Oil pressure sensor MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 49 of 284

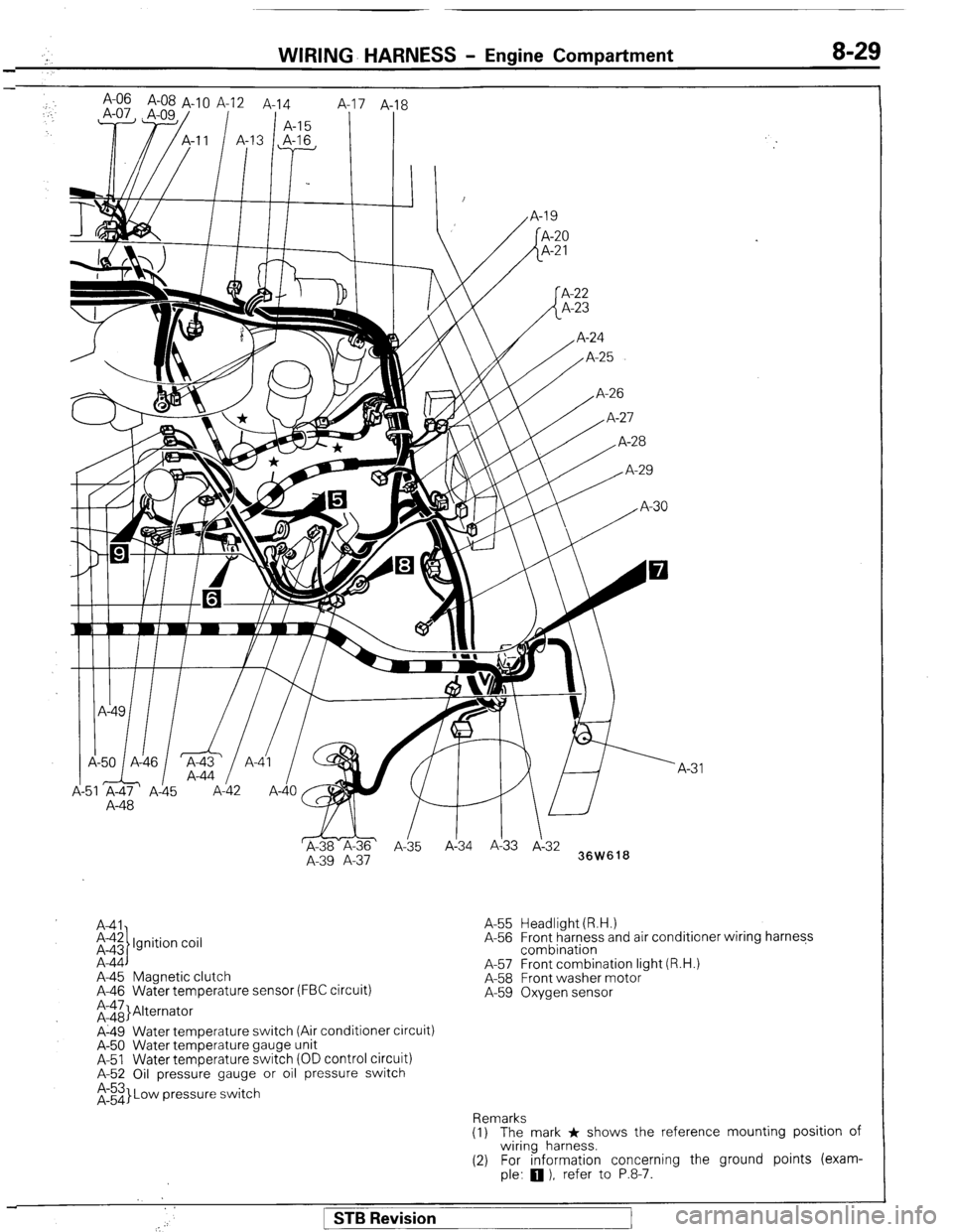

WIRING- HARNESS - Engine Compartment 8-29

; A-06 A-08 A-1 0 A-12 A-14

,.

