Blower relay MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 22 of 284

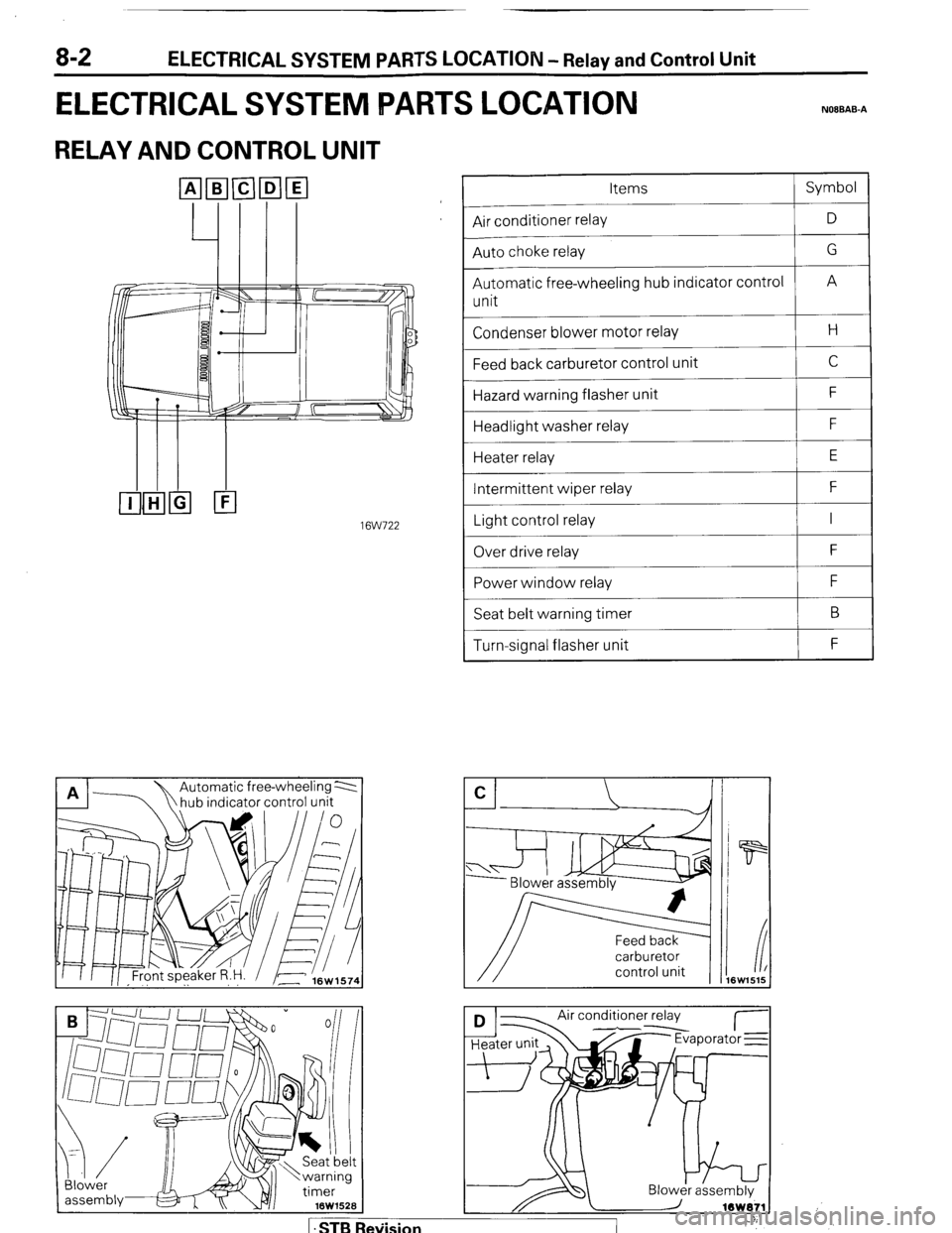

8-2 ELECTRICAL SYSTEM PARTS LOCATION - Relay and Control Unit

ELECTRICAL SYSTEM IPARTS LOCATION NOIBAB-A

RELAY AND CONTROL UNIT

16W722

n 17

hub indicator control unit A A Automatic free-wheeling 2

Blower

assembiy& x v/i 16W152B Items Symbol

--

Air conditioner relay D

--

Auto choke relay G

--

Automatic free-wheeling hub indicator control

A

unit

Condenser blower motor relay H

Feed back carburetor control unit C

Hazard warning flasher unit F

Headlight washer relay F

Heater relay E

Intermittent wiper relay F

~___

Light control relay I

~___

Over drive relay F

Power window relay F

Seat belt warning timer B

Turn-signal flasher unit F

carburetor

control unit

Air conditioner relay

d--- I- Jr Evaporator E

1 .STB Re\iision

Page 34 of 284

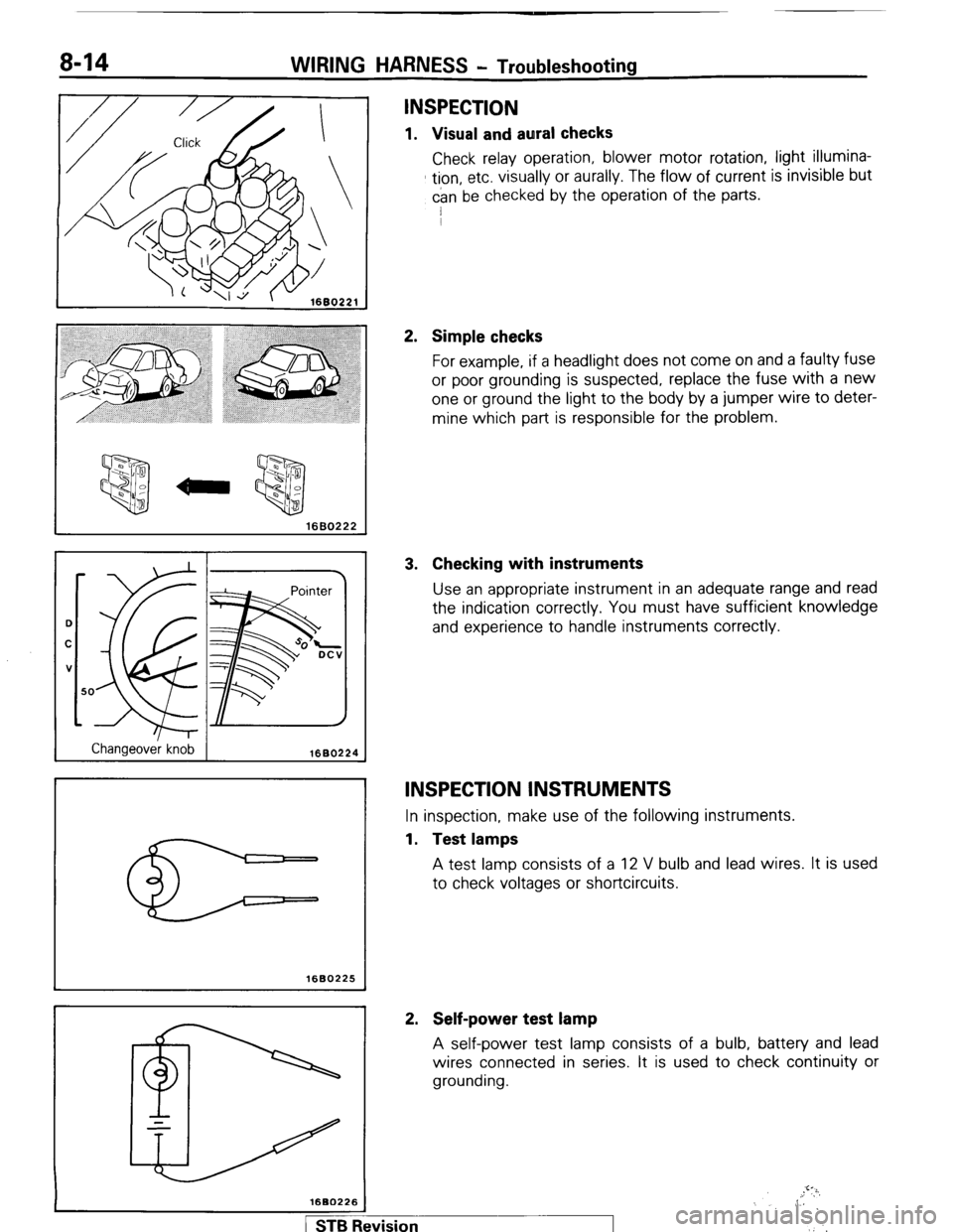

8-14 WIRING HARNESS - Troubleshooting

1680222

Changeover knob 1680224

1680225 1

1680226

INSPECTION

1. Visual and aural checks

Check relay operation, blower motor rotation, light illumina-

tion, etc. visually or aurally. The flow of current is invisible but

can be checked by the operation of the parts.

I

2. Simple checks

For example, if a headlight does not come on and a faulty fuse

or poor grounding is suspected, replace the fuse with a new

one or ground the light to the body by a jumper wire to deter-

mine which part is responsible for the problem.

3. Checking with instruments

Use an appropriate instrument in an adequate range and read

the indication correctly. You must have sufficient knowledge

and experience to handle instruments correctly.

INSPECTION INSTRUMENTS

In inspection, make use of the following instruments.

1. Test lamps

A test lamp consists of a 12 V bulb and lead wires. It is used

to check voltages or shortcircuits.

2. Self-power test lamp

A self-power test lamp consists of a bulb, battery and lead

wires connected in series. It is used to check continuity or

grounding.

,.!‘?i,

,, 6

,‘.’

