audio MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 1 of 284

Service Manual

MONTERO

1987 : Volume 2

FOREWORD

This Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

MITSUBISHI MOTOR SALES OF AMERICA. Inc.

Mitsubishi Motors corporation reserves the right to make changes in

design or to make additions to or improvements in its products without

imposing any obligations upon itself to install them on its products

previously manufactured.

I

GROUP/SECTION INDEX ‘kme-.

INTRODUCTION ..............................

Electrical ...........................................

Electrical System Parts

Location .........................................

Relays, Control Units, Sensors,

Fuses, Groundings

Inspection of Harness

Connector ......................................

Wiring Harness .............................

Charging System ..........................

Starting System ............................

Ignition System .............................

Meters and Gauges ......................

Lighting System .............................

Wiper and Washer System ..........

Horn ...............................................

Accessory ......................................

Audio System ................................

Back Door Window Defogger ......

Automatic Free-wheeling Hub

Indicator System ..........................

Heaters and Air-conditioning .........

Heaters ..........................................

Air-conditioning ............................

**, For Engine Chassis & Body refer to

0 1986 Mitsubishi Motors Corporation Printed in Japan

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 212 of 284

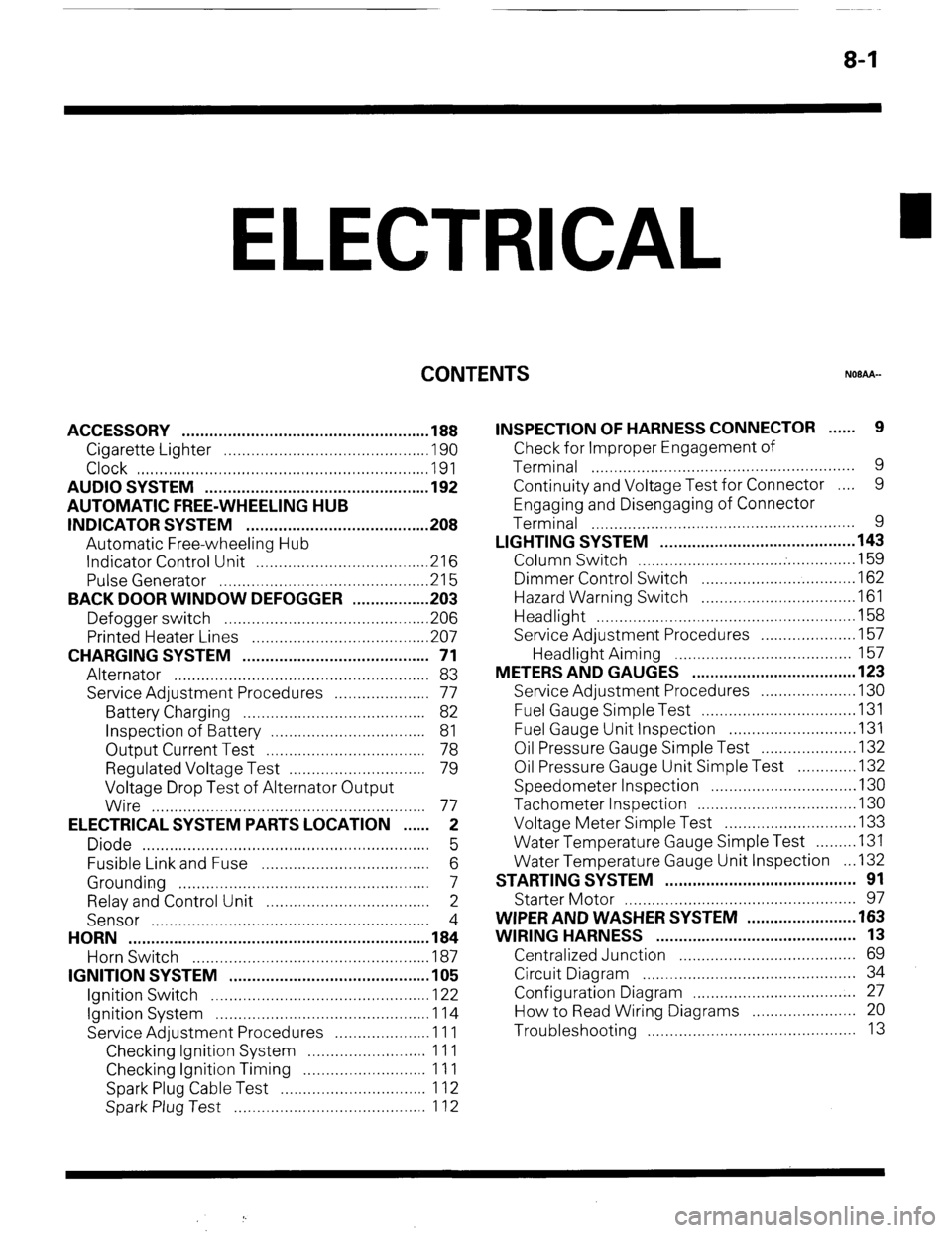

8-192 AUDIO SYSTEM - Specifications

AUDIO SYSTEM I

/

SPECIFICATIONS

GENERAL SPECIFICATIONS NOENB-

Items

Radio

Model

Receiving band

Tape player

Model

Speaker

Instrument panel

Model

Rated input power

Center pillar trim

Model.

