bulb MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 34 of 284

8-14 WIRING HARNESS - Troubleshooting

1680222

Changeover knob 1680224

1680225 1

1680226

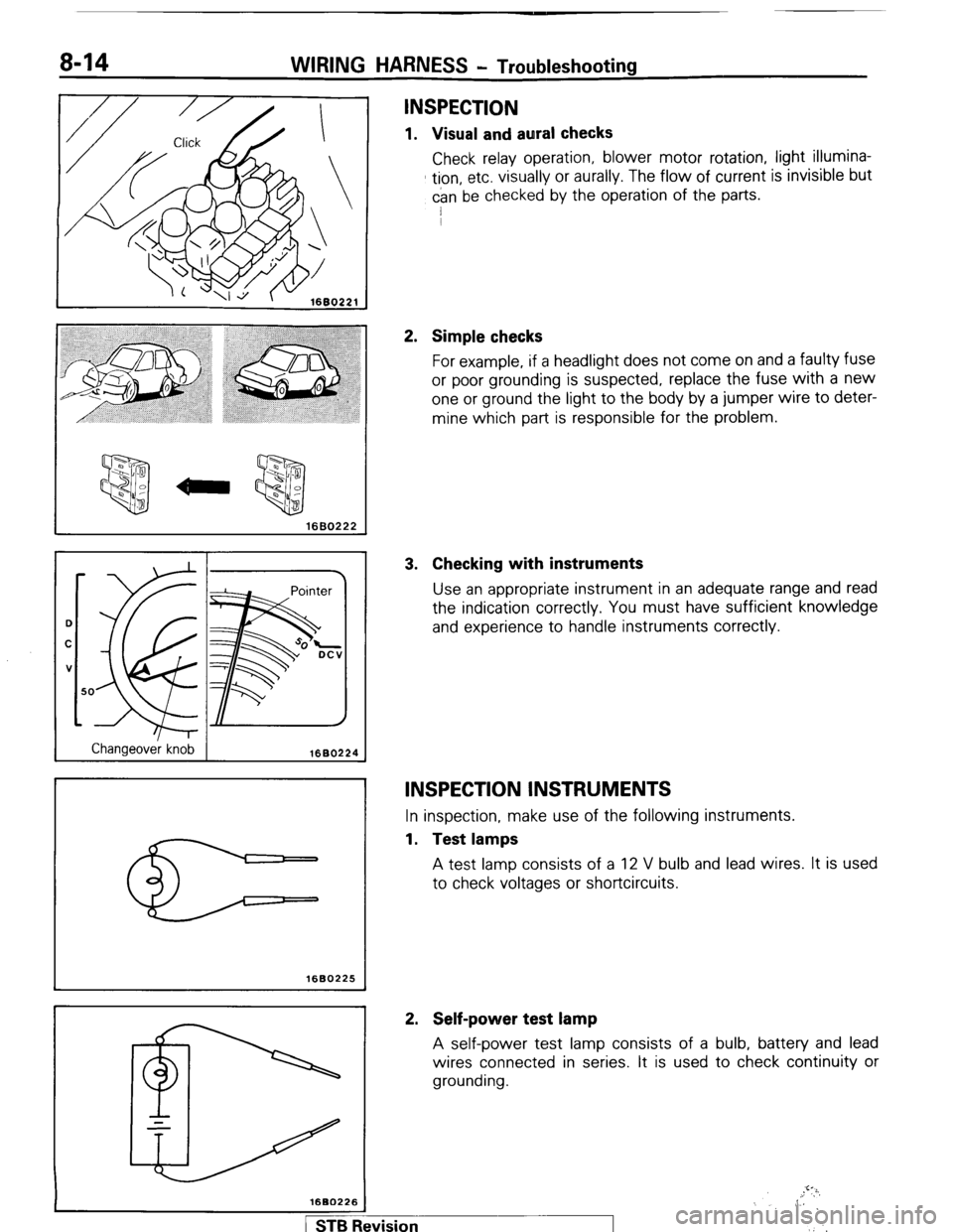

INSPECTION

1. Visual and aural checks

Check relay operation, blower motor rotation, light illumina-

tion, etc. visually or aurally. The flow of current is invisible but

can be checked by the operation of the parts.

I

2. Simple checks

For example, if a headlight does not come on and a faulty fuse

or poor grounding is suspected, replace the fuse with a new

one or ground the light to the body by a jumper wire to deter-

mine which part is responsible for the problem.