1 STB Revision

Page 52 of 284

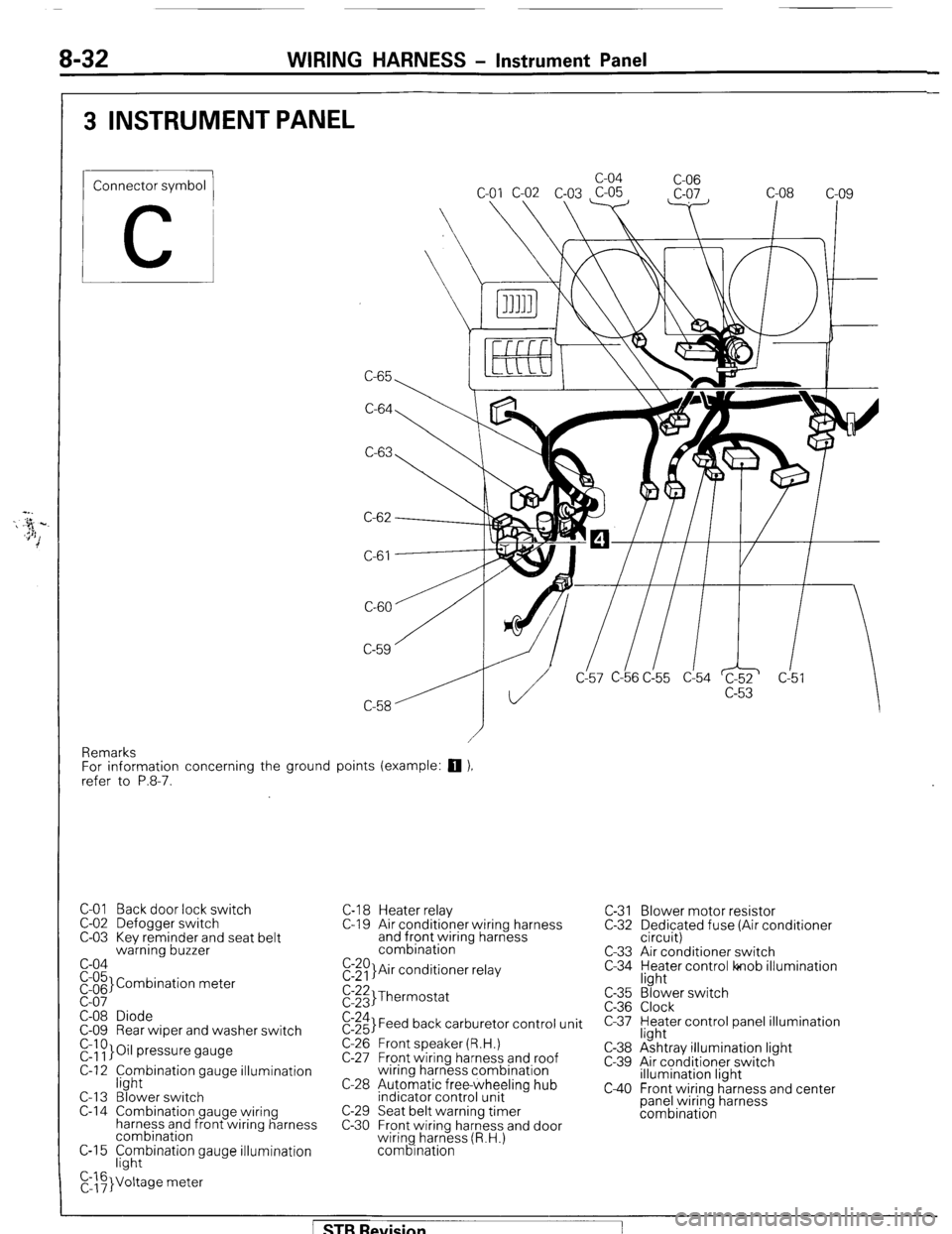

8-32 WIRING HARNESS - Instrument Panel

3 INSTRUMENT PANEL

Connector symbol

C

C-65 c-04

C-06

C-64

C-63

C-61

CL57 C-b6 C!55 d54 c!5

Remarks

For information concerning the ground points (example:

q ),

refer to P.8-7.

C-01 Back door lock switch

C-02 Defogger switch

C-03 Kev reminder and seat belt

warning buzzer

c-04

pi;’ Combination meter

C-08 Diode

C-09 Rear wiper and washer switch

r&~}Oil pressure gauge

C-12 f;hybination gauge illumination

C-l 3 Blower switch

C-14 Combination gauge wiring

harness and front wiring harness

combination

C-15 F;hybination gauge illumination

C,::F}Voltage meter C-l 8 Heater relay

C-l 9 Air conditioner wiring harness

and front wiring harness

combination

E:$)}Air conditioner relay C-31 Blower motor resistor

C-32 Dedicated fuse (Air conditioner

circuit)

C-33 Air conditioner switch

C-34 yl;Jer control lonob illumination

