change time MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 1 of 284

Service Manual

MONTERO

1987 : Volume 2

FOREWORD

This Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

MITSUBISHI MOTOR SALES OF AMERICA. Inc.

Mitsubishi Motors corporation reserves the right to make changes in

design or to make additions to or improvements in its products without

imposing any obligations upon itself to install them on its products

previously manufactured.

I

GROUP/SECTION INDEX ‘kme-.

INTRODUCTION ..............................

Electrical ...........................................

Electrical System Parts

Location .........................................

Relays, Control Units, Sensors,

Fuses, Groundings

Inspection of Harness

Connector ......................................

Wiring Harness .............................

Charging System ..........................

Starting System ............................

Ignition System .............................

Meters and Gauges ......................

Lighting System .............................

Wiper and Washer System ..........

Horn ...............................................

Accessory ......................................

Audio System ................................

Back Door Window Defogger ......

Automatic Free-wheeling Hub

Indicator System ..........................

Heaters and Air-conditioning .........

Heaters ..........................................

Air-conditioning ............................

**, For Engine Chassis & Body refer to

0 1986 Mitsubishi Motors Corporation Printed in Japan

Page 37 of 284

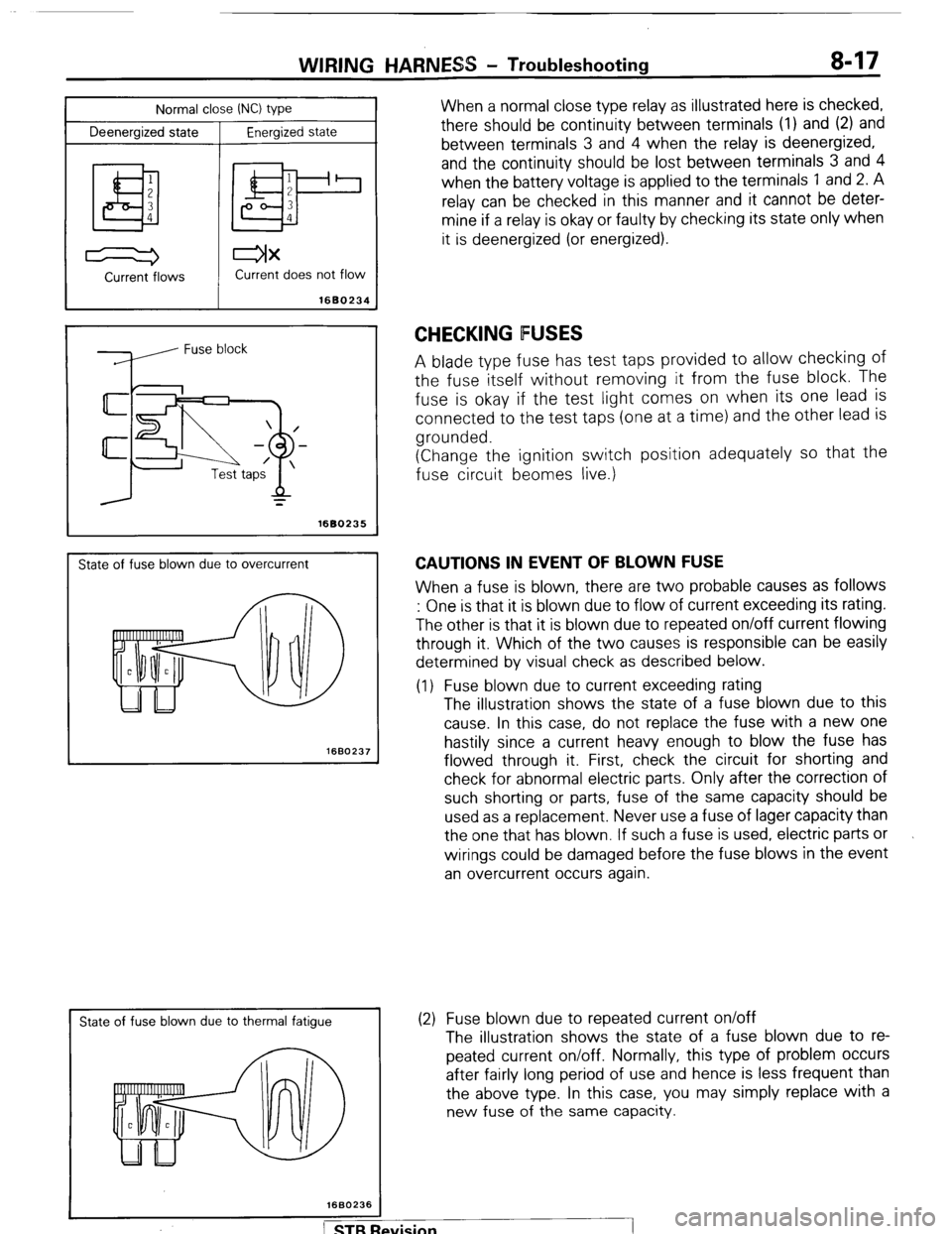

Normal close INC) type

Deenergized state

Energized state

I

WIRING HARNESS - Troubleshooting 8-17

When a normal close type relay as illustrated here is checked,

there should be continuity between terminals (1) and (2) and

between terminals 3 and 4 when the relay is deenergized,

and the continuity should be lost between terminals 3 and 4

when the battery voltage is applied to the terminals 1 and 2. A

relay can be checked in this manner and it cannot be deter-

mine if a relay is okay or faulty by checking its state only when

it is deenergized (or energized).

Current -flows Current does not flow

1680234

=

1680235

State of fuse blown due to overcurrent

1660237

I

State of fuse blown due to thermal fatigue

CHECKING FUSES

A blade type fuse has test taps provided to allow checking of

the fuse itself without removing it from the fuse block. The

fuse is okay if the test light comes on when its one lead is

connected to the test taps (one at a time) and the other lead is

grounded.

(Change the ignition switch position adequately so that the

fuse circuit beomes live.)

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are two probable causes as follows

: One is that it is blown due to flow of current exceeding its rating.

The other is that it is blown due to repeated on/off current flowing

through it. Which of the two causes is responsible can be easily

