ignition MITSUBISHI MONTERO 1989 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: MONTERO, Model: MITSUBISHI MONTERO 1989 1.GPages: 30, PDF Size: 1.61 MB

Page 9 of 30

INTRODUCTION AND MASTER TROUBLESHOOTING - Precautions Before Service 9

nm (in.)

smo59

PARTS

When replacing parts, use MITSUBISHI genuine parts

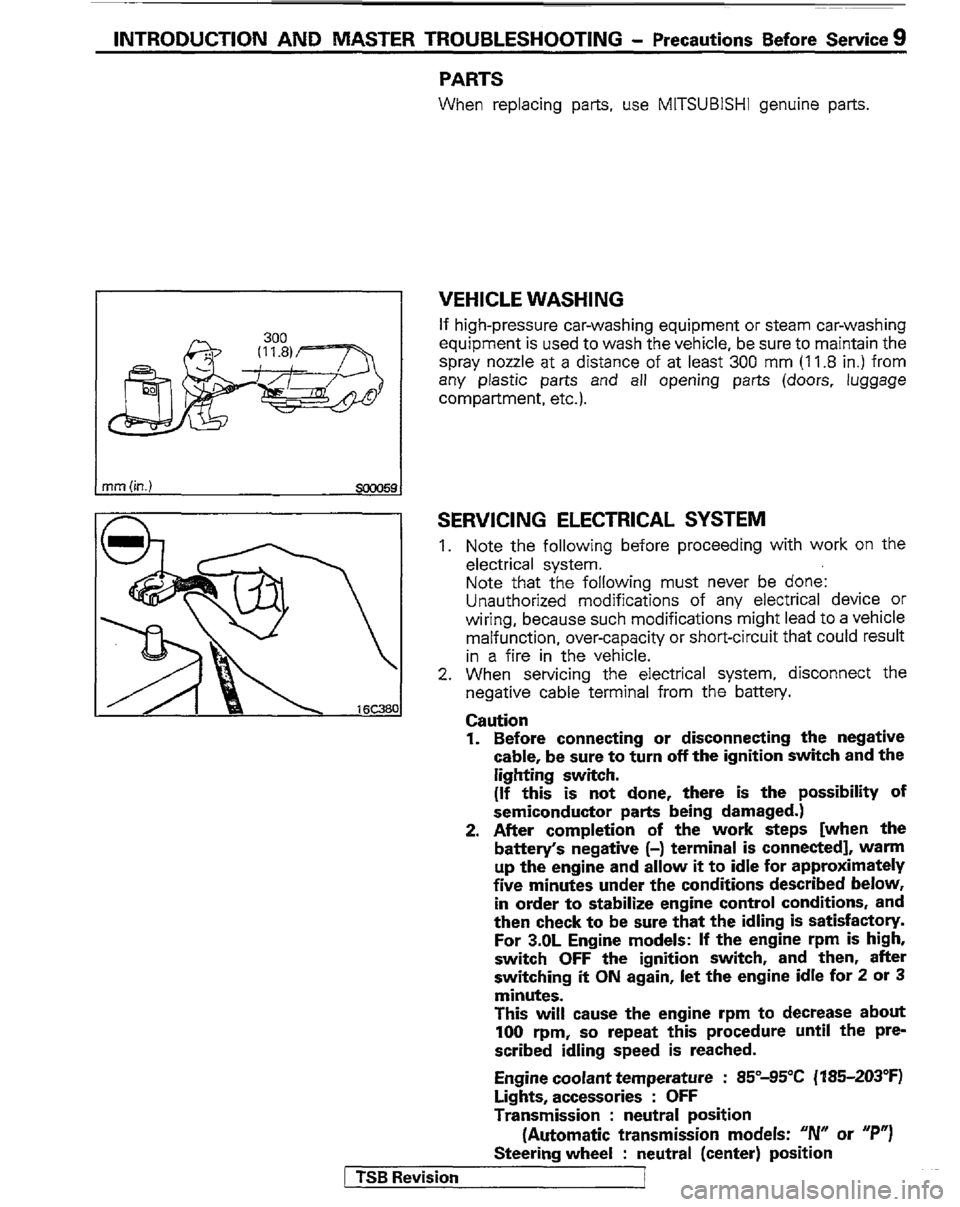

VEHICLE WASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (11.8 in.) from

any plastic parts and all opening parts (doors, luggage

compartment, etc.).

SERVICING ELECTRICAL SYSTEM

1. Note the following before proceeding with work on the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result

in a fire in the vehicle.

