headlight aiming MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 177 of 284

LIGHTING SYSTEM - Service Adjustment Procedures 8-157

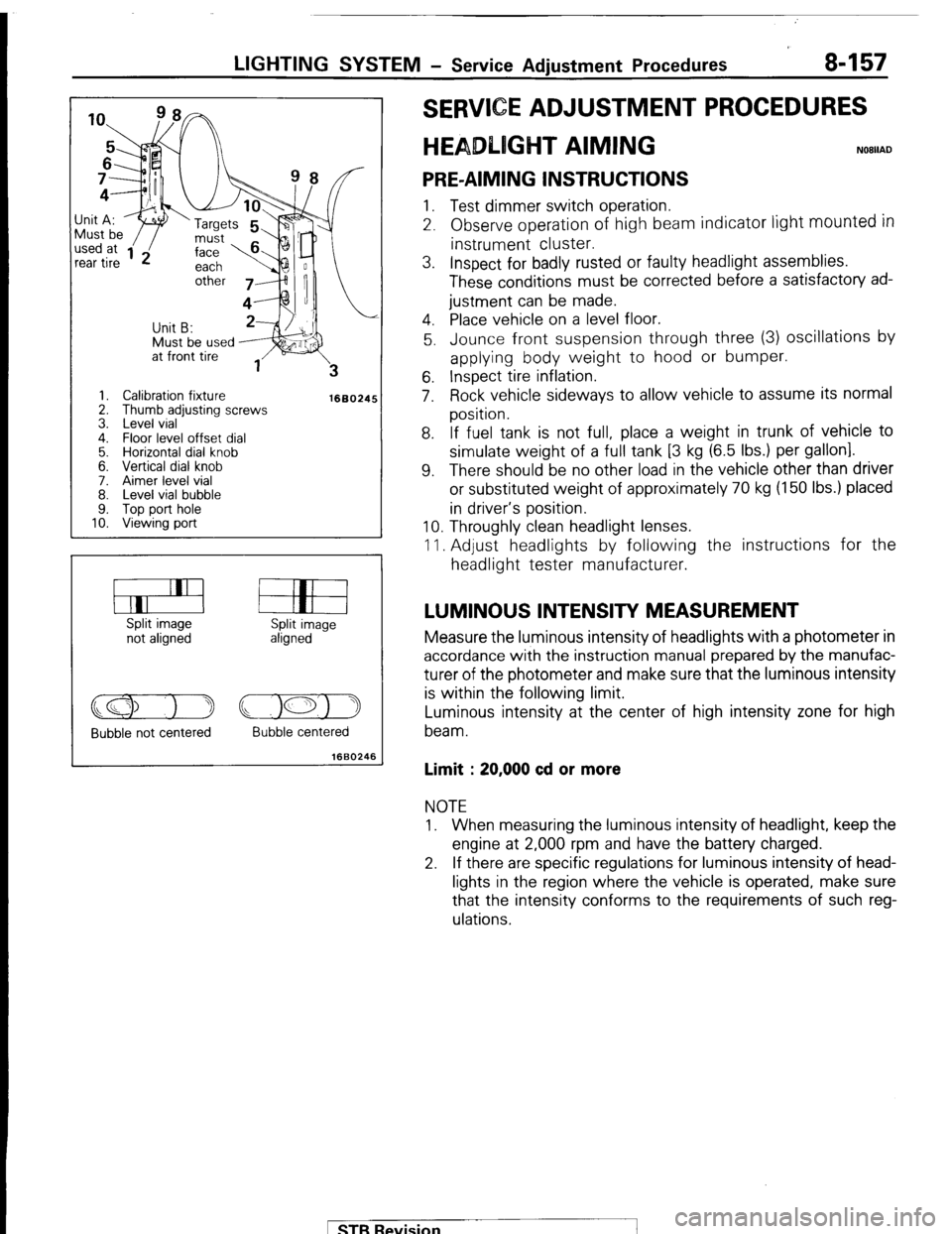

Must be used J;it A:

I ‘w ‘Targets

1. Calibration fixture

2. Thumb adjusting screws

3. Level vial

4. Floor level offset dial

5. Horizontal dial knob

6. Vertical dial knob

7. Aimer level vial

8. Level vial bubble

9. Top port hole

10. Viewing port

1660245

Split image

not aligned Split image

aligned

Bubble not centered Bubble centered

1660246

E ADJUSTMENT PROCEDURES

T AIMING

PRE-AIMING INSTRUCTIONS 1. Test dimmer switch operation.

2. Observe operation of high beam indicator light

mounted in instrument cluster.

3. Inspect for badly rusted or faulty headlight assemblies.

These conditions must be corrected before a satisfactory ad-

justment can be made.

4. Place vehicle on a level floor.

5. Jounce front suspension through three (3) oscillations by

applying body weight to hood or bumper.

6. Inspect tire inflation.

7. Rock vehicle sideways to allow vehicle to assume its normal

position.

8. If fuel tank is not full, place a weight in trunk of vehicle to

simulate weight of a full tank [3 kg (6.5 Ibs.) per gallon].

9. There should be no other load in the vehicle other than driver

or substituted weight of approximately 70 kg (150 Ibs.) placed

in driver’s position.

10. Throughly clean headlight lenses.

11. Adjust headlights by following the instructions for the

headlight tester manufacturer.

LUMINOUS INTENSITY MEASUREMENT Measure the luminous intensity of headlights with a photometer in

accordance with the instruction manual prepared by the manufac-

turer of the photometer and make sure that the luminous intensity

is within the following limit.

Luminous intensity at the center of high intensity zone for high

beam.

Limit : 20,000 cd or more NOTE

1. When measuring the luminous intensity of headlight, keep the

engine at 2,000 rpm and have the battery charged.

2. If there are specific regulations for luminous intensity of head-

lights in the region where the vehicle is operated, make sure

that the intensity conforms to the requirements of such reg-

ulations.

pTB Revision