fog light MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 1 of 284

Service Manual

MONTERO

1987 : Volume 2

FOREWORD

This Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

MITSUBISHI MOTOR SALES OF AMERICA. Inc.

Mitsubishi Motors corporation reserves the right to make changes in

design or to make additions to or improvements in its products without

imposing any obligations upon itself to install them on its products

previously manufactured.

I

GROUP/SECTION INDEX ‘kme-.

INTRODUCTION ..............................

Electrical ...........................................

Electrical System Parts

Location .........................................

Relays, Control Units, Sensors,

Fuses, Groundings

Inspection of Harness

Connector ......................................

Wiring Harness .............................

Charging System ..........................

Starting System ............................

Ignition System .............................

Meters and Gauges ......................

Lighting System .............................

Wiper and Washer System ..........

Horn ...............................................

Accessory ......................................

Audio System ................................

Back Door Window Defogger ......

Automatic Free-wheeling Hub

Indicator System ..........................

Heaters and Air-conditioning .........

Heaters ..........................................

Air-conditioning ............................

**, For Engine Chassis & Body refer to

0 1986 Mitsubishi Motors Corporation Printed in Japan

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 51 of 284

WIRING HARNESS - Interior and Frame 8-31

B-01 Dome light

B-02 Door switch (R.H.)

:::3 Rear speaker (R.H.) /&}License plate light (L.H.)

B-19 Back door lock actuator

B-20 Rear combination light (L.H.)

B-05 Defogger (-) B-21 Fuel gauge unit

B-06 Back door wiring harness and license plate light wiring B-22 Rear side marker light (L.H.)

harness combination

B-07 Rear wiper motor

B-08 Rear washer motor

B-09 Defogger (+)

B-l 0 Back door wiring harness and defogger cable (+)

combination

B-l 1 Rear side marker light (R.H.)

B-12 Frame wiring harness and back door wiring harness

B-13)combination B-23 Front wiring harness and frame wiring harness

;:g combination

E$ Rear speaker (L.H.)

:::g> Door switch (L.H.)

B-30 Power window main switch

B-31 Power window motor (L.H.)

B-14 Rear combination light (R.H.)

&z}License plate light (R.H.) B-32 Power window motor (R.H.)

B-33 Power window sub switch

Remark

The mark + shows the reference mounting position of wiring

harness.