$:;;I Thermostat

$:;;I Feed back carburetor control unit

C-26 Front speaker (R.H.)

C-27 Front wiring harness and roof

wiring harness combination

C-28 Automatic free-wheeling hub

indicator control unit

C-29 Seat belt warning timer

C-30 Front wiring harness and door

wiring harness (R.H.)

combination c-35

C-36

c-37

C-38

c-39

c40

“3’ ‘. Blower switch

Clock

Heater control panel illumination

light

Ashtray illumination light

Air conditioner switch

illumination light

Front wiring harness and center

panel wiring harness

combination

[ STB Revision

Page 75 of 284

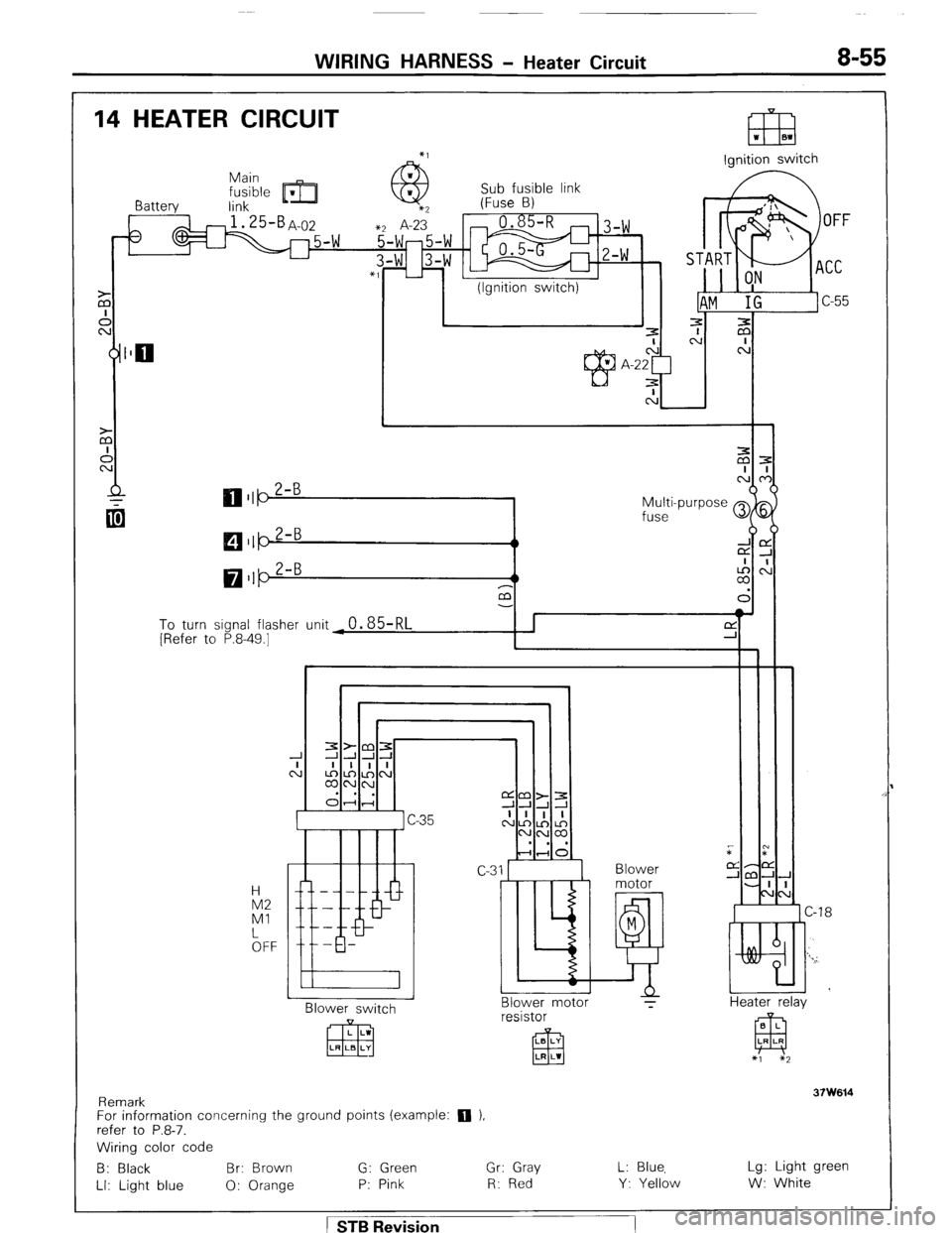

WIRING HARNESS - Heater Circuit 8-55

14 HEATER CIRCUIT

A’

Battery

0

(Ignition switch)

L

l!zEl *I BI

lonition switch

Multi-purpose

fuse

To turn signal flasher unit4 0.85-RL

[ [Refer to P.8-49.1

n

H

M2

Ml

bFF - -

P -

-

- -

I

Blower switch

Remark 37W614

For information concerning the ground points (example: 0 ),

refer to P.8-7.

