Ground MITSUBISHI MONTERO 1987 1.G Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 96 of 284

![MITSUBISHI MONTERO 1987 1.G Service Manual 8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A MITSUBISHI MONTERO 1987 1.G Service Manual 8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A](/img/19/7559/w960_7559-95.png)

8-76 CHARGING SYSTEM - Circuit Diagram

3 CHARGING CIRCUIT

Battery Ignition switch

OFF

Main

m fusible ’ L

link

A-02

fl.3-Br 1~5~~

, A-23 Sub fusible link

(IGN . SW)

IAM IG ] c-55

3

3

A m

A

To turn signal flasher

unit [Refer to P.8-49.1 Multi-

n, Irnn4P

ComSeter

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7. 37W605

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White

1 STB Revision

Page 97 of 284

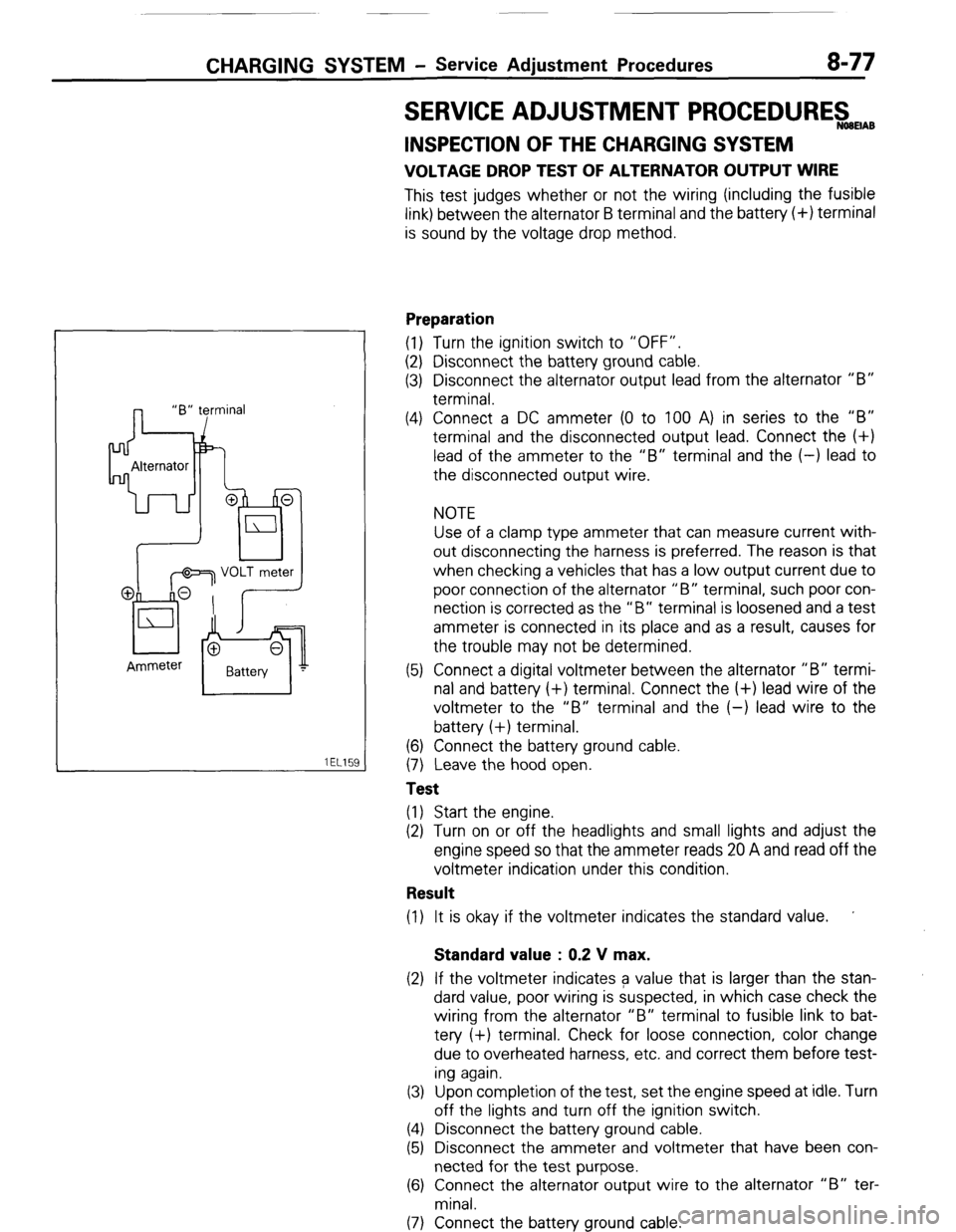

CHARGING SYSTEM - Service Adjustment Procedures 8-77

SERVICE ADJUSTMENT PROCEDUREswmAB

lEL15I

INSPECTION OF THE CHARGING SYSTEM

VOLTAGE DROP TEST OF ALTERNATOR OUTPUT WIRE

This test judges whether or not the wiring (including the fusible

link) between the alternator B terminal and the battery (+) terminal

is sound by the voltage drop method.

Preparation

(1) Turn the ignition switch to “OFF”.

(2) Disconnect the battery ground cable.

(3) Disconnect the alternator output lead from the alternator “B”

terminal.

(4) Connect a DC ammeter (0 to 100 A) in series to the “B”

terminal and the disconnected output lead. Connect the (+)

lead of the ammeter to the “B” terminal and the (-) lead to

the disconnected output wire.

NOTE

Use of a clamp type ammeter that can measure current with-

out disconnecting the harness is preferred. The reason is that

when checking a vehicles that has a low output current due to

poor connection of the alternator “B” terminal, such poor con-

nection is corrected as the “B” terminal is loosened and a test

ammeter is connected in its place and as a result, causes for

the trouble may not be determined.

(5) Connect a digital voltmeter between the alternator “B” termi-

nal and battery (+) terminal. Connect the (+) lead wire of the

voltmeter to the “B” terminal and the (-) lead wire to the

battery (+) terminal.

(6) Connect the battery ground cable.

(7) Leave the hood open.

Test

(1) Start the engine.

