ignition MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 601 of 1839

MITSUBISHI SC-Troubleshooting13E-12

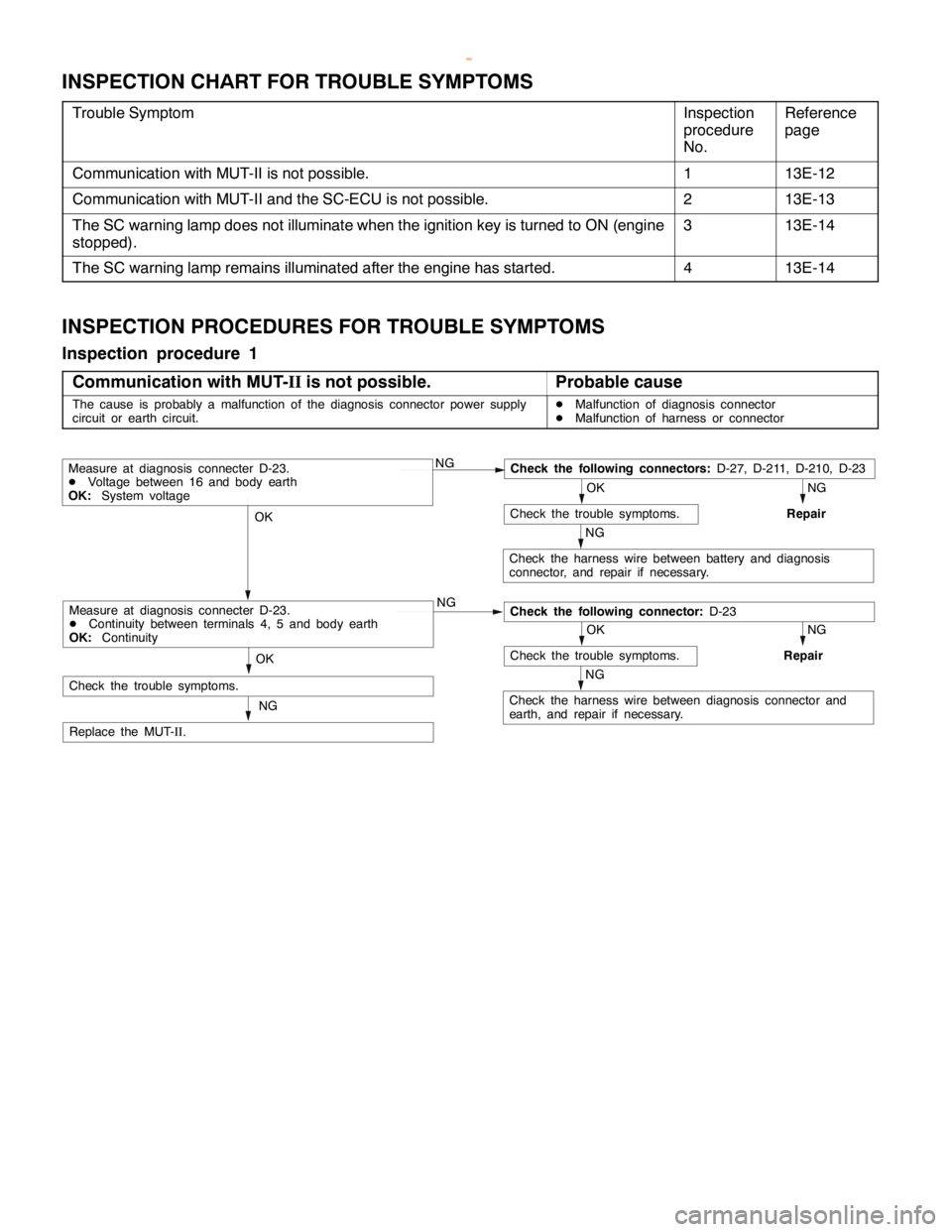

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble SymptomInspection

procedure

No.Reference

page

Communication with MUT-II is not possible.113E-12

Communication with MUT-II and the SC-ECU is not possible.213E-13

The SC warning lamp does not illuminate when the ignition key is turned to ON (engine

stopped).313E-14

The SC warning lamp remains illuminated after the engine has started.413E-14

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

Communication with MUT-

IIis not possible.