STB Revision

Page 52 of 284

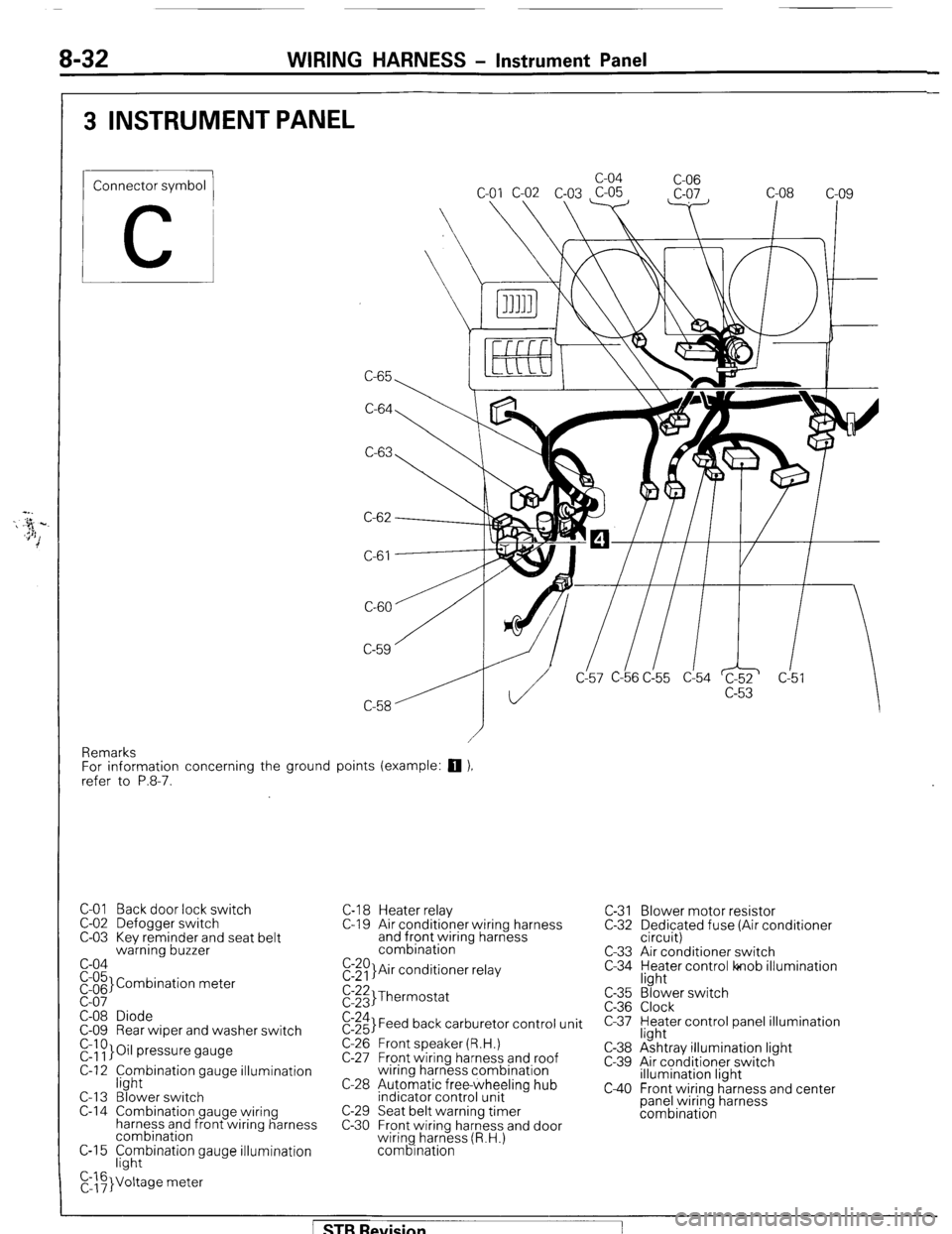

8-32 WIRING HARNESS - Instrument Panel

3 INSTRUMENT PANEL

Connector symbol

C

C-65 c-04

C-06

C-64

C-63

C-61

CL57 C-b6 C!55 d54 c!5

Remarks

For information concerning the ground points (example:

q ),

refer to P.8-7.

C-01 Back door lock switch

C-02 Defogger switch

C-03 Kev reminder and seat belt

warning buzzer

c-04

pi;’ Combination meter

C-08 Diode

C-09 Rear wiper and washer switch

r&~}Oil pressure gauge

C-12 f;hybination gauge illumination

C-l 3 Blower switch

C-14 Combination gauge wiring

harness and front wiring harness

combination

C-15 F;hybination gauge illumination

C,::F}Voltage meter C-l 8 Heater relay

C-l 9 Air conditioner wiring harness

and front wiring harness

combination

E:$)}Air conditioner relay C-31 Blower motor resistor

C-32 Dedicated fuse (Air conditioner

circuit)

C-33 Air conditioner switch

C-34 yl;Jer control lonob illumination

$:;;I Thermostat

$:;;I Feed back carburetor control unit

C-26 Front speaker (R.H.)

C-27 Front wiring harness and roof

wiring harness combination

C-28 Automatic free-wheeling hub

indicator control unit

C-29 Seat belt warning timer

C-30 Front wiring harness and door

wiring harness (R.H.)