determined by visual check as described below.

(1) Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse with a new one

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorting and

check for abnormal electric parts. Only after the correction of

such shorting or parts, fuse of the same capacity should be

used as a replacement. Never use a fuse of lager capacity than

the one that has blown. If such a fuse is used, electric parts or

wirings could be damaged before the fuse blows in the event

an overcurrent occurs again.

(2) Fuse blown due to repeated current on/off

The illustration shows the state of a fuse blown due to re-

peated current on/off. Normally, this type of problem occurs

after fairly long period of use and hence is less frequent than

the above type. In this case, you may simply replace with a

new fuse of the same capacity.

Page 99 of 284

CHARGING SYSTEM - Service Adjustment Procedures 8-79

Result

(1) The ammeter reading must be higher than the limit value. If it

is lower but the alternator output wire is normal, remove the

alternator from the vehicle and check it.

Limit value : 31 A min.

Caution

1. The nominal output current value is shown on the

nameplate affixed to the alternator body.

2. The output current value changes with the electrical

load and the temperature of the alternator itself.

Therefore, the nominal output current may not be ob-

tained if the vehicle electrical load at the time of test is

small. In such a case, keep the headlights on to cause

discharge of the battery or use lights of another vehi-

cle as a load to increase the electrical load. The nom-

inal output current may not be obtained if the temper-

ature of the alternator itself or abmient temperature is

too high. In such a case, reduce the temperature be-

fore testing again.

(2) Upon completion of the output current test, lower the engine

speed to the idle speed and turn off the ignition switch.

(3) Disconnect the battery ground cable.

(4) Remove the test ammeter and voltmeter and the engine ta-

chometer.

(5) connect the alternator output wire to the alternator “B” ter-

minal.

(6) Connect the battery ground cable.

REGULATED VOLTAGE TEST

The purpose of this test is to check that the electronic voltage

regulator controls the voltage correctly.

Preparation

(1) Prior to the test, check the following items and correct if nec-

essary.

(a) Check the battery installed on the vehicle to see that it is

fully charged. For battery checking method, see “BAT-

TERY”.

(b) Check the alternator drive belt tension. For belt tension

check, see “GROUP 7 COOLING - Service Adjustment

Procedures”.

(2) Turn the ignition switch to “OFF”.

(3) Disconnect the battery ground cable.

(4) Connect a digital voltmeter between the “S” terminal of the

alternator and ground. Connect the (+) lead of the voltmeter to

the “S” terminal of the alternator, inserting from the wire side

of the 2-way connector and connect the (-1 lead to sound

ground or battery (-) terminal.

