engine MITSUBISHI MONTERO 1998 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1998, Model line: MONTERO, Model: MITSUBISHI MONTERO 1998Pages: 1501, PDF Size: 25.81 MB

Page 1248 of 1501

profit organizations. MAP conducted pilot programs in twelve states

before announcing the program nationally in October, 1998. During the

pilots, participating repair shops demonstrated their adherence to the

Pledge and Standards and agreed to follow the UICS in communicating

the results of their inspection to their customers. To put some

"teeth" in the program, an accreditation requirement for shops was

initiated. The requirements are stringent, and a self-policing method

has been incorporated which includes the "mystery shopping" of

outlets.

We welcome you to join us as we continue our outreach... with

your support, both the automotive repair industry and your customers

will reap the benefits. Please visit MAP at our Internet site www.

motorist.org or contact us at:

1444 I Street, NW Suite 700

Washington, DC 20005

Phone (202) 712-9042 Fax (202) 216-9646

January 1999

MAP UNIFORM INSPECTION GENERAL GUIDELINES

OVERVIEW OF SERVICE REQUIREMENTS & SUGGESTIONS

It is MAP policy that all exhaust, brake, steering,

suspension, wheel alignment, drive-line, engine performance and

maintenance, and heating, ventilation and air conditioning, and

electrical services be offered and performed under the standards and

procedures specified in these sections.

Before any service is performed on a vehicle, an inspection

of the appropriate system must be performed. The results of this

inspection must be explained to the customer and documented on an

inspection form. The condition of the vehicle and its components will

indicate what services/part replacements may be "Required" or

"Suggested". In addition, suggestions may be made to satisfy the

requests expressed by the customer.

When a component is suggested or required to be repaired or

replaced, the decision to repair or replace must be made in the

customer's best interest, and at his or her choice given the options

available.

This section lists the various parts and conditions that

indicate a required or suggested service or part replacement.

Although this list is extensive, it is not fully inclusive. In

addition to this list, a technician may make a suggestion. However,

any suggestions must be based on substantial and informed experience,

or the vehicle manufacturer's recommended service interval and must be

documented.

Some conditions indicate that service or part replacement is

required because the part in question is no longer providing the

function for which it is intended, does not meet a vehicle

manufacturer's design specification or is missing.

Example:

An exhaust pipe has corroded severely and has a hole in it

through which exhaust gases are leaking. Replacement of the

exhaust pipe in this case is required due to functional

failure.

Example:

A brake rotor has been worn to the point where it measures

less than the vehicle manufacturer's discard specifications.

Replacement of the rotor is required because it does not meet

design specifications.

