bearings MITSUBISHI MONTERO 1989 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: MONTERO, Model: MITSUBISHI MONTERO 1989 1.GPages: 30, PDF Size: 1.61 MB

Page 28 of 30

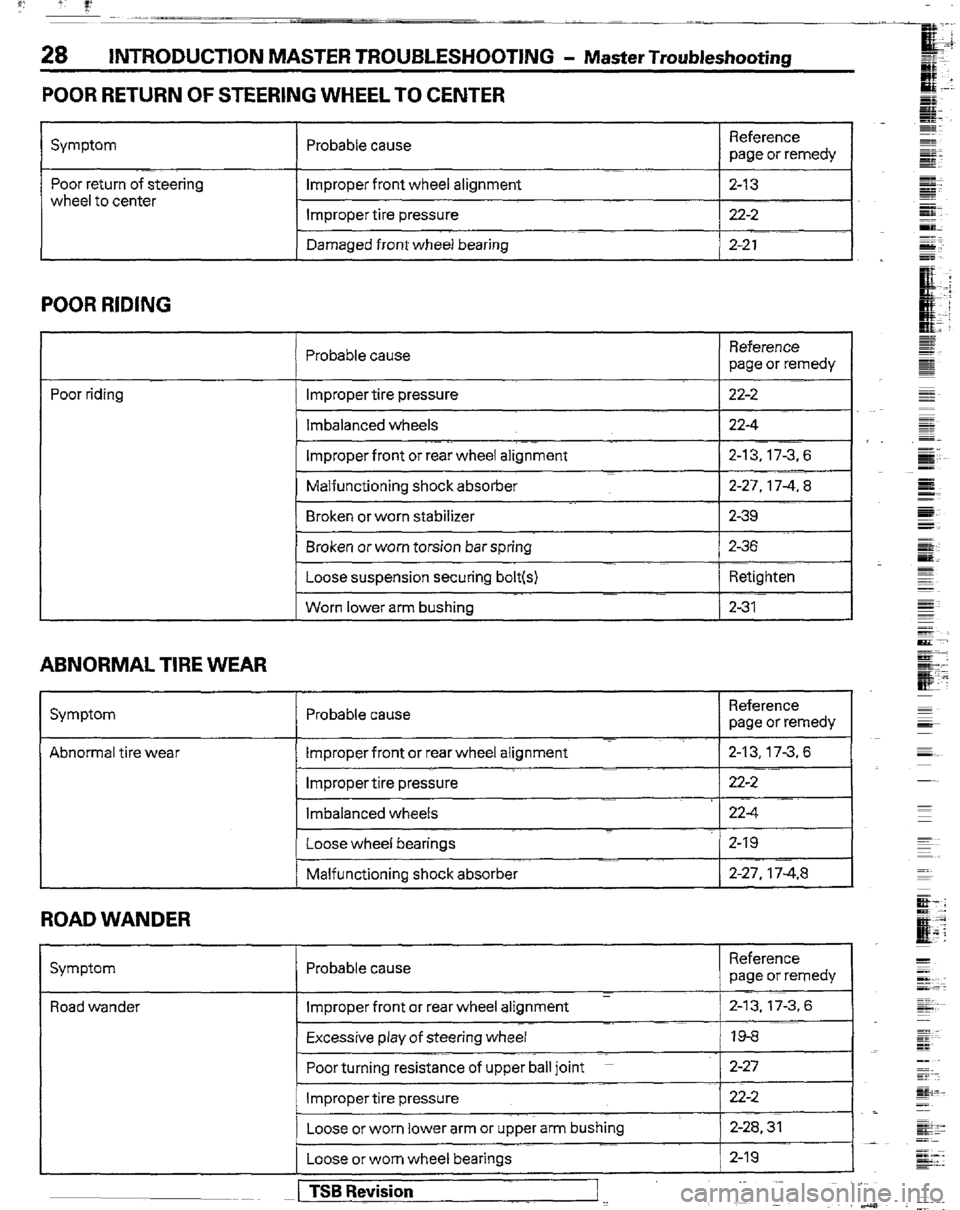

INTRODUCTION MASTER TROUBLESHOOTING - Master Troubleshootha

POOR RETURN OF STEERING WHEEL TO CENTER

Symptom Probable cause Reference

page or remedy

Poor return of steering

wheel to center improper front wheel alignment 2-13

Improper tire pressure 22-2

Damaged front wheel bearing 2-21

POOR RIDING

Probable cause Reference

page or remedy

Poor riding Impropertire pressure

lmbalanced wheels 22-2

22-4

1 Improper front or rear wheel alignment 1 2-13.17-3.6

1 Malfunctioning shock absorber 1 2-27,174.a

1 Broken or worn stabilizer

1 Broken or worn torsion bar spring j 2-36

I

Loose suspension securing bolt(s) Retighten

I

1 Worn lower arm bushing / 231

I

ABNORMAL TIRE WEAR

Symptom Probable cause Reference

page or remedy

Abnormal tire wear Improper front or rear wheel alignment 2-l 3,17-3.6

Improper tire pressure 22-2

lmbalanced wheels 22-4

Loose wheel bearings 2-19

Malfunctioning shock absorber 2-27. 174.8

ROAD WANDER

Symptom Probable cause Reference

page or remedy

Road wander z Improper front or rear wheel alignment 2-13. 17-3,6

Excessive play of steering wheel 19-6

Poor turning resistance of upper ball joint ~ 2-27

Improper tire pressure 22-2

/ Loose or worn lower arm or upper arm bushing 2-28.31

Loose or worn wheel bearinas

I

[ TSB Revision

I 2-19

1 ~- __

- rr.

