tow MITSUBISHI MONTERO 1989 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: MONTERO, Model: MITSUBISHI MONTERO 1989 1.GPages: 30, PDF Size: 1.61 MB

Page 17 of 30

INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting 17

TOWING AND HOISTING

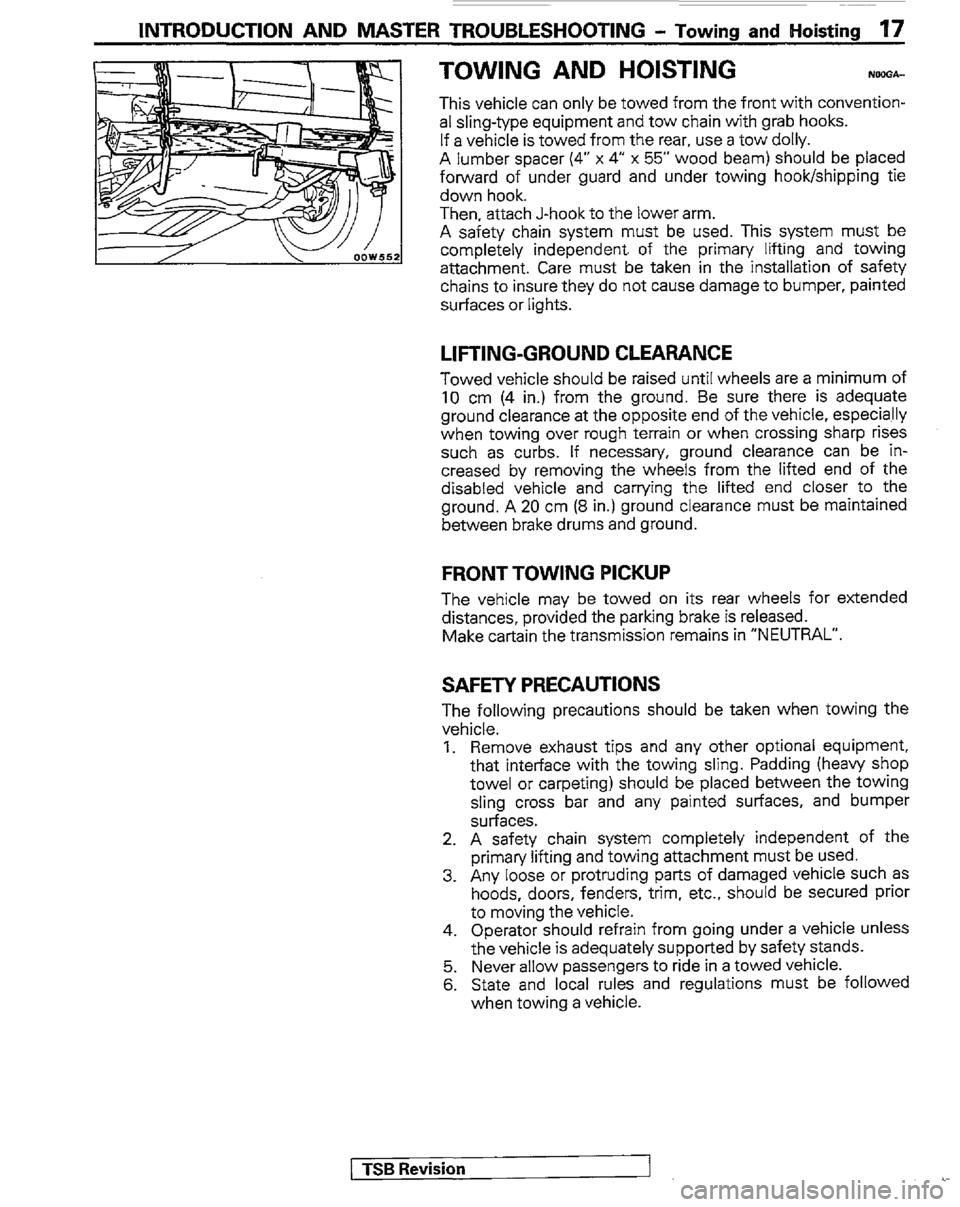

This vehicle can only be towed from the front with convention-

al sling-type equipment and tow chain with grab hooks.