(2) Turn on or off the headlights and small lights and adjust the

engine speed so that the ammeter reads 20 A and read off the

voltmeter indication under this condition.

Result

(1) It is okay if the voltmeter indicates the standard value. ’

Standard value : 0.2 V max.

(2) If the voltmeter indicates a value that is larger than the stan-

dard value, poor wiring is suspected, in which case check the

wiring from the alternator “B” terminal to fusible link to bat-

tery (+) terminal. Check for loose connection, color change

due to overheated harness, etc. and correct them before test-

ing again.

(3) Upon completion of the test, set the engine speed at idle. Turn

off the lights and turn off the ignition switch.

(4) Disconnect the battery ground cable.

(5) Disconnect the ammeter and voltmeter that have been con-

nected for the test purpose.

(6) Connect the alternator output wire to the alternator “B” ter-

minal.

(7) Connect the battery ground cable.

( STB Revision

Page 98 of 284

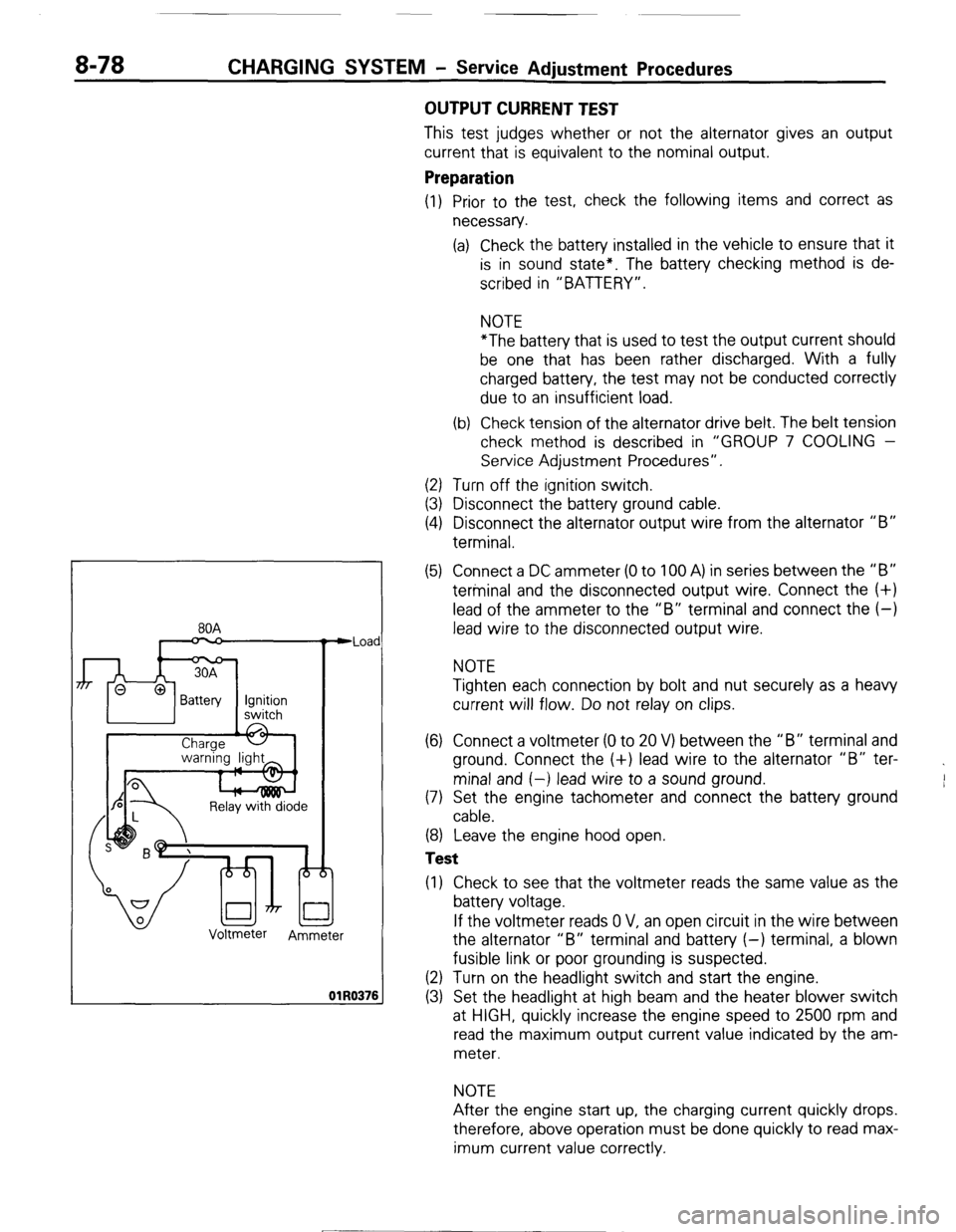

8-78 CHARGING SYSTEM - Service Adiustment Procedures

80A

n

Relay with diode

Voltmeter

Ammeter Iad

176

OUTPUT CURRENT TEST

This test judges whether or not the alternator gives an output

current that is equivalent to the nominal output.

Preparation

(1) Prior to the test, check the following items and correct as

necessary.

(a) Check the battery installed in the vehicle to ensure that it

is in sound state*. The battery checking method is de-

scribed in “BATTERY”.

NOTE

*The battery that is used to test the output current should

be one that has been rather discharged. With a fully

charged battery, the test may not be conducted correctly

due to an insufficient load.

(b) Check tension of the alternator drive belt. The belt tension

check method is described in “GROUP 7 COOLING -

Service Adjustment Procedures”.

(2) Turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Disconnect the alternator output wire from the alternator “B”

terminal.

(5) Connect a DC ammeter (0 to 100 A) in series between the “B”

terminal and the disconnected output wire. Connect the (+)

lead of the ammeter to the “B” terminal and connect the (-)

lead wire to the disconnected output wire.

NOTE

Tighten each connection by bolt and nut securely as a heavy

current will flow. Do not relay on clips.

(6) Connect a voltmeter (0 to 20 V) between the “B” terminal and

ground. Connect the (+) lead wire to the alternator “B” ter-

minal and (-) lead wire to a sound ground.