Probable cause

The cause is probably a malfunction of the diagnosis connector power supply

circuit or earth circuit.DMalfunction of diagnosis connector

DMalfunction of harness or connector

NGCheck the following connectors:

D-27, D-211, D-210, D-23

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire between battery and diagnosis

connector, and repair if necessary.

OK

NG

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire between diagnosis connector and

earth, and repair if necessary.

OK

NG

Replace the MUT-

II.

Measure at diagnosis connecter D-23.

DVoltage between 16 and body earth

OK:

System voltage

Check the following connector:

D-23Measure at diagnosis connecter D-23.

DContinuity between terminals 4, 5 and body earth

OK:

Continuity

Check the trouble symptoms.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 602 of 1839

MITSUBISHI SC-Troubleshooting13E-13

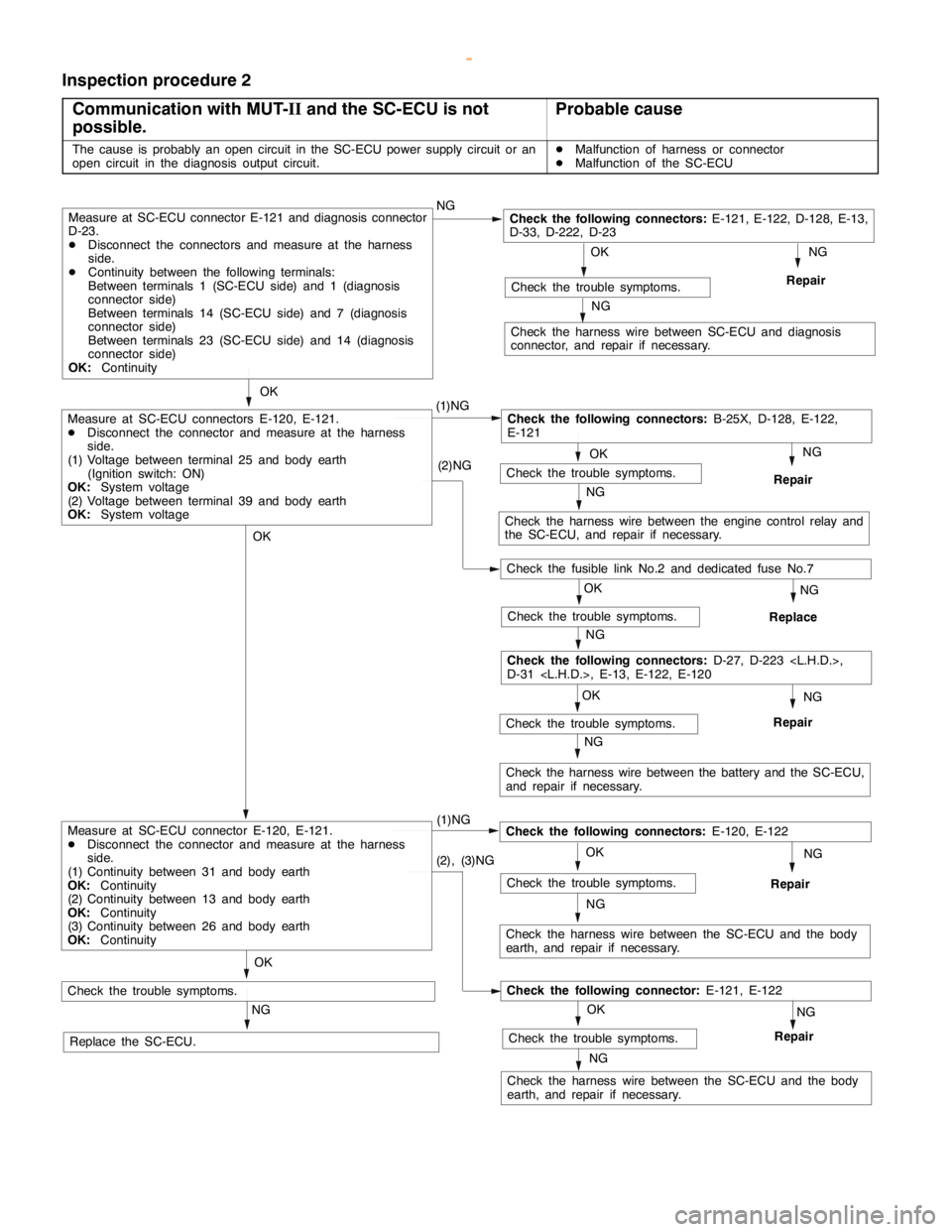

Inspection procedure 2

Communication with MUT-

IIand the SC-ECU is not

possible.