3. Checking with instruments

Use an appropriate instrument in an adequate range and read

the indication correctly. You must have sufficient knowledge

and experience to handle instruments correctly.

INSPECTION INSTRUMENTS

In inspection, make use of the following instruments.

1. Test lamps

A test lamp consists of a 12 V bulb and lead wires. It is used

to check voltages or shortcircuits.

2. Self-power test lamp

A self-power test lamp consists of a bulb, battery and lead

wires connected in series. It is used to check continuity or

grounding.

,.!‘?i,

,, 6

,‘.’

1 STB Revision

Page 46 of 284

8-26 WIRING HARNESS - HOW to Read Wiring Diagrams

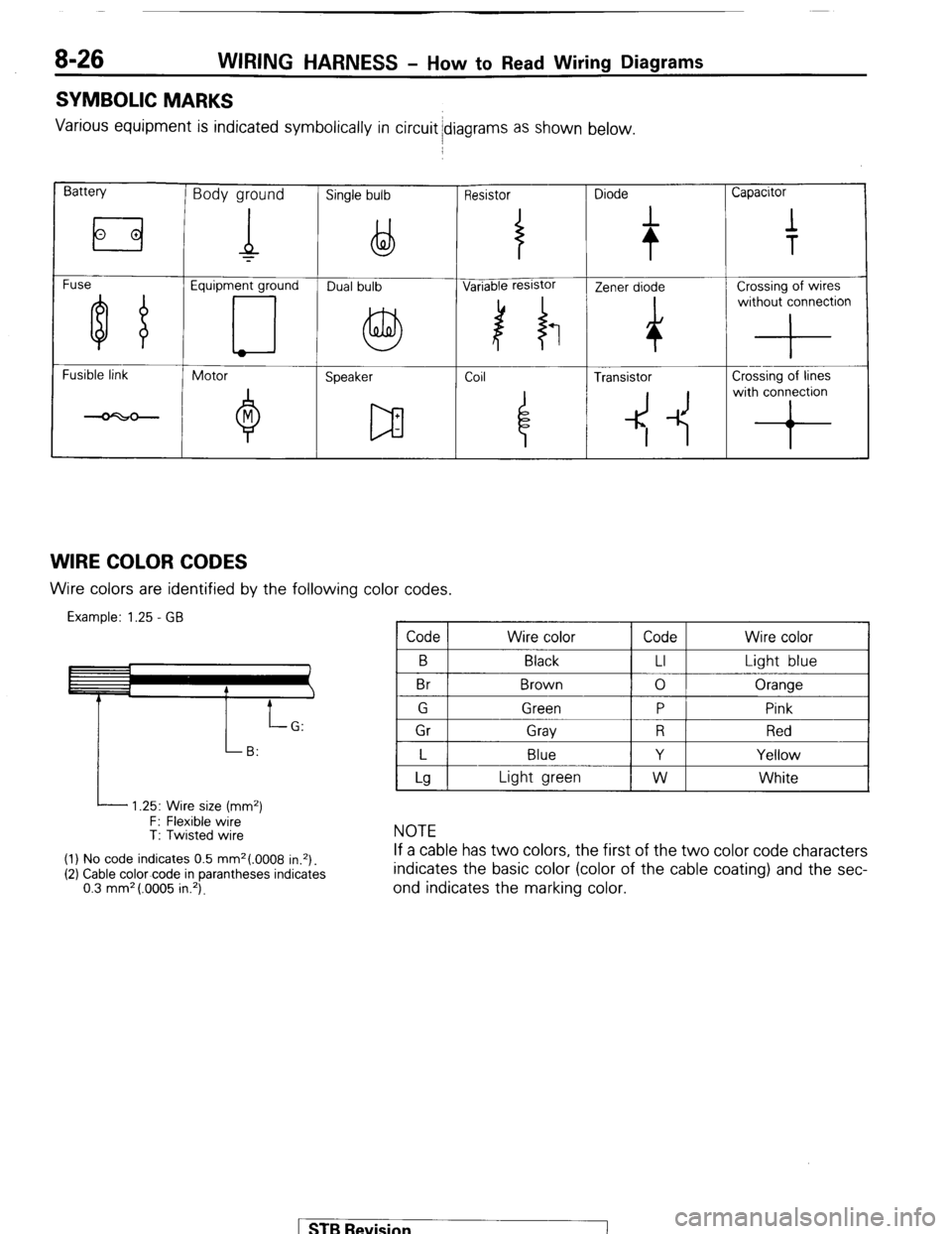

SYMBOLIC MARKS

Various equipment is indicated symbolically in circuit idiagrams as shown below.