1 A-15 8

I I

,I I I, I /

A-48

WI

&-ii& ’

A-35 Ai34 A!33 J-3:

A-39 A-37

36W618

A41

i-$ Ignition coil

A-44

A-45 Magnetic clutch

A-46 Water temperature sensor (FBC circuit)

;rii}Alternator

A-49 Water temperature switch (Air conditioner circuit)

A-50 Water temperature gauge unit

A-51 Water temperature switch (OD control circuit)

A-52 Oil pressure gauge or oil pressure switch

$3 Low pressure switch A-55 Headlight (R.H.)

A-56 Front harness and air conditioner wiring harness

combination

A-57 Front combination light (R.H.)

A-58 Front washer motor

A-59 Oxygen sensor

Remarks

(1) The mark * shows the reference mounting position of

wiring harness.

(2) For information concerning the ground points (exam-

ple:

q ), refer to P.8-7.

1 STB Revision

Page 73 of 284

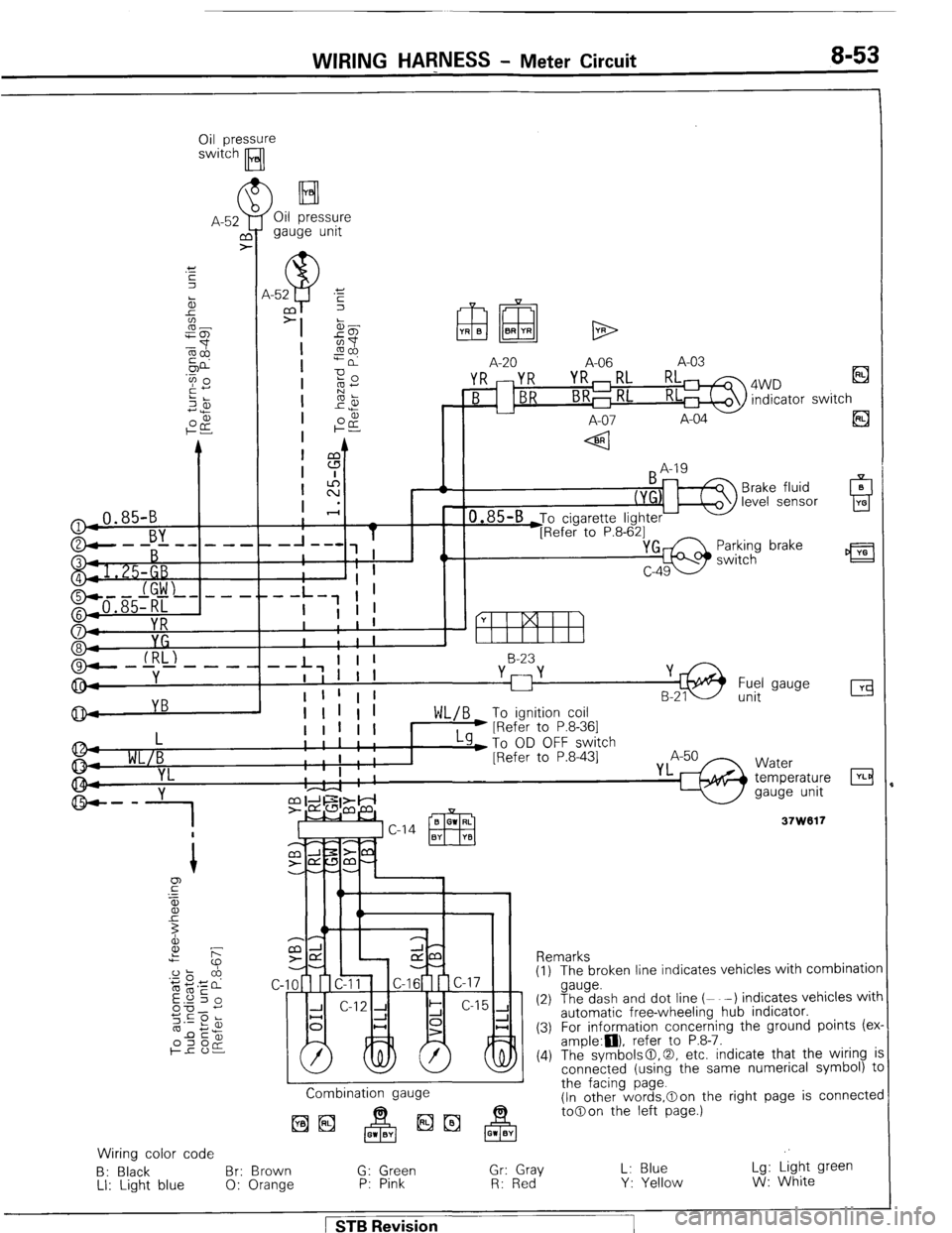

WIRING HAFNESS - Meter Circuit 8-53

O&y-ssure

[Eal

* - -,,- - - - -

YB

> El Oil pressure

gauge unit

ElxQ YR B BR YR

I.+

A-20

A-06 A-03

4WD Ei

indicator switch

A-07 A-04 I r-

’ fs A

I I

I

E

1 ,’

-I T

-- m-w

I ? I

I I ’

k-1 1 I

.- -

I

I ' 1

I I

I I I I 4

0.85-B Jo

cigarette lighter

[Refer to P.8-621 Brake fluid

level sensor

Parking brake

switch

L, I I 1 B-23

-- I , I I I

I !

Fuel gauge

unit

Water

temperature

gauge unit

37W617

les with combinatior

(2) %?zgdeash and dot line (- -) indicates vehicles wit1

automatic free-wheeling hub indicator.

(3) For information concerning the ground points (er

ample:n), refer to P.8-7.

(4) The symbols@,@, etc. indicate that the wiring i

connected (using the same numerical symbol) tl

Combination gauge the facing page.

(In other words,Oon the right page is connecter

to@on the left page.)

