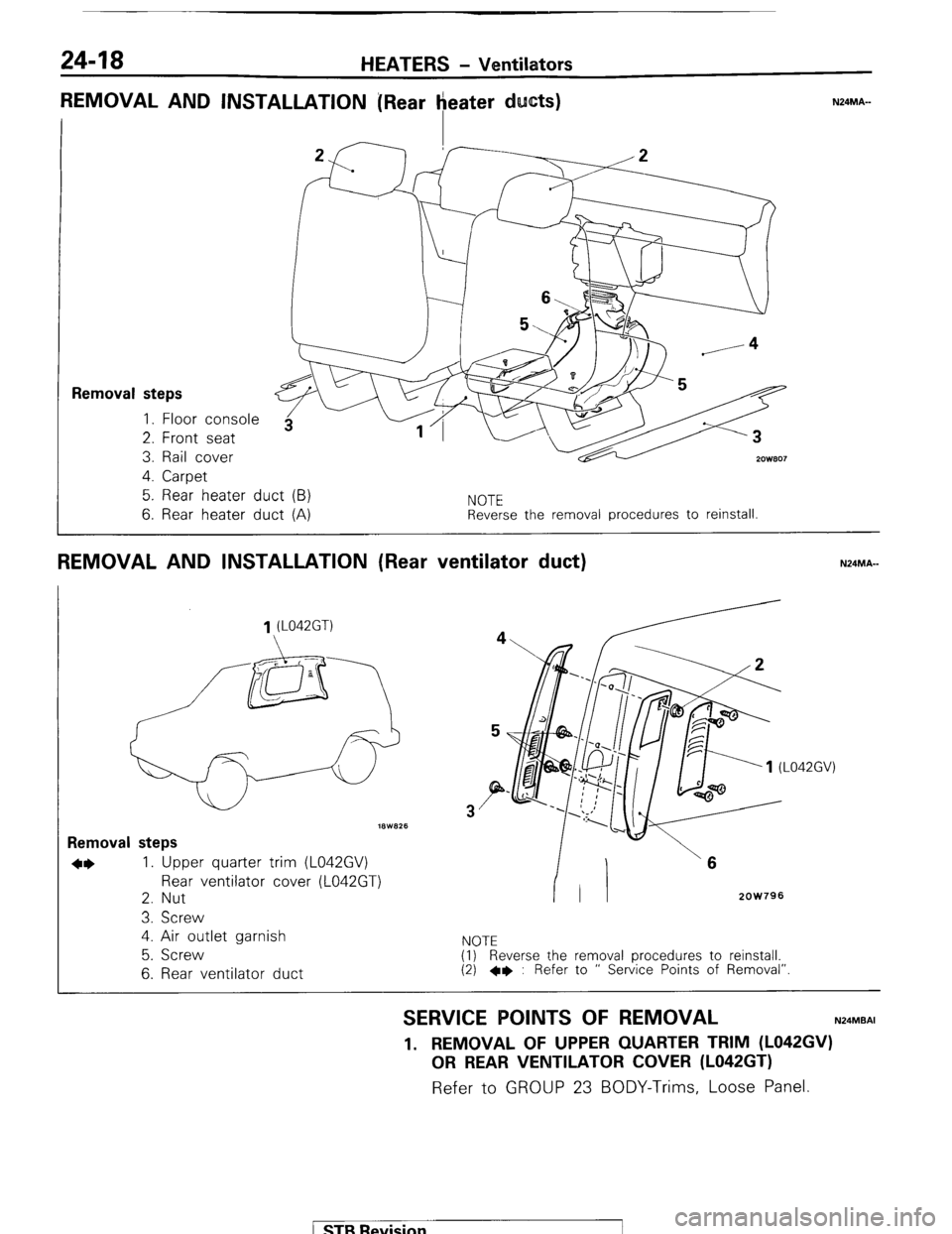

REMOVAL AND INSTALLATION [Rear heater ducts)

I 7F-T 'f------A

1

Removal steps 1. Floor console

2. Front seat

3. Rail cover

2ow.307 4. Carpet

5. Rear heater duct (B)

6. Rear heater duct (A)

NOTE

Reverse the removal procedures to reinstall.

