oil change MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 35 of 284

WIRING HARNESS - Troubleshooting 8-15

1660227

Black lead wire

Ground y

1680228

Normal open (NO) type

OFF

ax

Current does not flow ON

Current flows

Normal close (NC) type

OFF

l-2

Current flows ON

-op--

IX

Current does not flow

1680229

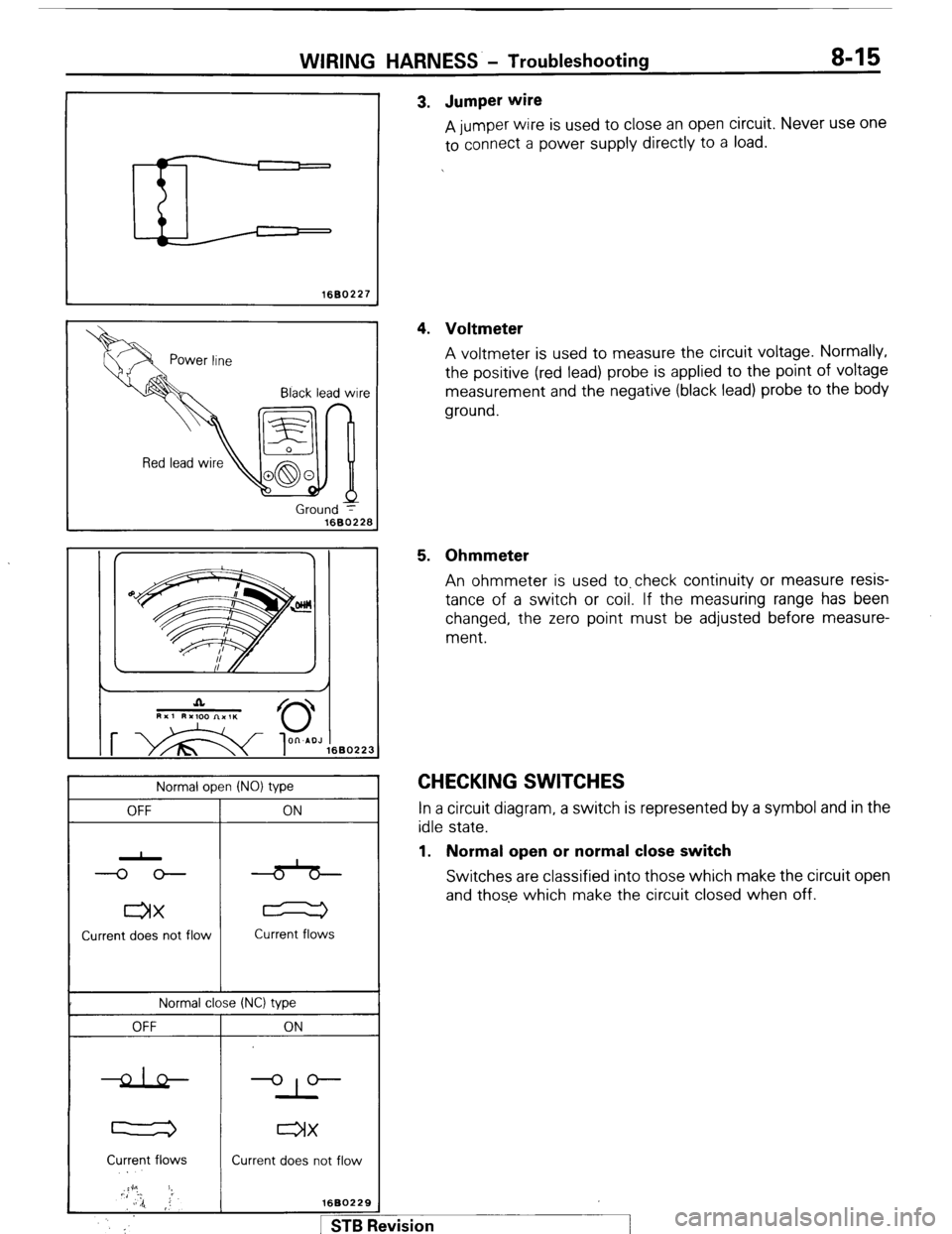

pm I 3. Jumper wire

A jumper wire is used to close an open circuit. Never use one

to connect a power supply directly to a load.

4. Voltmeter

A voltmeter is used to measure the circuit voltage. Normally,

the positive (red lead) probe is applied to the point of voltage

measurement and the negative (black lead) probe to the body

ground.

5. Ohmmeter

An ohmmeter is used to.check continuity or measure resis-

tance of a switch or coil. If the measuring range has been

changed, the zero point must be adjusted before measure-

ment.