Reted input power

Antenna

Type Spe,cifications

AR-7 127PY AR-7 177PY

AM/ FM AMI FM

-

CX-25Y

-_-

-

SR-28A4-Y K-2

5W (Max. 7W)

SG-13SL4-G2 (GRAY) or SG-13SL4-G2 (GRAY) or

SG-13SL4-BE87 (BEIGE) SG-13SL4-BE87 (BEIGE)

15W (Max. 30W) 15W (Max. 3OW)

Pole antenna Pole antenna

TROUBLESHOOTING

Symptom

NOTE

Number in circle indicates inspection sequence

( STB Revision

Page 213 of 284

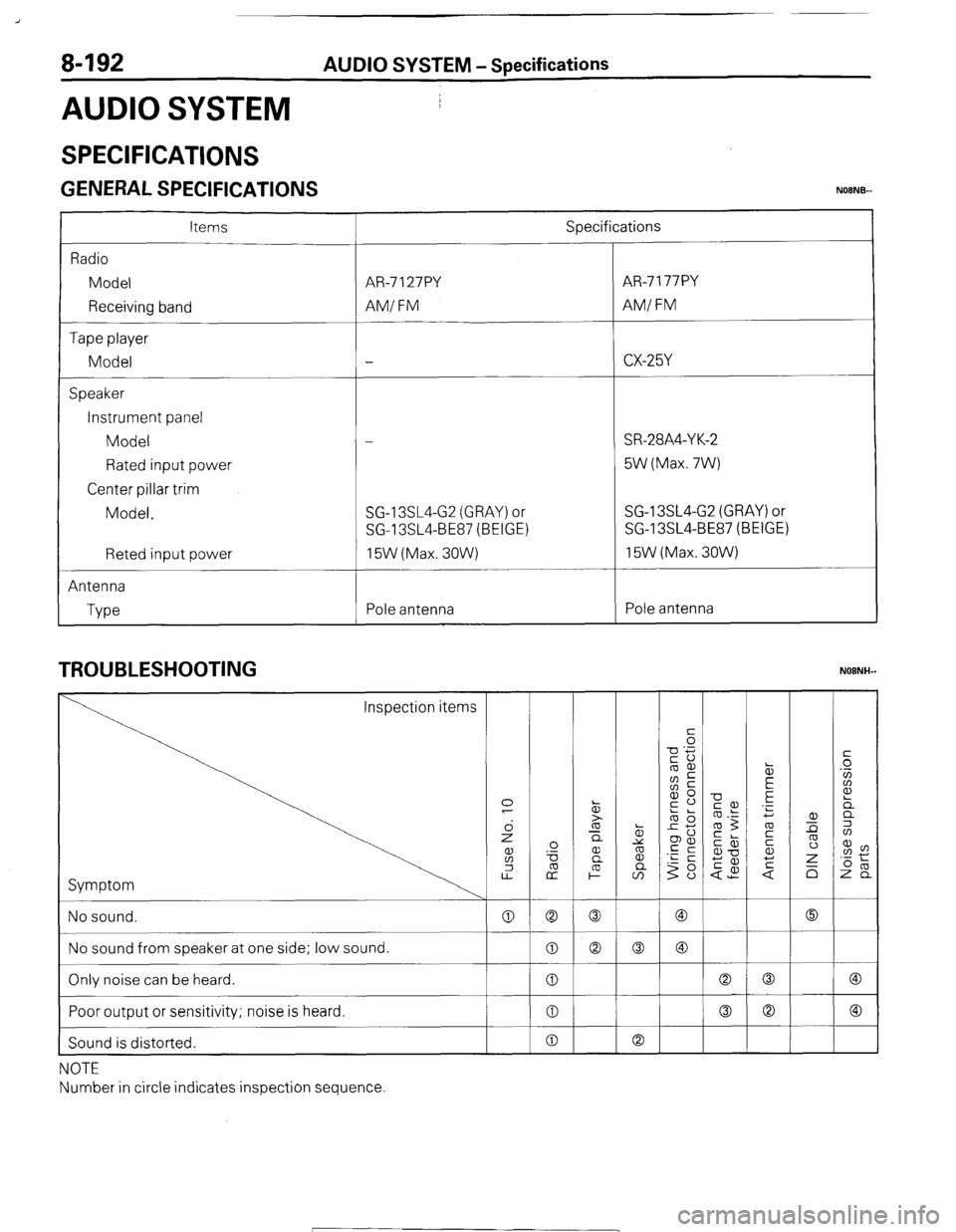

AUDIO SYSTEM - Specifications 8-193

NOISE SOURCES

Source of Electrical System Noise

Ignition system

(1) Spark plug

(2) High tension cable

(3) Distributor Power generation system

(1) Ripple at contact between alternator

armature and carbon brush

(2) Spark from voltage regulator contact

!