REMOVAL AND INSTALLATION (Rear ventilator duct) N24MA-

1 (L042GT)

18W825

Removal steps

*I) 1. Upper quarter trim (L042GV)

Rear ventilator cover (L042GT)

2. Nut

3. Screw

4. Air outlet garnish

5. Screw

6. Rear ventilator duct

3

2OW796

NOTE

(1) Reverse the removal procedures to reinstall.

(2) +e : Refer to ” Service Points of Removal”.

SERVICE POINTS OF REMOVAL N24MBAI

1. REMOVAL OF UPPER QUARTER TRIM (L042GV)

OR REAR VENTILATOR COVER (L042GT) Refer to GROUP 23 BODY-Trims, Loose Panel.

( STB Revision

Page 255 of 284

AIR-CONDITIONING-General Information 24-19

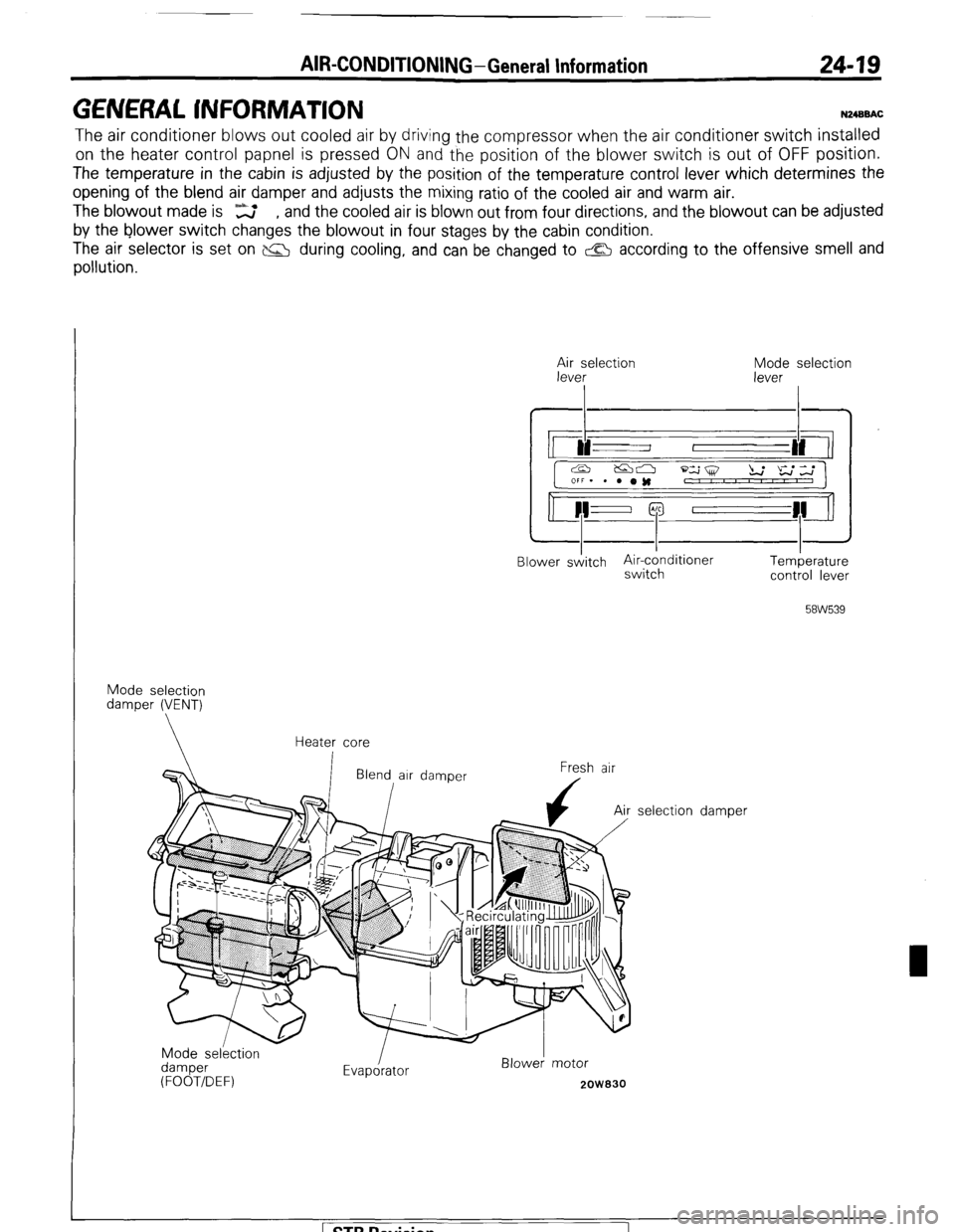

GENERAL INFORMATION N2400AC

The air conditioner blows out cooled air by driving the compressor when the air conditioner switch installed