(7) Set the engine tachometer and connect the battery ground

cable.

(8) Leave the engine hood open.

Test

(1) Check to see that the voltmeter reads the same value as the

battery voltage.

If the voltmeter reads 0 V, an open circuit in the wire between

the alternator “B” terminal and battery (-) terminal, a blown

fusible link or poor grounding is suspected.

(2) Turn on the headlight switch and start the engine.

(3) Set the headlight at high beam and the heater blower switch

at HIGH, quickly increase the engine speed to 2500 rpm and

read the maximum output current value indicated by the am-

meter.

NOTE

After the engine start up, the charging current quickly drops.

therefore, above operation must be done quickly to read max-

imum current value correctly.

[ STB Revision

--I

Page 99 of 284

CHARGING SYSTEM - Service Adjustment Procedures 8-79

Result

(1) The ammeter reading must be higher than the limit value. If it

is lower but the alternator output wire is normal, remove the

alternator from the vehicle and check it.

Limit value : 31 A min.

Caution

1. The nominal output current value is shown on the

nameplate affixed to the alternator body.

2. The output current value changes with the electrical

load and the temperature of the alternator itself.

Therefore, the nominal output current may not be ob-

tained if the vehicle electrical load at the time of test is

small. In such a case, keep the headlights on to cause

discharge of the battery or use lights of another vehi-

cle as a load to increase the electrical load. The nom-

inal output current may not be obtained if the temper-

ature of the alternator itself or abmient temperature is

too high. In such a case, reduce the temperature be-

fore testing again.

(2) Upon completion of the output current test, lower the engine

speed to the idle speed and turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Remove the test ammeter and voltmeter and the engine ta-

chometer.

(5) connect the alternator output wire to the alternator “B” ter-

minal.

(6) Connect the battery ground cable.

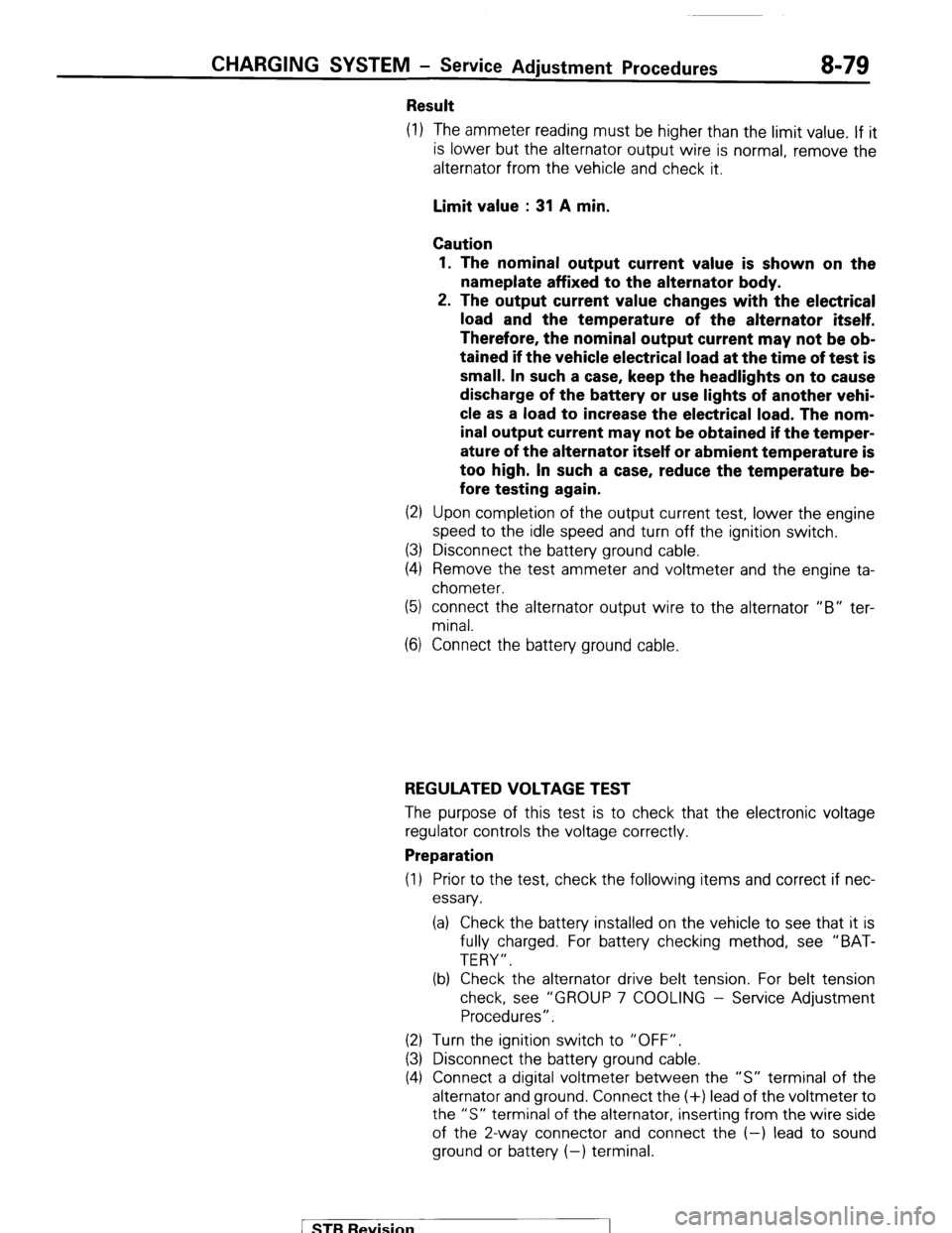

REGULATED VOLTAGE TEST

The purpose of this test is to check that the electronic voltage

regulator controls the voltage correctly.

Preparation

(1) Prior to the test, check the following items and correct if nec-

essary.

(a) Check the battery installed on the vehicle to see that it is

fully charged. For battery checking method, see “BAT-

TERY”.

(b) Check the alternator drive belt tension. For belt tension

check, see “GROUP 7 COOLING - Service Adjustment

Procedures”.

