width MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 17 of 284

INTRODUCTION - Geraeral Data and Specifications 17

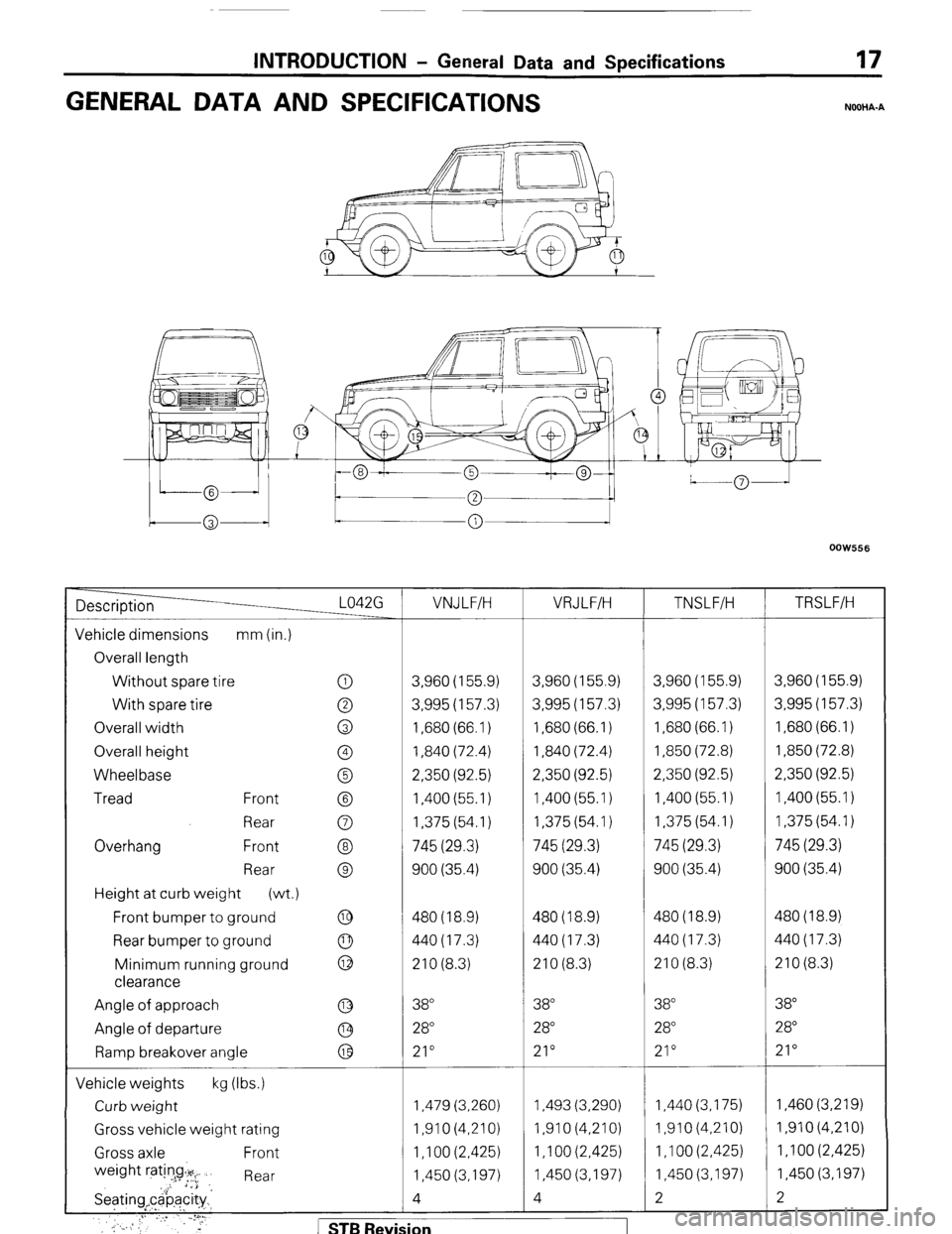

GENERAL DATA AND SPECIFICATIONS

NOOHA-A

OOW556

Description L042G VNJ LFIH VRJLFIH

TNSLFIH TRSLF/H

Vehicle dimensions mm (in.)

