light MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 1 of 284

Service Manual

MONTERO

1987 : Volume 2

FOREWORD

This Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

MITSUBISHI MOTOR SALES OF AMERICA. Inc.

Mitsubishi Motors corporation reserves the right to make changes in

design or to make additions to or improvements in its products without

imposing any obligations upon itself to install them on its products

previously manufactured.

I

GROUP/SECTION INDEX ‘kme-.

INTRODUCTION ..............................

Electrical ...........................................

Electrical System Parts

Location .........................................

Relays, Control Units, Sensors,

Fuses, Groundings

Inspection of Harness

Connector ......................................

Wiring Harness .............................

Charging System ..........................

Starting System ............................

Ignition System .............................

Meters and Gauges ......................

Lighting System .............................

Wiper and Washer System ..........

Horn ...............................................

Accessory ......................................

Audio System ................................

Back Door Window Defogger ......

Automatic Free-wheeling Hub

Indicator System ..........................

Heaters and Air-conditioning .........

Heaters ..........................................

Air-conditioning ............................

**, For Engine Chassis & Body refer to

0 1986 Mitsubishi Motors Corporation Printed in Japan

Page 5 of 284

INTRODUCTION - Vehicle Identification

VEHICLE IDENTIFICATION NUMBER LIST

FEDERAL

VIN (except sequence number) Brand Engine displacement

JA4FJ43EoHJ

JA4FJ43EoHJ MITSUBISHI 2.555 liters

JA7FJ23EoHJ MONTERO (155.9 C.I.D.)

JA7FJ23EoHJ

5

NOOCC-

Model code

L042GVNJLF

L042GVRJLF

L042GTNSLF

L042GTRSLF

CALIFORNIA (Can also be sold in Federal states.)

VIN (except sequence number)