on the heater control papnel is pressed ON and the position of the blower switch is out of OFF position.

The temperature in the cabin is adjusted by the position of the temperature control lever which determines the

opening of the blend air damper and adjusts the mixing ratio of the cooled air and warm air.

The blowout made is ‘z , and the cooled air is blown out from four directions, and the blowout can be adjusted

by the blower switch changes the blowout in four stages by the cabin condition.

The air selector is set on P&J during cooling, and can be changed to & according to the offensive smell and

pollution.

$;e;election

I Mode selection

lever

I

Blower sditch Air-cdnditioner

switch Temberature

control lever

58W539

Mode selection

damper (VENT)

Heater core

Fresh air

Mode selkction

damper

(FOOT/DEF) Evapdrator Blower! motor

2OW830

selection damper STB Revision

1

Page 256 of 284

24-20 AIR-CONDITION!NG-General Information

I

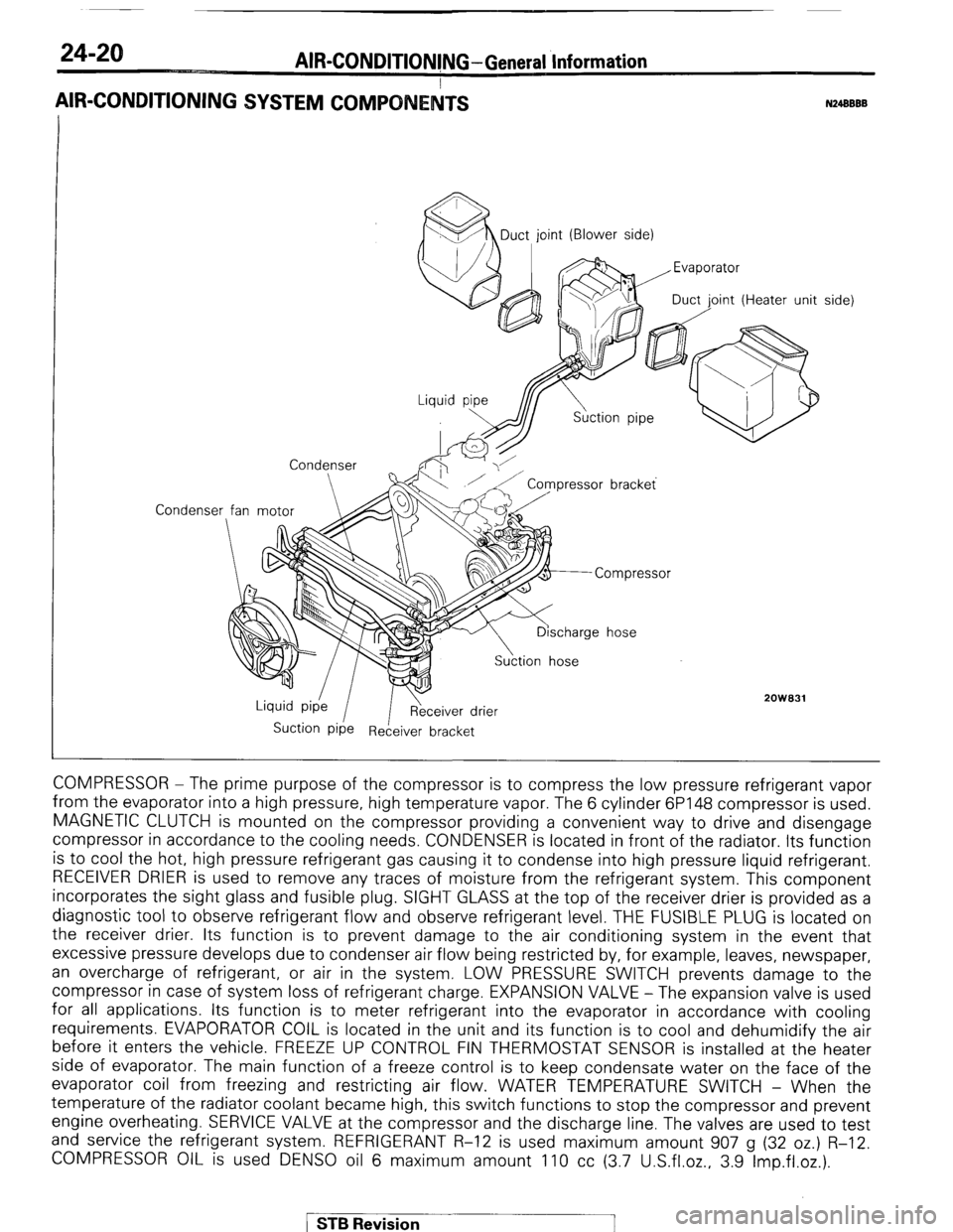

AIR-CONDITIONING SYSTEM COMPO

N24BBBB

Condenser MDuct, joint (Blower side)

oint (Heater unit

Condenser

2OWB31

Suction Pipe Receiver bracket side)

COMPRESSOR - The prime purpose of the compressor is to compress the low pressure refrigerant vapor

from the evaporator into a high pressure, high temperature vapor. The 6 cylinder 6P148 compressor is used.

MAGNETIC CLUTCH is mounted on the compressor providing a convenient way to drive and disengage

compressor in accordance to the cooling needs. CONDENSER is located in front of the radiator. Its function

is to cool the hot, high pressure refrigerant gas causing it to condense into high pressure liquid refrigerant.