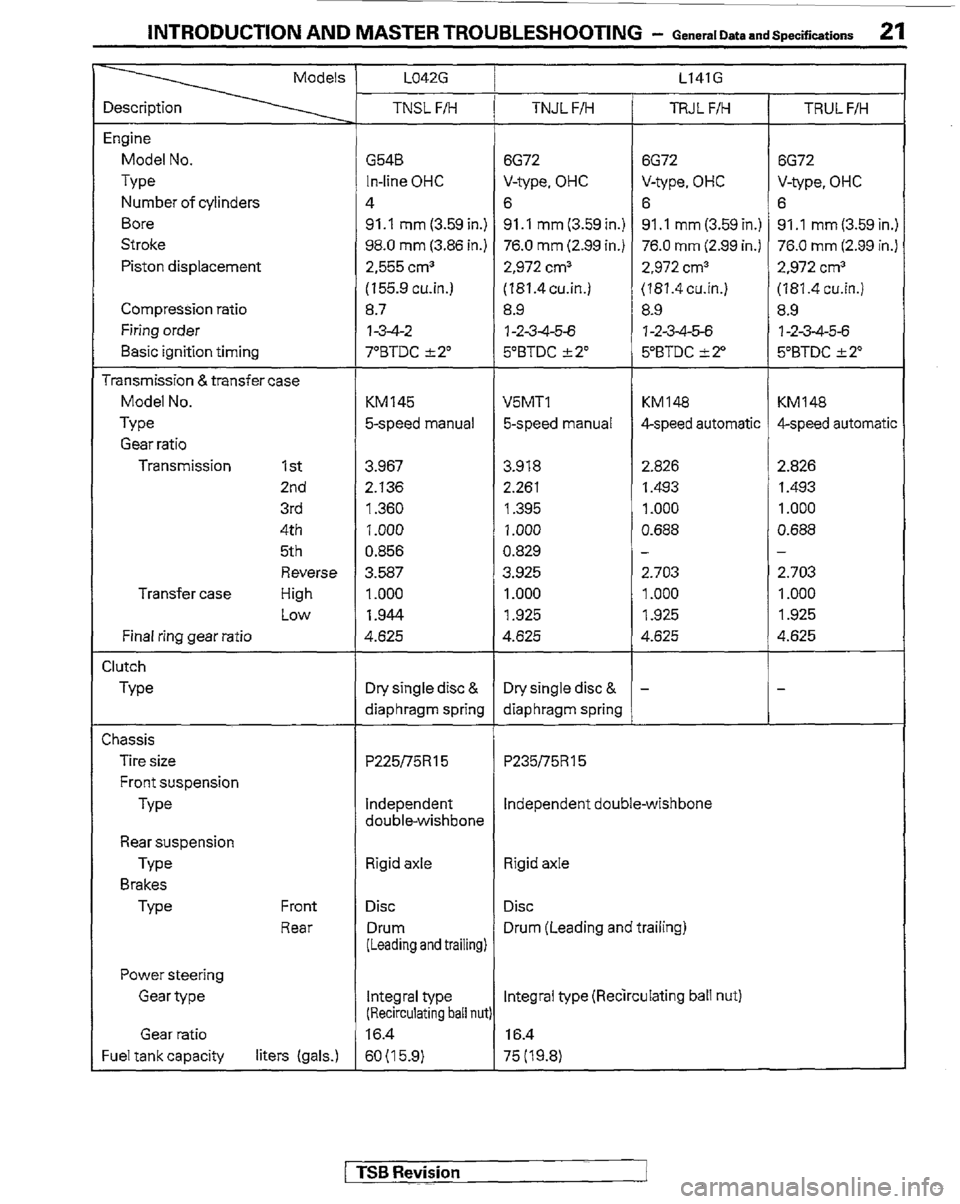

2. When servicing the electrical system, disconnect the

negative cable terminal from the battery.

Caution

1. Before connecting or disconnecting the negative

cable, be sure to turn off the ignition switch and the

fighting switch.

(If this is not done, there is the possibility of

semiconductor parts being damaged.)

2. After completion of the work steps [when the

battery’s negative (-) terminal is connected], warm

up the engine and allow it to idle for approximately

five minutes under the conditions described below,

in order to stabilize engine control conditions, and

then check to be sure that the idling is satisfactory.

For 3.OL Engine models: If the engine rpm is high,

switch OFF the ignition switch, and then, after

switching it ON again, let the engine idle for 2 or 3

minutes.

This will cause the engine rpm to decrease about

100 rpm, so repeat this procedure until the pre-

scribed idling speed is reached.

Engine coolant temperature : 85”-95°C (‘l85403”F)