JA4FJ43EoHJ

JA4FJ43EoHJ

JA7FJ23EoHJ

JB7FJ23EoHJ Brand

MITSUBISHI

MONTERO Engine displacement

2.555 liters

(155.9 C.I.D.) Model code

L042GVNJLH

L042GVRJLH

L042GTNSLH

1 L042GTNSLH

OOK520

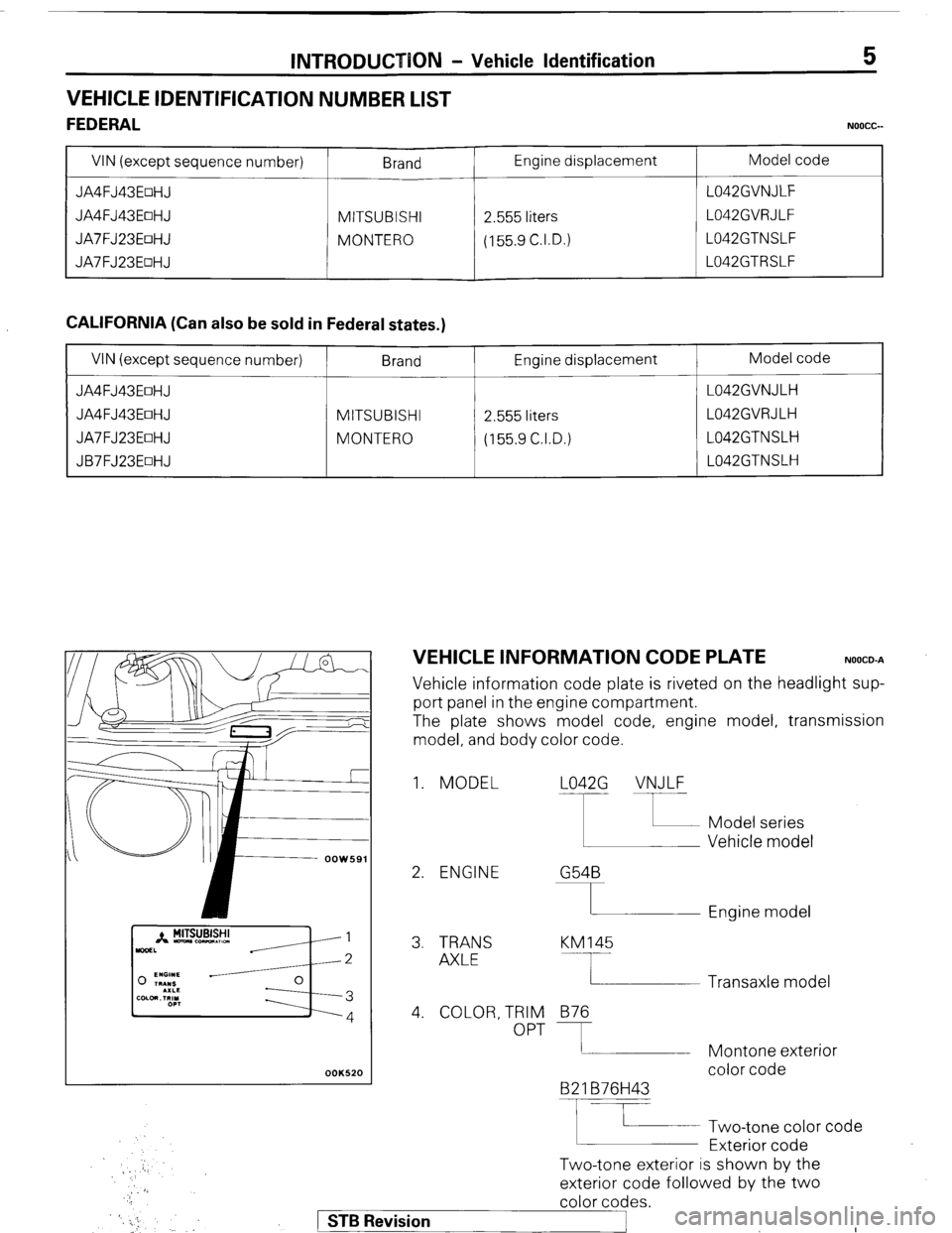

VEHICLE INFORMATION CODE PLATE NOOCO-A

Vehicle information code plate is riveted on the headlight sup-

port panel in the engine compartment.

The plate shows model code, engine model, transmission

model, and body color code.

1. MODEL L042G VNJLF

2. ENGINE G54B

I Engine model

3. TRANS

AXLE KM145

4. COLOR, TRIM

OPT 876

B2 1 B76H43

F

Two-tone exterior is shown by the Two-tone color code

Exterior code Transaxle model

Montone exterior

color code

exterior code followed by the two

color codes.

) STB Revision

._ :

Page 9 of 284

INTRODUCTION - Precautions Before Service 9

nm (in.)

so0059

PARTS

When replacing parts, use MITSUBISHI genuine parts.