combination c-35

C-36

c-37

C-38

c-39

c40

“3’ ‘. Blower switch

Clock

Heater control panel illumination

light

Ashtray illumination light

Air conditioner switch

illumination light

Front wiring harness and center

panel wiring harness

combination

[ STB Revision

Page 83 of 284

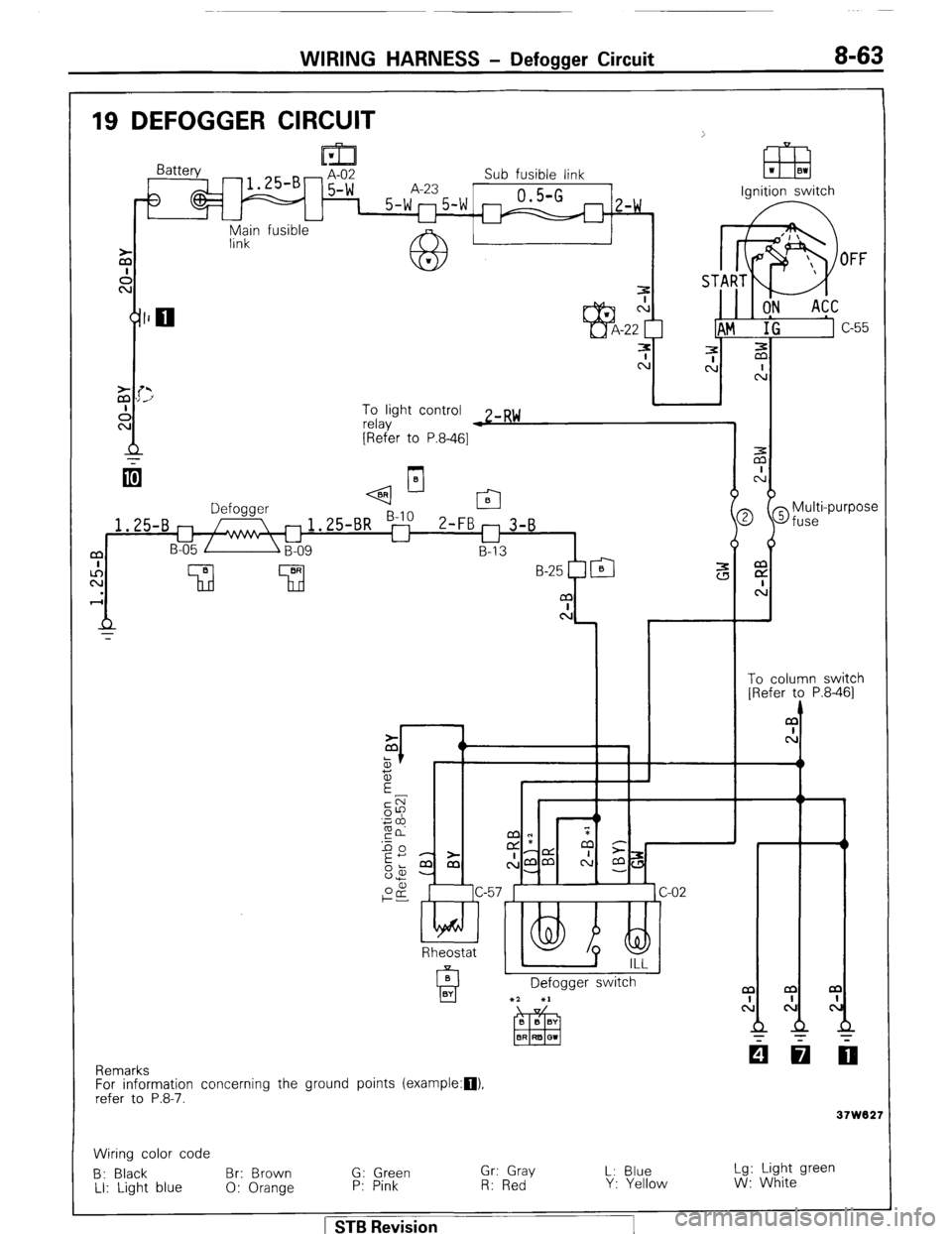

WIRING HARNESS - Defogger Circuit 8-63

19 DEFOGGER CIRCUIT

Sub fusible link

A-23

0.5-G

5-wn5-w I

U z-w ,

ynlin fusible

1

z

I

l%

7

(#IO N

-22

EEH I ml

Ignition switch

A

To light control

u

relay ~-RN

w

[Refer to P.8-461

+!I0 pFJ 0 Defogger

1.25-B m / 1.25-BR

Bg 2-FB m 3-B

B-05 / L-l U m B-13

I

Ki B

Q BR

Q

.

4

37W62’ ?