Probable cause

The cause is probably an open circuit in the SC-ECU power supply circuit or an

open circuit in the diagnosis output circuit.DMalfunction of harness or connector

DMalfunction of the SC-ECU

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire between SC-ECU and diagnosis

connector, and repair if necessary.

OK

Measure at SC-ECU connector E-121 and diagnosis connector

D-23.

DDisconnect the connectors and measure at the harness

side.

DContinuity between the following terminals:

Between terminals 1 (SC-ECU side) and 1 (diagnosis

connector side)

Between terminals 14 (SC-ECU side) and 7 (diagnosis

connector side)

Between terminals 23 (SC-ECU side) and 14 (diagnosis

connector side)

OK:

ContinuityNGCheck the following connectors:

E-121, E-122, D-128, E-13,

D-33, D-222, D-23

OK

NG

Repair

OK

Check the trouble symptoms.

NG

OKNG

Repair

OK

(1)NGCheck the following connectors:

B-25X, D-128, E-122,

E-121

NG

Check the harness wire between the engine control relay and

the SC-ECU, and repair if necessary. (2)NG

OK

Check the trouble symptoms.

NG

Replace

NG

Check the harness wire between the battery and the SC-ECU,

and repair if necessary.

Check the following connectors:

D-27, D-223

D-31

Measure at SC-ECU connectors E-120, E-121.

DDisconnect the connector and measure at the harness

side.

(1) Voltage between terminal 25 and body earth

(Ignition switch: ON)

OK:

System voltage

(2) Voltage between terminal 39 and body earth

OK:

System voltage

NG (1)NG

Check the harness wire between the SC-ECU and the body

earth, and repair if necessary.

Repair

NG

Replace the SC-ECU.

Check the trouble symptoms.

Check the following connectors:

E-120, E-122

NG

(2), (3)NG

Check the harness wire between the SC-ECU and the body

earth, and repair if necessary.

OK

NG

Repair

NGCheck the trouble symptoms.

Check the following connector:

E-121, E-122

OK

Check the trouble symptoms.

Measure at SC-ECU connector E-120, E-121.

DDisconnect the connector and measure at the harness

side.

(1) Continuity between 31 and body earth

OK:

Continuity

(2) Continuity between 13 and body earth

OK:

Continuity

(3) Continuity between 26 and body earth

OK:

Continuity

Check the trouble symptoms.