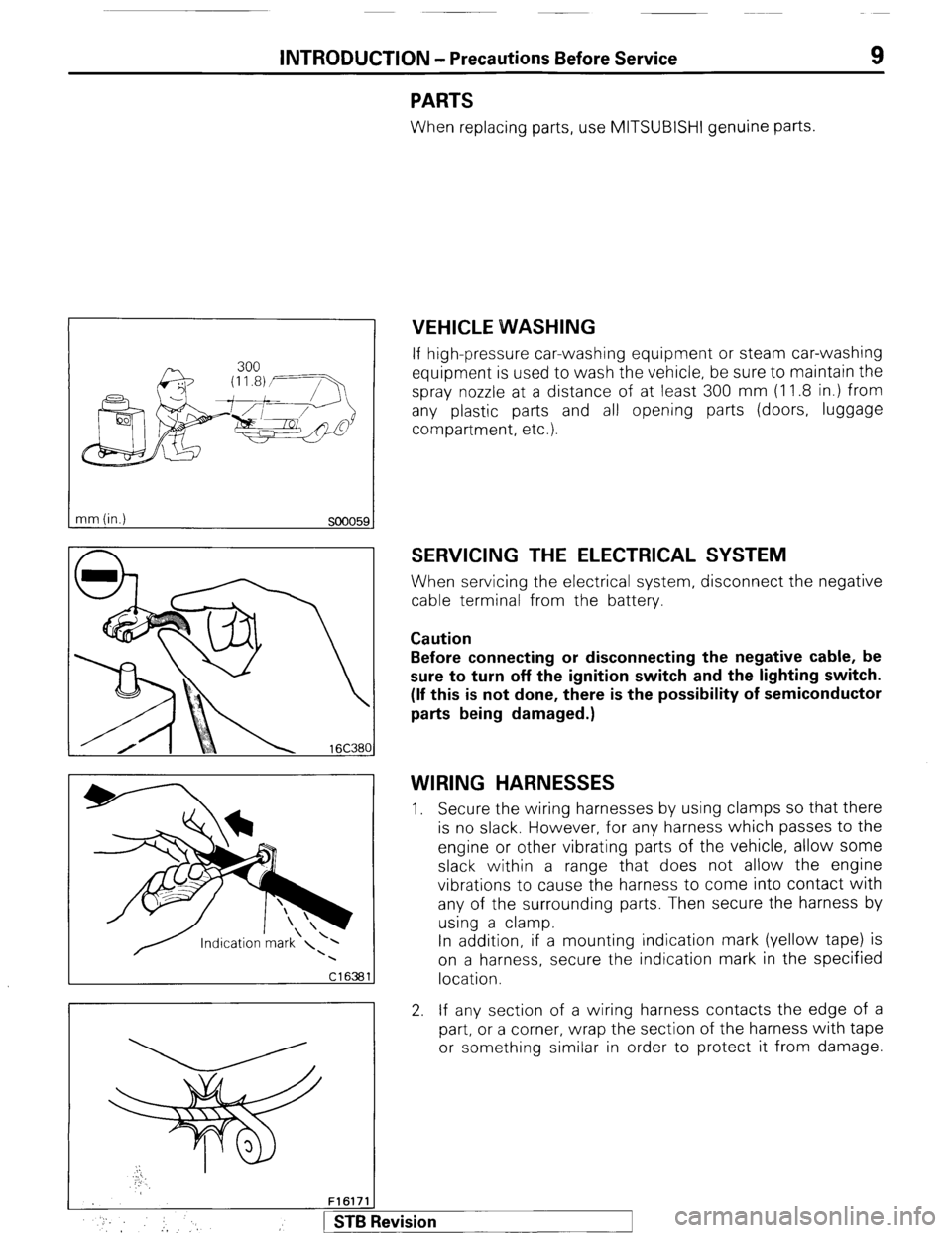

VEHICLE WVASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (1 1.8 in.) from

any plastic parts and all opening parts (doors, luggage

compartment, etc.).

SERVICING THE ELECTRICAL SYSTEM

When servicing the electrical system, disconnect the negative

cable terminal from the battery.

Caution

Before connecting or disconnecting the negative cable, be

sure to turn off the ignition switch and the lighting switch.

(If this is not done, there is the possibility of semiconductor

parts being damaged.)

WIRING HARNESSES

1. Secure the wiring harnesses by using clamps so that there

is no slack. However, for any harness which passes to the

engine or other vibrating parts of the vehicle, allow some

slack within a range that does not allow the engine

vibrations to cause the harness to come into contact with

any of the surrounding parts. Then secure the harness by

using a clamp.

In addition, if a mounting indication mark (yellow tape) is

on a harness, secure the indication mark in the specified

location.

2. If any section of a wiring harness contacts the edge of a

part, or a corner, wrap the section of the harness with tape

or something similar in order to protect it from damage.