Page 1302 of 1501

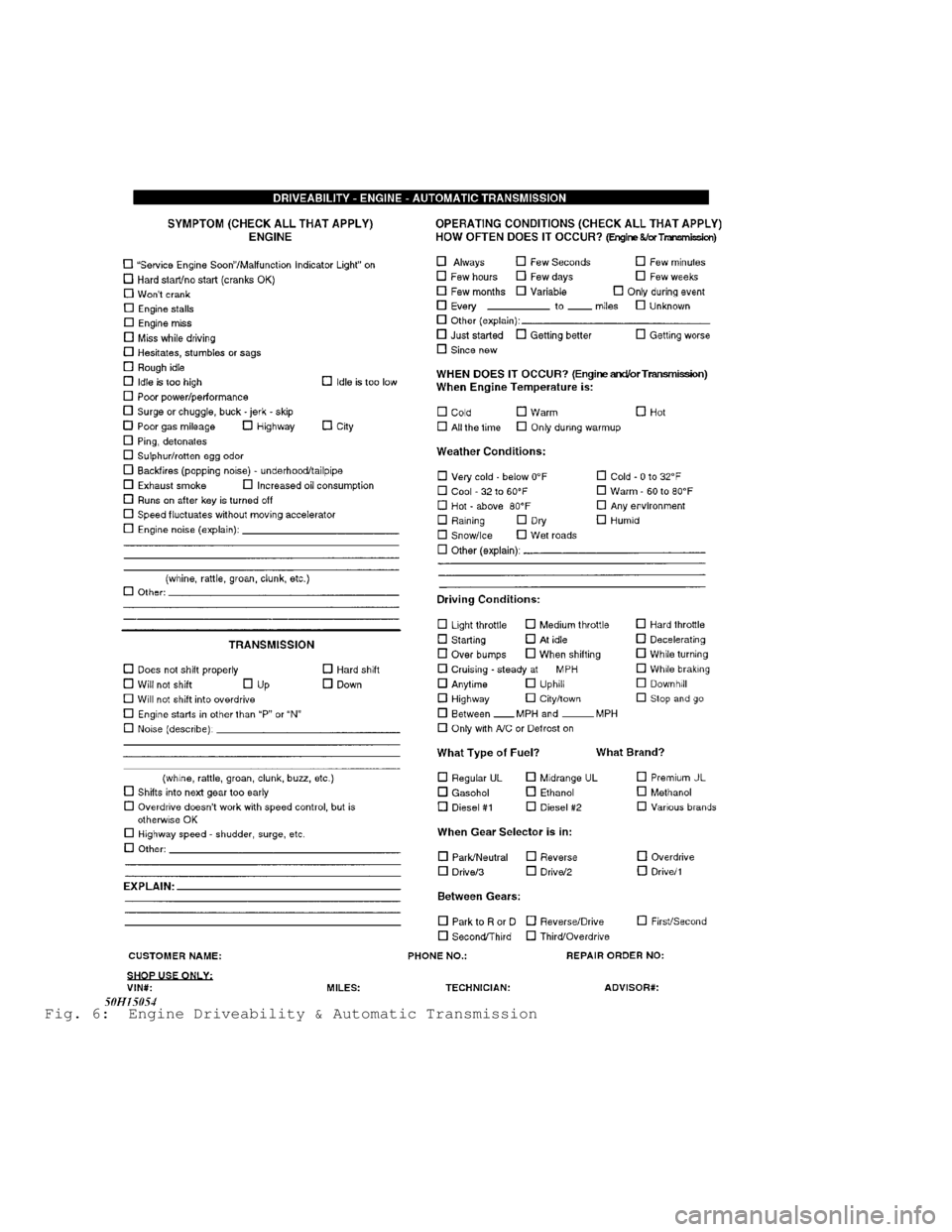

Fig. 6: Engine Driveability & Automatic Transmission

Page 1316 of 1501