Check the fusible link No.2 and dedicated fuse No.7

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 603 of 1839

MITSUBISHI SC-Troubleshooting13E-14

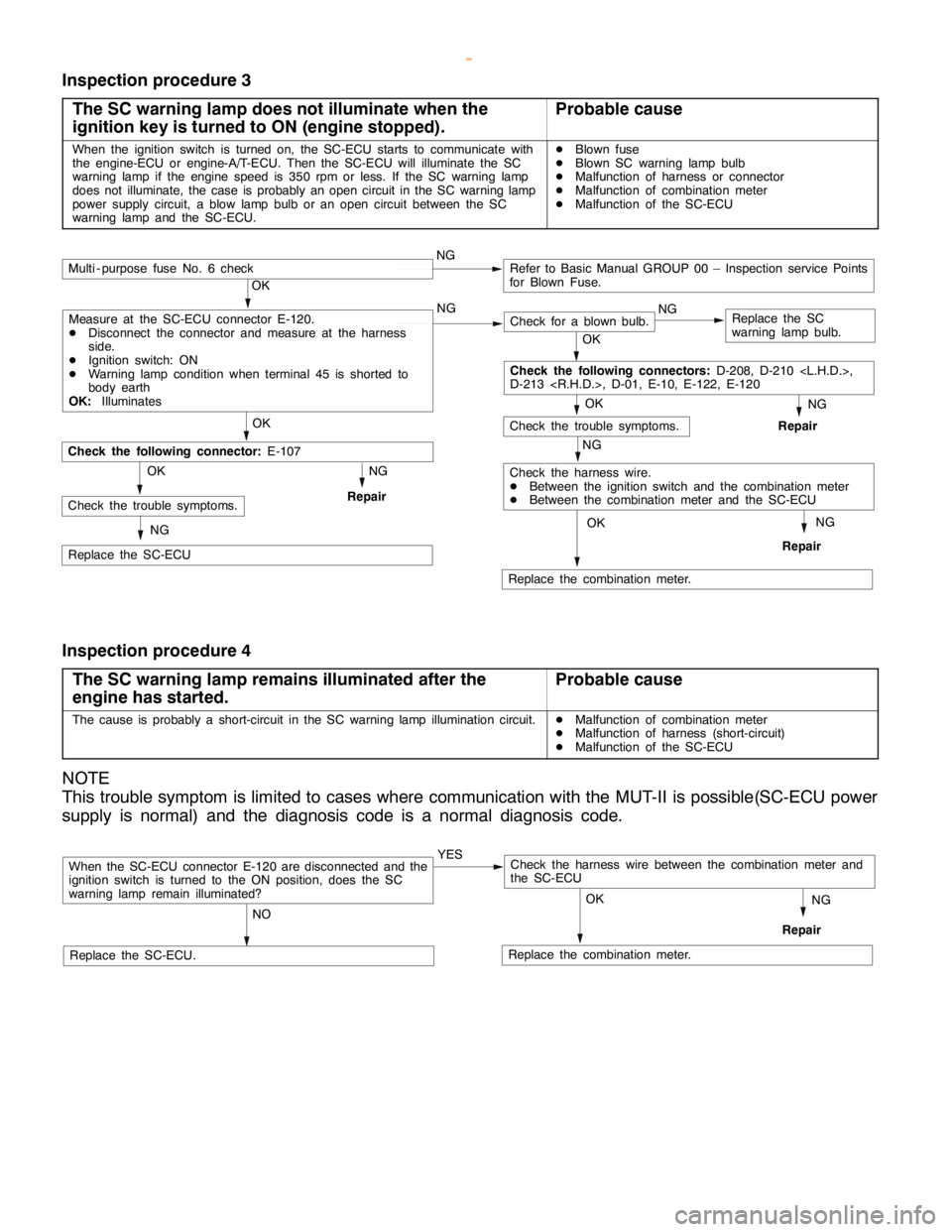

Inspection procedure 3

The SC warning lamp does not illuminate when the

ignition key is turned to ON (engine stopped).

Probable cause

When the ignition switch is turned on, the SC-ECU starts to communicate with

the engine-ECU or engine-A/T-ECU. Then the SC-ECU will illuminate the SC

warning lamp if the engine speed is 350 rpm or less. If the SC warning lamp

does not illuminate, the case is probably an open circuit in the SC warning lamp

power supply circuit, a blow lamp bulb or an open circuit between the SC

warning lamp and the SC-ECU.DBlown fuse

DBlown SC warning lamp bulb

DMalfunction of harness or connector

DMalfunction of combination meter

DMalfunction of the SC-ECU

NG

Replace the combination meter.

NG

Repair

OK

NG

Check for a blown bulb.Replace the SC

warning lamp bulb.

OK

NG

Repair

OK

Check the trouble symptoms.

Multi - purpose fuse No. 6 checkNGRefer to Basic Manual GROUP 00 – Inspection service Points

for Blown Fuse.

NG

Check the harness wire.

DBetween the ignition switch and the combination meter

DBetween the combination meter and the SC-ECU

OK

OK

Replace the SC-ECU

Check the following connector:

E-107

NG

RepairCheck the trouble symptoms.OK

NG

Check the following connectors:

D-208, D-210

D-213

Measure at the SC-ECU connector E-120.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DWarning lamp condition when terminal 45 is shorted to

body earth

OK:

Illuminates

Inspection procedure 4

The SC warning lamp remains illuminated after the

engine has started.

Probable cause

The cause is probably a short-circuit in the SC warning lamp illumination circuit.DMalfunction of combination meter

DMalfunction of harness (short-circuit)

DMalfunction of the SC-ECU

NOTE

This trouble symptom is limited to cases where communication with the MUT-II is possible(SC-ECU power

supply is normal) and the diagnosis code is a normal diagnosis code.

When the SC-ECU connector E-120 are disconnected and the

ignition switch is turned to the ON position, does the SC

warning lamp remain illuminated?YES

NO

Replace the SC-ECU.Replace the combination meter.