Overall length

Without tire

spare 0 3,960 (155.9) 3,960 (155.9) 3,960 (155.9) 3,960 (155.9)

With tire spare 0 3,995 (157.3) 3,995 (157.3) 3,995 (157.3) 3,995 (157.3)

Overall width 0 1,680 (66.1) 1,680 (66.1) 1,680 (66.1) 1,680 (66.1)

Overall height 0 1,840 (72.4) 1,840 (72.4) 1,850 (72.8) 1,850 (72.8)

Wheelbase 0 2,350 (92.5) 2,350 (92.5) 2,350 (92.5) 2,350 (92.5)

Tread Front @ 1,400 (55.1) 1,400 (55.1) 1,400 (55.1) 1,400 (55.1)

Rear 0 1,375 (54.1) 1,375 (54.1) 1,375 (54.1) 1,375 (54.1)

Overhang Front @ 745 (29.3) 745 (29.3) 745 (29.3) 745 (29.3)

Rear @ 900 (35.4) 900 (35.4) 900 (35.4) 900 (35.4)

Height at curb weight

(wt.)

Front bumper to ground

@ 480 (18.9) 480 (18.9) 480(18.9) 480 (18.9)

Rear bumper to ground 440(17.3) 440(17.3) 440(17.3) 440(17.3)

Minimum running ground : 210 (8.3) 210 (8.3) 210 (8.3) 210 (8.3)

clearance

Angle of approach @ 38 38 38” 38

Angle of departure @ 28 28” 28 28

Ramp breakover angle

@ 21” 21” 21” 21”

Vehicle weights kg (Ibs.)

Curb weight 1,479 (3,260) 1,493 (3,290) 1,440 (3,175) 1,460 (3,219)

Gross vehicle weight rating 1,910 (4,210) I,91 0 (4,210) 1,910(4,210) I,91 0 (4.210)

Gross axle Front 1 ,I 00 (2,425) 1 ,I 00 (2,425) 1 ,I 00 (2,425) 1,100 (2,425)

weight ratin!g~:+y~ Rear 1,450 (3,197) 1,450 (3,197) 1,450 (3,197) 1,450 (3,197)

Seating,c&ac&~ 4 4 2 2

.’ .’ :I’ ;.,* ..,, VU.,

,: ‘,_. : ., ”