(2) Turn the ignition switch to “OFF”.

(3) Disconnect the battery ground cable.

(4) Connect a digital voltmeter between the “S” terminal of the

alternator and ground. Connect the (+) lead of the voltmeter to

the “S” terminal of the alternator, inserting from the wire side

of the 2-way connector and connect the (-1 lead to sound

ground or battery (-) terminal.

1 ST6 Revision

Page 100 of 284

8-80 CHARGING SYSTEM - Service Adjustment Procedures

Ignition

switch Alternator

Voltmeter

I

lid-hi! @ Ammeter e Load

6EK52

(5) Disconnect the alternator output wire from the alternator “B”

terminal.

(6) Connect a DC ammeter (0 to 100 A) in series between the “B”

terminal and the disconnected output wire. Connect the (+I

lead of the ammeter to the “B” terminal and connect the (-1

lead wire to the disconnected output wire.

(7) Set the engine tachometer and connect the battery ground

cable.

Test

(1) Turn on the ignition switch and-check that the voltmeter indi-

cates the following value.

Voltage : Battery voltage

If it reads 0 V, there is an open circuit in the wire between the

alternator “S” terminal and the battery (+) or the fusible link

is blown.

(2) Start the engine. Keep all lights and accessories off.

(3) Run the engine at a speed of about 2500 rpm and read the

voltmeter when the alternator output current drops to 10 A or

less.

Result

(1) If the voltmeter reading agrees with the value listed in the

regulating voltage table below, the voltage regulator is func-

tioning correctly. If the reading is other than the standard

value, the voltage regulator or the alternator is faulty.

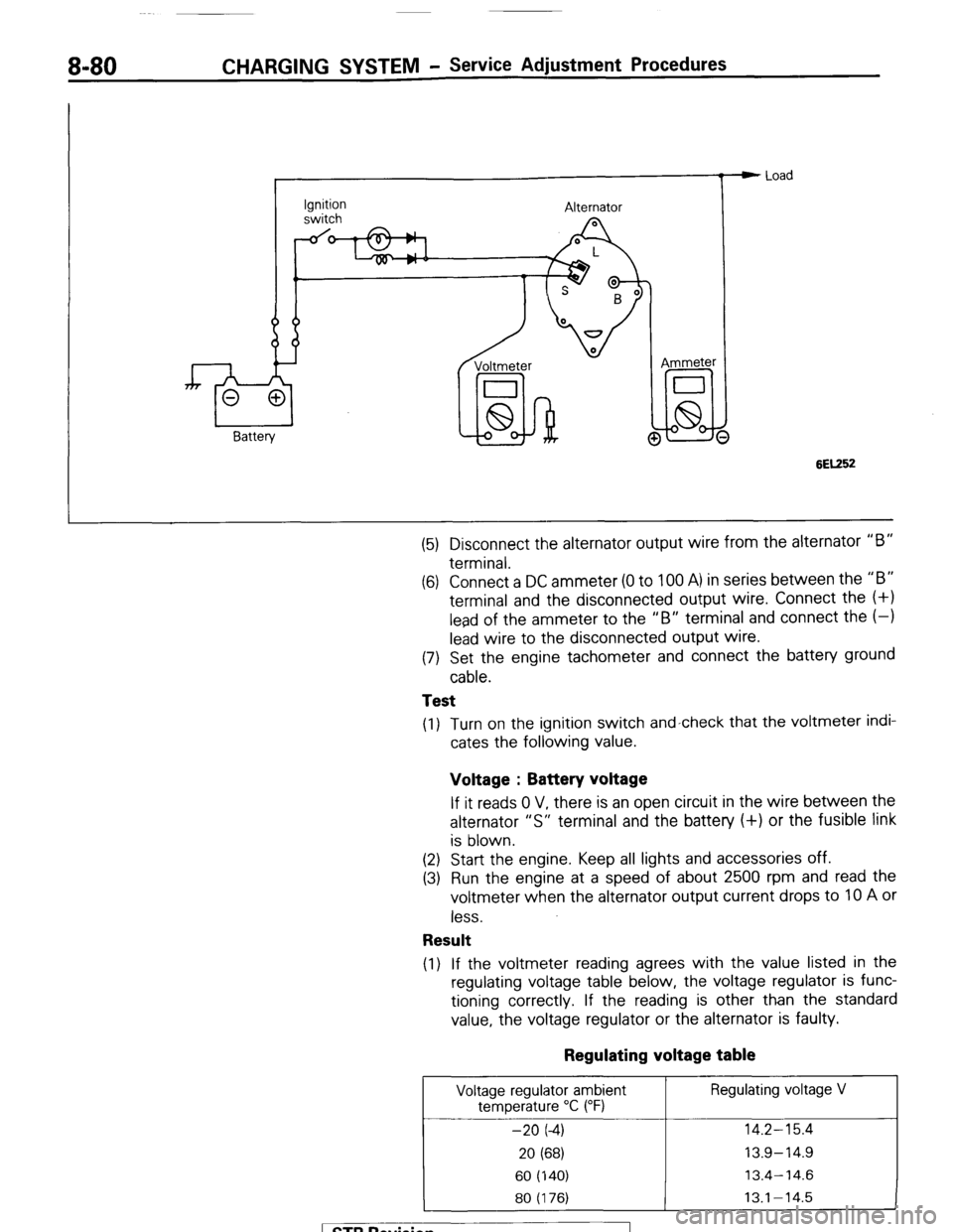

Regulating voltage table

Voltage regulator ambient Regulating voltage V

temperature “C (“F)

-20 (-4) 14.2-15.4

20 (68) 13.9-14.9

60 (140) 13.4-14.6

80 (176) 13.1-14.5

1 STB Revision

Page 101 of 284

CHARGING SYSTEM - Service Adjustment Procedures 8-81

(2) Upon completion of the test, set the engine speed at idle and

turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Remove the test voltmeter and ammeter and the engine ta-

chometer.

(5) Connect the alternator output wire to the alternator “B” ter-

minal.

(6) Connect the battery ground cable.

ll3Y1848 2. Remove battery from vehicle.