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue, Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White Blower motor

resistor

LB LI

El3 LR LW

Blower

motor

M

!! T i

C-18

I

Heater relay

8 L

El LR LR

*1 *2

STB Revision

Page 76 of 284

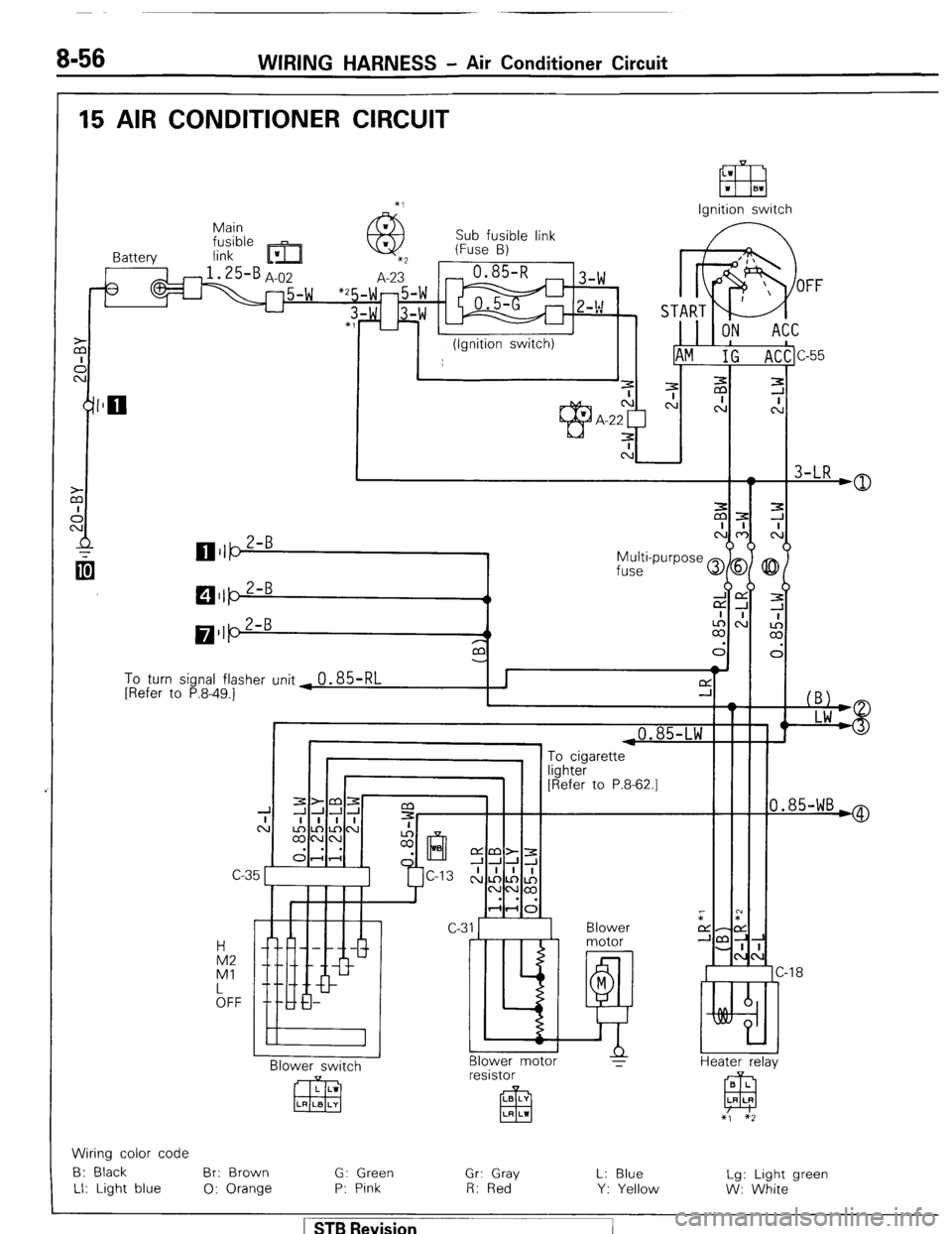

8-56 WIRING HARNESS - Air Conditioner Circuit

15 AIR CONDITIONER CIRCUIT

Main

fusible m

I;..,, 1 Ignition switch

Sub fusible link

(Fuse B)

+2 0.85-R

I I

(lonition switch)

I I ,!..I ’ ’