F161711

* :, :, 1 STB Revision

Page 14 of 284

INTRODUCTION - Towing and Hoisting

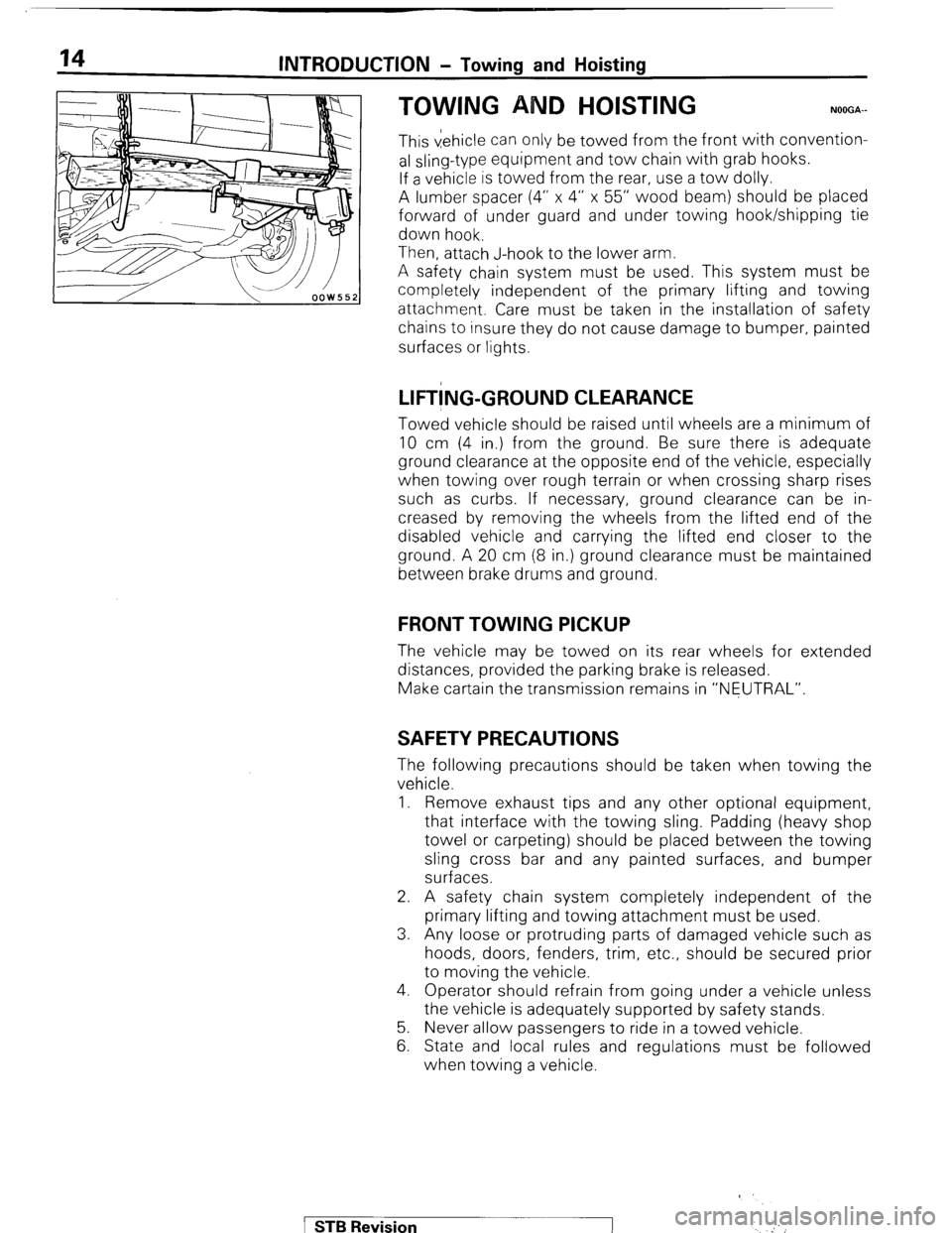

TOWING AND HOISTING NOOGA-

This vehicle can only be towed from the front with convention-

al sling-type equipment and tow chain with grab hooks.

If a vehicle is towed from the rear, use a tow dolly.

A lumber spacer (4” x 4” x 55” wood beam) should be placed

forward of under guard and under towing hook/shipping tie

down hook.

Then, attach J-hook to the lower arm.

A safety chain system must be used. This system must be

completely independent of the primary lifting and towing

attachment. Care must be taken in the installation of safety

chains to insure they do not cause damage to bumper, painted

surfaces or lights.

LIFT!NG-GROUND CLEARANCE

Towed vehicle should be raised until wheels are a minimum of

10 cm (4 in.) from the ground. Be sure there is adequate

ground clearance at the opposite end of the vehicle, especially

when towing over rough terrain or when crossing sharp rises

such as curbs. If necessary, ground clearance can be in-

creased by removing the wheels from the lifted end of the

disabled vehicle and carrying the lifted end closer to the

ground. A 20 cm (8 in.) ground clearance must be maintained

between brake drums and ground.

FRONT TOWING PICKUP

The vehicle may be towed on its rear wheels for extended

distances, provided the parking brake is released.

Make cartain the transmission remains in “NEUTRAL”.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle.

1. Remove exhaust tips and any other optional equipment,

that interface with the towing sling. Padding (heavy shop

towel or carpeting) should be placed between the towing

sling cross bar and any painted surfaces, and bumper

surfaces.

2. A safety chain system completely independent of the

primary lifting and towing attachment must be used.

3. Any loose or protruding parts of damaged vehicle such as

hoods, doors, fenders, trim, etc., should be secured prior

to moving the vehicle.

4. Operator should refrain from going under a vehicle unless

the vehicle is adequately supported by safety stands.

5. Never allow passengers to ride in a towed vehicle.

6. State and local rules and regulations must be followed

when towing a vehicle.