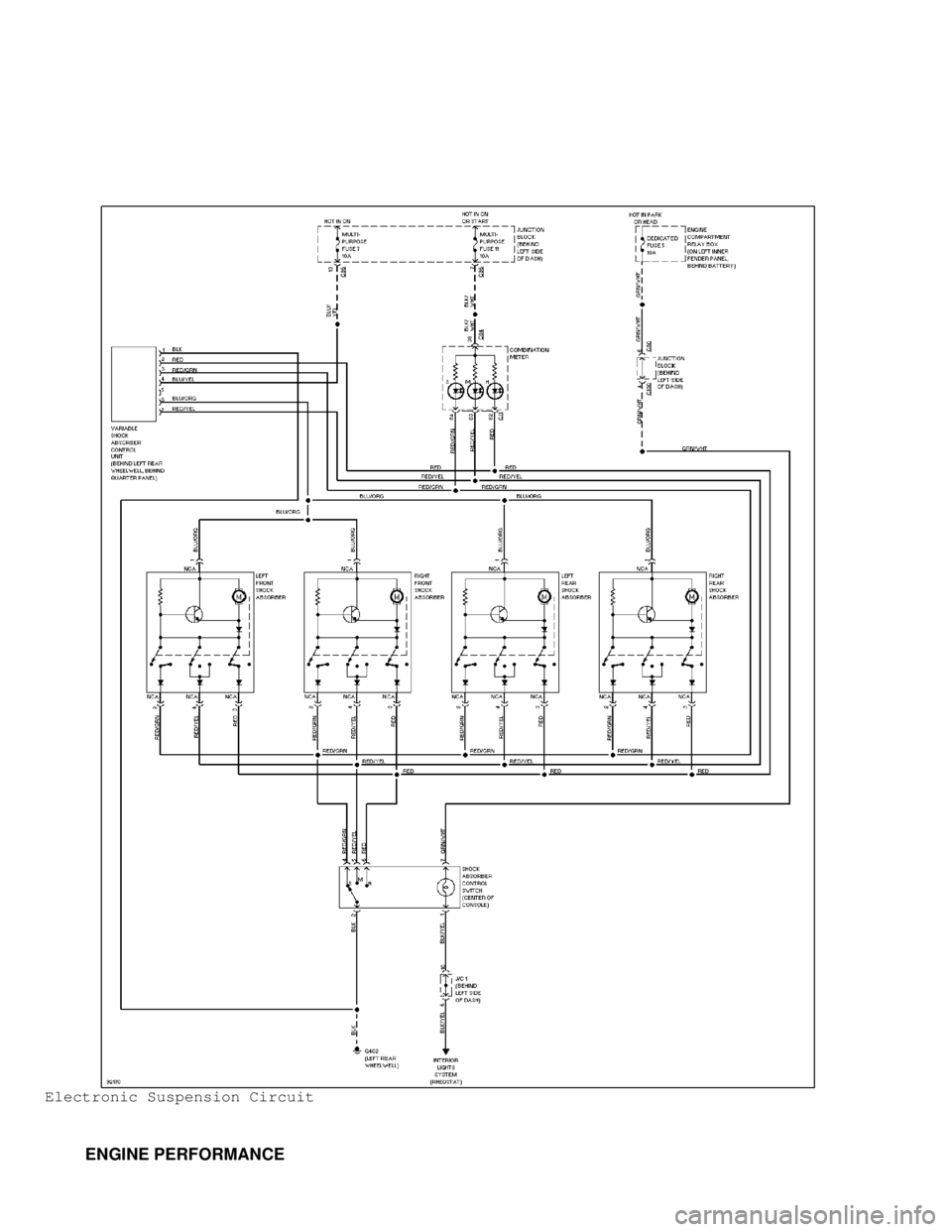

Electronic Suspension Circuit

ENGINE PERFORMANCE

Page 1317 of 1501