Battery Body ground Single bulb Resistor Diode Capacitor

Fuse Equipment ground

Fusible link

Motor

Speaker Coil ~

4 Transistor Crossing of lines

4 -1~ with conron

WIRE COLOR CODES Wire colors are identified by the following color codes.

Example: 1.25 - GB Code Wire color Code Wire color

B

Br Black

Brown LI

0 Light blue

Oranqe

I P

i 1 Gr 1 Grav 1 R 1 Red I

I L I Blue

I Y I Yellow I

L 1.25: Wire size (mm2)

F: Flexible wire

T: Twisted wire

(1) No code indicates 0.5 mm2(.0008 in.*).

(2) Cable color-code in parantheses indicates

0.3 mm* (.0005 in.‘).

Lg Light green W White

NOTE

If a cable has two colors, the first of the two color code characters

indicates the basic color (color of the cable coating) and the sec-

ond indicates the marking color.

STB Revision

Page 147 of 284

METERS AND GAUGES -Troubleshooting 8-127

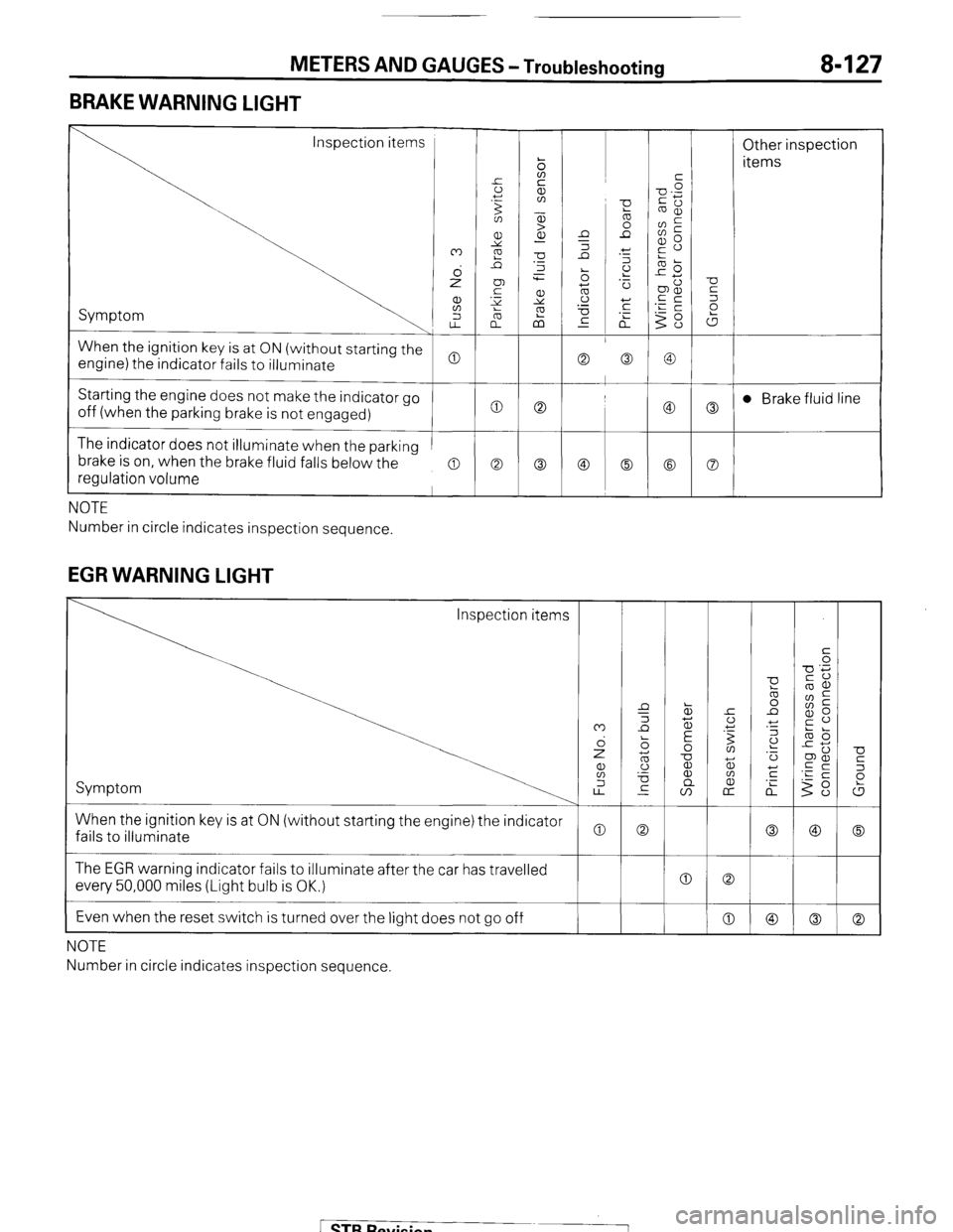

BRAKE WARNING LIGHT

Inspection items

Other inspection

items

Symptom

When the ignition key is at ON (without starting the

engine) the indicator fails to illuminate

Starting the engine does not make the indicator go

off (when the parking brake is not engaged) t 0 0

c

The indicator does not illuminate when the parking

brake is on, when the brake fluid falls below the

regulation volume

a a Co

NOTE

Number in circle indicates inspection sequence.

EGR WARNING LIGHT

U

5

P

W

0

Co When the ignition key is at ON (without starting the engine) the indicator

fails to illuminate

0 The EGR warning indicator fails to illuminate after the car has travelled

every 50,000 miles (Light bulb is OK.)

Even when the reset switch is turned over the light does not go off 0 0

0

I

NOTE

Number in circle indicates inspection sequence.