Caution

White

I Blue

I Care should be taken in the event battery case is cracked

or leaking to protect hands from the electrolyte. A suit-

able pair of rubber gloves (not the household type) should

be worn when removing battery by hand.

3. Inspect battery carrier for damage caused by loss of acid from

battery. If acid damage is present, it will be necessary to clean

area with a solution of clean warm water and baking soda.

Scrub area with a stiff bristle brush and wipe off with a cloth

moistened with ammonia or baking soda in water.

4. Clean top of battery with same solutions as described in Step

(3).

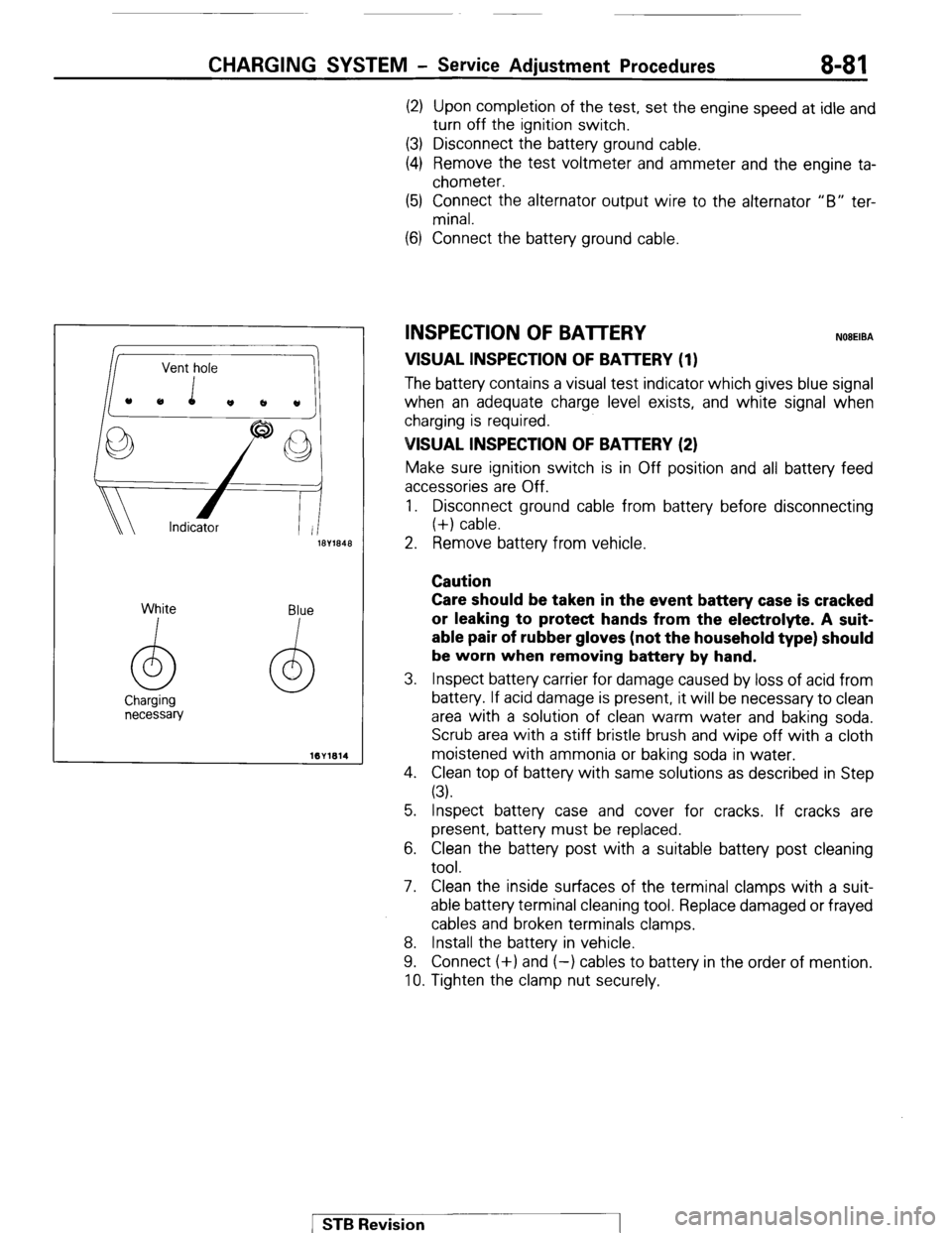

INSPECTION OF BATTERY NOBEIBA

VISUAL INSPECTION OF BATTERY (1)

The batten/ contains a visual test indicator which gives blue signal

when an adequate charge level exists, and white signal when

charging is required.

VISUAL INSPECTION OF BAlTERY (2)

Make sure ignition switch is in Off position and all battery feed

accessories are Off.

1. Disconnect ground cable from battery before disconnecting

(+) cable.

5. Inspect battery case and cover for cracks. If cracks are

present, battery must be replaced.

6. Clean the battery post with a suitable battery post cleaning

tool.

7. Clean the inside surfaces of the terminal clamps with a suit-

able battery terminal cleaning tool. Replace damaged or frayed

cables and broken terminals clamps.