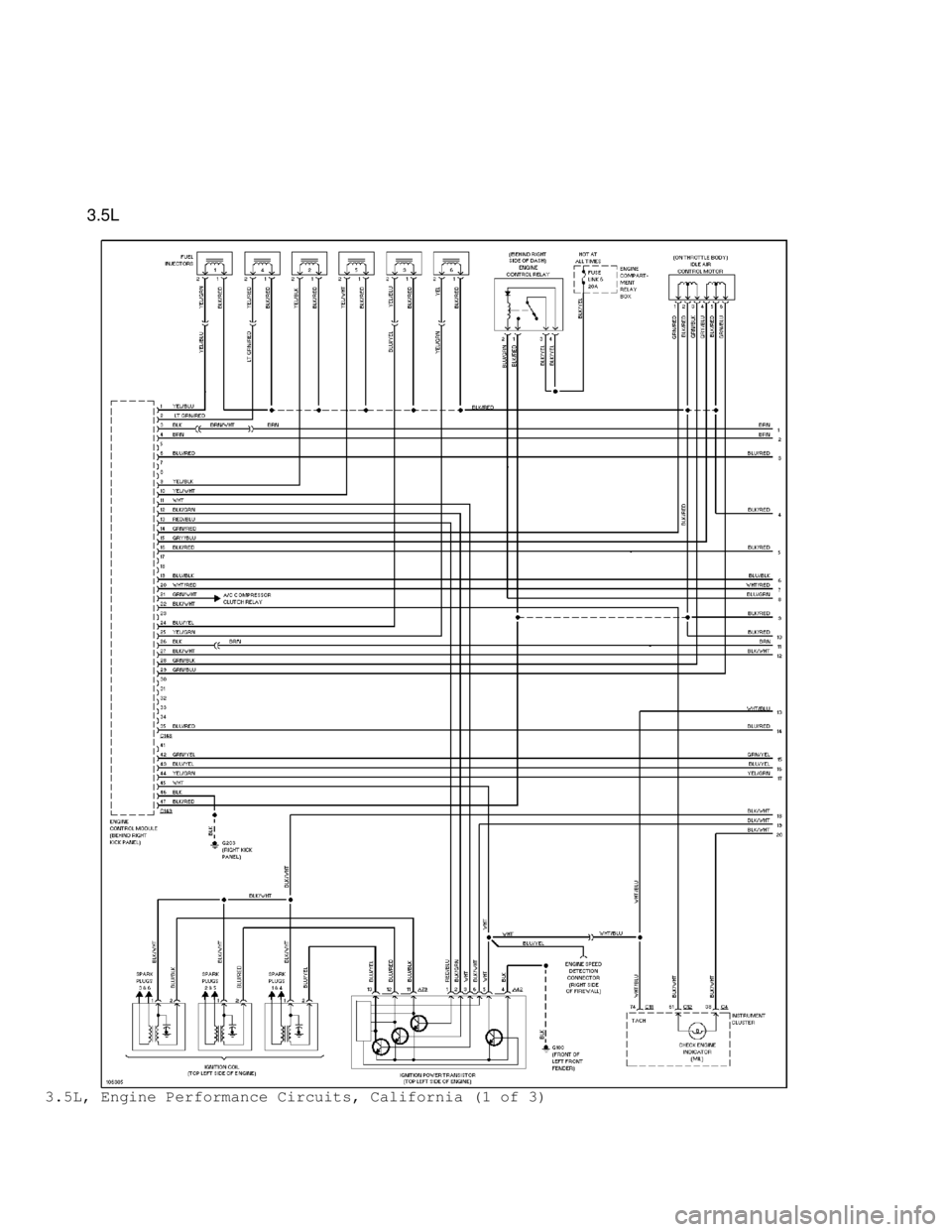

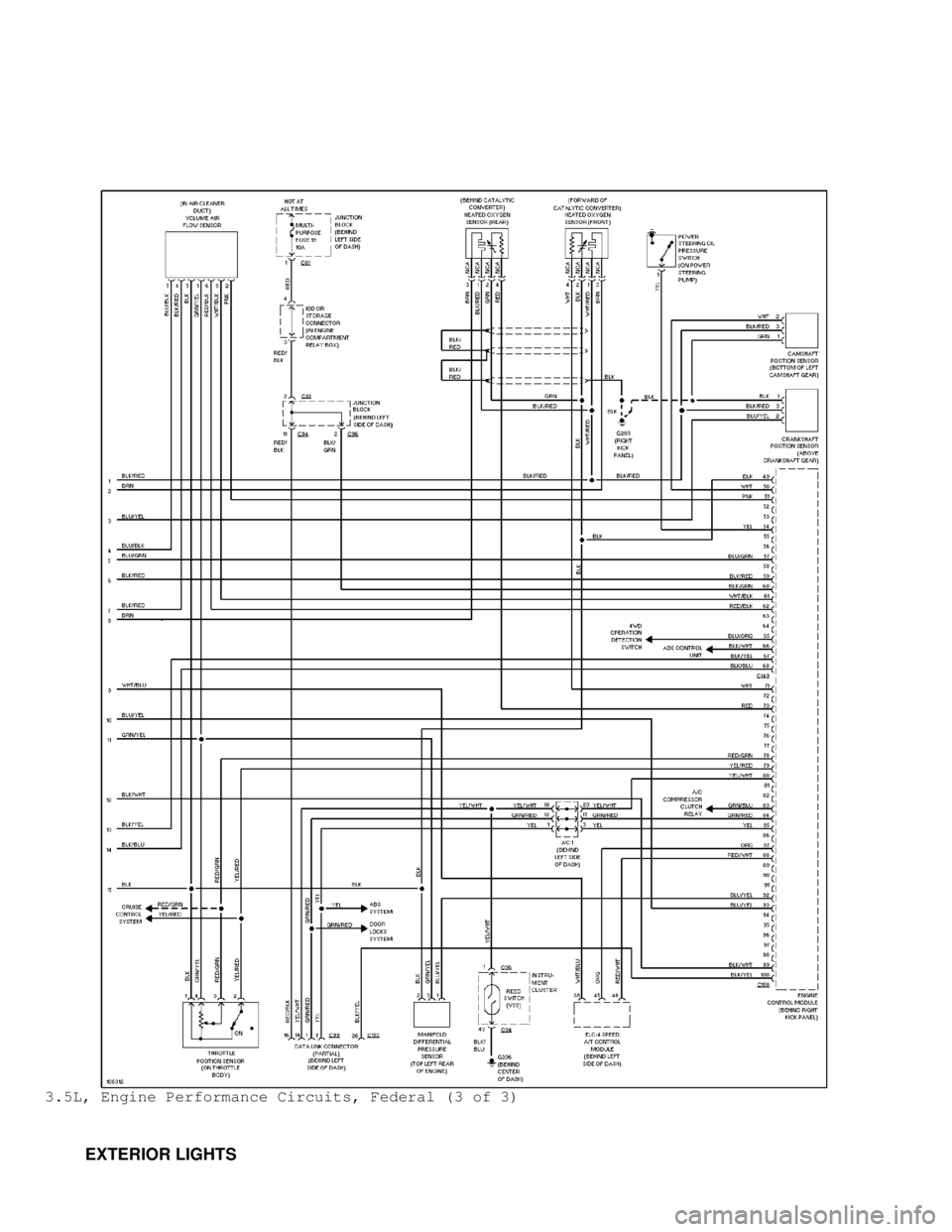

3.5L

3.5L, Engine Performance Circuits, California (1 of 3)