Lights, accessories : OFF

Transmission : neutral position

(Automatic transmission models: “IV or “P”J

Steering wheel : neutral (center) position

1 TSB Revision

Page 21 of 30

INTRODUCTION AND MASTERTROUBLESHOOTING - GeneralDataandSpecmcations 21

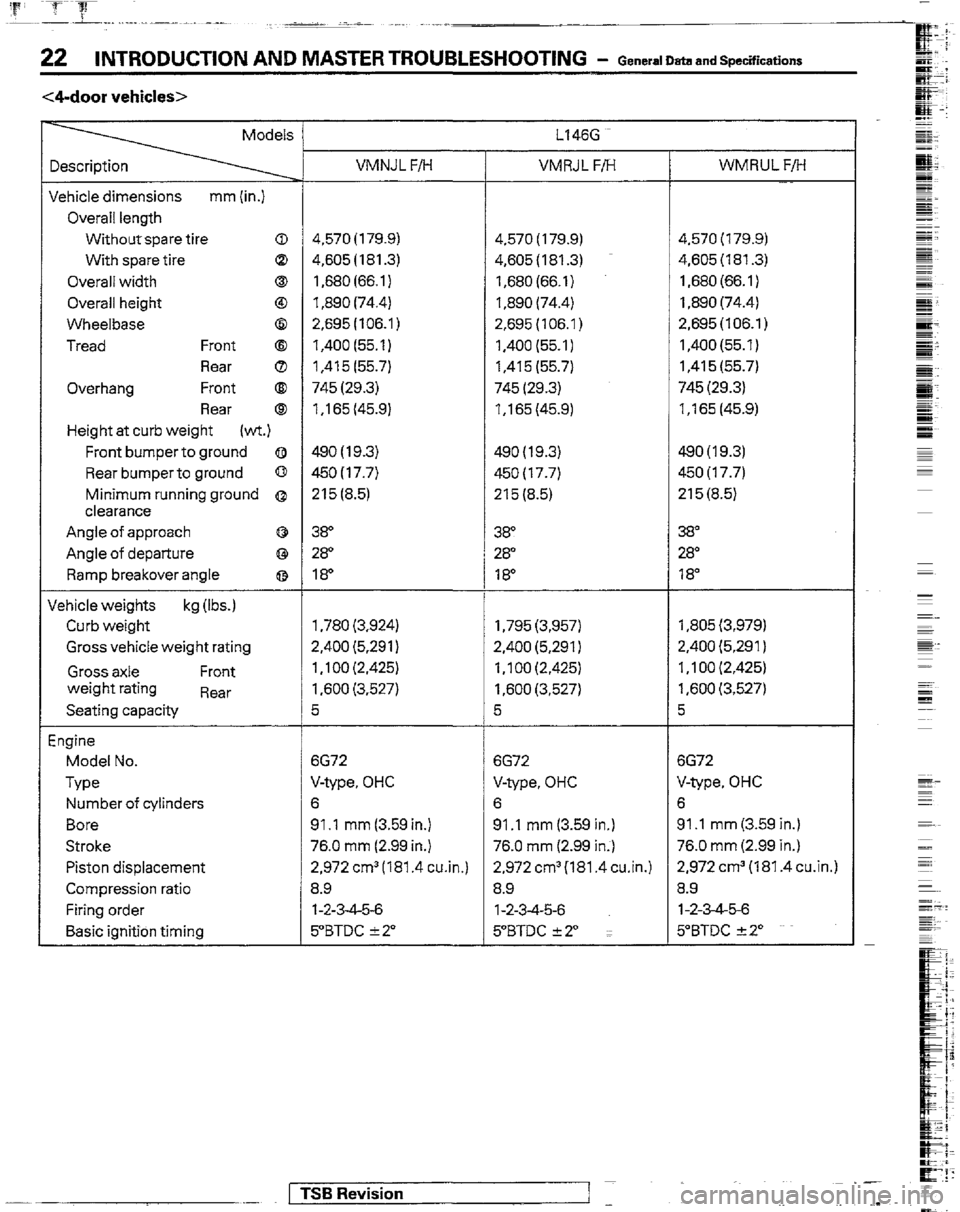

L042G L141G

TNSL FM TNJL F/H

TRJL F/H TRUL F/H

Engine

Model No. G54B 6672 6672 6672

Type In-line OHC V-type, OHC V-type, OHC

V-type, OHC

Number of cylinders 4 6 6 6

Bore 91.1 mm(3.59in.j 91.1 mm(3.59in.j 91.1 mm(3.59in.) 91.1 mm(3.59in.

Stroke 98.0 mm (3.86 in.) 76.0 mm (2.99 in.) 76.0 mm (2.99 in.) 76.0 mm (2.99 in.

Piston displacement 2,555 cm3 2,972 cm3 2,972 cm3 2,972 cm3

(155.9 cuin.) (181.4cu.in.) (181.4cu.in.) (181.4 cuin.)

Compression ratio 8.7 8.9 8.9 8.9

Firing order 1-3-4-2 1-2-3-4-5-6 I -2-345-5 1-2-3-4.5-8

Basic ignition timing 7”BTDC 22” 5”BTDC 22” 5”BTDC i 2” 5”BTDC +-2”

Transmission &transfer case

Model No. KM145 V5MTl KM148 KM148

Type S-speed manual 5-speed manual &peed automatic &peed automatic

Gear ratio

Transmission 1st 3.967 3.918 2.826 2.826

2nd 2.136 2.261 1.493 1.493

3rd 1.360 1.395 1 .ooo 1.000

4th 1 .ooo 1.000 0.688 0.688

5th 0.856 0.829 -

Reverse 3.587 3.925 2.703 2.703

Transfer case High 1 .ooo 1 .ooo 1 .ooo 1 .ooo

Low 1.944 1.925 1.925 1.925

Final ring ratio gear 4.625 4.625 4.625 4.625

Clutch

Type Dry single disc & Dry single disc & -

diaphragm spring diaphragm spring

Chassis

Tire size

Front suspension

Type

Rear suspension

Type

Brakes

Type Front

Rear P225ff 5Rl5 P235ff5Rl5

independent Independent double-wishbone

double-wishbone

Rigid axle Rigid axle

Disc Disc

Drum Drum (Leading and trailing)