If a vehicle is towed from the rear, use a tow dolly.

A lumber spacer (4” x 4” x 55” wood beam) should be placed

forward of under guard and under towing hook/shipping tie

down hook.

Then, attach J-hook to the lower arm.

A safety chain system must be used. This system must be

completely independent. of the primary lifting and towing

attachment. Care must be taken in the installation of safety

chains to insure they do not cause damage to bumper, painted

surfaces or lights.

LIFTING-GROUND CLEARANCE

Towed vehicle should be raised until wheels are a minimum of

10 cm (4 in.) from the ground. Be sure there is adequate

ground clearance at the opposite end of the vehicle, especially

when towing over rough terrain or when crossing sharp rises

such as curbs. If necessary, ground clearance can be in-

creased by removing the wheels from the lifted end of the

disabled vehicle and carrying the lifted end closer to the

ground. A 20 cm (8 in.) ground clearance must be maintained

between brake drums and ground.

FRONT TOWING PICKUP

The vehicle may be towed on its rear wheels for extended

distances, provided the parking brake is released.

Make cartain the transmission remains in “NEUTRAL”.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle.

1. Remove exhaust tips and any other optional equipment,

that interface with the towing sling. Padding (heavy shop

towel or carpeting) should be placed between the towing

sling cross bar and any painted surfaces, and bumper

surfaces.

2. A safety chain system completely independent of the

primary lifting and towing attachment must be used.

3. Any loose or protruding parts of damaged vehicle such as

hoods, doors, fenders, trim, etc., should be secured prior

to moving the vehicle.

4. Operator should refrain from going under a vehicle unless

the vehicle is adequately supported by safety stands.

5.

Never allow passengers to ride in a towed vehicle.

6. State and local rules and regulations must be followed

when towing a vehicle.