1 STB Revision

‘

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 22 of 284

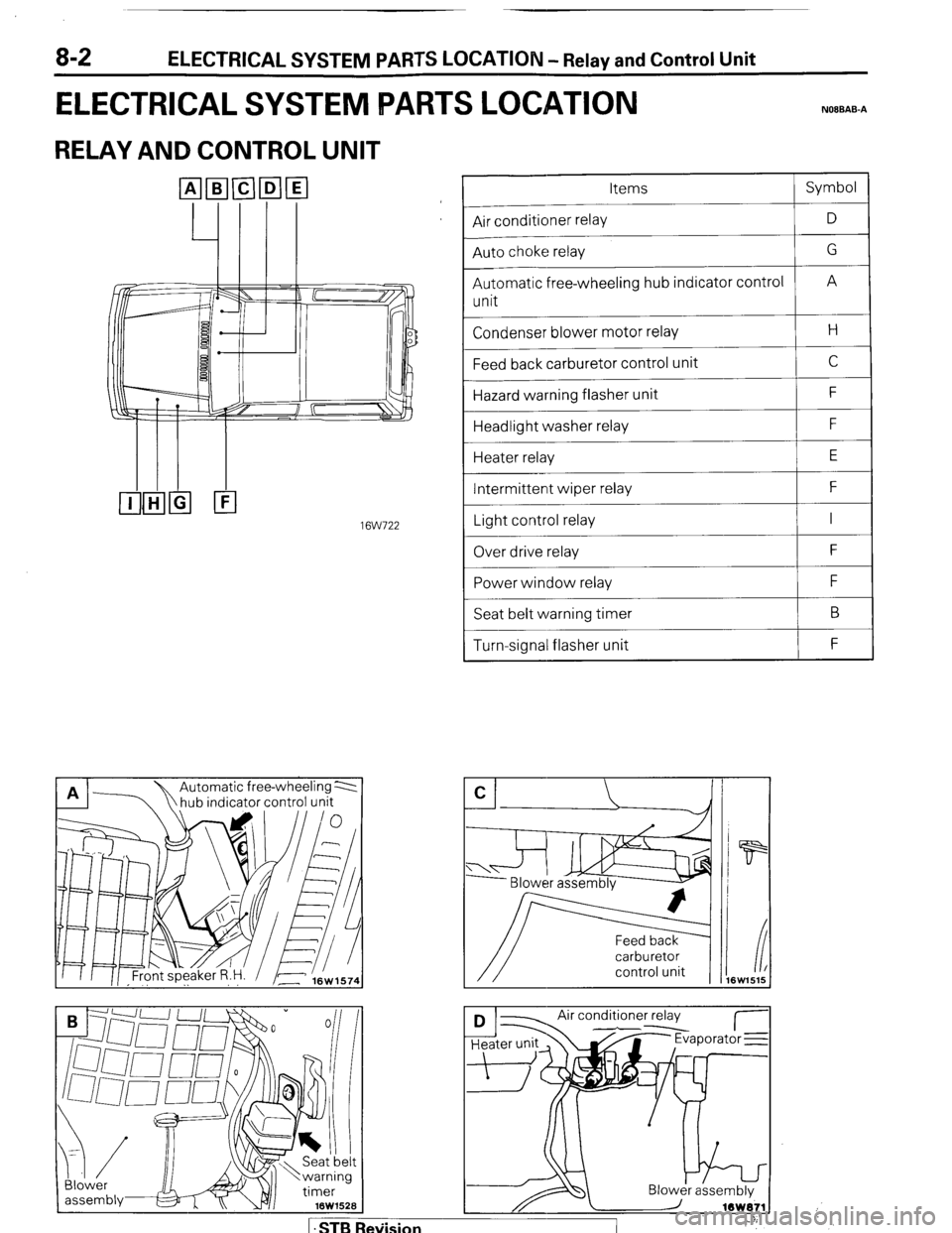

8-2 ELECTRICAL SYSTEM PARTS LOCATION - Relay and Control Unit

ELECTRICAL SYSTEM IPARTS LOCATION NOIBAB-A

RELAY AND CONTROL UNIT

16W722

n 17

hub indicator control unit A A Automatic free-wheeling 2

Blower

assembiy& x v/i 16W152B Items Symbol

--

Air conditioner relay D

--

Auto choke relay G

--

Automatic free-wheeling hub indicator control

A

unit