[ STB Revision

Page 162 of 284

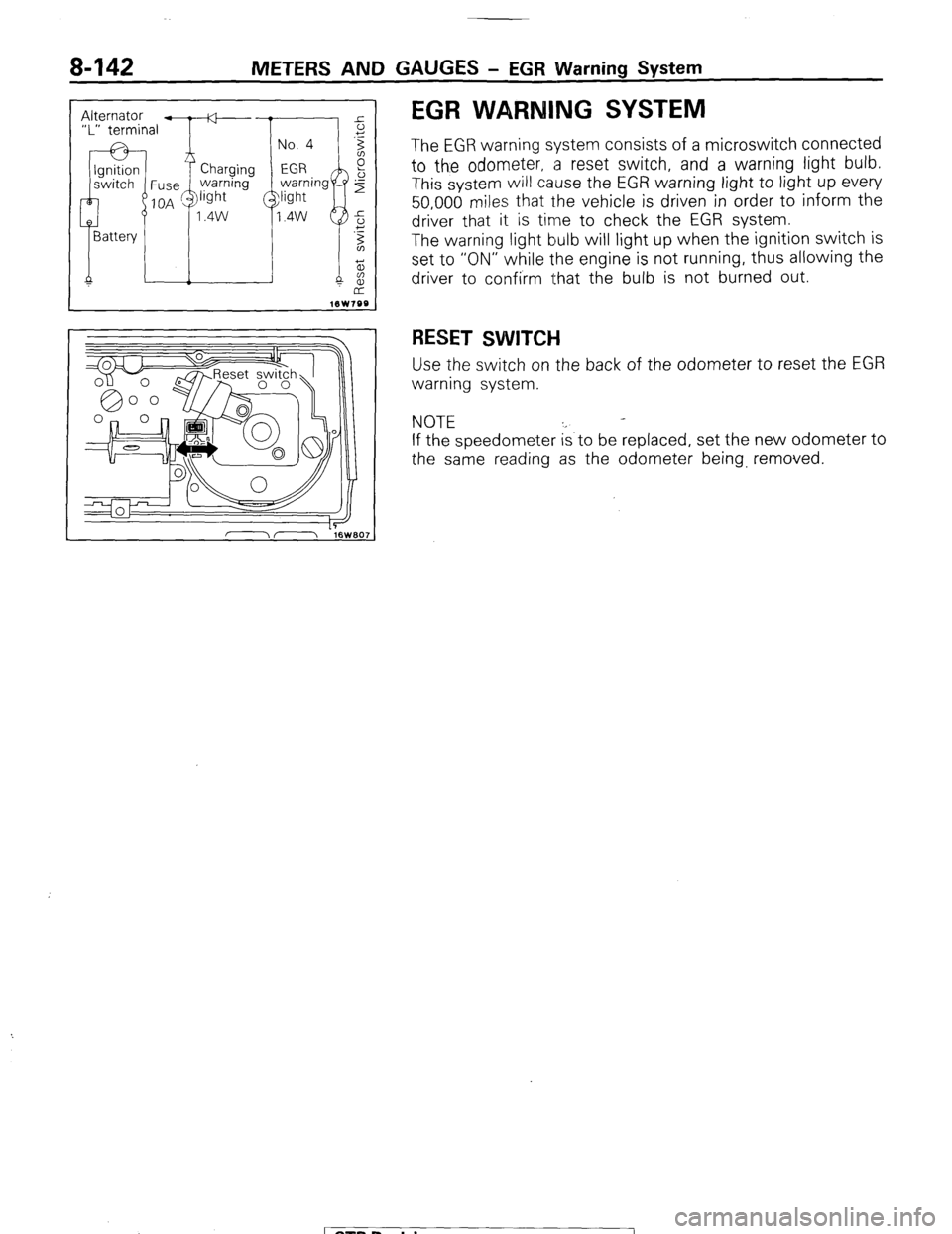

8-142 METERS AND GAUGES - EGR Warning System

EGR WARNING SYSTEM

The EGR warning system consists of a microswitch connected

to the odometer, a reset switch, and a warning light bulb.

This system will cause the EGR warning light to light up every

50,000 miles that the vehicle is driven in order to inform the

driver that it is time to check the EGR system.

The warning light bulb will light up when the ignition switch is

set to “ON” while the engine is not running, thus allowing the

driver to confirm that the bulb is not burned out.

RESET SWITCH

Use the switch on the back of the odometer to reset the EGR

warning system.

NOTE

If the speedometer is to be replaced, set the new odometer to

the same reading as the odometer being, removed.