RECEIVER DRIER is used to remove any traces of moisture from the refrigerant system. This component

incorporates the sight glass and fusible plug. SIGHT GLASS at the top of the receiver drier is provided as a

diagnostic tool to observe refrigerant flow and observe refrigerant level. THE FUSIBLE PLUG is located on

the receiver drier. Its function is to prevent damage to the air conditioning system in the event that

excessive pressure develops due to condenser air flow being restricted by, for example, leaves, newspaper,

an overcharge of refrigerant, or air in the system. LOW PRESSURE SWITCH prevents damage to the

compressor in case of system loss of refrigerant charge. EXPANSION VALVE - The expansion valve is used

for all applications. Its function is to meter refrigerant into the evaporator in accordance with cooling

requirements. EVAPORATOR COIL is located in the unit and its function is to cool and dehumidify the air

before it enters the vehicle. FREEZE UP CONTROL FIN THERMOSTAT SENSOR is installed at the heater

side of evaporator. The main function of a freeze control is to keep condensate water on the face of the

evaporator coil from freezing and restricting air flow. WATER TEMPERATURE SWITCH - When the

temperature of the radiator coolant became high, this switch functions to stop the compressor and prevent

engine overheating. SERVICE VALVE at the compressor and the discharge line. The valves are used to test

and service the refrigerant system. REFRIGERANT R-12 is used maximum amount 907 g (32 oz.) R-12.

COMPRESSOR OIL is used DENS0 oil 6 maximum amount 110 cc (3.7 U.S.fl.oz., 3.9 Imp.fl.oz.).