Page 30 of 30

I”! 1: 1’ --- -~~

30 INTRODUCTION AND MASTER TROUBLESHOOTING

- Master Troubleshooting

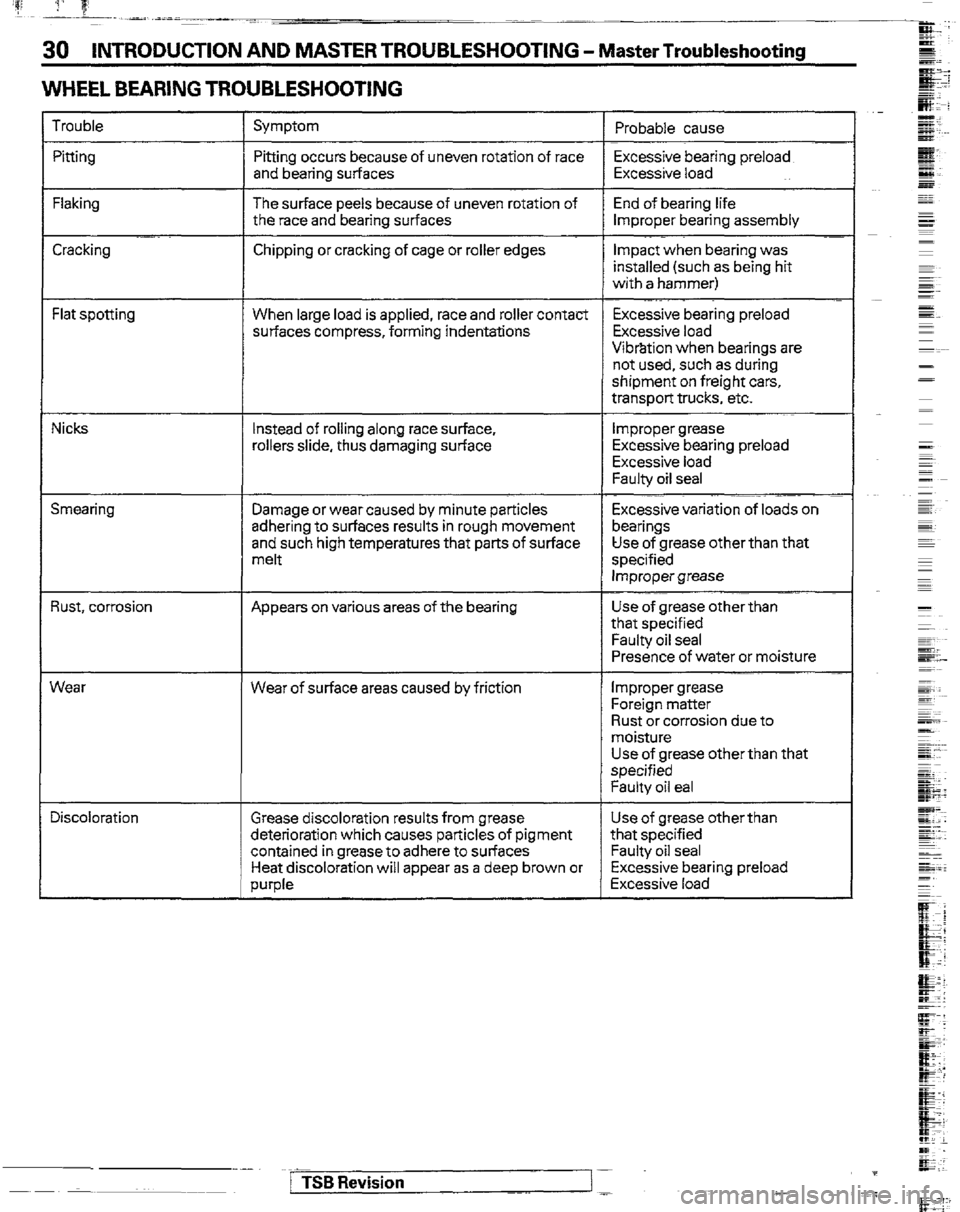

WHEEL BEARING TROUBLESHOOTING

Trouble Symptom

Probable cause

Pitting

Flaking

Cracking Chipping or cracking of cage or roller edges

Flat spotting When large load is applied, race and roller contact

surfaces compress, forming indentations

Nicks

?ust, corrosion

Near

Xscoioration Pitting occurs because of uneven rotation of race

and bearing surfaces

The surface peels because of uneven rotation of

the race and bearing surfaces

Instead of rolling along race surface,

rollers slide, thus damaging surface

Damage or wear caused by minute particles

adhering to surfaces results in rough movement

and such high temperatures that parts of surface

melt

Appears on various areas of the bearing

Wear of surface areas caused by friction

Grease discoloration results from grease

deterioration which causes particles of pigment

contained in grease to adhere to surfaces

Heat discoloration will appear as a deep brown or

purple Excessive bearing preload

Excessive load

End of bearing life

Improper bearing assembly

Impact when bearing was

installed (such as being hit

with a hammer)

Excessive bearing preload

Excessive load

Vibration when bearings are

not used, such as during

shipment on freight cars,

transport trucks, etc.

Improper grease

Excessive bearing preload

Excessive load

Faulty oil seal

Excessive variation of loads on

bearings

Use of grease other than that

specified

Improper grease

Use of grease otherthan

that specified

Faulty oil seal

Presence of water or moisture

Improper grease

Foreign matter

Rust or corrosion due to

moisture

Use of grease otherthan that

specified

Faulty oil eal

Use of grease other than

that specified

Faulty oil seal

Excessive bearing preload

Excessive load