T

3-LRwQ

To turn signal flasher unit ~ 0.85-RL [Refer to P.849.1 J

L

I

I , ,0.85-LW

FA2 Ml

bFF To cigarette

lighter

[Refer to P.8-62.1

I f Y

Blower

motor

8 I

M

4JY motor

T-

Ii

1

Blower switch lower 1C-18 l!!!a Heater relay

0.85-WB@

Wiring color code

B: Black Br: Brown

G: Green

Gr: Gray L: Blue Lg: Light green

LI: Light blue

0: Orange P: Pink I?: Red

Y: Yellow W: White -

STB Revision

II/

Page 77 of 284

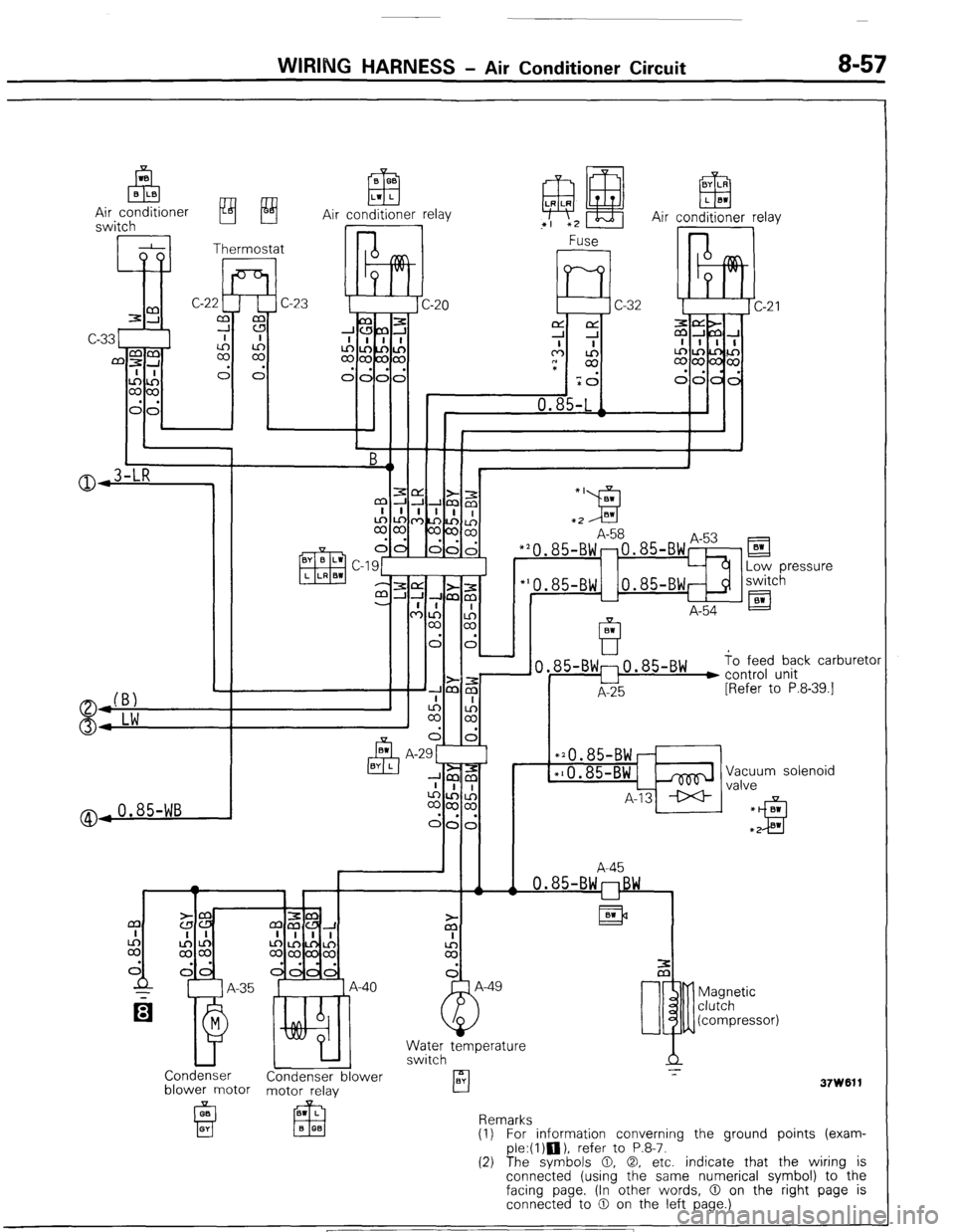

WIRING HARNESS - Air Conditioner Circuit 8-57

0

(Bl

0: Lw

@,0.85-WB B 0.3

ElFI Lvf L

Air conditioner relay I @ H ‘I *2 Air :on!$!er rela

85-Bw:o.85-Bw ) to feed back carburetor

u control unit

A-25 [Refer to P.8-39.1

l 20.85-BWr

l 10.85-BWL&

A-13 * Vacuum solenoid

valve

A-45

0.85-BWnBW

Is*la

Magnetic

clutch

(compressor)

U

Water temperature

switch

Condenser

Condenser blower -I-

BY

blower motor motor relay rl

37W611

Remarks

(1) For information converning the ground points (exam-

ple:(l)n), refer to P.8-7.