Wiring color code

B: Black

LI: Light blue Br: Brown G: Green Gr: Gray

L: Blue Lg: Light green

0: Orange P: Pink R: Red Y: Yellow W: White 1 STB Revision

LY!ii!T Rheostat

Detogger switch

x7. *I

z

A

i

Multi-purpose

D @fuse m

of

A

To column switch

[Refer to P.8-461

Remarks

For information concerning the ground points (example:a),

refer to P.8-7.

Page 90 of 284

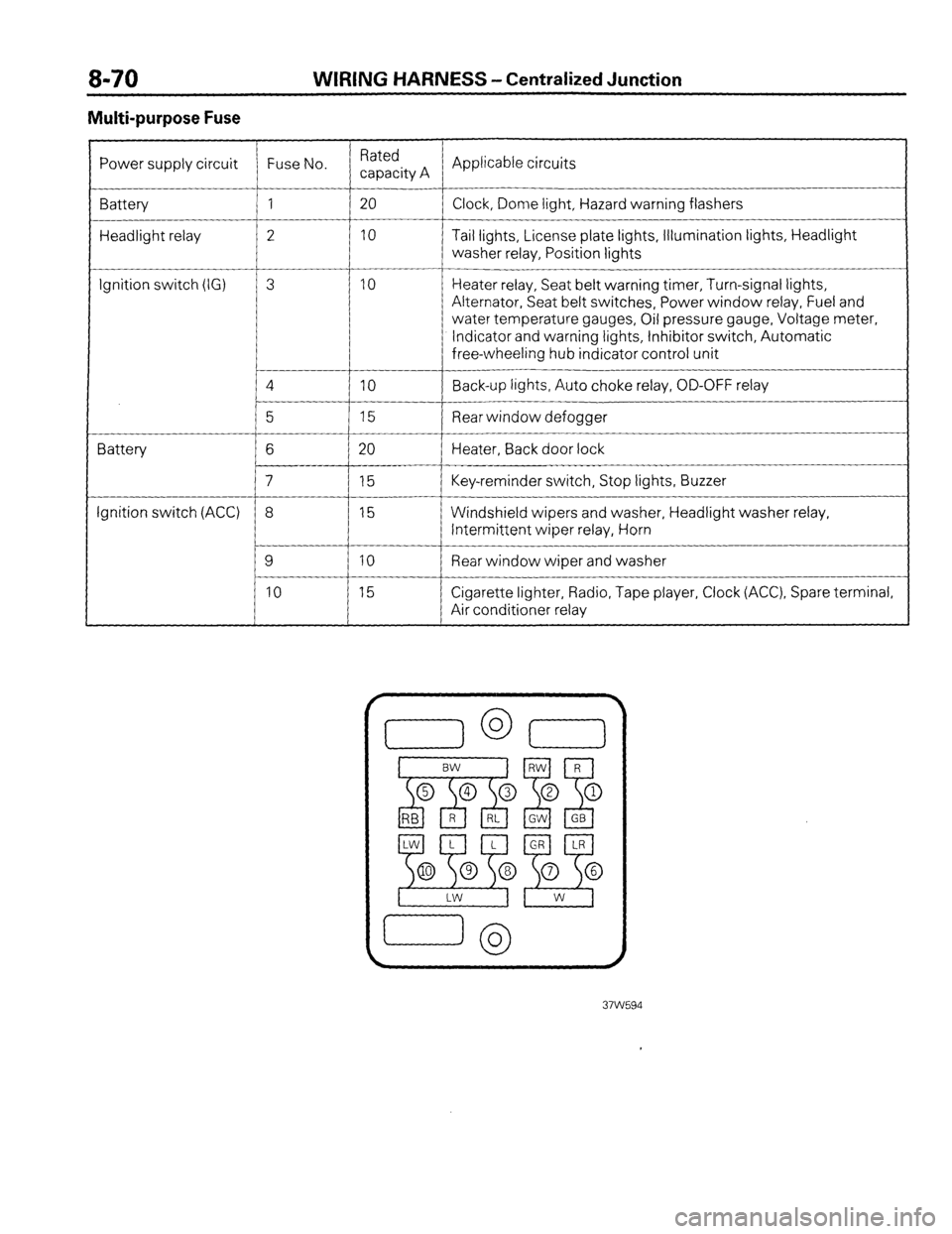

WIRING HARNESS - Centralized Junction

Multi-purpose Fuse

Power supply circuit Fuse No. Rated

capacity A Applicable circuits

Battery 1 20

Clock, Dome light, Hazard warning flashers

Headlight relay 2 10 Tail lights, License plate lights, Illumination lights, Headlight

washer relay, Position lights

__-

Ignition switch (IG) 3 10 Heater relay, Seat belt warning timer, Turn-signal lights,