(Leading and trailing)

Power steering

Gear type

Gear ratio

Fuel tank capacity Integral type Integral type (Recirculating ball nut)

(Recirculating ball nut)

16.4 16.4

liters (gals.) 60 (15.9) 75 (19.8)

[ TSB Revision

Page 22 of 30

-_-

22 INTRODUCTION AND MASTER TROUBLESHOOTING - General Data and Specifications

<&door vehicles>

L-

chicle dimensions mm (in.)

Overall length

Withoutspare tire a

With spare tire @

Overall width 0

Overall height @

Wheelbase Q

Tread Front @

Rear 8

Overhang Front @

Rear @

Height at curb weight

Wt.)

Front bumperto ground @

Rear bumper to ground 0

Minimum running ground @

clearance

Angle of approach 8

Angle of departure

8

Ramp breakover angle

63

,hicle weights kg (Ibs.)

Curb weight

Gross vehicle weight rating

Gross axle Front

weight rating

Rear

Seating capacity

gine

Model No.

Type

Number of cylinders

Bore

Stroke

Piston displacement

Compression ratio

Firing order

Basic ignition timing VMNJL F/H VMRJL F/H

4,570 (179.9)

4,605 (181.3)

1,680 (66.1)

1,890 (74.4)

2,695 (106.1)

1,400 (55.1)

I,41 5 (55.7)

745 (29.3)

1 ,I 65 (45.9) 4,570 ( 179.9)

4,605(181.3)

1,680 (66.1)

1,890 (74.4)

2,695(106.1)

1.400(55.1)

1,415 (55.7)

745 (29.3)

1,165(45.9)

490 (19.3)

450(17.7)

215 (8.5) 490 (19.3)

450(17.7)

215 (8.5)

38”

28”

18” 38”

28

18”

-i

1,780 (3,924)

2,400 (5,291)

1,100(2,425)

1,600 (3,527)

5 1,795 (3,957)

2,400 (5,291)

1,100(2.425)

1,600 (3,527)

5

6672

V-type, OHC

6

91 .I mm (3.59 in.)

76.0 mm (2.99 in.)

2,972 cm3 (181.4 cu.in.)

8.9

l-2-3-4-5-6

5”BTDC i2” 6672

V-type, OHC

6

91 .l mm (3.59 in.)

76.0 mm (2.99 in.)

2,972 cm3 (181.4 cuin.)

8.9

1-2-3-4-5-6

5”BTDC 22” : L146G

L

_-. 1 TSB Revision I

.- WMRUL F/H

4.570 (179.9)

4,605 (181.3)

1,680 (66.1)

1,890 (74.4)

2,695(106.1)

1,400(55.1)

1,415 (55.7)

745 (29.3)

1,165 (45.9)

490 (19.3)

450 (17.7)

215 (8.5)

38”

28”

18

1,805 (3,979)

2,400 (5,291)

1 ,100 (2,425)

1,600 (3,527)

5

3072

V-type, OHC

3

31 .l mm (3.59 in.)

76.0 mm (2.99 in.)

2,972 cm3 (181.4 cu.in.)

3.9

l-2-3-4-5-6

5”BTDC 22”