1 STB Revision

Page 270 of 284

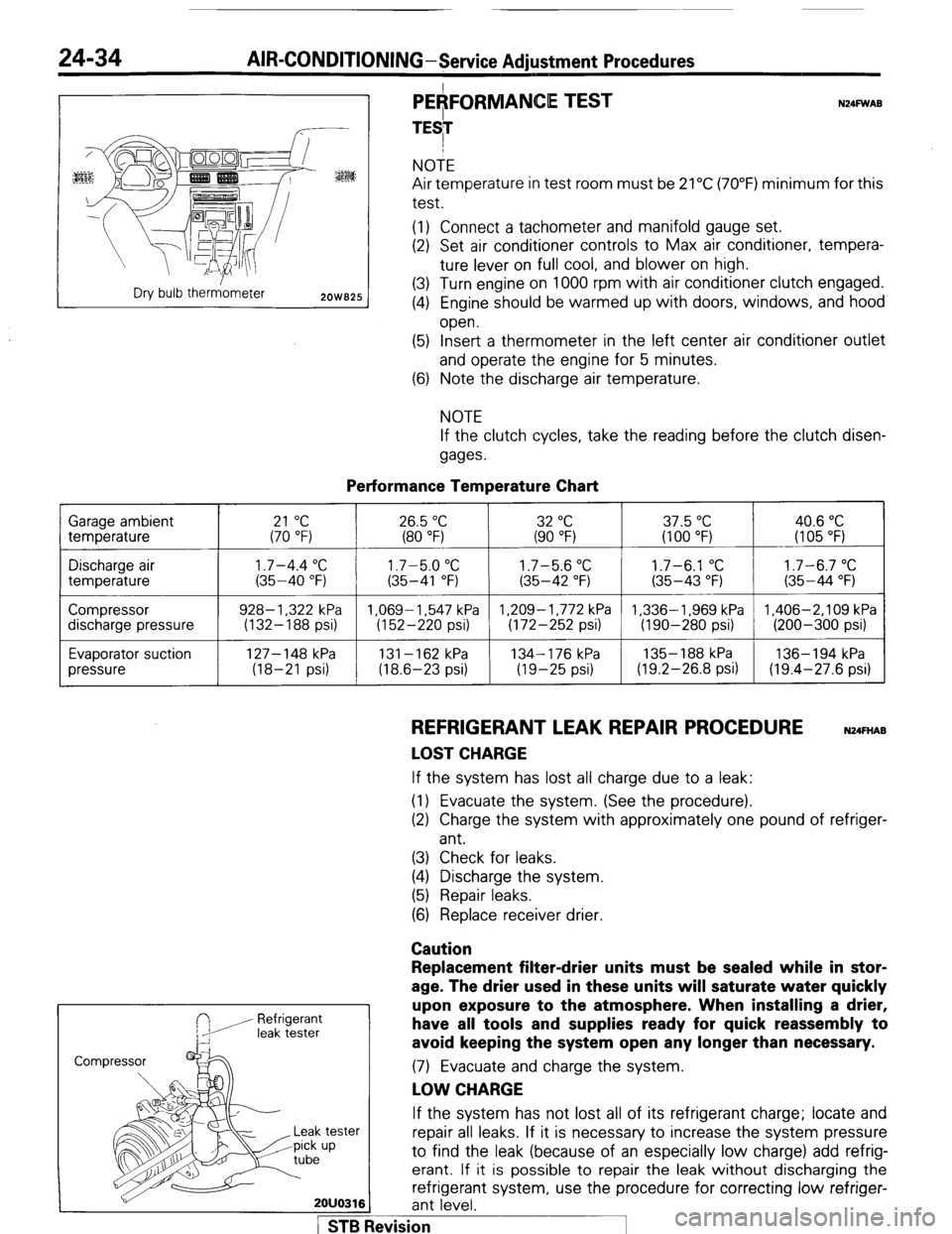

24-34 AIR-CONDITIONING-Service Adiustment Procedures

r---- :

:ES

Dry bulb therr&neter

2OW825

PEAFORMANCE TEST

TESI N24FWAB NOTE

Air temperature in test room must be 21°C (70°F) minimum for this

test.

(1) Connect a tachometer and manifold gauge set.

(2) Set air conditioner controls to Max air conditioner, tempera-

ture lever on full cool, and blower on high.

(3) Turn engine on 1000 rpm with air conditioner clutch engaged.

(4) Engine should be warmed up with doors, windows, and hood

open.

(5) Insert a thermometer in the left center air conditioner outlet

and operate the engine for 5 minutes.

(6) Note the discharge air temperature.

NOTE

If the clutch cycles, take the reading before the clutch disen-

gages.

Performance Temperature Chart Garage ambient

temperature

21 “C 26.5 “C 32 “C 37.5 “C 40.6 “C (70 “F) (80 “F) (90 “F) (100 “F) (I 05 “F)

Discharge air

temperature

Compressor

discharge pressure

Evaporator suction

pressure

1.7-4.4 “C 1.7-5.0 “C 1.7-5.6 “C 1.7-6.1 “C 1.7-6.7 “C (35-40 “F) (35-41 “F) (35-42 “F) (35-43 “F) (35-44 “F)

928- 1,322 kPa 1.069-1.547 kPa 1,209-1,772 kPa 1,336-1,969 kPa 1,406-2,109 kPa