NG

Repair

OK

Check the harness wire between the combination meter and

the SC-ECU

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 604 of 1839

MITSUBISHI SC-Troubleshooting13E-15

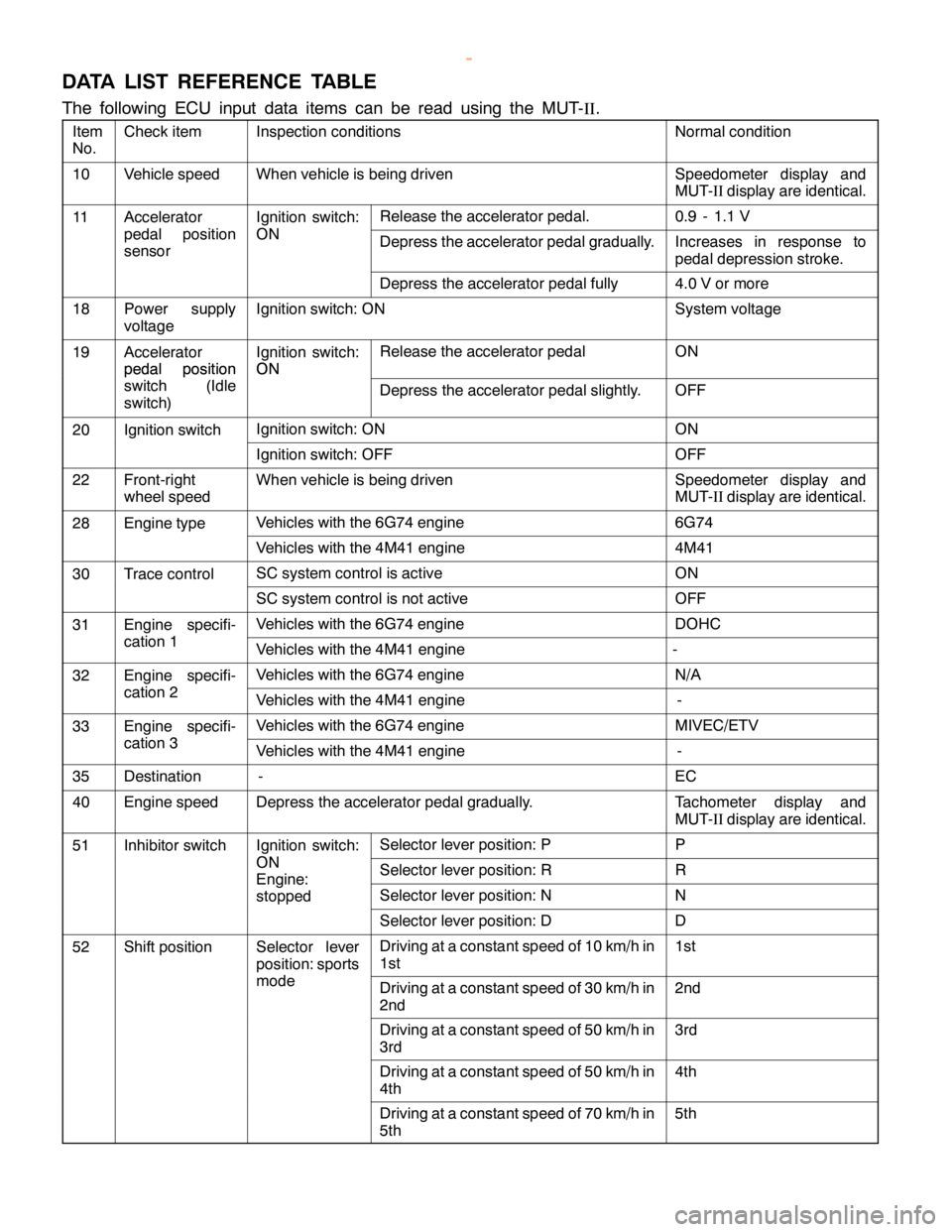

DATA LIST REFERENCE TABLE

The following ECU input data items can be read using the MUT-

II.

Item

No.Check itemInspection conditionsNormal condition

10Vehicle speedWhen vehicle is being drivenSpeedometer display and

MUT-IIdisplay are identical.

11AcceleratorIgnition switch:Release the accelerator pedal.0.9 - 1.1 V

pedal position

sensorONDepress the accelerator pedal gradually.Increases in response to

pedal depression stroke.

Depress the accelerator pedal fully4.0 V or more

18Power supply

voltageIgnition switch: ONSystem voltage

19Accelerator

pedal positionIgnition switch:

ONRelease the accelerator pedalON

pedal position

switch (Idle

switch)ON

Depress the accelerator pedal slightly.OFF

20Ignition switchIgnition switch: ONON

Ignition switch: OFFOFF

22Front-right

wheel speedWhen vehicle is being drivenSpeedometer display and

MUT-IIdisplay are identical.