Page 24 of 30

24 INTRODUCTION AND MASTER TROUBLESHOOTING - WasterTroubleshooting Tightening Torque I

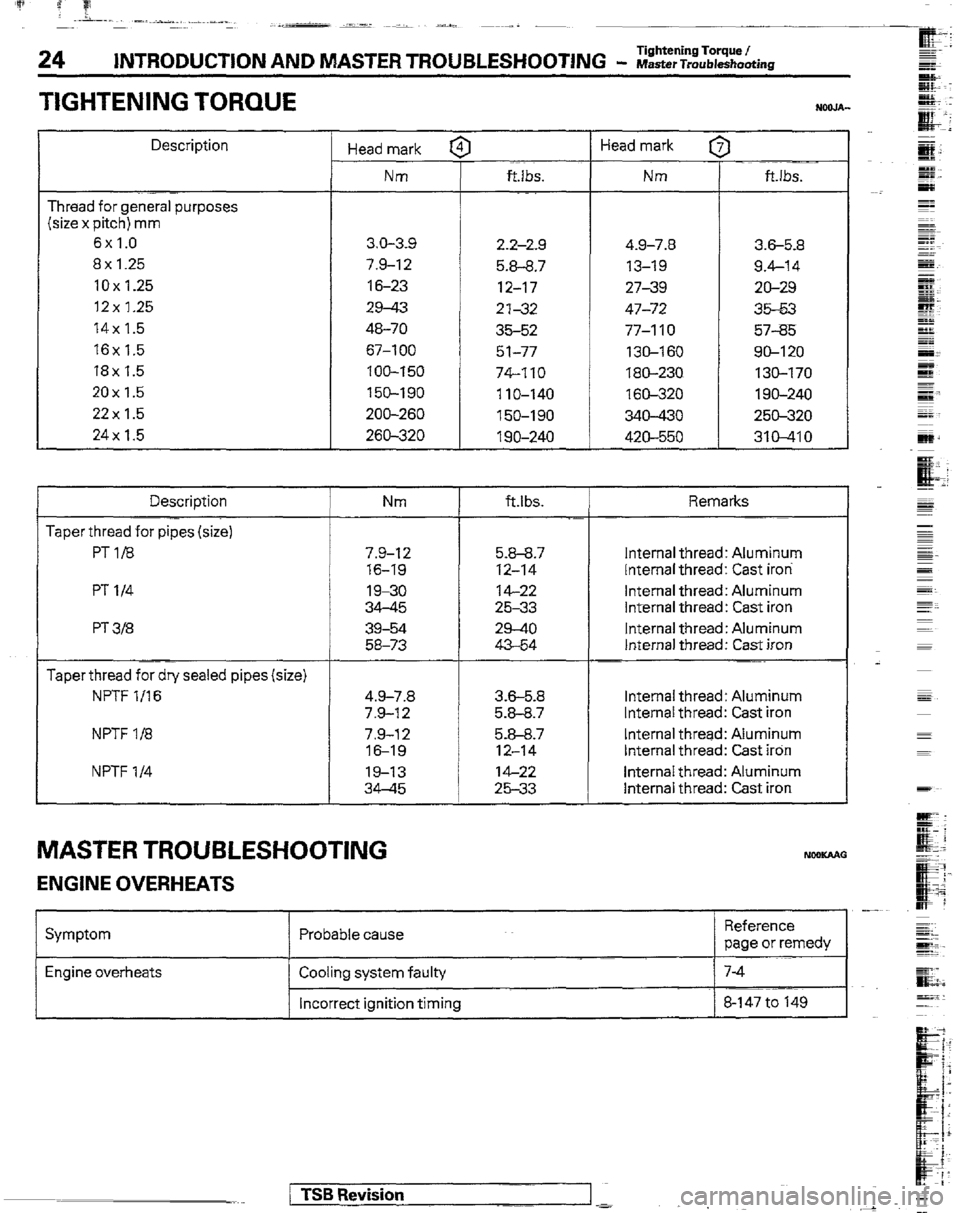

TIGHTENING TORQUE

Description

Thread for general purposes

(size x pitch) mm

6x1.0

8x 1.25

10x1.25

12x 1.25

14x 1.5

16x 1.5

18x 1.5

20x1.5

22x 1.5

24x 1.5

Description

Taper thread for pipes (size)

PT1/8

PT l/4

PT 3B

Taper thread for dry sealed pipes (size)

NF’TF l/16

NPTF l/8

NPTF l/4 Head mark f

Nm

3.0-3-s

7.9-12

16-23

29-43

46-70

67-l 00

100-150

150-190

ZOO-260

269-320 ft.lbs.

2.2-2.9 4.9-7.8

3.6-5.8

5.8-8.7 13-19 9.4-14

12-17 27-39 20-29

2’132 47-72 35-53

35-52 77-110 57-35

51-77 130-160 SO-120

74-110 180-230 130-170

110-140 160-320 1 go-240

150-190 340-430 250-320

1 go-240 420-550 310-410 Head mark [

Nm I

ft.lbs.