Condenser blower motor relay H

Feed back carburetor control unit C

Hazard warning flasher unit F

Headlight washer relay F

Heater relay E

Intermittent wiper relay F

~___

Light control relay I

~___

Over drive relay F

Power window relay F

Seat belt warning timer B

Turn-signal flasher unit F

carburetor

control unit

Air conditioner relay

d--- I- Jr Evaporator E

1 .STB Re\iision

Page 23 of 284

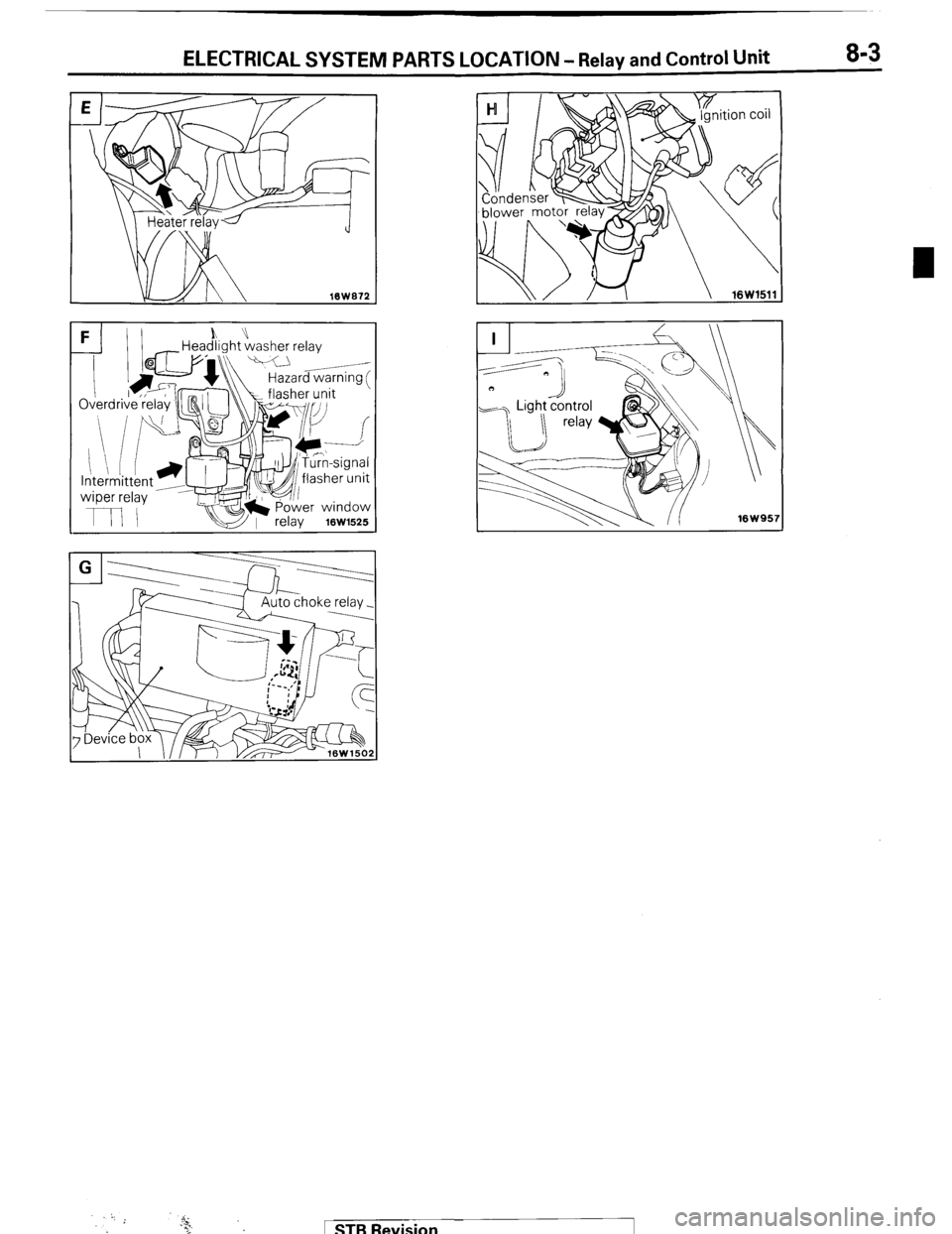

ELECTRICAL SYSTEM PARTS LOCATION - Relay and Control Unit 8-3