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue Lg: Light green

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow W: White

1 STB Revision

Page 256 of 284

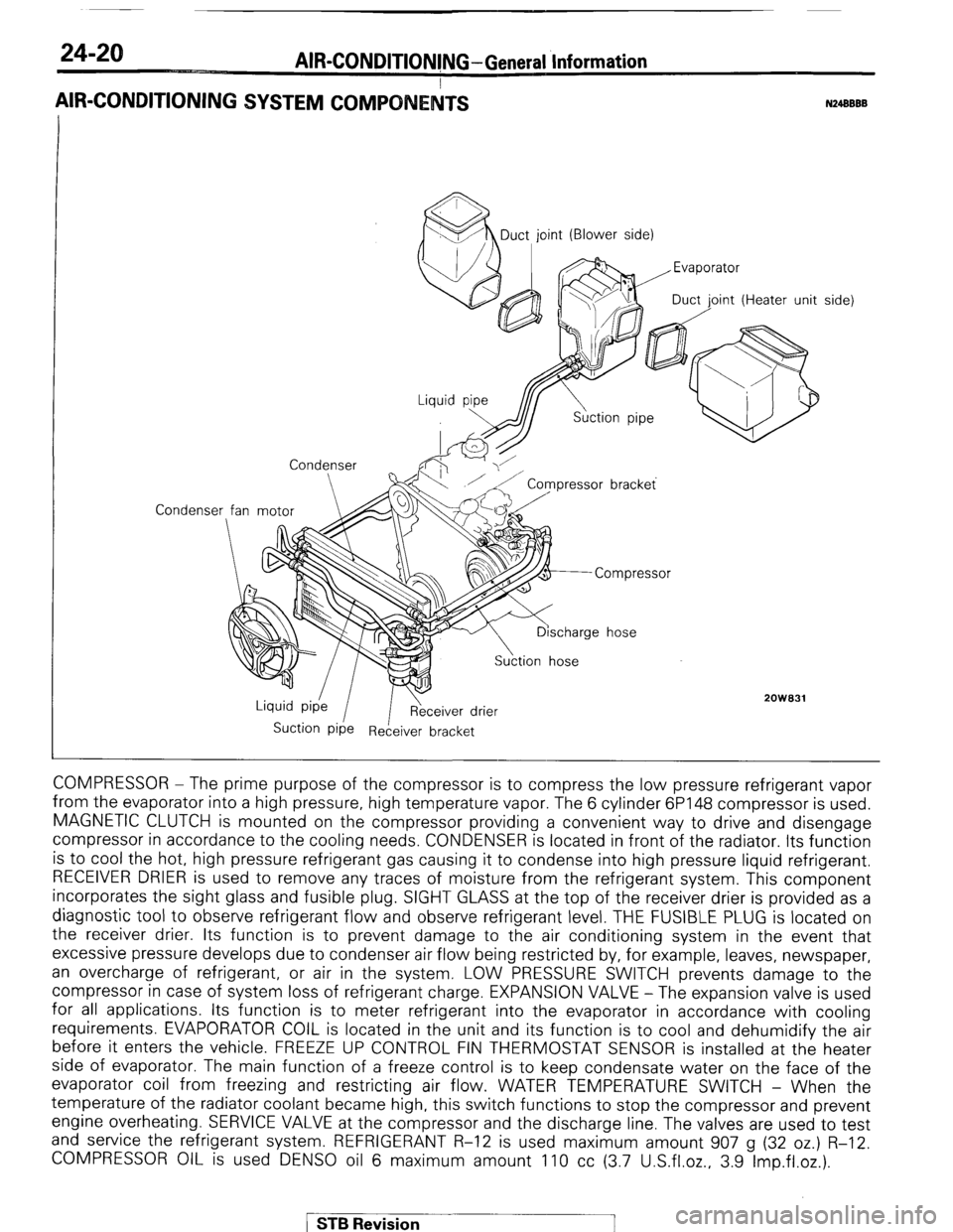

24-20 AIR-CONDITION!NG-General Information

I

AIR-CONDITIONING SYSTEM COMPO

N24BBBB

Condenser MDuct, joint (Blower side)

oint (Heater unit

Condenser

2OWB31

Suction Pipe Receiver bracket side)

COMPRESSOR - The prime purpose of the compressor is to compress the low pressure refrigerant vapor

from the evaporator into a high pressure, high temperature vapor. The 6 cylinder 6P148 compressor is used.

MAGNETIC CLUTCH is mounted on the compressor providing a convenient way to drive and disengage

compressor in accordance to the cooling needs. CONDENSER is located in front of the radiator. Its function

is to cool the hot, high pressure refrigerant gas causing it to condense into high pressure liquid refrigerant.

RECEIVER DRIER is used to remove any traces of moisture from the refrigerant system. This component

incorporates the sight glass and fusible plug. SIGHT GLASS at the top of the receiver drier is provided as a

diagnostic tool to observe refrigerant flow and observe refrigerant level. THE FUSIBLE PLUG is located on

the receiver drier. Its function is to prevent damage to the air conditioning system in the event that

excessive pressure develops due to condenser air flow being restricted by, for example, leaves, newspaper,

an overcharge of refrigerant, or air in the system. LOW PRESSURE SWITCH prevents damage to the

compressor in case of system loss of refrigerant charge. EXPANSION VALVE - The expansion valve is used

for all applications. Its function is to meter refrigerant into the evaporator in accordance with cooling

requirements. EVAPORATOR COIL is located in the unit and its function is to cool and dehumidify the air

before it enters the vehicle. FREEZE UP CONTROL FIN THERMOSTAT SENSOR is installed at the heater

side of evaporator. The main function of a freeze control is to keep condensate water on the face of the

evaporator coil from freezing and restricting air flow. WATER TEMPERATURE SWITCH - When the

temperature of the radiator coolant became high, this switch functions to stop the compressor and prevent

engine overheating. SERVICE VALVE at the compressor and the discharge line. The valves are used to test

and service the refrigerant system. REFRIGERANT R-12 is used maximum amount 907 g (32 oz.) R-12.

COMPRESSOR OIL is used DENS0 oil 6 maximum amount 110 cc (3.7 U.S.fl.oz., 3.9 Imp.fl.oz.).

/ STB Revision