CHECKING SWITCHES In a circuit diagram, a switch is represented by a symbol and in the

idle state.

1. Normal open or normal close switch

Switches are classified into those which make the circuit open

and those which make the circuit closed when off.

#vision

I

Page 213 of 284

AUDIO SYSTEM - Specifications 8-193

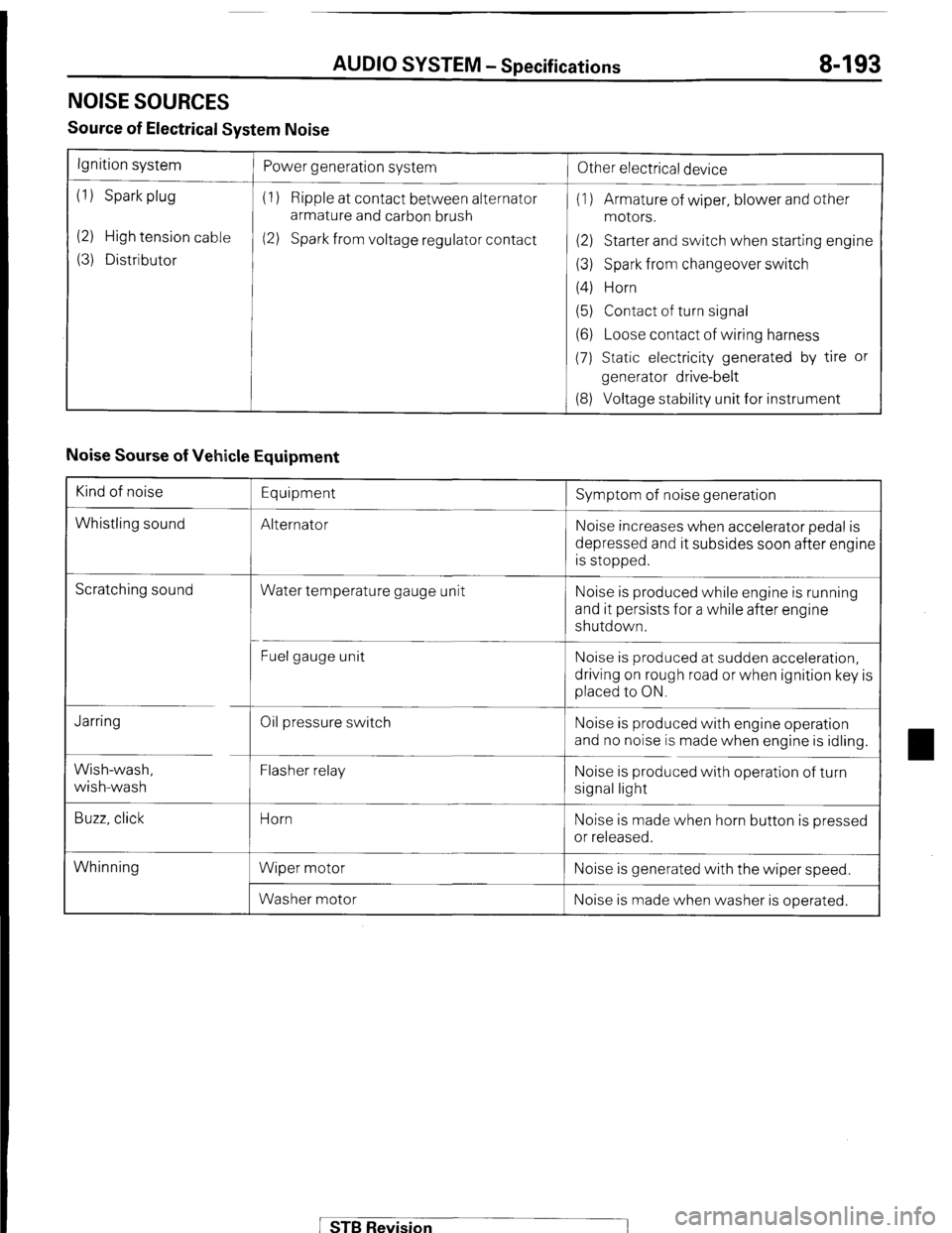

NOISE SOURCES

Source of Electrical System Noise

Ignition system

(1) Spark plug

(2) High tension cable

(3) Distributor Power generation system

(1) Ripple at contact between alternator

armature and carbon brush

(2) Spark from voltage regulator contact

!

Other electrical device

(1) Armature of wiper, blower and other

motors.

(2) Starter and switch when starting engine

(3) Spark from changeover switch

(4) Horn

(5) Contact of turn signal

(6) Loose contact of wiring harness

(7) Static electricity generated by tire or

generator drive-belt

(8) Voltage stability unit for instrument

Noise Sourse of Vehicle Equipment

Kind of noise

Whistling sound Equipment

Alternator Symptom of noise generation

Noise increases when accelerator pedal is

depressed and it subsides soon after engine

is stopped.