Page 1318 of 1501

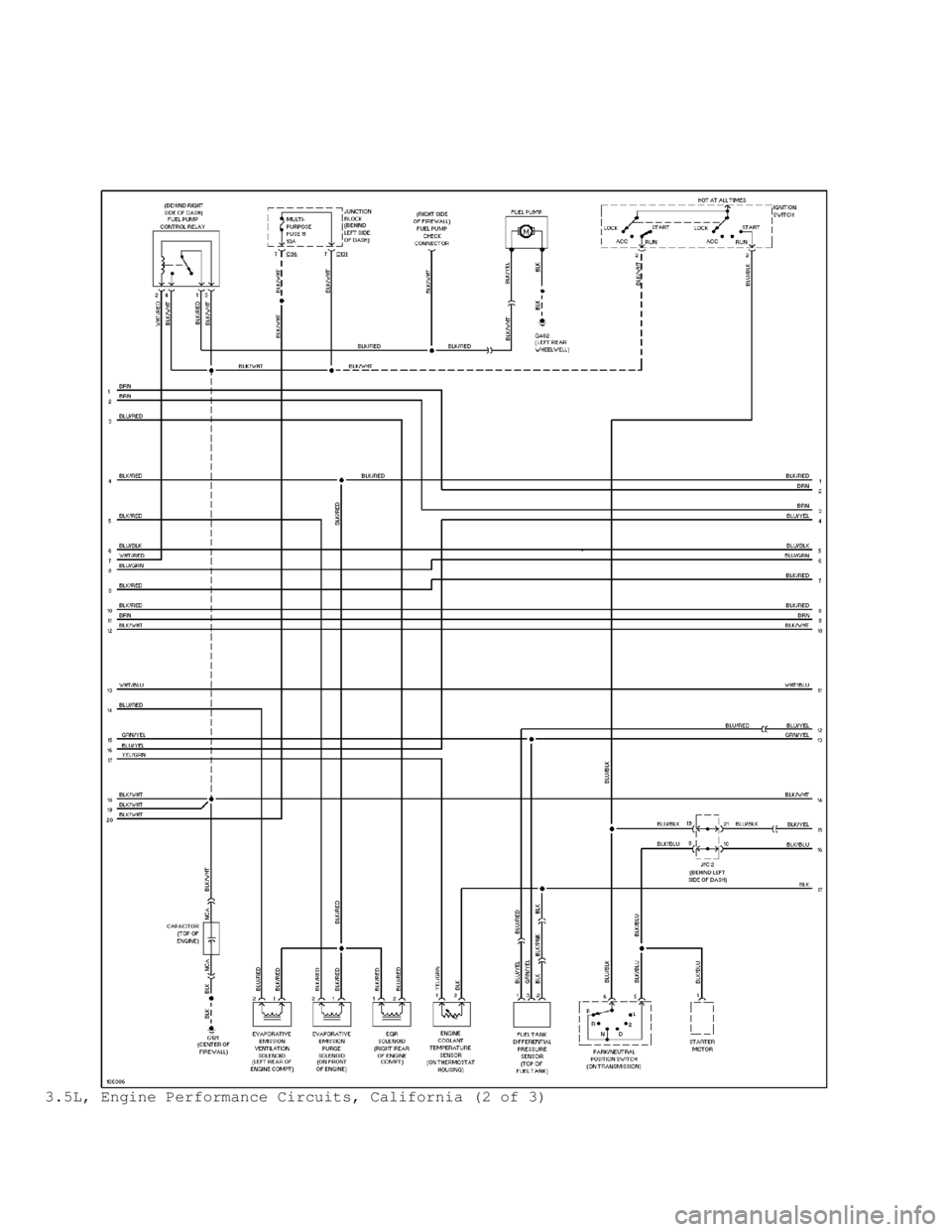

3.5L, Engine Performance Circuits, California (2 of 3)