(132-188 psi) (152-220 psi) (172-252 psi) (190-280 psi) (200-300 psi)

127-148 kPa

131-162 kPa 134-176 kPa 135- 188 kPa 136-194 kPa

(18-21 psi) (18.6-23 psi) (19-25 psi) (19.2-26.8 psi) (19.4-27.6 psi)

REFRIGERANT LEAK REPAIR PROCEDURE N24FnAB

LOST CHARGE If the system has lost all charge due to a leak:

(1) Evacuate the system. (See the procedure).

(2) Charge the system with approximately one pound of refriger-

ant.

(3) Check for leaks.

(4) Discharge the system.

(5) Repair leaks.

(6) Replace receiver drier.

Caution

Refrigerant

leak tester

Replacement filter-drier units must be sealed while in stor-

age. The drier used in these units will saturate water quickly

upon exposure to the atmosphere. When installing a drier,

have all tools and supplies ready for quick reassembly to

avoid keeping the system open any longer than necessary. (7) Evacuate and charge the system.

LOW CHARGE If the system has not lost all of its refrigerant charge; locate and

tester repair all leaks. If it is necessary to increase the system pressure

up to find the leak (because of an especially low charge) add refrig-

erant. If it is possible to repair the leak without discharging the

refrigerant system, use the procedure for correcting low refriger-

2OUO316 ant level.

1 STB Revision