Alternator, Seat belt switches, Power window relay, Fuel and

water temperature gauges, Oil pressure gauge, Voltage meter,

Indicator and warning lights, Inhibitor switch, Automatic

free-wheeling hub indicator control unit

4

IO Back-up lights, Auto choke relay, OD-OFF relay

__-

5 15 Rear window defogger

Battery 6 20 Heater, Back door lock

7 15 Key-reminder switch, Stop lights, Buzzer

Ignition switch (ACC) 8 15 Windshield wipers and washer, Headlight washer relay,

Intermittent wiper relay, Horn

9 10 Rear window wiper and washer

10 15 Cigarette lighter, Radio, Tape player, Clock (ACC), Spare terminal,

Air conditioner relay

Page 225 of 284

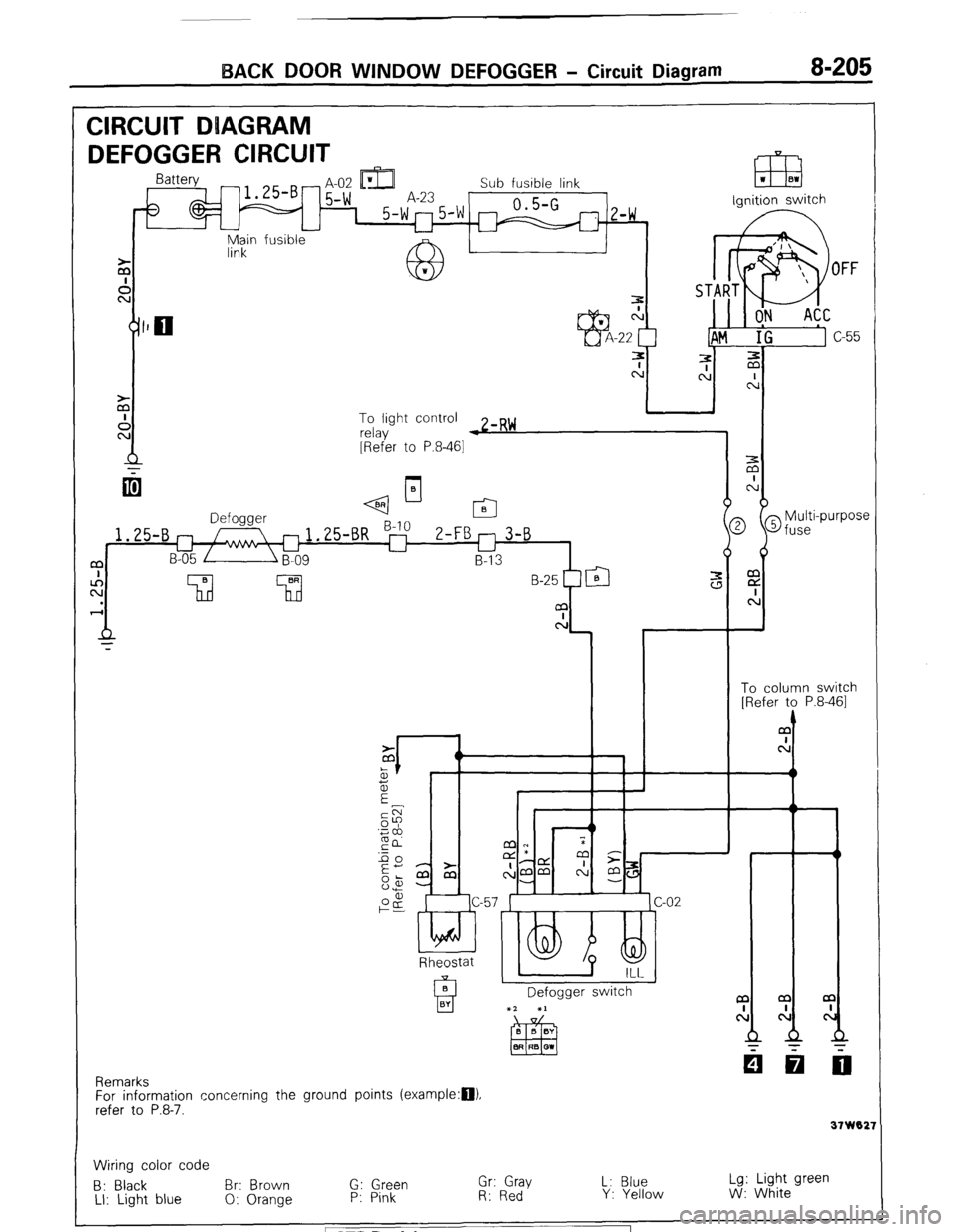

BACK DOOR WINDOW DEFOGGER - Circuit Diagram 8-205

CIRCUIT DUAGRAM

DEFOGGER CIRCUIT -t IDI L

m

- H-UL Ll&J Sub fusible link

5-w A-23 0.5-G 1 5-w"5'w m

z-w ,

u

fusible ignition switch

Main

link

To light control

relay w zmR~

[Refer to P.8-461

q--l-

2 @fuse

i

Multi-purpose m

E

c:

t

To column switch

[Refer to P.8-461

1.25-B

a

c!

Rheostat

Defogger switch a

cl

31 W02:

Remarks

For information concerning the ground points (example:D).

refer to P.8-7.