/ STB Revision

Page 262 of 284

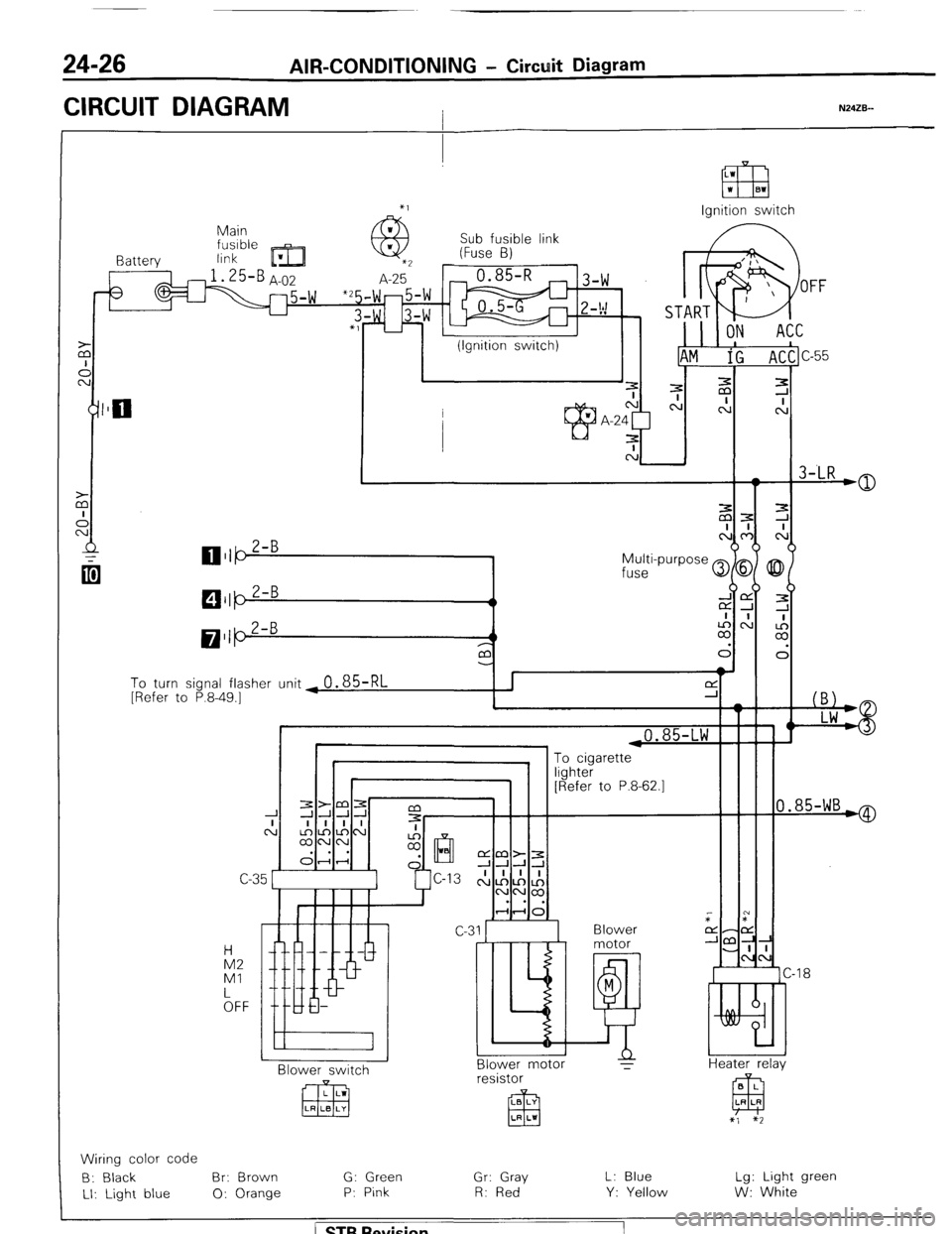

24-26 AIR-CONDITIONING - Circuit Diagram

CIRCUIT DIAGRAM I N24ZB--

Ignition switch

Main

link Sub fusible link

(Fuse B)