8. Install the battery in vehicle.

9. Connect (+) and (-) cables to battery in the order of mention.

10. Tighten the clamp nut securely.

1 STB Revision

Page 108 of 284

8-88 CHARGING SYSTEM-Alternator

6EL115

3ELOlO

lELll0

lELll1

A

) STBRc

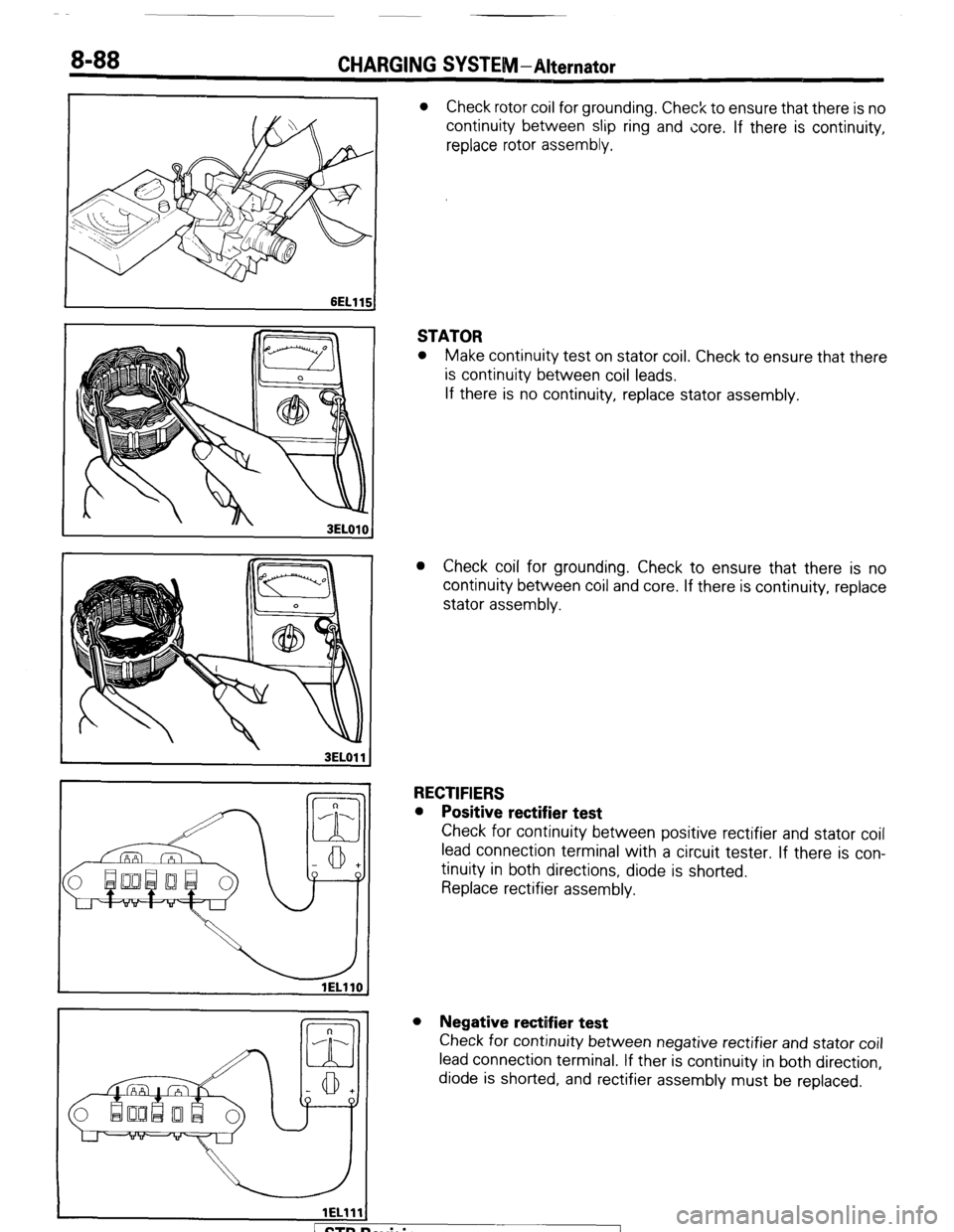

l Check rotor coil for grounding. Check to ensure that there is no

continuity between slip ring and core. If there is continuity,

replace rotor assembly.

STATOR

l Make continuity test on stator coil. Check to ensure that there

is continuity between coil leads.

If there is no continuity, replace stator assembly.

l Check coil for grounding. Check to ensure that there is no

continuity between coil and core. If there is continuity, replace

stator assembly.

RECTIFIERS

l Positive rectifier test

Check for continuity between positive rectifier and stator coil

lead connection terminal with a circuit tester. If there is con-

tinuity in both directions, diode is shorted.

Replace rectifier assembly.

l Negative rectifier test

Check for continuity between negative rectifier and stator coil

lead connection terminal. If ther is continuity in both direction,

diode is shorted, and rectifier assembly must be replaced.