Other electrical device

(1) Armature of wiper, blower and other

motors.

(2) Starter and switch when starting engine

(3) Spark from changeover switch

(4) Horn

(5) Contact of turn signal

(6) Loose contact of wiring harness

(7) Static electricity generated by tire or

generator drive-belt

(8) Voltage stability unit for instrument

Noise Sourse of Vehicle Equipment

Kind of noise

Whistling sound Equipment

Alternator Symptom of noise generation

Noise increases when accelerator pedal is

depressed and it subsides soon after engine

is stopped.

Scratching sound

Water temperature gauge unit Noise is produced while engine is running

and it persists for a while after engine

shutdown.

Fuel gauge unit Noise is produced at sudden acceleration,

driving on rough road or when ignition key is

placed to ON.

Jarring

Wish-wash,

wish-wash

Buzz, click Oil pressure switch

Flasher relay

Horn

Wiper motor

Washer motor Noise is produced with engine operation

and no noise is made when engine is idling.

Noise is produced with operation of turn

signal light

Noise is made when horn button is pressed

or released.

Whinning Noise is generated with the wiper speed.

Noise is made when washer is operated.

STB Revision

Page 214 of 284

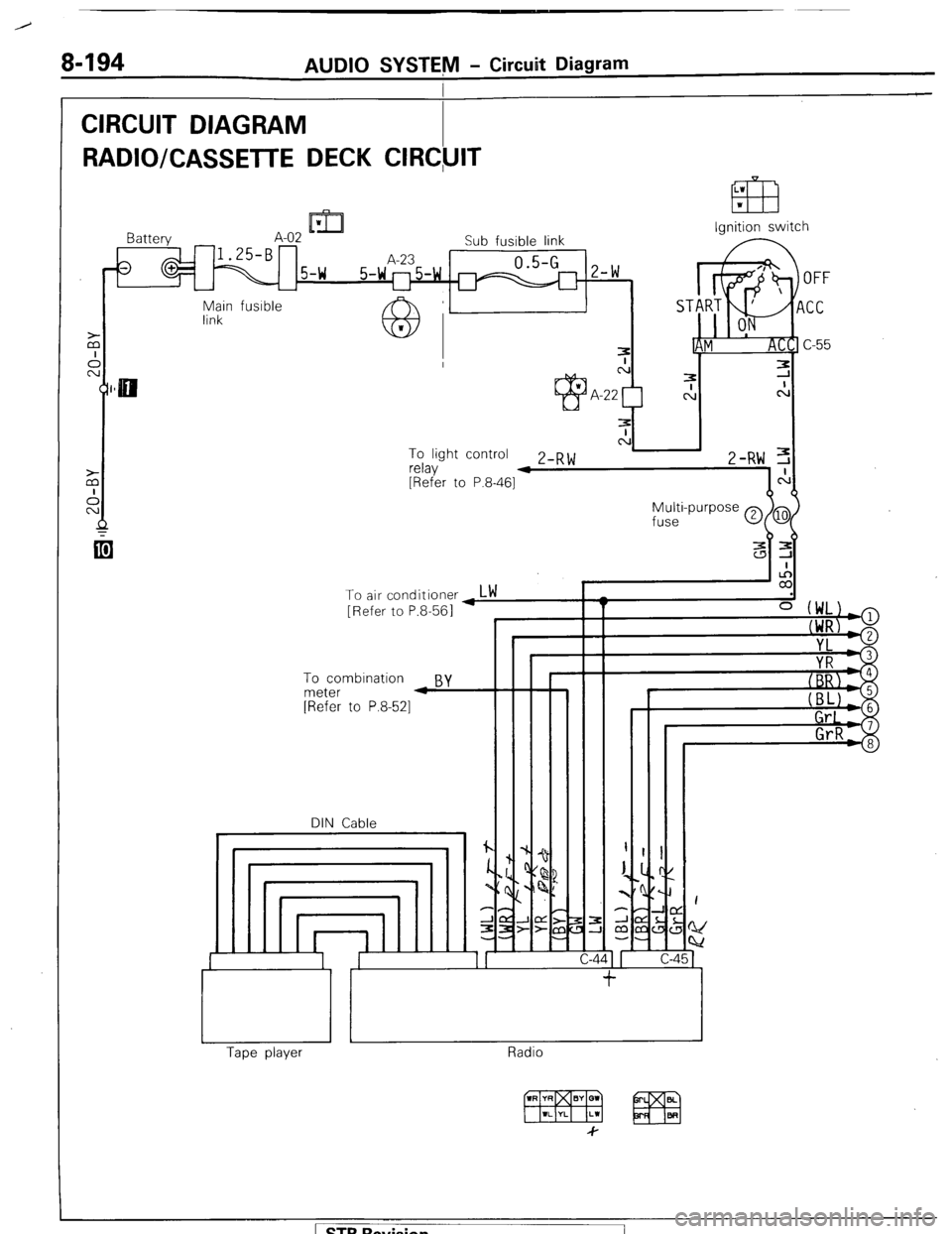

8-194 AUDIO SYSTEM - Circuit Diagram

CIRCUIT DIAGRAM

I

RADIO/CASSETTE DECK CIRC,UIT

LW

033 w

Ignition switch

Battery A-02 IL-

Sub fusible link

0 1.25-B A-23 0.5-G 2 w

1 5-w 5-w ll5-w m -

u

Main fusible

link

N To light control

relav Z-RW 3 4

[Refer to P.8-461

Z-RW,,:

To air conditioner,LW

[Refer to P.8-561

To combination

By meter 4

[Refer to P.8-521

DIN Cable

I

/

J

I Y

=z

I

c- 45 -

It, /II

1 L

Radio Tape player

[ STB Revision

Page 215 of 284

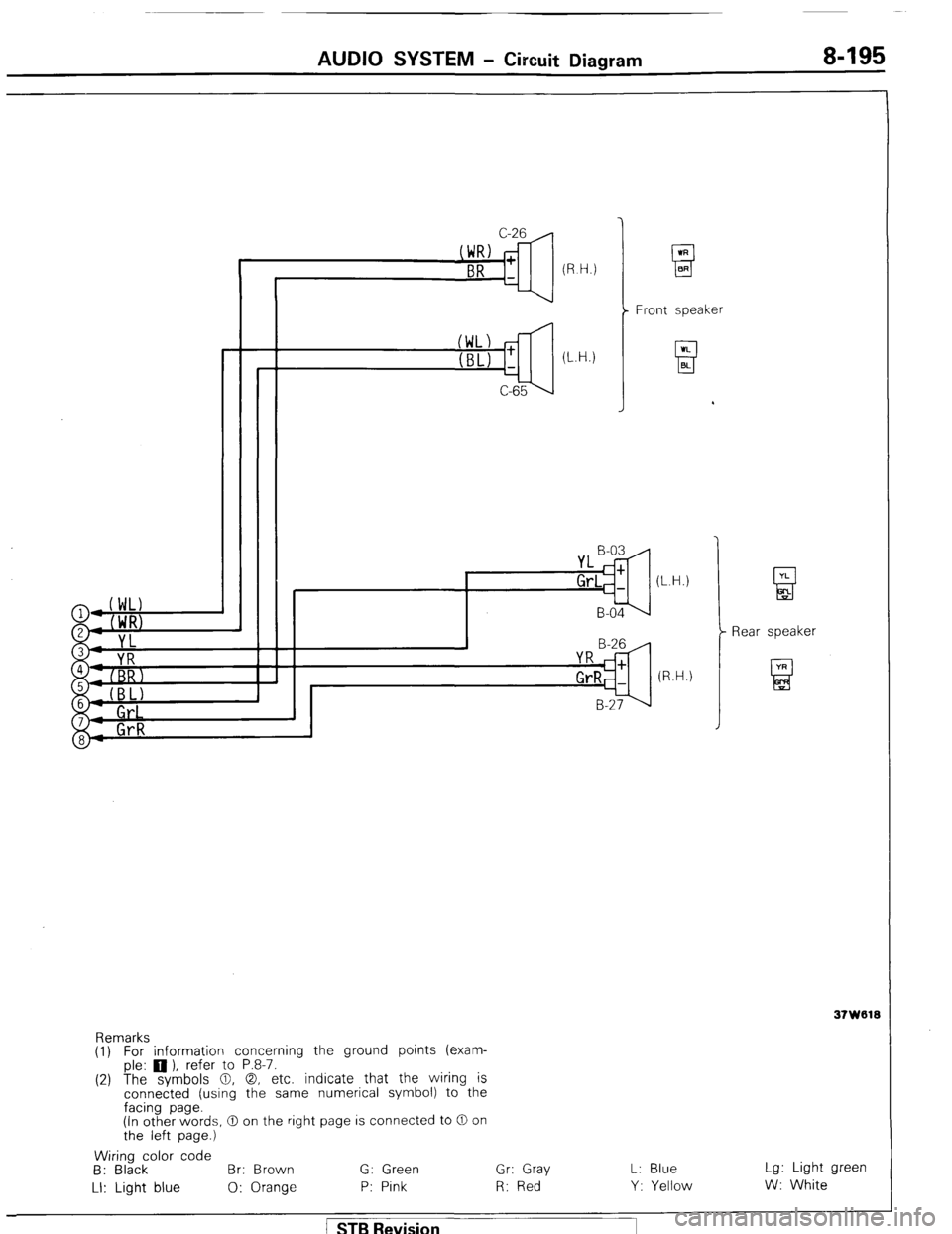

AUDIO SYSTEM - Circuit Diagram 8-195

(L.H.)