Nm ftlbs. Remarks

7.9-I 2 5.9-9.7 Internal thread: Aluminum

76-19 12-14 Internal thread: Cast iron

19-30 14-22 Internal thread: Aluminum

34-45 25-33 Internal thread: Cast iron

39-54 29-40 Internal thread: Aluminum

58-73 43-54 Internal thread: Cast iron

4.9-7.8 3.6-5.8 Internal thread: Aluminum

7.9-12 5.8-8.7 Internal thread: Cast iron

7.9-12 5.8-8.7 Internal thread: Aluminum

16-1s 12-14 Internal thread: Cast iron

19-13 14-22 Internal thread: Aluminum

34-45 25-33 Internal thread: Cast iron

MASTER TROUBLESHOOTING NceKAAO

ENGINE OVERHEATS

Symptom Probable cause -

Reference

page or remedy

Engine overheats Cooling system faulty

Incorrect ignition timing

1 TSB Revision

Page 25 of 30

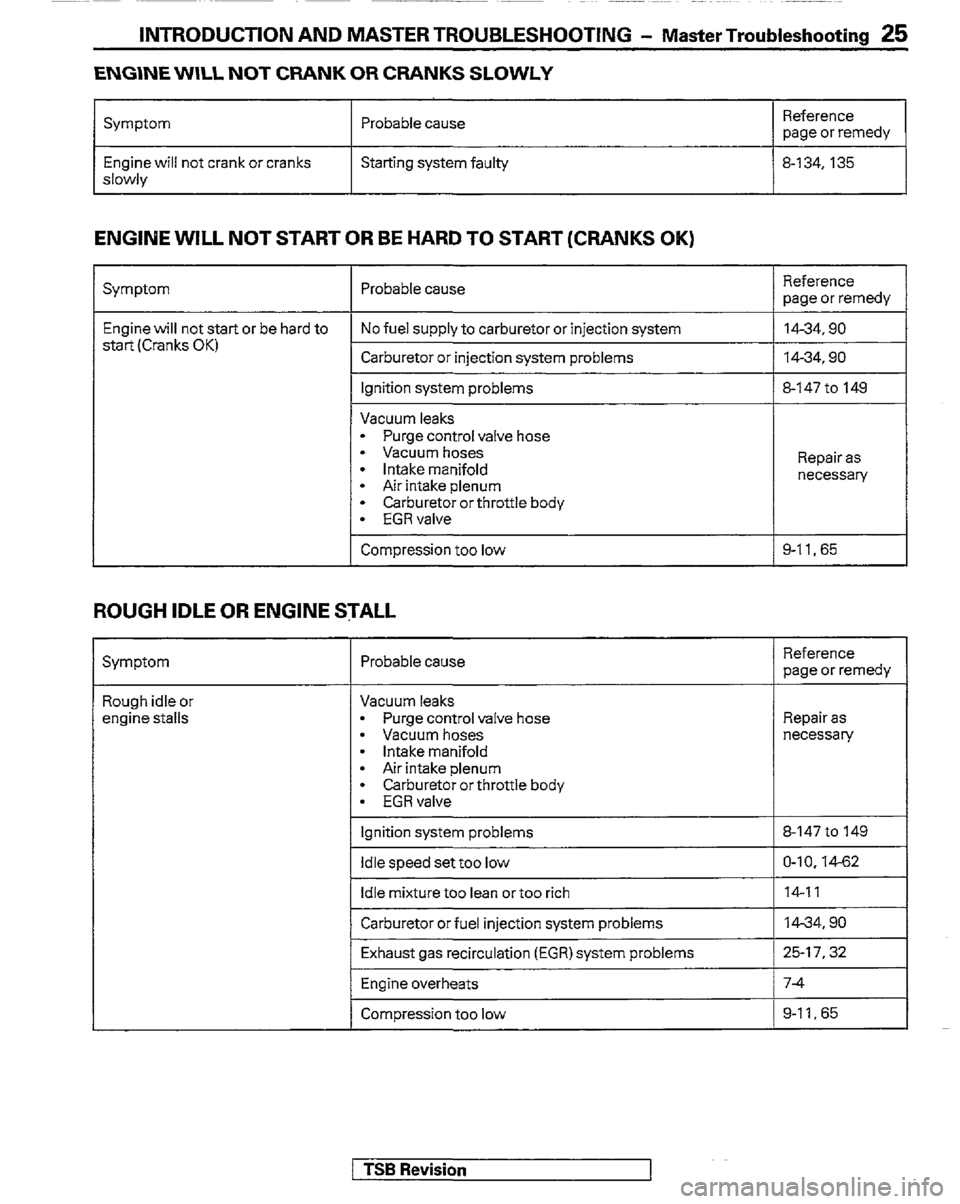

INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting 25

ENGINE WILL NOT CRANK OR CRANKS SLOWLY

Symptom

Engine will not crank or cranks

slowly Probable cause

Starting system faulty Reference

page or remedy

8-134.135

ENGINE WILL NOT START OR BE HARD TO START (CRANKS OK)

Symptom

Engine will not start or be hard to

start(Cranks OK)