evision

-7

Page 116 of 284

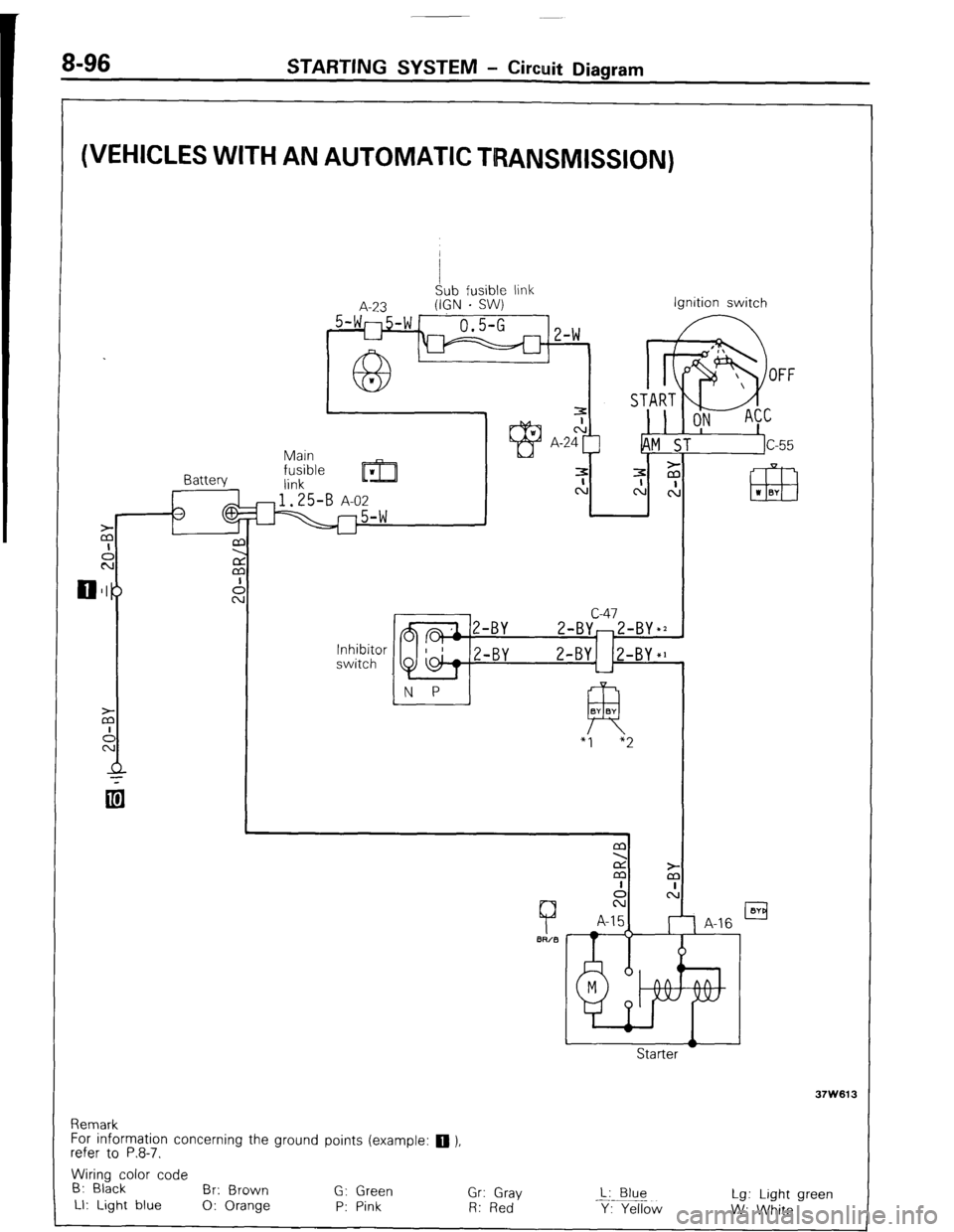

8-96 STARTING SYSTEM - Circuit Diagram

(VEHICLES WITH AN AUTOMATIC TRANSMISSION)

I

Sub fusible link

A-23 (IGN . SW)

_ 5-WI-754 1

0.5-G 1, 1,

L-l m 1 L-W

Battery Ignition switch

c-47

2-BY-Z-BY*2

N P

!-BY Z-BY1 (Z-BY*]

L-l

R BY BY

“I “2

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7.

Wiring color code

B: Black

Br: Brown

G: Green

Gr: Gray L: Blue

LI: Light blue

0: Orange P: Pink Lg: Light green

R: Red

Y: Yellow

W: White

STB Revision

Page 123 of 284

STARTING SYSTEM -Starter Motor 8-103

E i&l

-Limit line

1ELOlI

New brush

Soidered

(Make sure that

there is no excess

solder on brush

surface)

Surface marked If

1ELM

6EL082

1FL 108

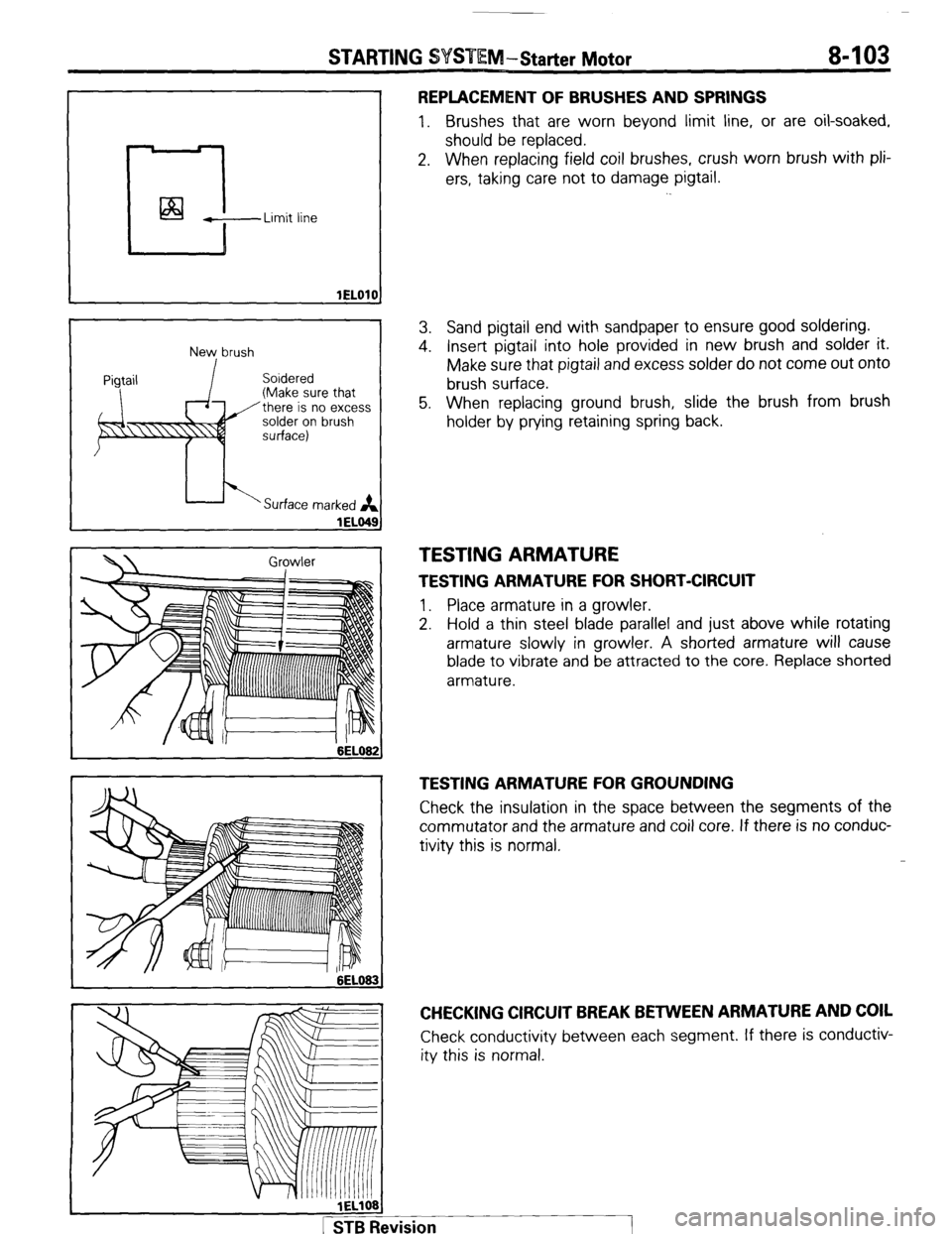

REPLACEMENT OF BRUSHES AND SPRINGS

1. Brushes that are worn beyond limit line, or are oil-soaked,

should be replaced.