C-65 Front speaker

YL B-03

Gr,=: (L.H.)

B-04

B-29

YR c

GrRC+

(R.H.)

B-2?’

Remarks

(1) For information concerning the ground points (exam-

ple: 0 ), refer to P.8-7.

(2) The symbols 0, 0, etc. indicate that the wiring is

connected (using the same numerical symbol) to the

facing page.

(in other words, 0 on the right page is connected to 0 on

the left page.)

Wiring color code

B: Black Br: Brown G: Green Gr: Gray L: Blue

LI: Light blue 0: Orange P: Pink R: Red Y: Yellow Rear speaker

Lg: Light green

W: White

/ STB Revision

Page 216 of 284

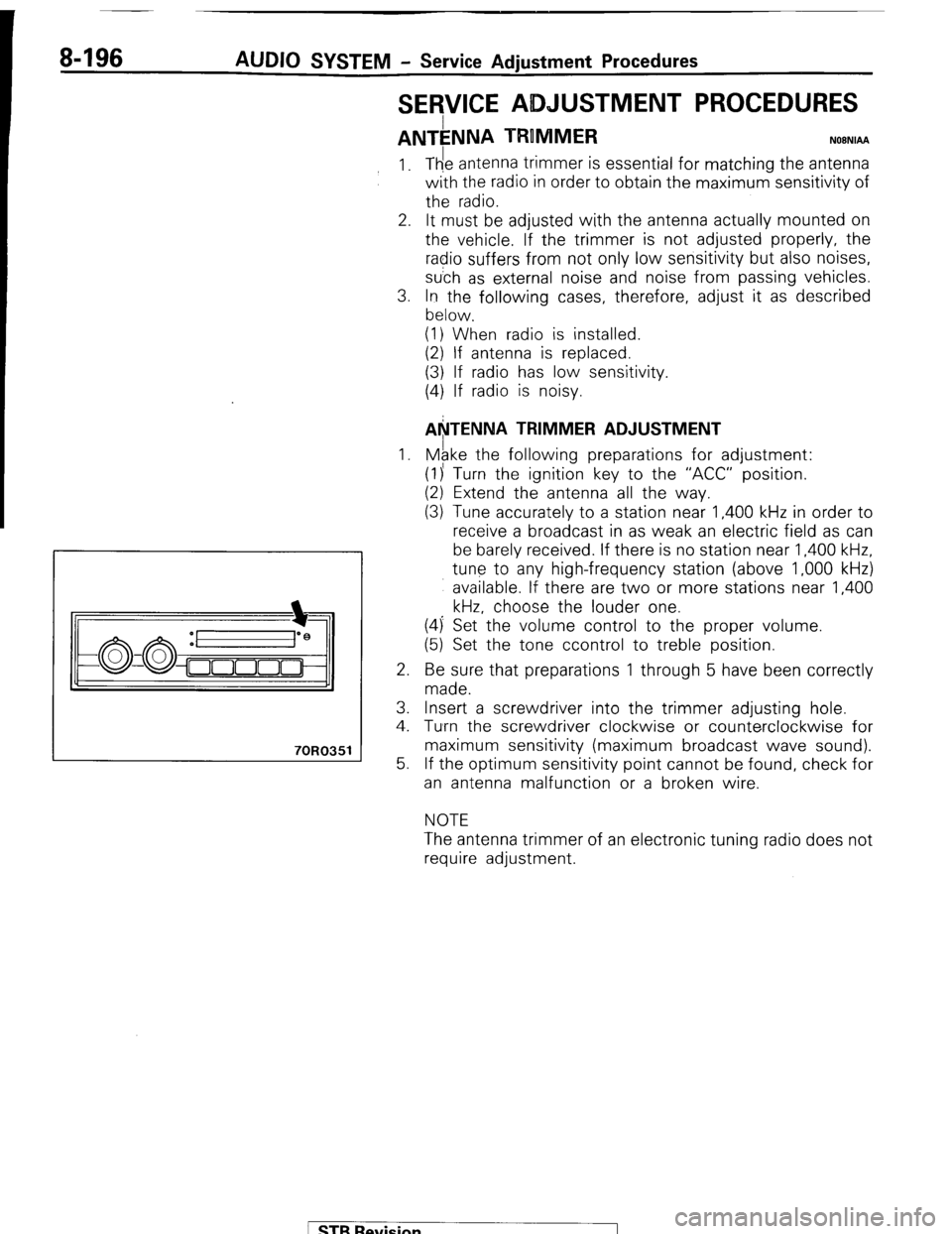

8-196 AUDIO SYSTEM - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

ANTkNNA TRUMMER NOBNIAA

70R0351

1.

2.

3.

1.

2.

3.

4.

5. The antenna trimmer is essential for matching the antenna

with the radio in order to obtain the maximum sensitivity of

the radio.