1 TSB Revision

Page 18 of 30

.$i ~[ r

18 INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting

HOISTING

POST TYPE

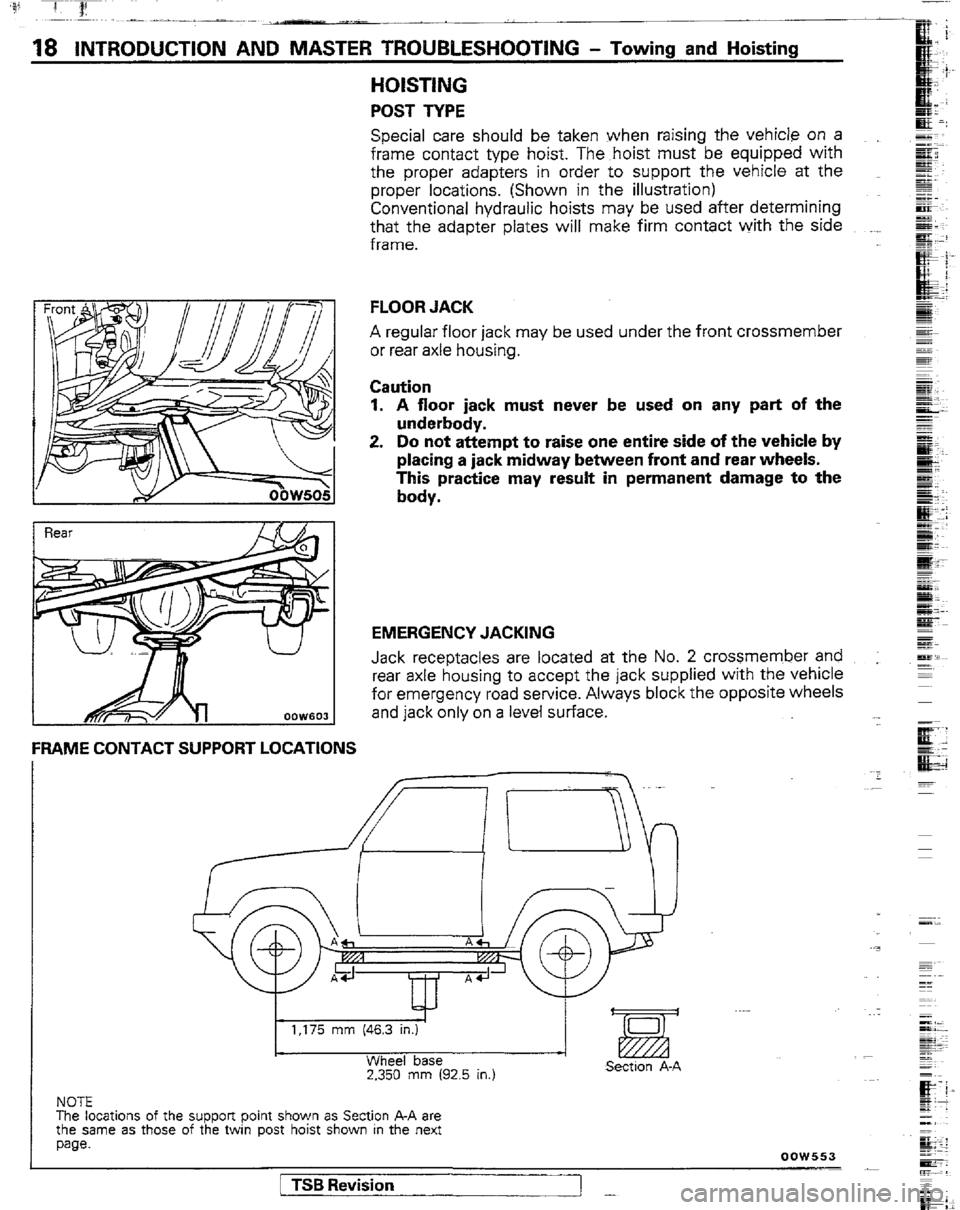

Special care should be taken when raising the vehicle on a

frame contact type hoist. The hoist must be equipped with

the proper adapters in order to support the vehicle at the

proper locations. (Shown in the illustration)

Conventional hydraulic hoists may be used after determining

that the adapter plates will make firm contact with the side ._

frame.

FLOOR JACK

A regular floor jack may be used under the front crossmember

or rear axle housing.

Caution

1. A floor jack must never be used on any part of the

underbody.

2. Do not attempt to raise one entire side of the vehicle by

placing a jack midway between front and rear wheels.

This practice may result in permanent damage to the

body.

EMERGENCY JACKING

Jack receptacles are located at the No. 2 crossmember and .

rear axle housing to accept the jack supplied with the vehicle

for emergency road service. Always block the opposite wheels

and jack only on a level surface.

FRAME CONTACT SUPPORT LOCATIONS

1,175 mm (46.3 in.)

Wheel base

2.350 mm (92.5 in.) Sectlon A-A

NOTE

The

locations of the support point shown as Section A-A are

the same as those of the twin post hoist shown in the next

paw.