Scratching sound

Water temperature gauge unit Noise is produced while engine is running

and it persists for a while after engine

shutdown.

Fuel gauge unit Noise is produced at sudden acceleration,

driving on rough road or when ignition key is

placed to ON.

Jarring

Wish-wash,

wish-wash

Buzz, click Oil pressure switch

Flasher relay

Horn

Wiper motor

Washer motor Noise is produced with engine operation

and no noise is made when engine is idling.

Noise is produced with operation of turn

signal light

Noise is made when horn button is pressed

or released.

Whinning Noise is generated with the wiper speed.

Noise is made when washer is operated.

STB Revision

Page 231 of 284

AUTOMATIC FREE-WHEELING HUB INDICATOR SYSTEM - Generallnformation 8-211

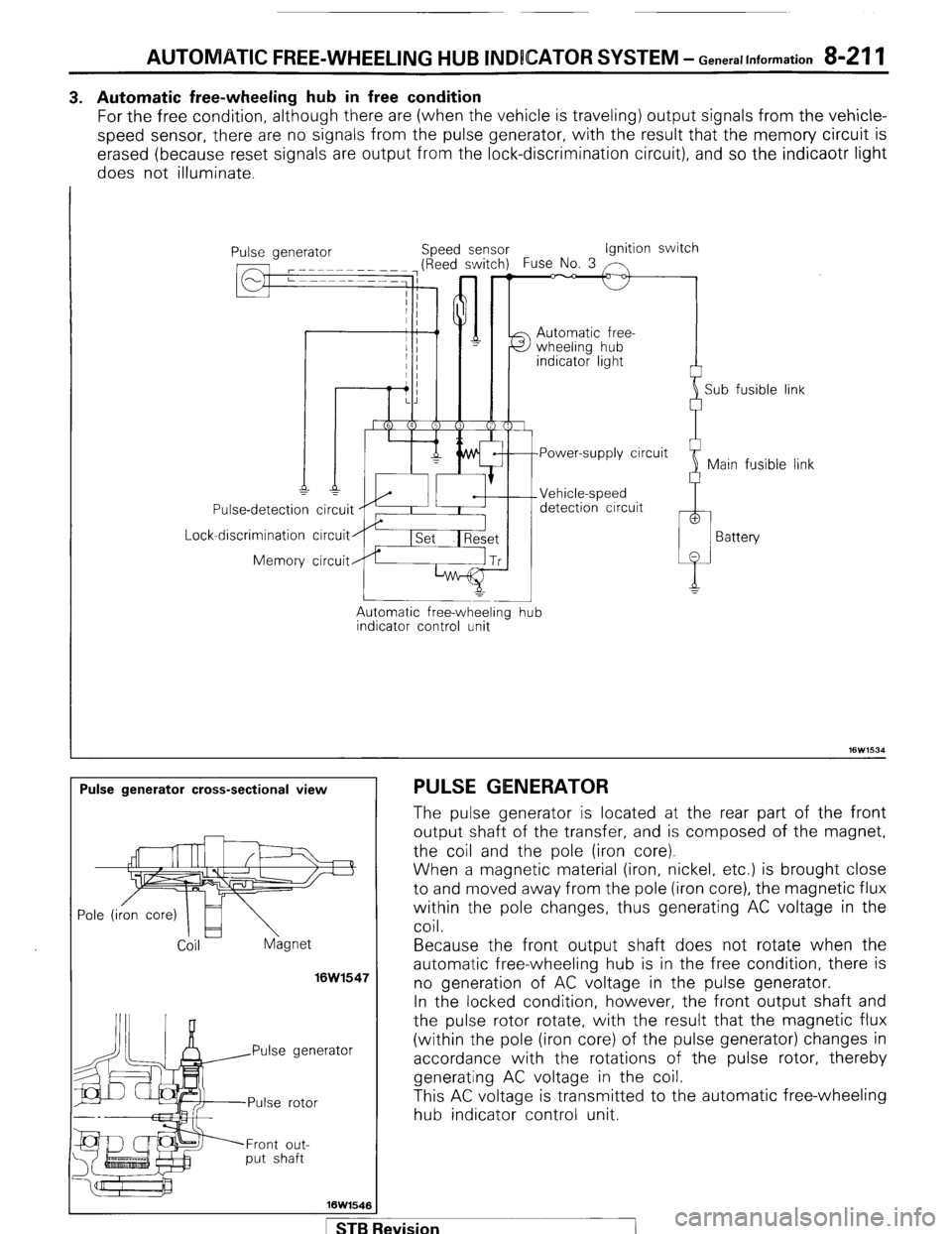

3. Automatic free-wheeling hub in free condition

For the free condition, although there are (when the vehicle is traveling) output signals from the vehicle-

speed sensor, there are no signals from the pulse generator, with the result that the memory circuit is

erased (because reset signals are output from the lock-discrimination circuit), and so the indicaotr light

does not illuminate.