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White STB Revision

Page 226 of 284

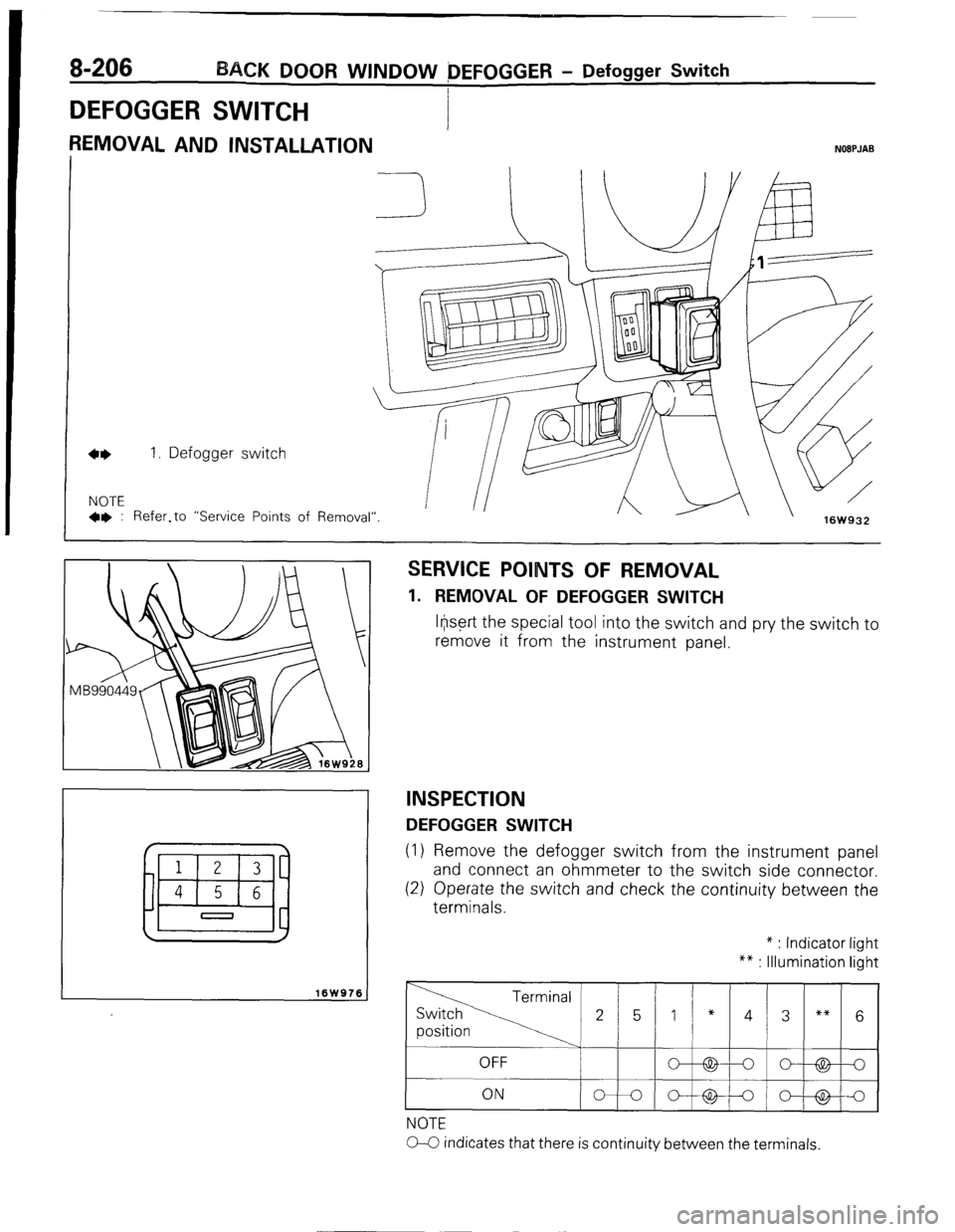

DEFOGGER SWITCH

1

REMOVAL AND INSTALLATION

8-206 BACK DOOR WINDOW OEFOGGER - Defogger Switch

I

NOEPJAB

1. Defogger switch

NOTE

+* : Refer.to “Service Points . ^

I_ A w

ot Kernoval” 16W932

I

16W976 J

SERVICE POINTS OF REMOVAL

1. REMOVAL OF DEFOGGER SWITCH

lr@rt the special tool into the switch and pry the switch to

remove it from the instrument panel.

INSPECTION

DEFOGGER SWITCH

(1) Remove the defogger switch from the instrument panel

and connect an ohmmeter to the switch side connector.

(2) Operate the switch and check the continuity between the

terminals. * : Indicator light

** : Illumination light

NOTE

0-C indicates that there is continuity between the terminals.