28Engine typeVehicles with the 6G74 engine6G74

Vehicles with the 4M41 engine4M41

30Trace controlSC system control is activeON

SC system control is not activeOFF

31Engine specifi-Vehicles with the 6G74 engineDOHC

cation 1Vehicles with the 4M41 engine-

32Engine specifi-Vehicles with the 6G74 engineN/A

cation 2Vehicles with the 4M41 engine-

33Engine specifi-Vehicles with the 6G74 engineMIVEC/ETV

cation 3Vehicles with the 4M41 engine-

35Destination-EC

40Engine speedDepress the accelerator pedal gradually.Tachometer display and

MUT-IIdisplay are identical.

51Inhibitor switchIgnition switch:Selector lever position: PP

ONSelector lever position: RREngine:

stopped

Selector lever position: NN

Selector lever position: DD

52Shift positionSelector lever

position: sportsDriving at a constant speed of 10 km/h in

1st1st

modeDriving at a constant speed of 30 km/h in

2nd2nd

Driving at a constant speed of 50 km/h in

3rd3rd

Driving at a constant speed of 50 km/h in

4th4th

Driving at a constant speed of 70 km/h in

5th5th

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 607 of 1839

MITSUBISHI SC-Troubleshooting/On-vehicle Service13E-18

Terminal No.Signal nameNormal condition

Between terminal 13 and body earthEarthContinuity

Between terminal 26 and body earthEarth

Between terminal 31 and body earthEarth

ON-VEHICLE SERVICE

OPERATION TEST OF MITSUBISHI SC

1. Connect the MUT-

IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the LOCK (OFF) position

when connecting and disconnecting the MUT-

II.

2. Move the shift lever to the neutral

lever to the P range.

3. Start the engine.

4. Use the MUT-

IIto activate the Actuator Test (item No.05)

while depressing the accelerator pedal fully. Check that

the engine speed should decrease gradually.

Caution

Activate the Actuator Test for three seconds.

Release the accelerator pedal immediately after the

Actuator Test is complete, or the engine speed will

rise.

NOTE

During the Actuator Test, the SC-ECU transmits the signal,

which requests no torque and wide open throttle, to the

engine-ECU or engine-A/T-ECU for three seconds.

WHEEL SPEED SENSOR (FR) CHECK

Refer to Basic Manual GROUP 35B - On-vehicle service.

VEHICLE SPEED SENSOR CHECK

Refer to Basic Manual GROUP 54A - Combination Meter.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 612 of 1839

DIESEL FUEL <4D5-stepIII>-General/General Information13E-2

GENERAL

OUTLINE OF CHANGE

An electronically-controlled injection pump has been added in order to comply with Regulation STEP

III. Due to this, the following service procedures have been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 619 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-9