1 ST6 Revision

Page 229 of 284

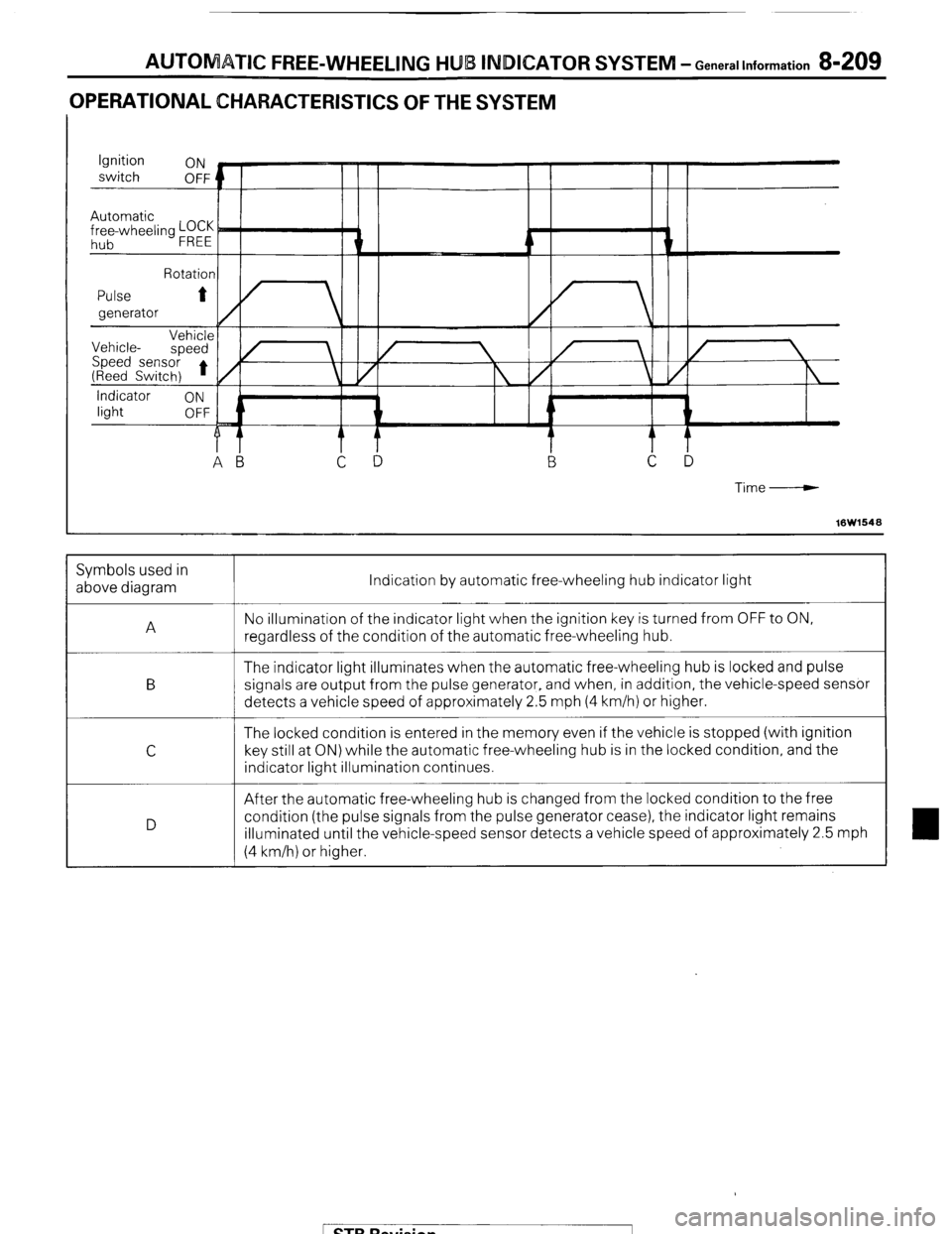

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - General Information 8-209

OPERATIONAL CHARACTERISTICS OF THE SYSTEM

Time-----w

16W1548 Indication by automatic free-wheeling hub indicator light

No illumination of the indicator light when the ignition key is turned from OFF to ON,

regardless of the condition of the automatic free-wheeling hub.

The indicator light illuminates when the automatic free-wheeling hub is locked and pulse

signals are output from the pulse generator, and when, in addition, the vehicle-speed sensor

detects a vehicle speed of approximately 2.5 mph (4 km/h) or higher.

The locked condition is entered in the memory even if the vehicle is stopped (with ignition

key still at ON) while the automatic free-wheeling hub is in the locked condition, and the

indicator light illumination continues.

After the automatic free-wheeling hub is changed from the locked condition to the free

condition (the pulse signals from the pulse generator cease), the indicator light remains

illuminated until the vehicle-speed sensor detects a vehicle speed of approximately 2.5 mph

(4 km/h) or higher. Symbols used in

above diagram

A

B

C

D

1 STB Revision