1 TSB Revision

I -

Page 19 of 30

INTRODUCTION AND MASTER TROUBLESHOOTING - Towing and Hoisting 19

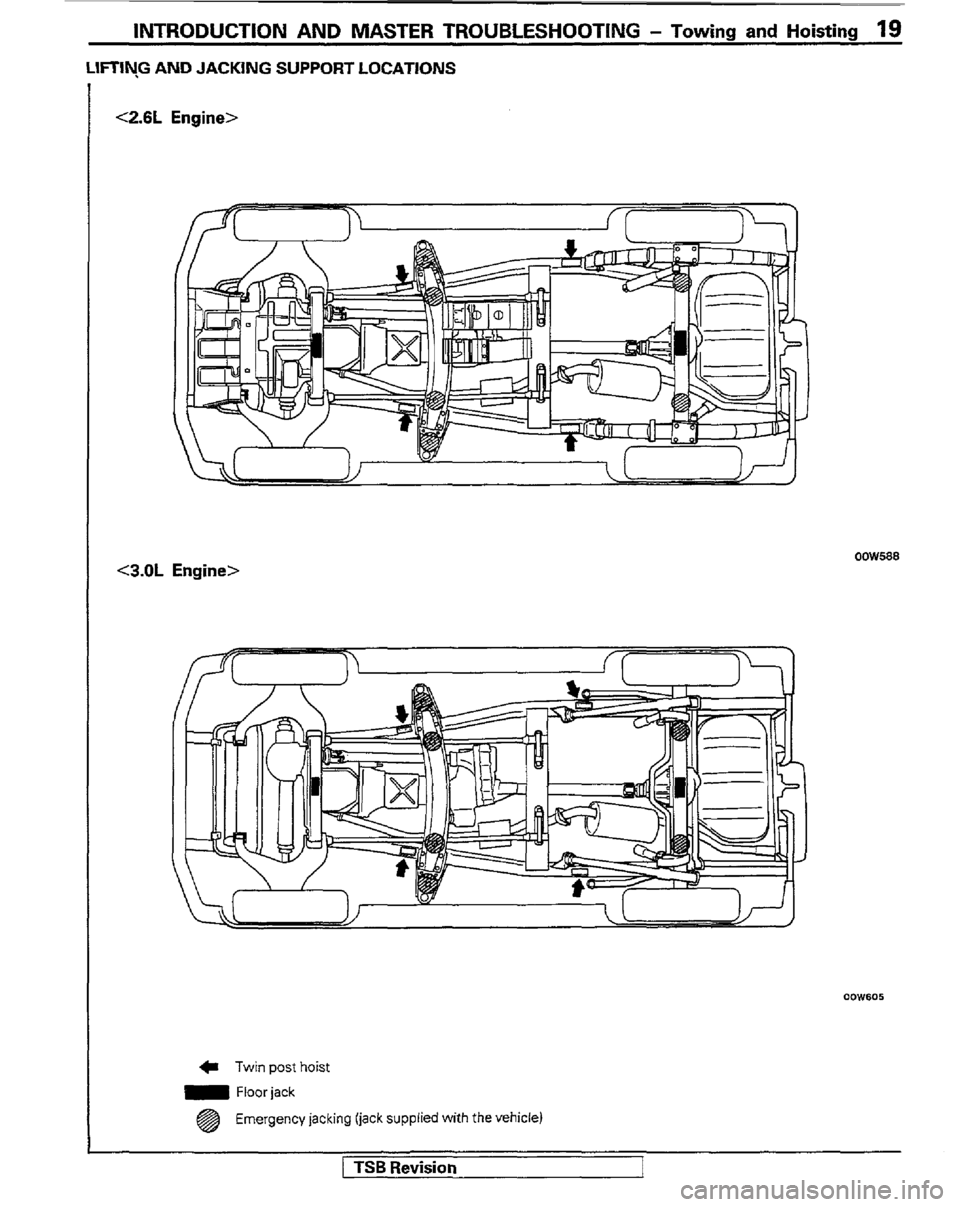

LIFTIYG AND JACKING SUPPORT LOCATIONS

<2.6L Engine> <2.6L Engine>

<3.OL Engine> <3.OL Engine>

C Twin post hoist C Twin post hoist

m Floor jack m Floor jack

@ @ Emergency jacking (jack supplied with the vehicle) Emergency jacking (jack supplied with the vehicle)

TSB Revision TSB Revision