(2) The svmbols 0, 0, etc. indicate that the wiring is

connedted (using the same numerical symbol) to-the

facing page. (In other words, 0 on the right page is

connected to 0 on the left page.) ) STB Revision

Page 98 of 284

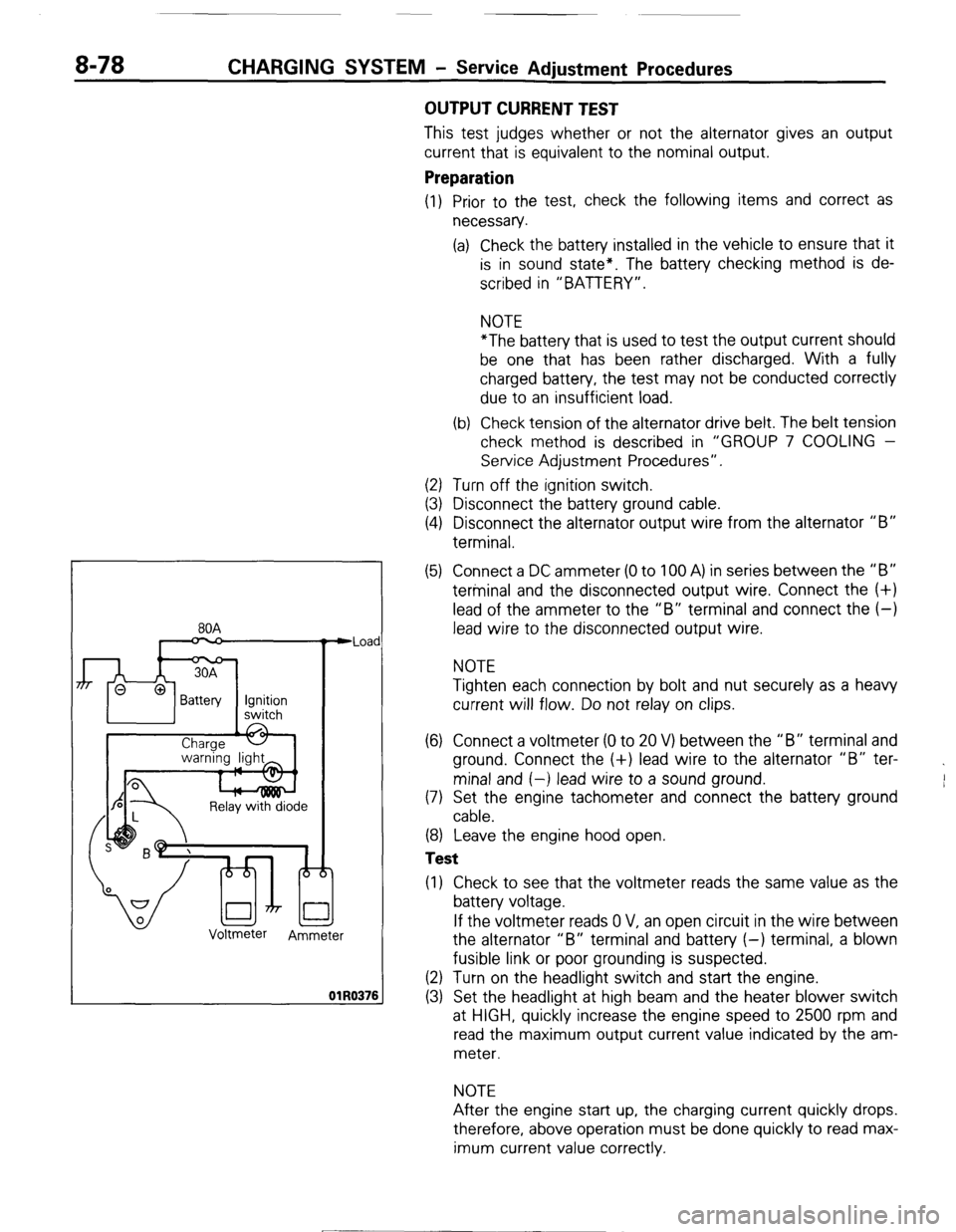

8-78 CHARGING SYSTEM - Service Adiustment Procedures

80A

n

Relay with diode

Voltmeter

Ammeter Iad

176

OUTPUT CURRENT TEST

This test judges whether or not the alternator gives an output

current that is equivalent to the nominal output.

Preparation

(1) Prior to the test, check the following items and correct as

necessary.

(a) Check the battery installed in the vehicle to ensure that it

is in sound state*. The battery checking method is de-

scribed in “BATTERY”.

NOTE

*The battery that is used to test the output current should

be one that has been rather discharged. With a fully

charged battery, the test may not be conducted correctly

due to an insufficient load.

(b) Check tension of the alternator drive belt. The belt tension

check method is described in “GROUP 7 COOLING -

Service Adjustment Procedures”.

(2) Turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Disconnect the alternator output wire from the alternator “B”

terminal.

(5) Connect a DC ammeter (0 to 100 A) in series between the “B”

terminal and the disconnected output wire. Connect the (+)

lead of the ammeter to the “B” terminal and connect the (-)

lead wire to the disconnected output wire.

NOTE

Tighten each connection by bolt and nut securely as a heavy

current will flow. Do not relay on clips.

(6) Connect a voltmeter (0 to 20 V) between the “B” terminal and

ground. Connect the (+) lead wire to the alternator “B” ter-

minal and (-) lead wire to a sound ground.

(7) Set the engine tachometer and connect the battery ground

cable.

(8) Leave the engine hood open.

Test

(1) Check to see that the voltmeter reads the same value as the

battery voltage.

If the voltmeter reads 0 V, an open circuit in the wire between

the alternator “B” terminal and battery (-) terminal, a blown

fusible link or poor grounding is suspected.

(2) Turn on the headlight switch and start the engine.

(3) Set the headlight at high beam and the heater blower switch

at HIGH, quickly increase the engine speed to 2500 rpm and

read the maximum output current value indicated by the am-

meter.

NOTE

After the engine start up, the charging current quickly drops.

therefore, above operation must be done quickly to read max-

imum current value correctly.