Page 1319 of 1501

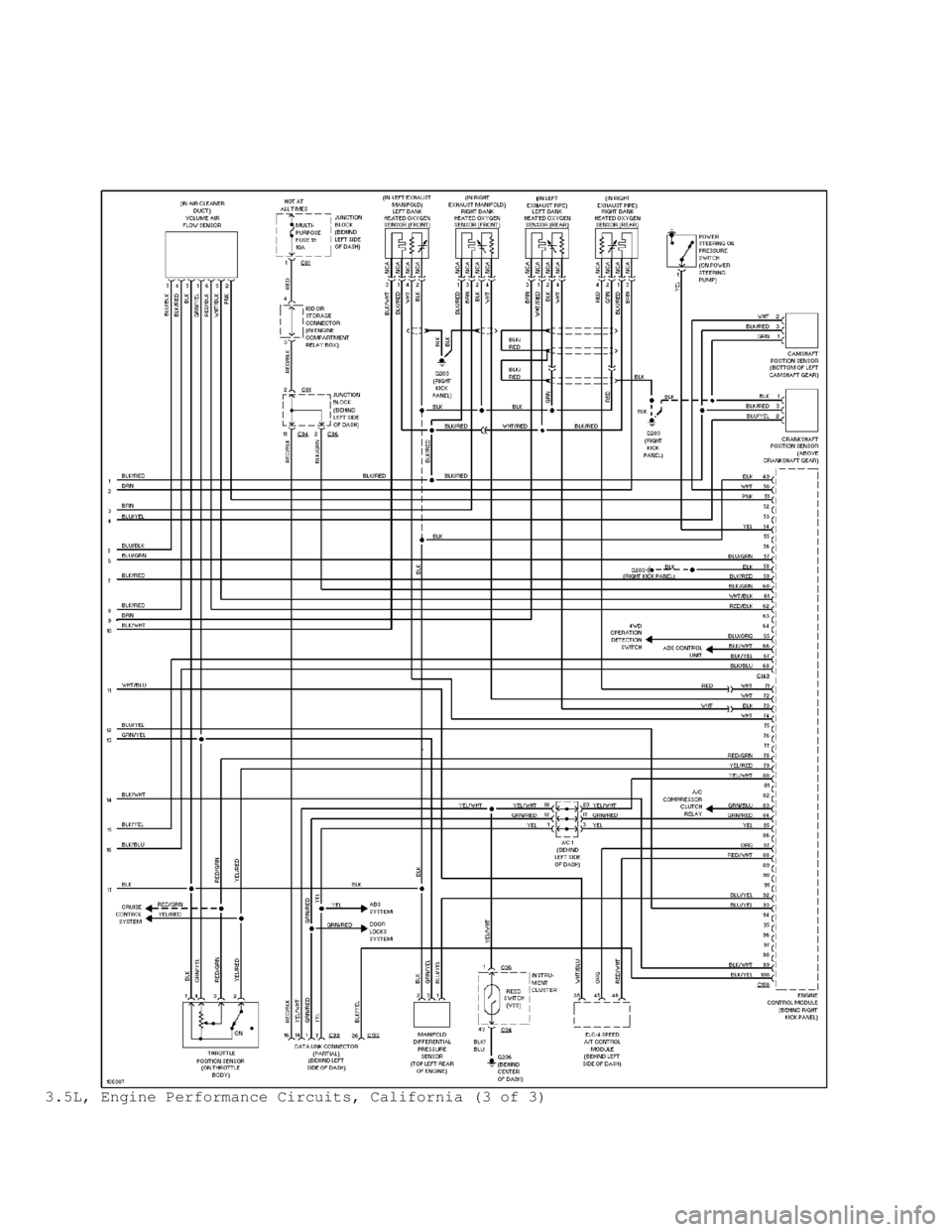

3.5L, Engine Performance Circuits, California (3 of 3)