FI)I h” -Headlight washer relay

k\\ Hazard warnina f

1 STB Revision

Page 25 of 284

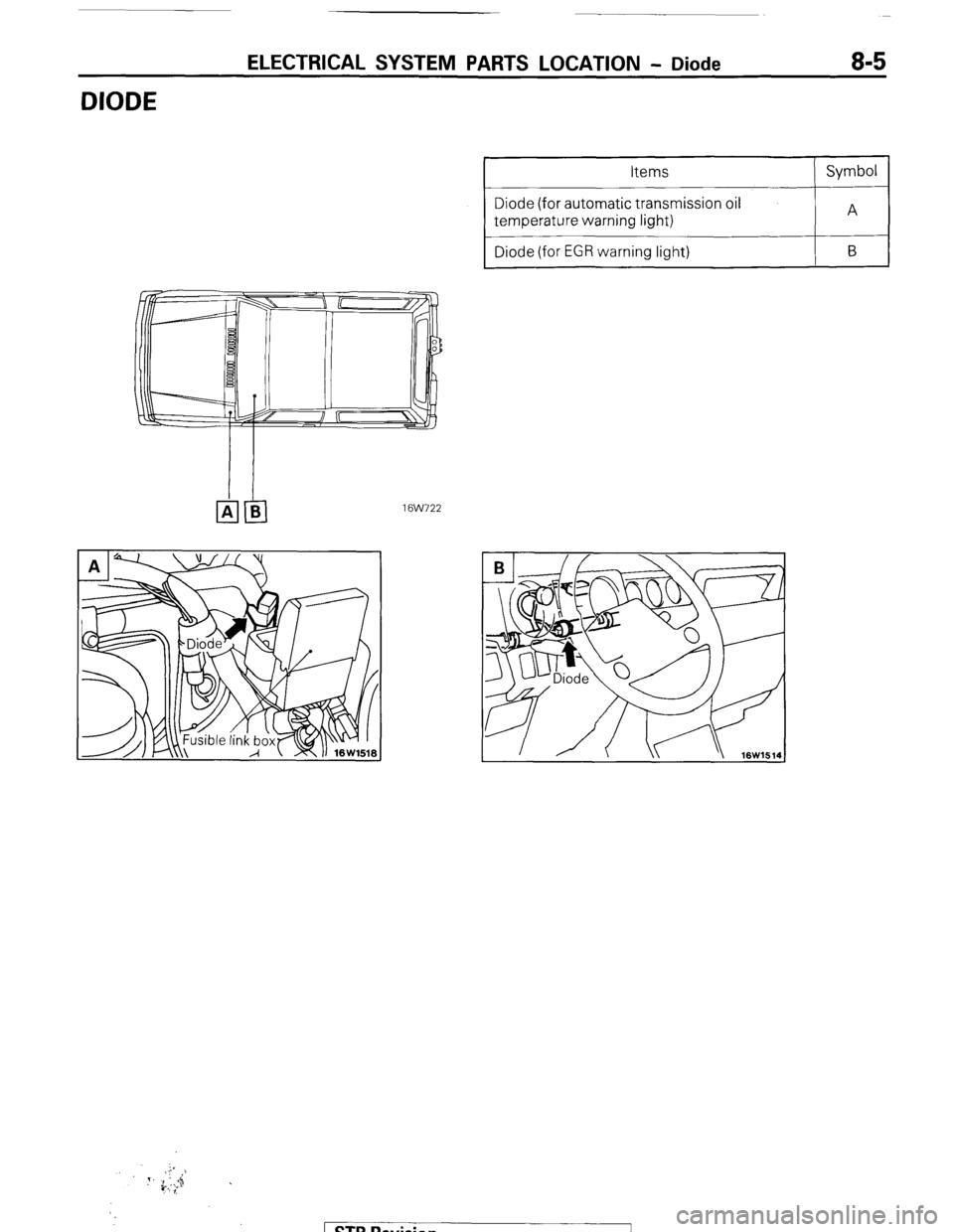

DIODE

ELECTRICAL SYSTEM PARTS LOCATION - Diode 8-5

Diode (for automatic transmission oil

Diode (for EGR warning light)

1 @NJ22

STB Revision

Page 26 of 284

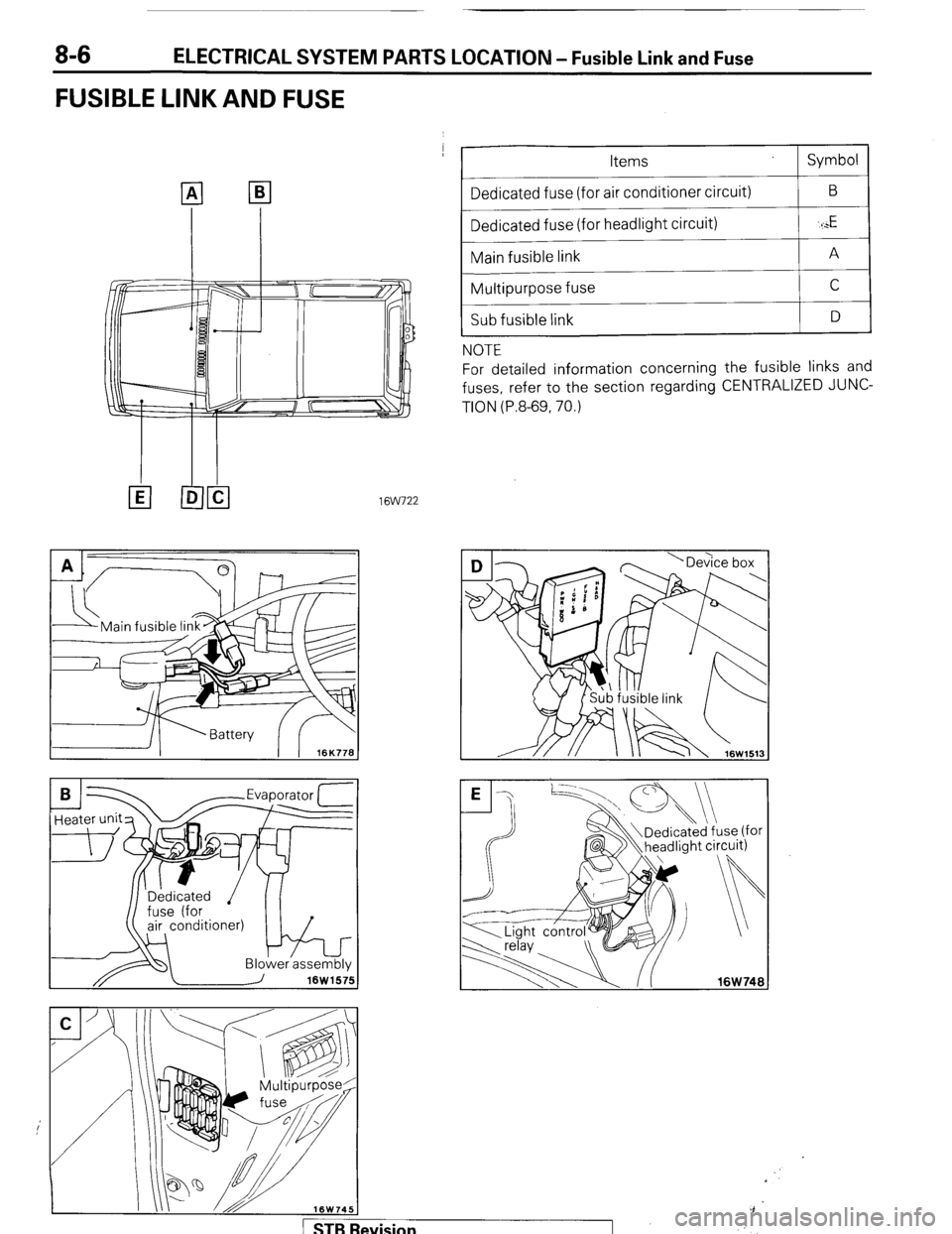

ELECTRICAL SYSTEM PARTS LOCATION - Fusible Link and Fuse

FUSIBLE LINK AND FUSE

--

Items

Dedicated fuse (for air conditioner circuit)