ROUGH IDLE OR ENGINE STALL

Probable cause

No fuel supply to carburetor or injection system

Carburetor or injection system problems

Ignition system problems

Vacuum leaks

- Purge control valve hose

- Vacuum hoses

l intake manifold

- Air intake plenum

l Carburetor or throttle body

l EGRvalve

Compression too low Reference

page or remedy

14-34,90

14-34,90

3-147 to 149

Repair as

necessary

3-11.65

Symptom Probable cause Reference

page or remedy

Rough idle or

engine stalls Vacuum leaks

l Purge control valve hose

l Vacuum hoses

l Intake manifold

l Air intake plenum

l Carburetor or throttle body

l EGRvalve

1 Ignition system problems Repair as

necessary

8-147 to 149

Idle speed set too low 1 O-10.14-62

1~ ~ . Idle mrxture too lean or too rich 14-11

Carburetor or fuel injection system problems

Exhaust gas recirculation (EGR) system problems m-34.90

25-17.32

Engine overheats 7-4

Compression too low 9-11, 65

1 TSB Revision

Page 26 of 30

‘p ? f! .., .-, _-_ ,_- ____ ____ _L(

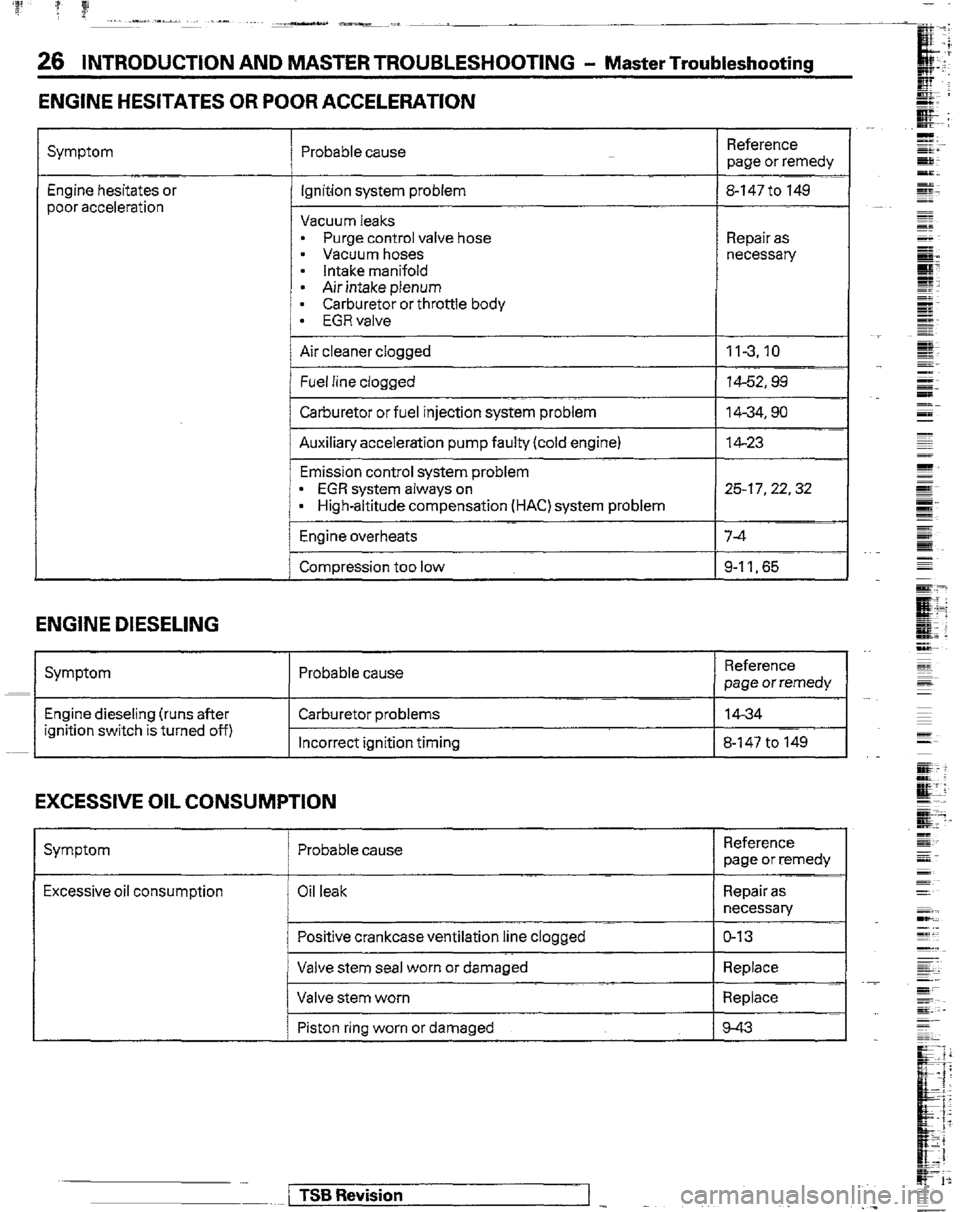

26 INTRODUCTION AND MASTER TROUBLESHOOTlNG - Master Troubleshooting

ENGINE HESITATES OR POOR ACCELERATION

Symptom Probable cause

Engine hesitates or

poor acceleration

-I

Ignition system problem

Vacuum leaks

l Purge control valve hose

l Vacuum hoses

- intake manifold

l Air intake plenum

* Carburetor or throttle body

l EGRvalve

ENGINE DIESELING

Reference

page or remedy

8-147 to 149

Repair as

necessary

Air cleaner clogged

Fuel line clogged 113.10

1442.99

Carburetor or fuel injection system problem

Auxiliary acceleration pump faulty (cold engine)

Emission control system problem

l EGR system always on

- High-altitude compensation (HAC) system problem

Engine overheats 14-34.90

14-23

25-77.22.32

7-4

Compression too low g-II.65

I Symptom Probable cause I

Reference

page or remedy

I I I I -..