[ STB Revision

--I

Page 213 of 284

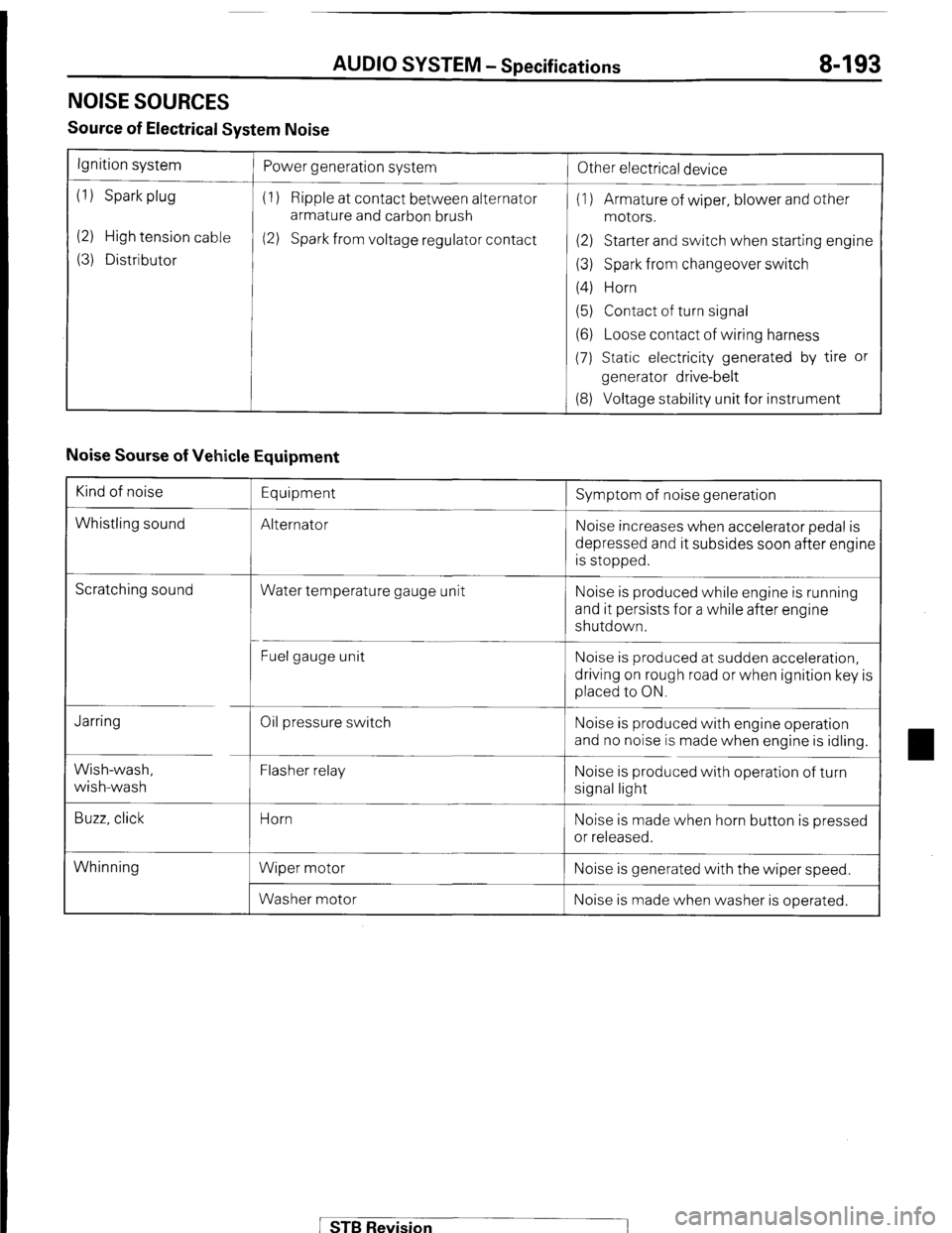

AUDIO SYSTEM - Specifications 8-193

NOISE SOURCES

Source of Electrical System Noise

Ignition system

(1) Spark plug

(2) High tension cable

(3) Distributor Power generation system

(1) Ripple at contact between alternator

armature and carbon brush

(2) Spark from voltage regulator contact

!

Other electrical device

(1) Armature of wiper, blower and other

motors.

(2) Starter and switch when starting engine

(3) Spark from changeover switch

(4) Horn

(5) Contact of turn signal

(6) Loose contact of wiring harness

(7) Static electricity generated by tire or

generator drive-belt

(8) Voltage stability unit for instrument

Noise Sourse of Vehicle Equipment

Kind of noise

Whistling sound Equipment

Alternator Symptom of noise generation

Noise increases when accelerator pedal is

depressed and it subsides soon after engine

is stopped.

Scratching sound

Water temperature gauge unit Noise is produced while engine is running

and it persists for a while after engine

shutdown.

Fuel gauge unit Noise is produced at sudden acceleration,

driving on rough road or when ignition key is

placed to ON.

Jarring

Wish-wash,

wish-wash

Buzz, click Oil pressure switch

Flasher relay

Horn

Wiper motor

Washer motor Noise is produced with engine operation

and no noise is made when engine is idling.

Noise is produced with operation of turn

signal light

Noise is made when horn button is pressed

or released.

Whinning Noise is generated with the wiper speed.

Noise is made when washer is operated.

STB Revision

Page 258 of 284

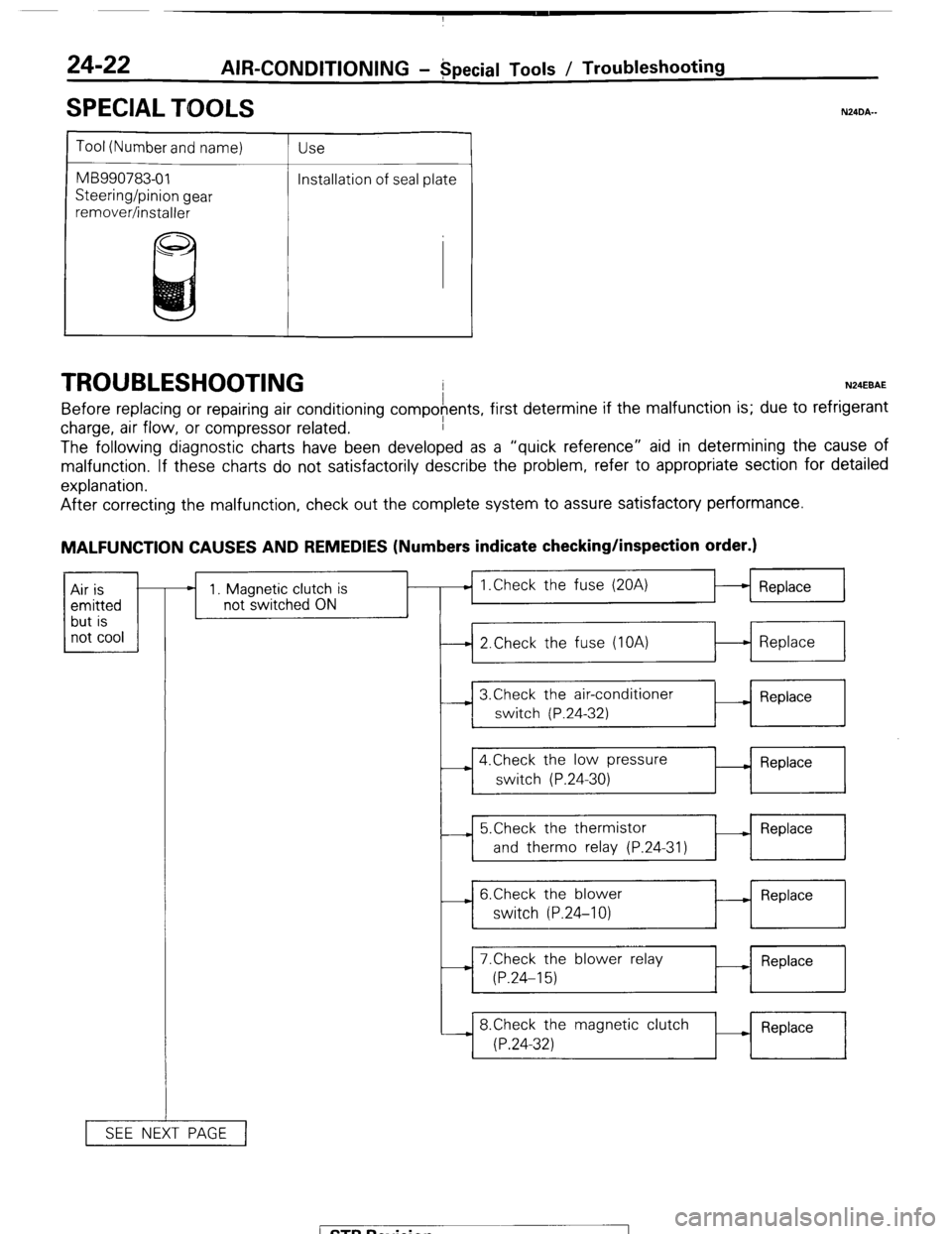

24-22 AIR-CONDITIONING - Special TOOIS / Troubleshooting

SPECIAL TOOLS

Tool (Number and name)

MB990783-01

Steering/pinion gear

remover/installer Use

Installation of seal plate

TROUBLESHOOTING N24EBAE

Before replacing or repairing air conditioning compofents, first determine if the malfunction is; due to refrigerant

charge, air flow, or compressor related.