It must be adjusted with the antenna actually mounted on

the vehicle. If the trimmer is not adjusted properly, the

radio suffers from not only low sensitivity but also noises,

su’ch as external noise and noise from passing vehicles.

In the following cases, therefore, adjust it as described

below.

(1) When radio is installed.

(2) If antenna is replaced.

(3) If radio has low sensitivity.

(4) If radio is noisy.

AkTENNA TRIMMER ADJUSTMENT

Mgke the following preparations for adjustment:

(1)’ Turn the ignition key to the “ACC” position.

(2) Extend the antenna all the way.

(3) Tune accurately to a station near 1,400 kHz in order to

receive a broadcast in as weak an electric field as can

be barely received. If there is no station near 1,400 kHz,

tune to any high-frequency station (above 1,000 kHz)

available. If there are two or more stations near 1,400

kHz, choose the louder one.

(4) Set the volume control to the proper volume.

(5) Set the tone ccontrol to treble position.

Be sure that preparations 1 through 5 have been correctly

made.

Insert a screwdriver into the trimmer adjusting hole.

Tumrn the screwdriver clockwise or counterclockwise for

maximum sensitivity (maximum broadcast wave sound).

If the optimum sensitivity point cannot be found, check for

an antenna malfunction or a broken wire.

NOTE

The antenna trimmer of an electronic tuning radio does not

require adjustment.