Dedicated fuse (for headlight circuit)

Main fusible link

Multipurpose fuse

Sub fusible link

NOTE Symbol

B

‘I

E

A

C

D

For detailed information concerning the fusible links and

fuses, refer to the section regarding CENTRALIZED JUNC-

TION (P.8-69, 70.)

16W722

-Evaoorator 1

/ STBI levision

Page 27 of 284

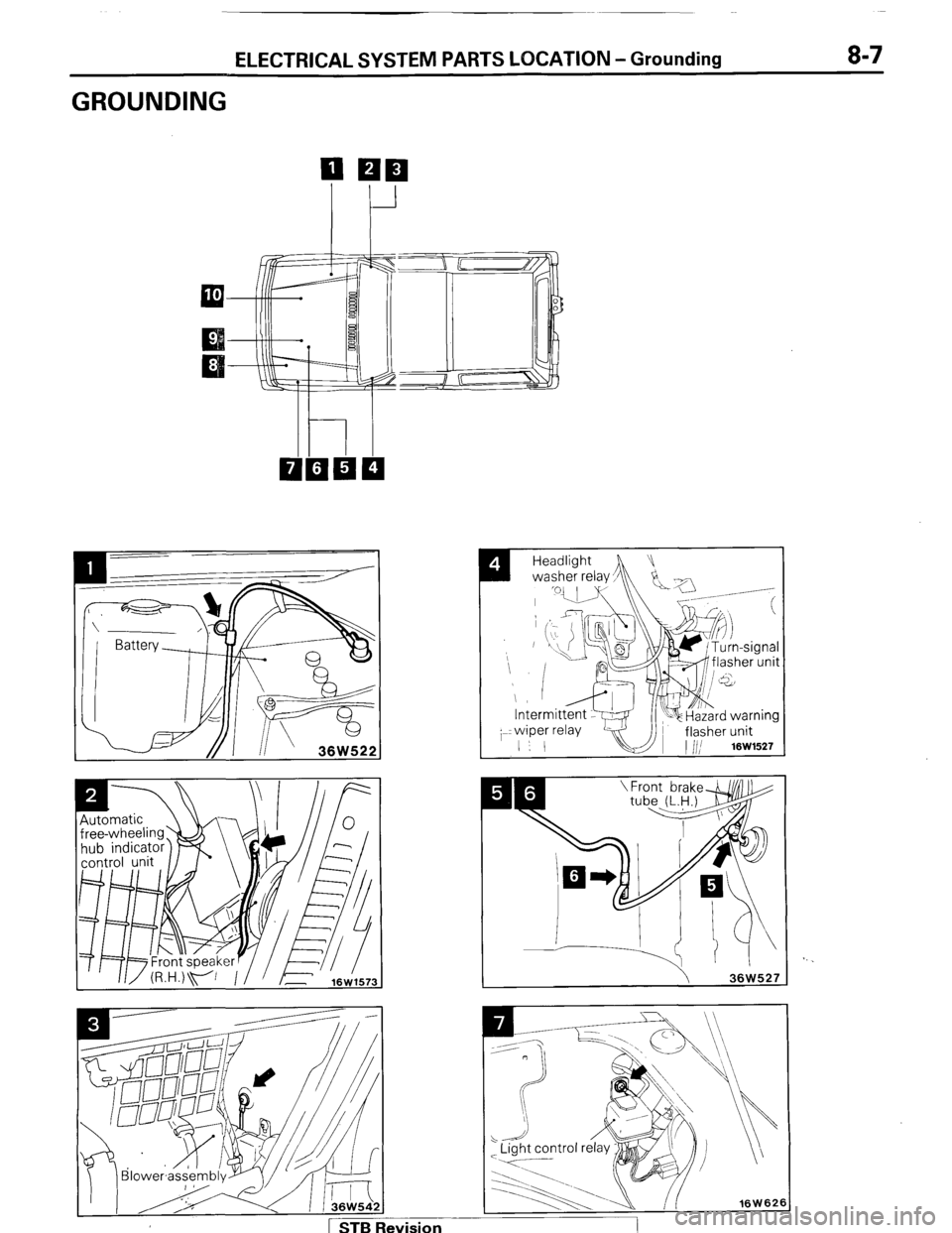

ELECTRICAL SYSTEM PARTS LOCATION -Grounding 8-7

GROUNDING

I

Headlight

washer relay,

h !Ja -/

_ .-----

/ 1 STB Revision