1 STB Revision

~-E

Page 227 of 284

BACK DOOR WINDOW DEFOGGER - Printed Heater Lines B-207

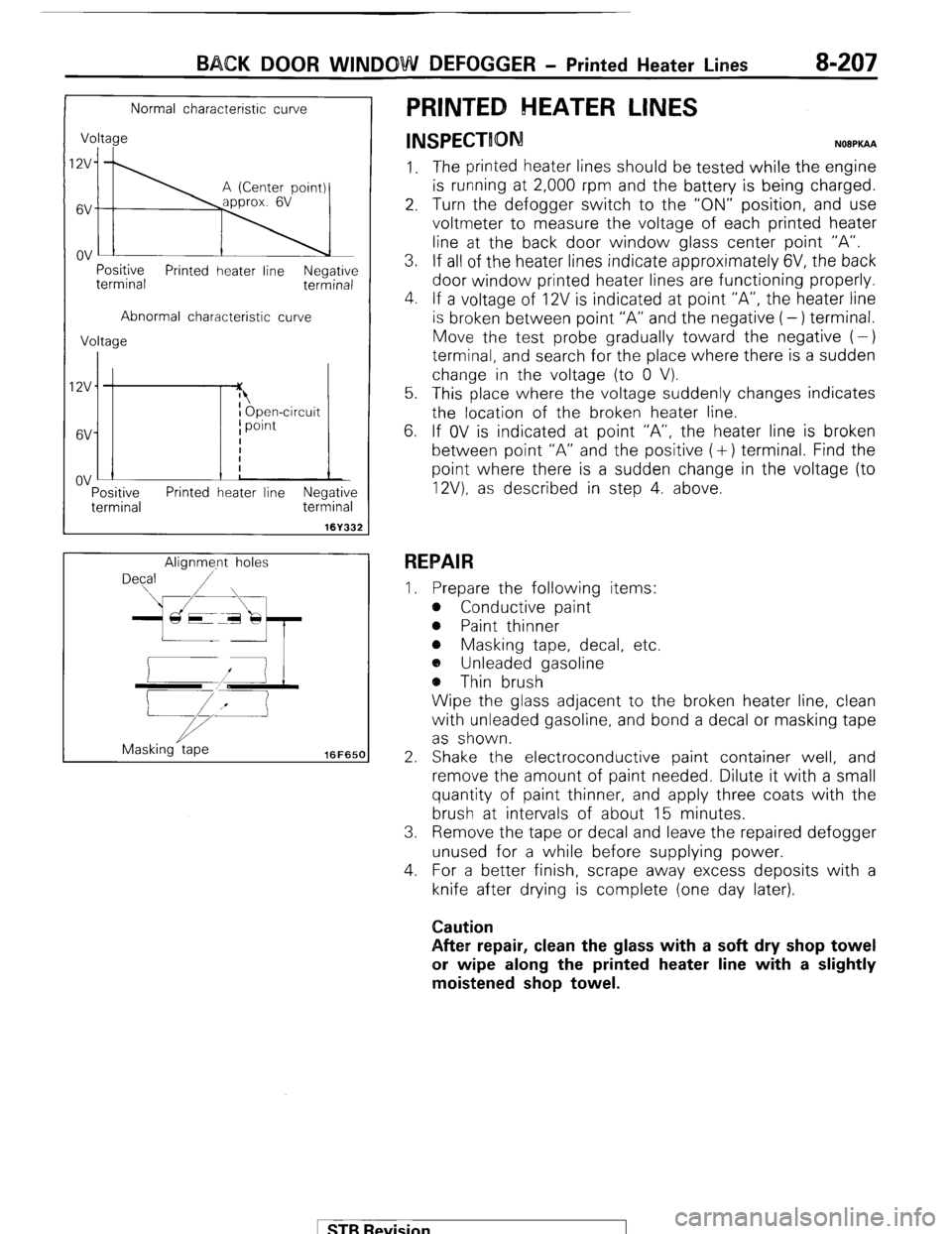

Normal characteristic curve

Voltage

I;\

Positive

terminal Printed heater line Negative

terminal

Abnormal characteristic curve

Voltage

IZV

6V

ov :-

Tf I Open-circuit

I point

I

i

!

Positive Printed heater line Negative

terminal terminal

161332

Alignme.nt holes

Masking tape

16FfiSCl

PRINTED HEATER LINES

INSPECTION N08PKAA

1. The printed heater lines should be tested while the engine

is running at 2,000 rpm and the battery is being charged.

2. Turn the defogger switch to the “ON” position, and use

voltmeter to measure the voltage of each printed heater

line at the back door window glass center point “A”.

3. If all of the heater lines indicate approximately 6V, the back

door window printed heater lines are functioning properly.

4. If a voltage of 12V is indicated at point “A”, the heater line

is broken between point “A” and the negative (-) terminal.

Move the test probe gradually toward the negative (-)

terminal, and search for the place where there is a sudden

change in the voltage (to 0 V).

5. This place where the voltage suddenly changes indicates

the location of the broken heater line.

6. If OV is indicated at point “A”, the heater line is broken

between point “A” and the positive (+) terminal. Find the

point where there is a sudden change in the voltage (to

12V). as described in step 4. above.

REPAIR

I. Prepare the following items:

e Conductive paint

@ Paint thinner

e Masking tape, decal, etc.

a, Unleaded gasoline

@ Thin brush

Wipe the glass adjacent to the broken heater line, clean

with unleaded gasoline, and bond a decal or masking tape

as shown.

2. Shake the electroconductive paint container well, and

remove the amount of paint needed. Dilute it with a small

quantity of paint thinner, and apply three coats with the

brush at intervals of about 15 minutes.

3. Remove the tape or decal and leave the repaired defogger

unused for a while before supplying power.

4. For a better finish, scrape away excess deposits with a

knife after drying is complete (one day later).

Caution

After repair, clean the glass with a soft dry shop towel

or wipe along the printed heater line with a slightly

moistened shop towel.

1 STB Revision