I Battery

3

To turn signal flasher unit ~

0.85-RL [Refer to P.8-49.1

i

I 1 ,0.85-LW F

0.85-WB*

“yl lLG1 [Refer to P.8-62.1

C-C

Blower

motor

M

E!! Blower motor

T IA2

Ml

kFF -18

Heater relav N BI ower switch B L

EEJ LR LR resistor

LB LY

El3 LR LI

x’, $2

Wiring color code

B: Black Br: Brown G: Green

Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red

Y: Yellow W: White

/ ST6 Revision

Page 278 of 284

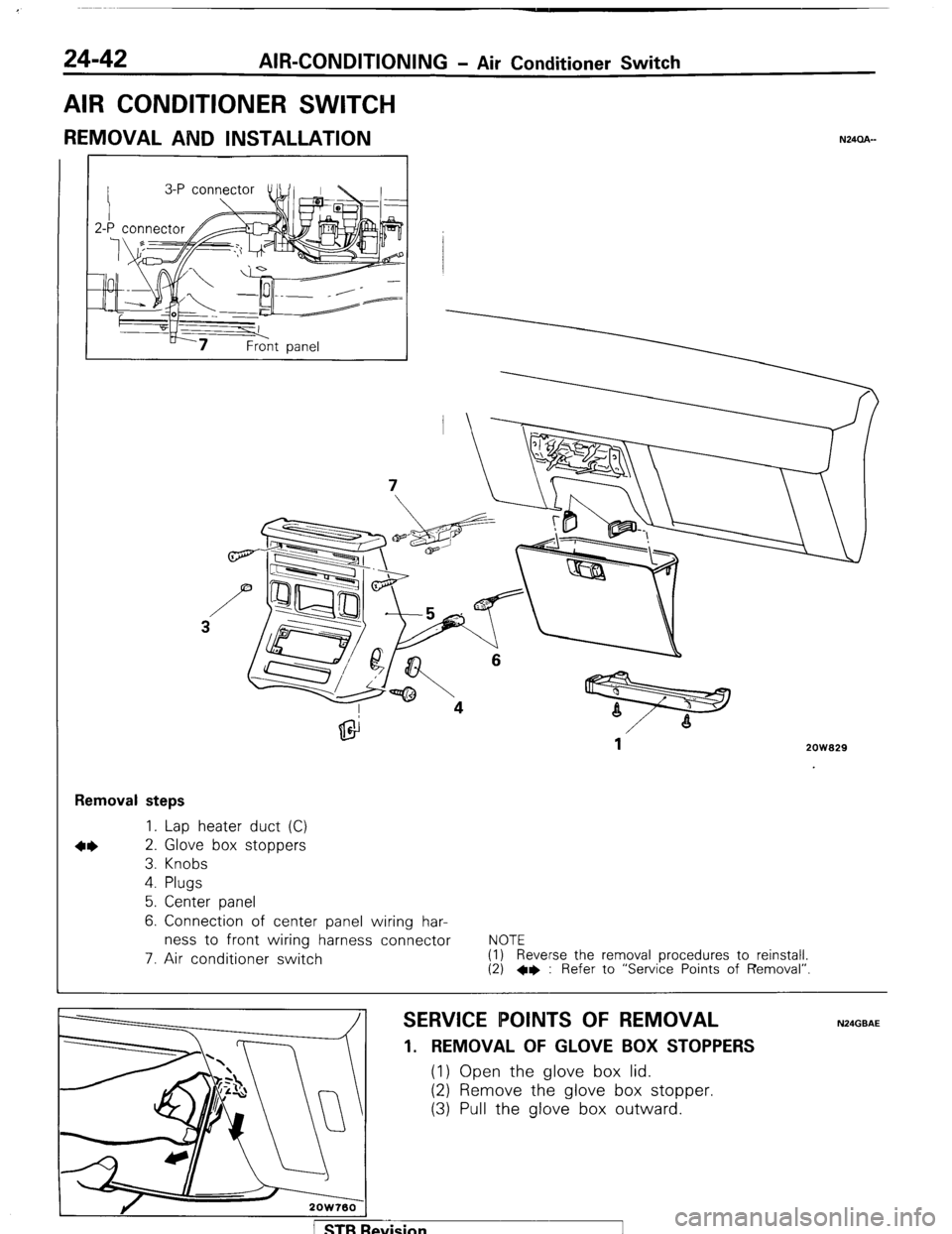

24-42 AIR-CONDITIONING - Air Conditioner Switch

AIR CONDITIONER SWITCH

REMOVAL AND INSTALLATION N24CLA-

2ow929

Removal steps

1. Lap heater duct (C)

2. Glove box stoppers

3. Knobs

4. Plugs

5. Center panel

6. Connection of center panel wiring har-

ness to front wiring harness connector

7. Air conditioner switch

NOTE

(1) Reverse the removal procedures to reinstall. (2) +e : Refer to “Service Points of Removal”

SERVICE POINTS OF REMOVAL

1. REMOVAL OF GLOVE BOX STOPPERS

(1) Open the glove box lid.

(2) Remove the glove box stopper.

(3) Pull the glove box outward.

1 STB Revision