Engine dieseling (runs after

ignition switch is turned off) Carburetor problems

Incorrect ignition timing 14-34

8-14710 149

EXCESSIVE OIL CONSUMPTION

Symptom Probable cause Reference

page or remedy

Excessive oil consumption Oil leak

Positive crankcaseventilation line clogged

Valve stem seal worn or damaged

Valve stem worn

Piston ring worn or damaged Repair as

necessary

o-13

Replace

Replace

9-43

1 TSB Revision

Page 27 of 30

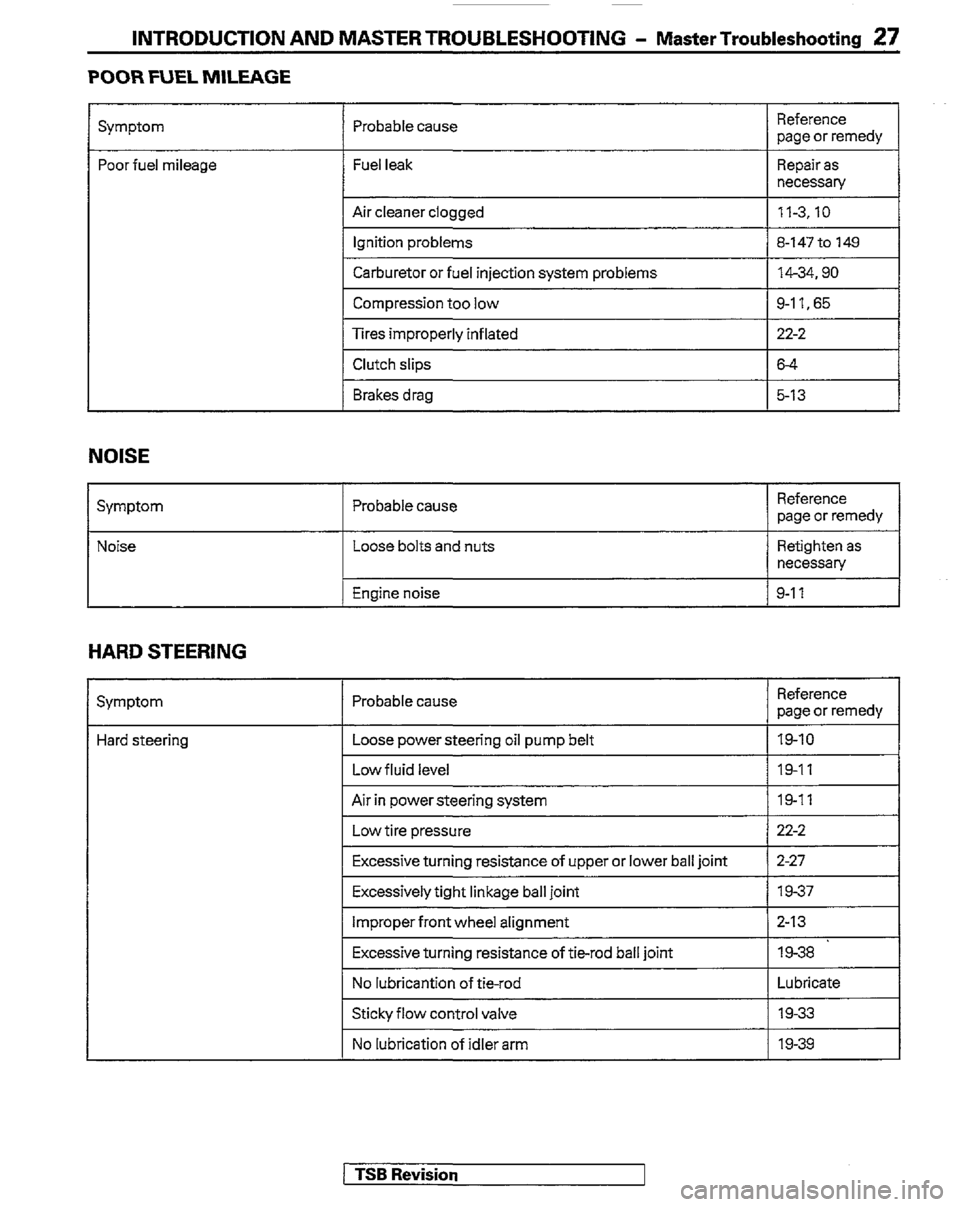

INTRODUCTION AND MASTER TROUBLESHOOTING - Master Troubleshooting 27

POOR FUEL MILEAGE

Symptom Probable cause Reference

page or remedy

Poor fuel mileage Fuel leak Repair as

necessary

I

1 Air cleaner clogged

1 Ignition problems 1 11-3.10 1

1 8-147to 149 1

Carburetor or fuel injection system problems 1434.90

I

Compression too low

1 g-II.65 1

Tires improperly inflated 1 22-2

I

Clutch slips

16-4 I

Brakes drag 1 5-13 I

NOISE

Probable cause Reference

page or remedy

Noise Loose bolts and nuts Retighten as

necessary

I

1 Enaine noise

I 9-11 I

HARD STEERING

Symptom

Hard steering Probable cause

Loose power steering oil pump belt

Low fluid level

Air in power steering system

Low tire pressure

Excessive turning resistance of upper or lower ball joint

Excessivelytight linkage ball joint

Improperfrontwheel alignment

Excessive turning resistance of tie-rod ball joint

No lubricantion of tie-rod

Sticky flow control valve

No lubrication of idler arm Reference

page or remedy

19-10

19-11

19-11

22-2

2-27

1937

2-13

19-38 ’

Lubricate

19-33

19-39

) TSB Revision