/ STB Revision

Page 217 of 284

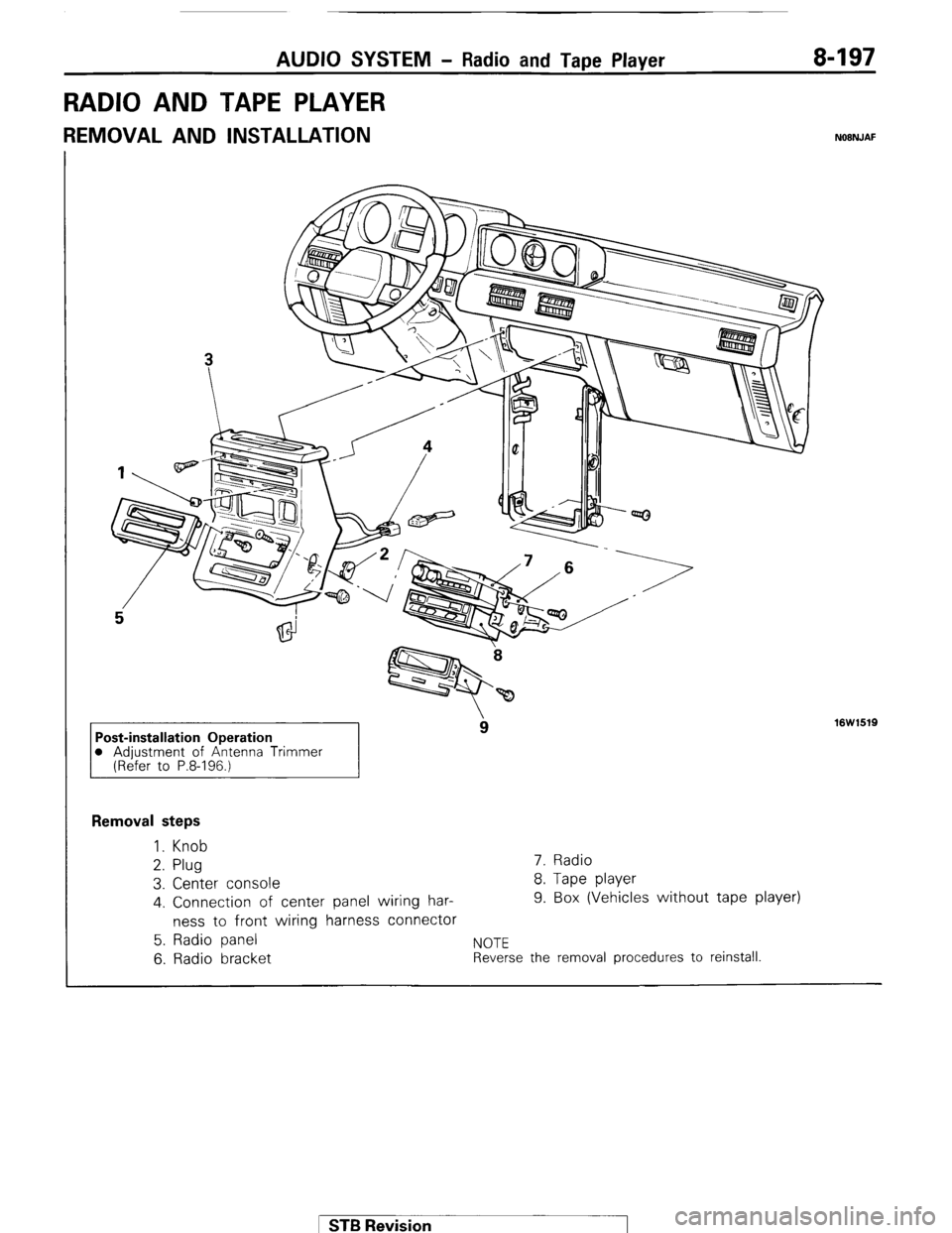

AUDIO SYSTEM - Radio and Tape Player e-197

RADIO AND TAPE PLAYER

REMOVAL AND INSTALLATION NOINJAF

16W1519

Post-installation Operation l Adjustment of Antenna Trimmer

(Refer to P.8-196.) Removal steps

1. Knob

2. Plug

3. Center console

4. Connection of center panel wiring har-

ness to front wiring harness connector 7. Radio

8. Tape player

9. Box (Vehicles without tape player)

5. Radio panel

6. Radio bracket NOTE

Reverse the removal procedures to reinstall. 1 STB Revision

Page 218 of 284

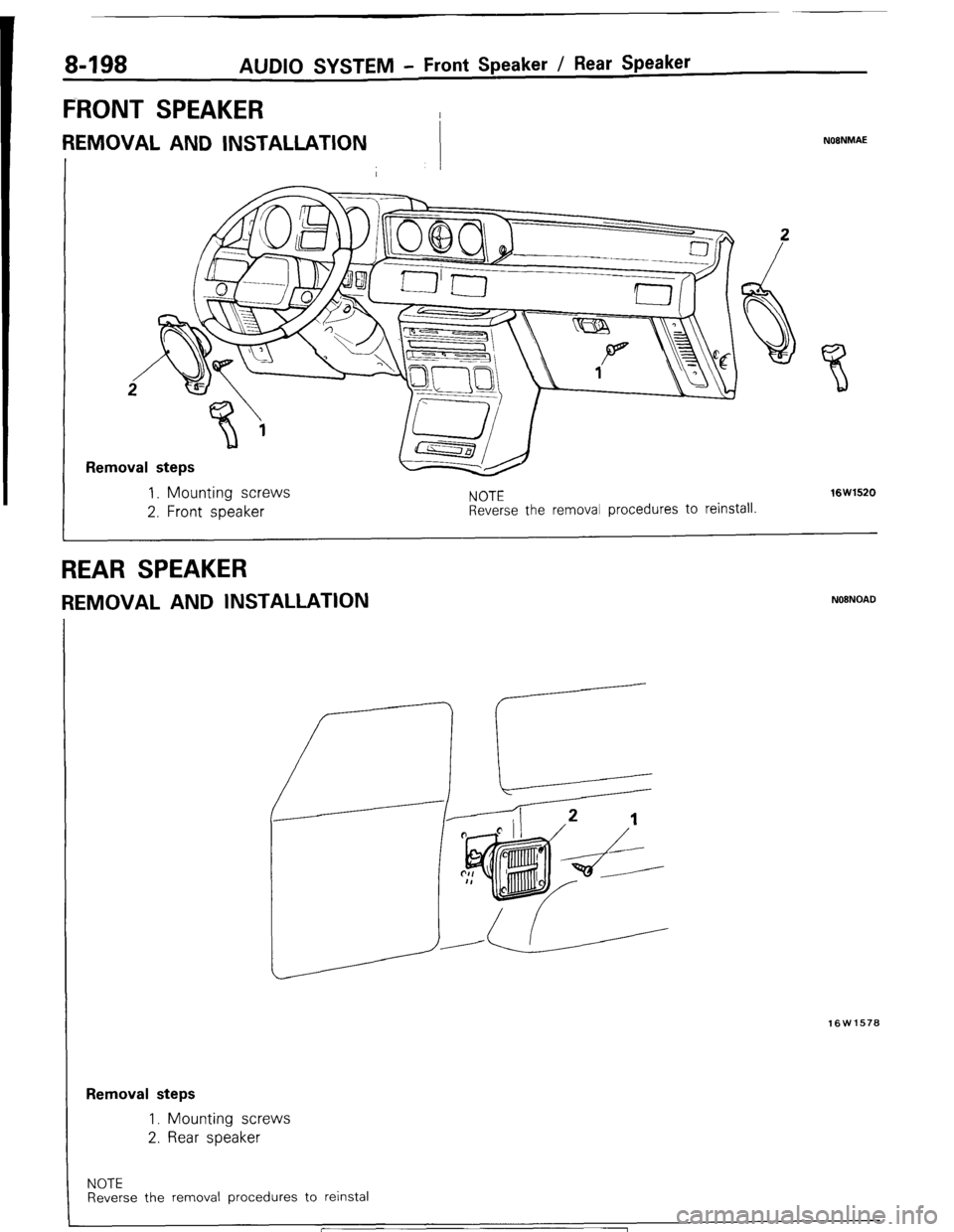

8-198 AUDIO SYSTEM - Front Speaker / Rear Speaker

FRONT SPEAKER

REMOVAL AND INSTALLATION NOONMAE

Removal steps

1. Mounting screws