2. When replacing field coil brushes, crush worn brush with pli-

ers, taking care not to damage pigtail.

3. Sand pigtail end with sandpaper to ensure good soldering.

4. Insert pigtail into hole provided in new brush and solder it.

Make sure that pigtail and excess solder do not come out onto

brush surface.

5. When replacing ground brush, slide the brush from brush

holder by prying retaining spring back.

TESTING ARMATURE

TESTING ARMATURE FOR SHORT-CIRCUIT

1. Place armature in a growler.

2. Hold a thin steel blade parallel and just above while rotating

armature slowly in growler. A shorted armature will cause

blade to vibrate and be attracted to the core. Replace shorted

armature.

TESTING ARMATURE FOR GROUNDING

Check the insulation in the space between the segments of the

commutator and the armature and coil core. If there is no conduc-

tivity this is normal.

CHECKING CIRCUIT BREAK BETWEEN ARMATURE AND COIL

Check conductivity between each segment. If there is conductiv-

ity this is normal.

1 STB Revision

Page 130 of 284

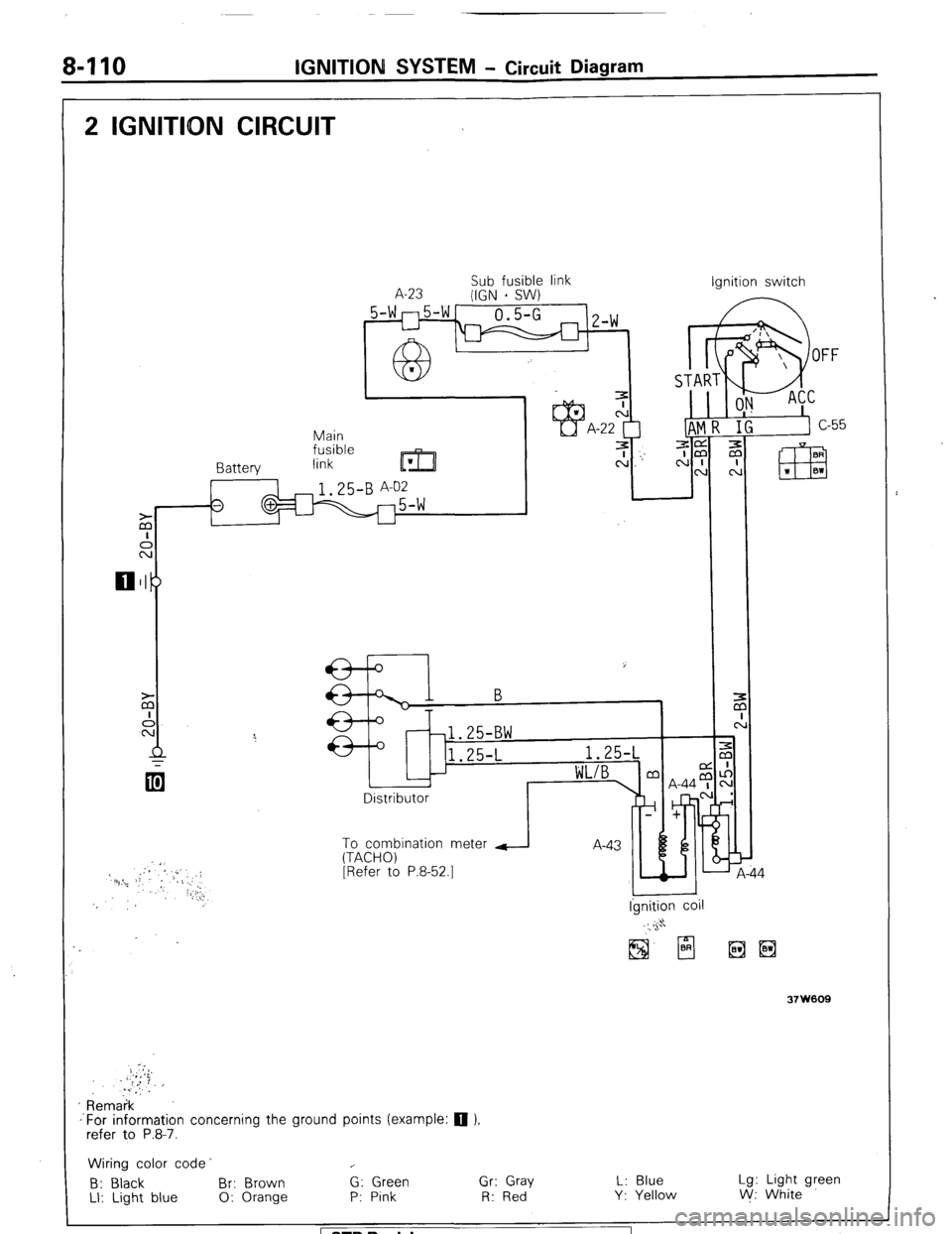

8-110 IGNITION SYSTEM - Circuit Diagram

2 IGNITDN CIRCUIT

Sub fusible link

A-23

(IGN - SW) Ignition switch

5-wn5-w-

0.5-G 1

u

63- Z-W

I

IAT

Main 1

fusible

Rnttprv link

m

ze 3 cj _-’ A:“p m

N CL

I 64-b I I I m

I

Ei

I

L Disi

To combination meter d A-an b

(TACHO)

[Refer to P.8-52.1

I I Ignition coil

37 w009

Remaik

-‘For information concerning the ground points (example: q ),

refer to P.8-7.

Wiring color code’ c

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow V/: White

1 STB Revision 1