Page 1320 of 1501

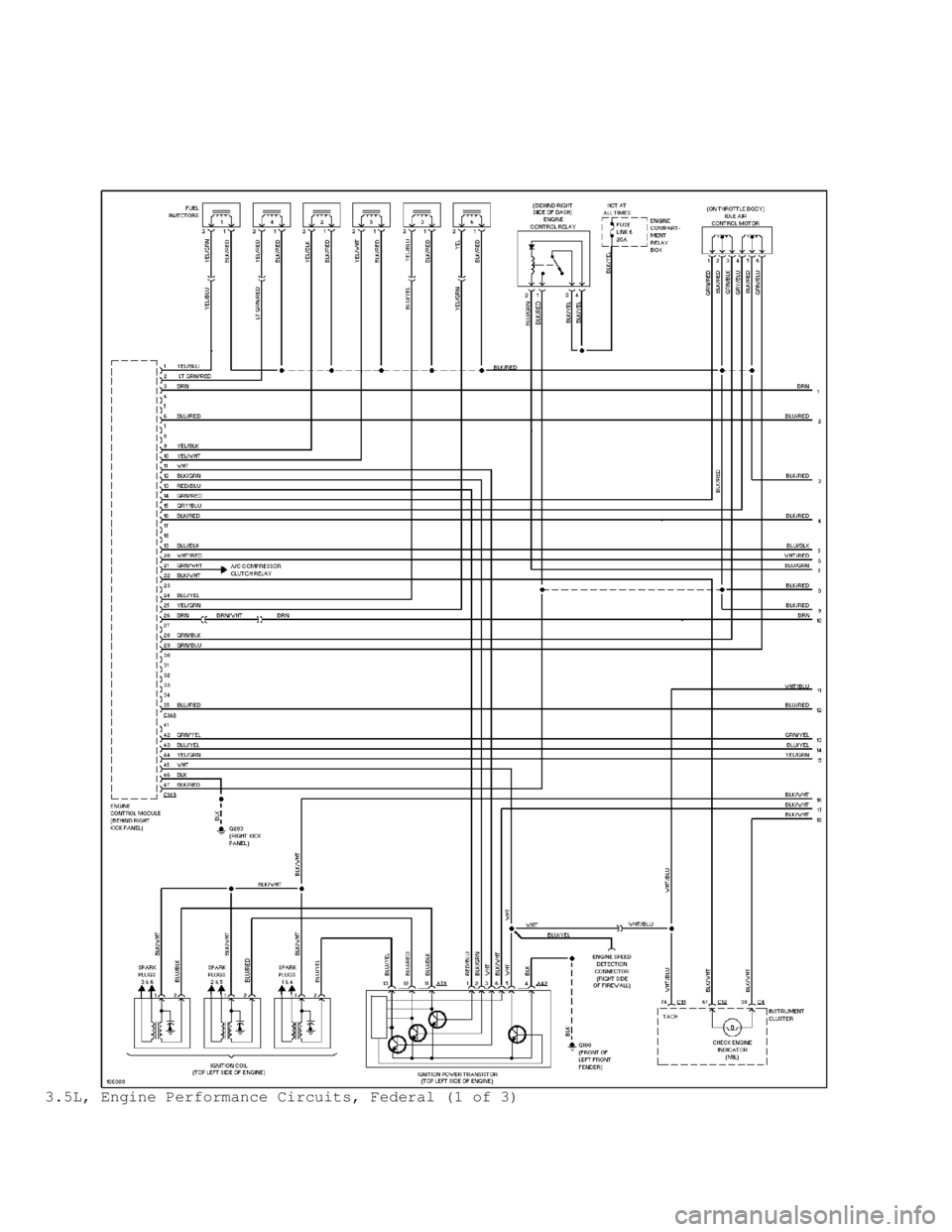

3.5L, Engine Performance Circuits, Federal (1 of 3)