,_;. ,; ,: 3,‘. r STB Revision

Page 29 of 284

INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector 8-9

Connect to

harness

16UO500

16R1317

8; 4 16R1319

INSPECTION OF HARNESS

CONNECTOR

NOECAM

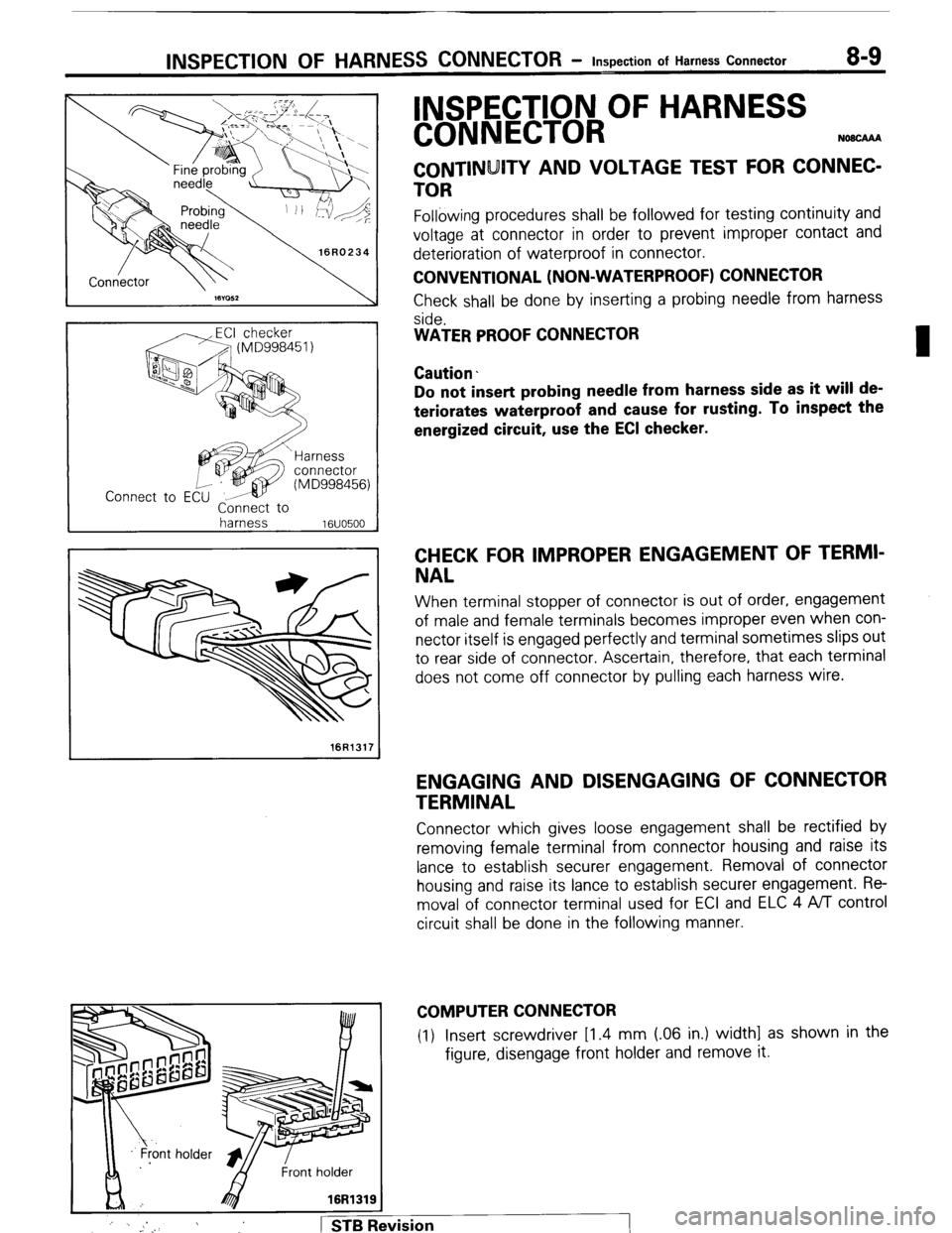

CONTINUITY AND VOLTAGE TEST FOR CONNEC-

TOR

Following procedures shall be followed for testing continuity and

voltage at connector in order to prevent improper contact and

deterioration of waterproof in connector.

CONVENTIONAL (NON-WATERPROOF) CONNECTOR

Check shall be done by inserting a probing needle from harness

side.

WATER PROOF CONNECTOR

Caution.

Do not insert probing needle from harness side as it will de-

teriorates waterproof and cause for rusting. To inspect the

energized circuit, use the ECI checker.

CHECK FOR IMPROPER ENGAGEMENT OF TERMI-

NAL

When terminal stopper of connector is out of order, engagement

of male and female terminals becomes improper even when con-

nector itself is engaged perfectly and terminal sometimes slips out

to rear side of connector. Ascertain, therefore, that each terminal

does not come off connector by pulling each harness wire.

ENGAGING AND DISENGAGING OF CONNECTOR

TERMINAL

Connector which gives loose engagement shall be rectified by

removing female terminal from connector housing and raise its

lance to establish securer engagement. Removal of connector

housing and raise its lance to establish securer engagement. Re-

moval of connector terminal used for ECI and ELC 4 ,4/l control

circuit shall be done in the following manner.

COMPUTER CONNECTOR

(1) Insert screwdriver [1.4 mm (06 in.) width] as shown in the

figure, disengage front holder and remove it.

:

j ’ . _. 1 STB Revision

Page 30 of 284

8-10 INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector

Housing lance

-5

1 16R1321

’ Needle

16Ffi322

Housing lance

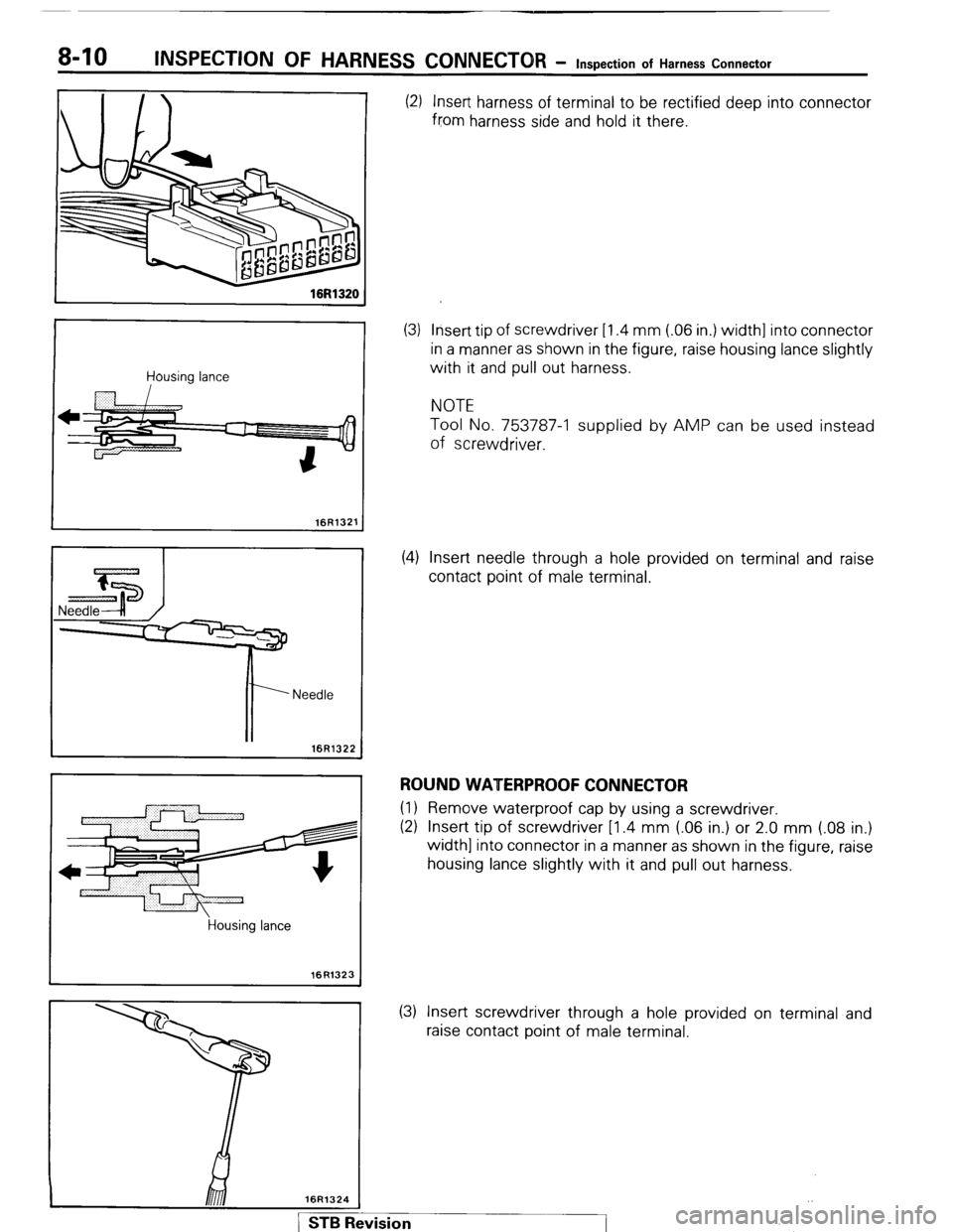

16R1323 (2) Insert harness of terminal to be rectified deep into connector

from harness side and hold it there.

(3) Insert tip of screwdriver [1.4 mm (.06 in.) width] into connector

in a manner as shown in the figure, raise housing lance slightly

with it and pull out harness.

NOTE

Tool No. 753787-l supplied by AMP can be used instead

of screwdriver.

(4) Insert needle through a hole provided on terminal and raise

contact point of male terminal.

ROUND WATERPROOF CONNECTOR (1) Remove waterproof cap by using a screwdriver.

(2) Insert tip of screwdriver [1.4 mm (.06 in.) or 2.0 mm (.08 in.)

width] into connector in a manner as shown in the figure, raise

housing lance slightly with it and pull out harness.

(3) Insert screwdriver through a hole provided on terminal and

raise contact point of male terminal.

Page 31 of 284

INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector 8-71

RECTANGULAR WATERPROOF CONNECTOR

(1) Disengage front holder by using a screwdriver and remove it.

(2) Insert tip of screwdriver [*0.8 mm (03 in.) width] into connec-

tor in a manner as shown in the figure, push it lightly to raise

housing lancer and pull out harness.

*If right size screwdriver is not available, convert a conven-

tional driver to suit the size.

Housing lance

16R13 26

16R1329

L 16R1326)

(2)

Terminal lance

16Rl330

1 STB Revision (3) Press contact point of male terminal down by holding a screw-

driver [1.4 mm (.06 in.) width] in a manner as shown in the

figure.

INJECTOR CONNECTOR

(1) Remove waterproof cap.

Insert tip of screwdriver [1.4

in a manner as shown in the

pull out harness. mm (06 in.) width] into connector

figure, press in terminal lance and

Page 32 of 284

![MITSUBISHI MONTERO 1987 1.G Workshop Manual 8-12 INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector

16R132i

(3) Press contact point of male terminal down by holding a screw-

driver Il.4 mm (.06 in.) width] in a manner as shown MITSUBISHI MONTERO 1987 1.G Workshop Manual 8-12 INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector

16R132i

(3) Press contact point of male terminal down by holding a screw-

driver Il.4 mm (.06 in.) width] in a manner as shown](/img/19/7559/w960_7559-31.png)

8-12 INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector

16R132i

(3) Press contact point of male terminal down by holding a screw-

driver Il.4 mm (.06 in.) width] in a manner as shown in the

figure.

Caution

Correct lancer to be in proper condition before terminal is

inserted into connector.

I

1 STB Revision