The following diagnostic charts have been developed as a “quick reference” aid in determining the cause of

malfunction. If these charts do not satisfactorily describe the problem, refer to appropriate section for detailed

explanation.

N24DA.-

After correcting the malfunction, check out the complete system to assure satisfactory performance.

MALFUNCTION CAUSES AND REMEDIES (Numbers indicate checking/inspection order.)

1 not cool 1 Air is

emitted

but is * 1. Magnetic clutch is

not switched ON

SEE NEXT PAGE 1 Replace

1

I

I I

-4 2.Check the fuse (IOA)

t-l Replace

I

I I

I ,

I

3,Check the air-conditioner

__) Replace

switch (P.24-32)

I

4.Check the low pressure

switch (P.24-30) - Replace

---L 5.Check the thermistor

- Replace

and therm0 relay (P.24-31)

- 6.Check the blower

switch (P.24-10) - Replace

-i 7.Check the blower relay

M Replace

(P.24-15)

8.Check the magnetic clutch

(P.24-32) Replace

I

1 STB Revision

Page 261 of 284

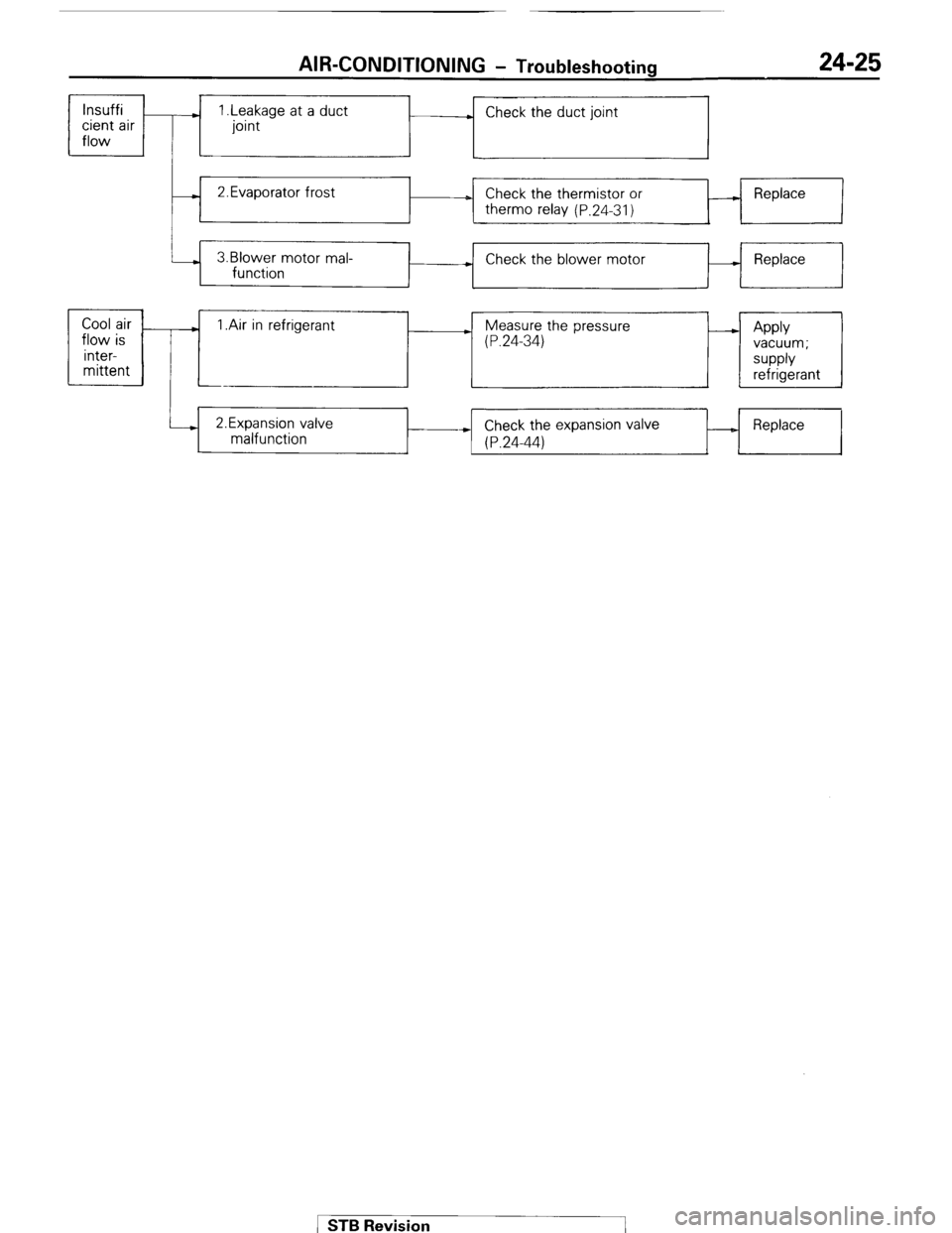

AIR-CONDITIONING - Troubleshooting 24-25

lnsuffi

cient air

flow ) 1 .Leakage at a duct

joint . Check the duct joint

- 2.Evaporator frost

D Check the thermistor or

therm0 relay (P.24-31) A Replace

3.Blower motor mal-

function + Check the blower motor - Replace

+

Cool air

.

flow is 1 .Air in refrigerant ) Measure the pressure

(P.24-34) - Apply

inter- vacuum;

mittent supply

refrigerant

i--) 2.Expansion valve

malfunction Check the expansion valve

* (P.24-44) _ Replace STB Revision