Page 1321 of 1501

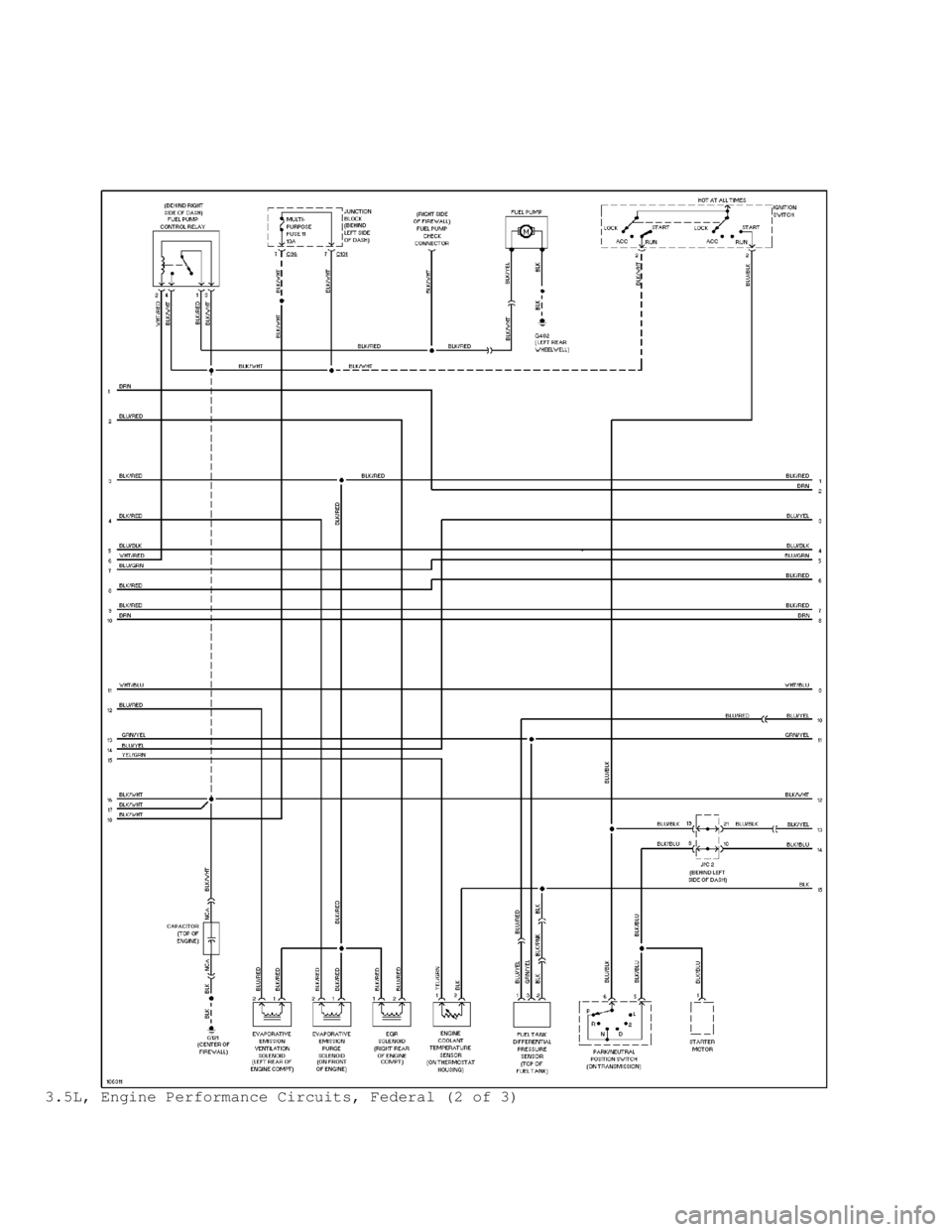

3.5L, Engine Performance Circuits, Federal (2 of 3)

Page 1322 of 1501

3.5L, Engine Performance Circuits, Federal (3 of 3)

EXTERIOR LIGHTS

Page 1354 of 1501

TRANSMISSION REMOVAL & INSTALLATION - A/T

1998 Mitsubishi Montero

1997-98 TRANSMISSION SERVICING

Mitsubishi Transmission Removal & Installation

Diamante, Eclipse, Galant, Mirage, Montero, 3000GT

REMOVAL & INSTALLATION

AWD & FWD MODELS

Removal

1) On all models except Galant, remove battery and battery

tray. On 3000GT, remove washer tank. On all models, remove air cleaner

cover with air inlet hose assembly. Raise and support vehicle. Remove

wheels. Remove undercover(s) (if equipped). Disconnect control cable\

s

at transaxle. Drain transaxle fluid.

2) On AWD models, remove front exhaust pipe. On all models,

disconnect neutral safety switch connector, oil cooler hoses and

electrical connectors from transaxle. Disconnect speedometer cable and

throttle control cable (if equipped). Remove starter motor.

3) Separate tie rod end. Separate lower ball joint. Separate

stabilizer bar connection (if necessary). Remove axle shafts. See

appropriate AXLE SHAFTS article in DRIVE AXLES. Remove center

crossmember assembly.

4) On AWD models, separate transfer assembly from transaxle.

Reference mark transfer assembly-to-drive shaft and remove transfer

assembly.

5) On all models, remove transmission inspection (dust)

cover. Place index mark on torque converter and drive plate for

reassembly reference. Remove torque converter-to-drive plate bolts.

Push torque converter away from engine into transaxle.

6) On all 4-cylinder models, support engine. On all models,

support transaxle with jack. Remove bolts from transaxle mounts.

Remove mounting brackets and remaining transaxle-to-engine bolts.

Slide transaxle assembly to right and lower to remove.

CAUTION: Ensure torque converter is fully seated in transaxle before

installation. Always install new snap rings on inner

constant velocity joints.

Installation

1) To install, reverse removal procedure. Tighten transaxle-

to-engine bolts and torque converter-to-drive plate bolts to

specification. See TORQUE SPECIFICATIONS .

2) Ensure reference marks on torque converter-to-drive plate

and transfer assembly-to-drive shaft align. Tighten mounting bolts

with weight of engine and transaxle on mounts. Refill transaxle fluid

to specified level. See LUBRICATION in TRANSMISSION SERVICING - A/T

article. Adjust all control cables. See ADJUSTMENTS in

TRANSMISSION SERVICING - A/T article.

RWD & 4WD MODELS

Removal

1) Disconnect negative battery cable. On Montero 4WD, remove

transfer case shift lever knob, dust boot and retainer plate or

console. Remove transfer case gearshift assembly.

2) On all models, raise and support vehicle. Remove

undercarriage cover and/or skid plate(s). Drain transmission and

transfer case (if applicable). Place reference mark on drive shaft(s)\