2. Front speaker

NOTE

Reverse the removal procedures to reinstall. 16W1520

REAR SPEAKER

REMOVAL AND INSTALLATION

16Wl570

Removal steps

1. Mounting screws

2. Rear speaker

NOTE

Reverse the removal procedures to reinstal

1 STB Revision

Page 219 of 284

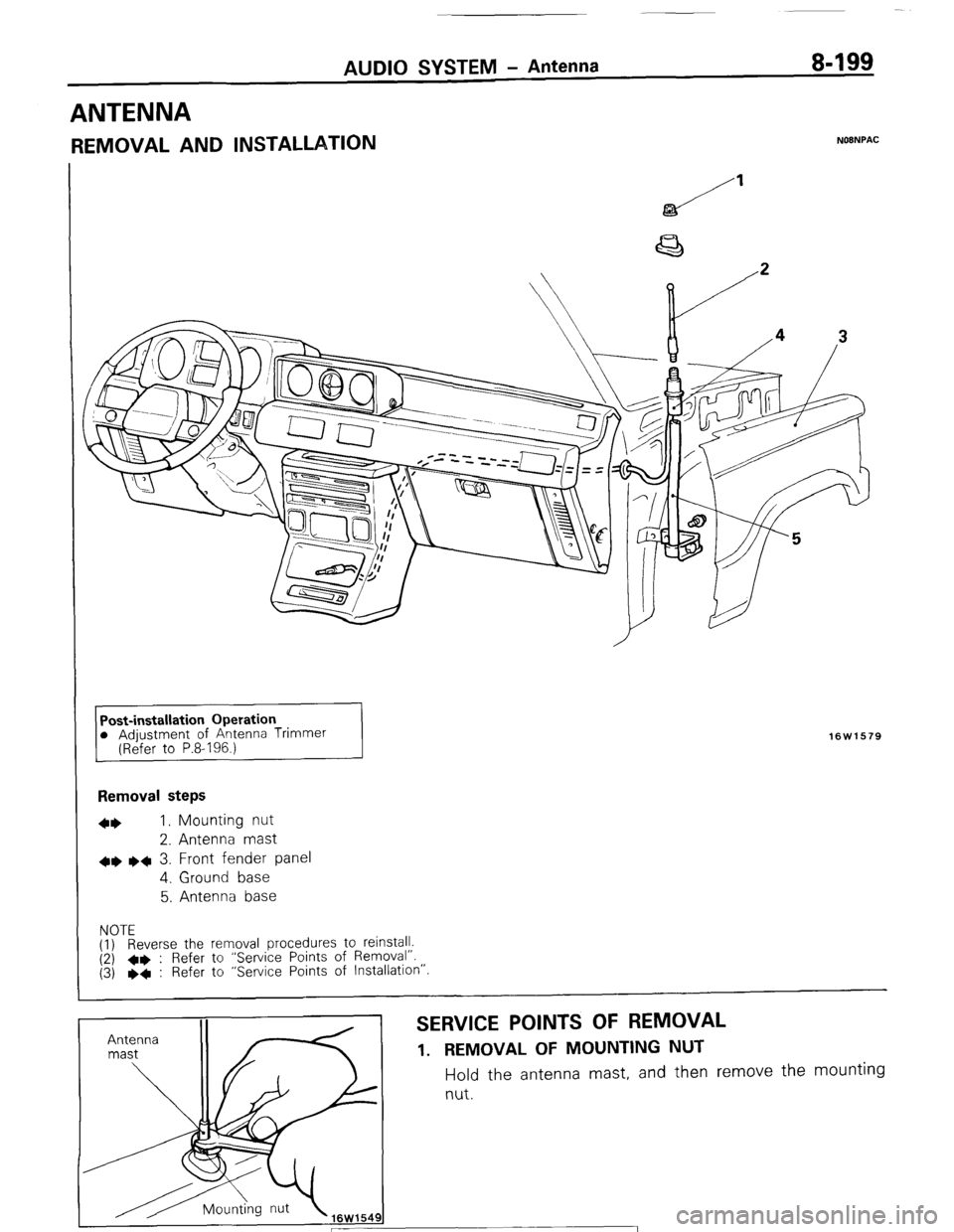

AUDIO SYSTEM - Antenna 8-199

ANTENNA

REMOVAL AND INSTALLATION NOSNPAC

Removal steps

4* 1. Mounting nut

2. Antenna mast

+e w+ 3. Front fender panel

4. Ground base

5. Antenna base

NOTE

(1) Reverse the removal procedures to reinstall.

(2) +* : Refer to “Service Points of Removal”.

(3) l

* : Refer to “Service Points of Installation”

16W1579

SERVICE POINTS OF REMOVAL

1. REMOVAL OF MOUNTING NUT

Hold the antenna

mast, and then remove the mounting