I

Lock Use-detection

-discrimination

Memory ipeed sensor Ignition switch

Automatic free-

detection circuit

circuit

circuit

Automatic free-wheeling

indicator control unit -

hub i

Sub fusible link

link

Pulse generator cross-sectional view PULSE GENERATOR

Coil hgnet

16W1547

rator

Front out-

put shaft

16W1546 The pulse generator is located at the rear part of the front

output shaft of the transfer, and is composed of the magnet,

the coil and the pole (iron core).

When a magnetic material (iron, nickel, etc.) is brought close

to and moved away from the pole (iron core), the magnetic flux

within the pole changes, thus generating AC voltage in the

coil.

Because the front output shaft does not rotate when the

automatic free-wheeling hub is in the free condition, there is

no generation of AC voltage in the pulse generator.

In the locked condition, however, the front output shaft and

the pulse rotor rotate, with the result that the magnetic flux

(within the p o e I (’ Iron core) of the pulse generator) changes in

accordance with the rotations of the pulse rotor, thereby

generating AC voltage in the coil.

This AC voltage is transmitted to the automatic free-wheeling

hub indicator control unit.

STB Revision

Page 272 of 284

COllector

can

2OUO315

24-36 AIR-CONDITIONING-Service Adjustment Procedures

D&ARG,NG THE SYSTEM

Since the air conditioning refrigerant system is pressurized, it will

be necessary to completely discharge the system (in a well ven-

tilated area) before replacing any refrigerant component. The pro-

cedure is as follows:

(1) Install manifold gauge set. Make sure the gauge set valves are

closed before attaching the hoses to the refrigerant system.

(2) Install a long hose to the manifold gauge set connector. Run

this hose to the oil collector can near a shop exhaust system.

A good oil collector can may be made from a large empty

coffee can with a plastic top. Slit the plastic top in the form of

a Y to make an entrance for the refrigerant hose and an exit for

the gas.

(3) Open the compressor discharge and suction line pressure

valves and blow the refrigerant into the oil collect can. Watch

to make sure the hose does not blow out of the collector can.

(4) When the system has been completely discharged, measure

the amount of oil collected in the can. The amount of oil mea-

sured should be added to the refrigerant system before it is

re-charged. Add new oil-discard the used oil.

Caution

It is important to have the correct amount of oil in the refrig-

erant system.

Too little oil will provide inadequate compressor lubrication and

cause a compressor failure. Too much oil will increase discharge

air temperature.

When a 6P148 compressor is installed at the factory, it

contains 110 c.c. (3.7 U.S.fl.oz., 3.9 Imp.fl.oz.) of refrigerant oil.

While the air conditioning system is in operation, the oil is

carried through the entire system by the refrigerant. Some of

this oil will be trapped and retained in various parts of the

system.

When the following system components are changed, it is nec-

essary to add oil to the system to replace the oil being removed

with the component.

Compressor - 4Occ (1.4 U.S.fl.oz., 1.4 Imp.fl.oz.)

Condenser - 30 cc (1.0 U.S.fl.oz., 1.1 Imp.fl.oz.)

Evaporator - 60 cc (2.0 U.S.fl.oz., 2.1 Imp.fl.oz.)

Piping - 10 cc (.3 U.S.fl.oz., .4 Imp.fl.oz.)

Receiver drier - 0 cc (0 U.S.fl.oz., 0 Imp.fl.oz.)

EVACUATING THE SYSTEM

2OUO31

Whenever the system has been opened to the atmosphere, it is

absolutely essential that the system be evacuated or “vacuumed”

to remove all the air and moisture. Air in the refrigerant system

causes high compressor discharge pressures, a loss in system

performance, and oxidation of the compressor oil into gum and

varnish. Moisture in the refrigerant system can cause the expan-

sion valve to malfunction. Under certain conditions, water can

react with the refrigerant to form destructive acids. It is necessary

to adhere to the following procedure to keep air and moisture out

of the system.

(1) Install manifold gauge set. Make sure the gauge set valves are

closed before attaching the hoses to the refrigerant system.

(2) Discharge the system if the manifold gauge set indicates pres-

sure in the system.

(3) Connect a long test hoses from gauge set manifold center

connection to vacuum pump.

(4) Open both manifold gauge set valves.

/

/vision I