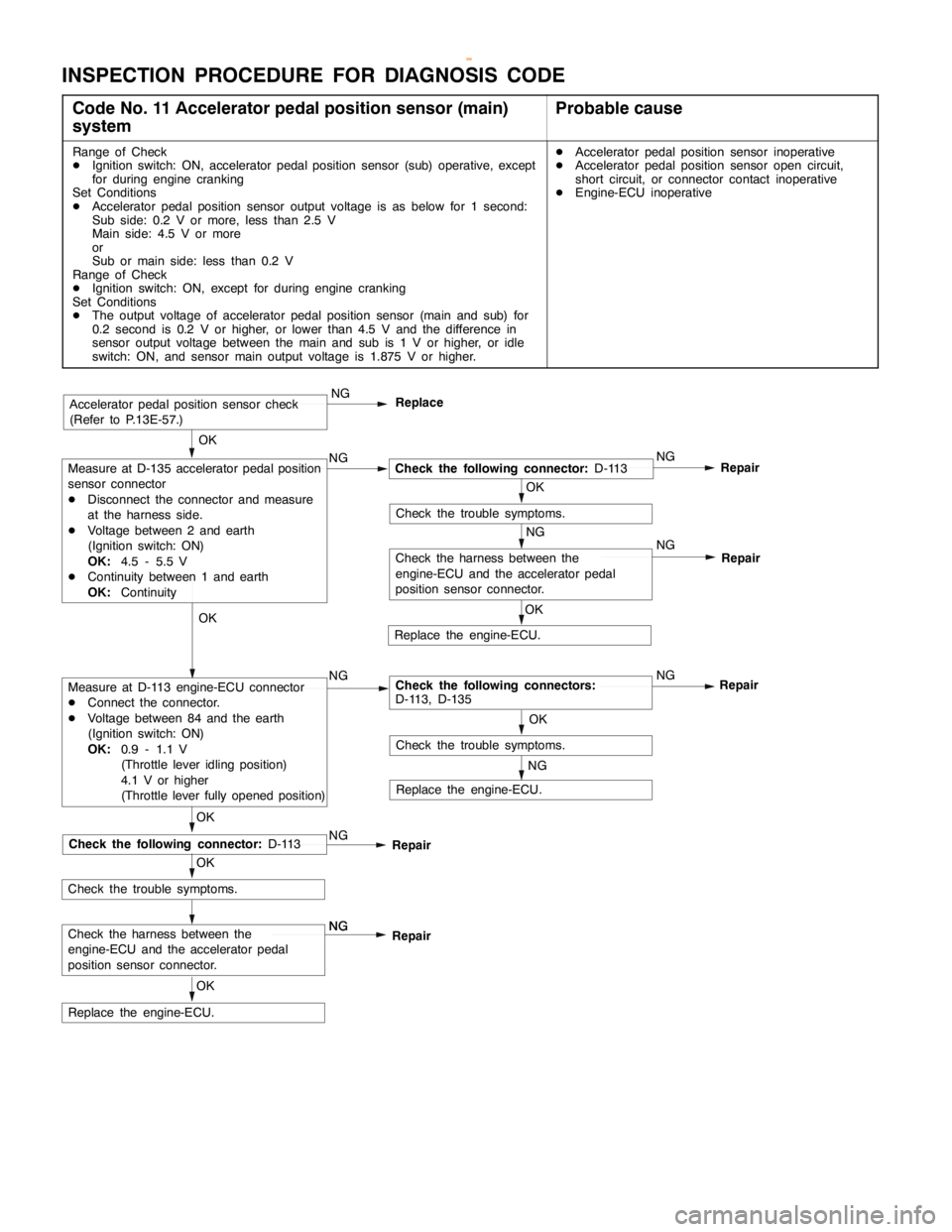

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No. 11 Accelerator pedal position sensor (main)

systemProbable cause

Range of Check

DIgnition switch: ON, accelerator pedal position sensor (sub) operative, except

for during engine cranking

Set Conditions

DAccelerator pedal position sensor output voltage is as below for 1 second:

Sub side: 0.2 V or more, less than 2.5 V

Main side: 4.5 V or more

or

Sub or main side: less than 0.2 V

Range of Check

DIgnition switch: ON, except for during engine cranking

Set Conditions

DThe output voltage of accelerator pedal position sensor (main and sub) for

0.2 second is 0.2 V or higher, or lower than 4.5 V and the difference in

sensor output voltage between the main and sub is 1 V or higher, or idle

switch: ON, and sensor main output voltage is 1.875 V or higher.DAccelerator pedal position sensor inoperative

DAccelerator pedal position sensor open circuit,

short circuit, or connector contact inoperative

DEngine-ECU inoperative

NGOK

OK

Measure at D-135 accelerator pedal position

sensor connector

DDisconnect the connector and measure

at the harness side.

DVoltage between 2 and earth

(Ignition switch: ON)

OK:4.5 - 5.5 V

DContinuity between 1 and earth

OK:ContinuityNGCheck the following connector:D-113NG

Repair

OK

OKRepair

NGAccelerator pedal position sensor check

(Refer to P.13E-57.)Replace

Check the trouble symptoms.

Replace the engine-ECU.NG

Check the trouble symptoms.

NG

Replace the engine-ECU.

NG

RepairCheck the following connectors:

D-113, D-135

OK NG

NG

Check the following connector:D-113NG

Repair

OK

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

OK

Measure at D-113 engine-ECU connector

DConnect the connector.

DVoltage between 84 and the earth

(Ignition switch: ON)

OK:0.9 - 1.1 V

(Throttle lever idling position)

4.1 V or higher

(Throttle lever fully opened position)

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

NG

Repair NG NG

NG

NG

NG

Check the trouble symptoms.

OK

Replace the engine-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 620 of 1839

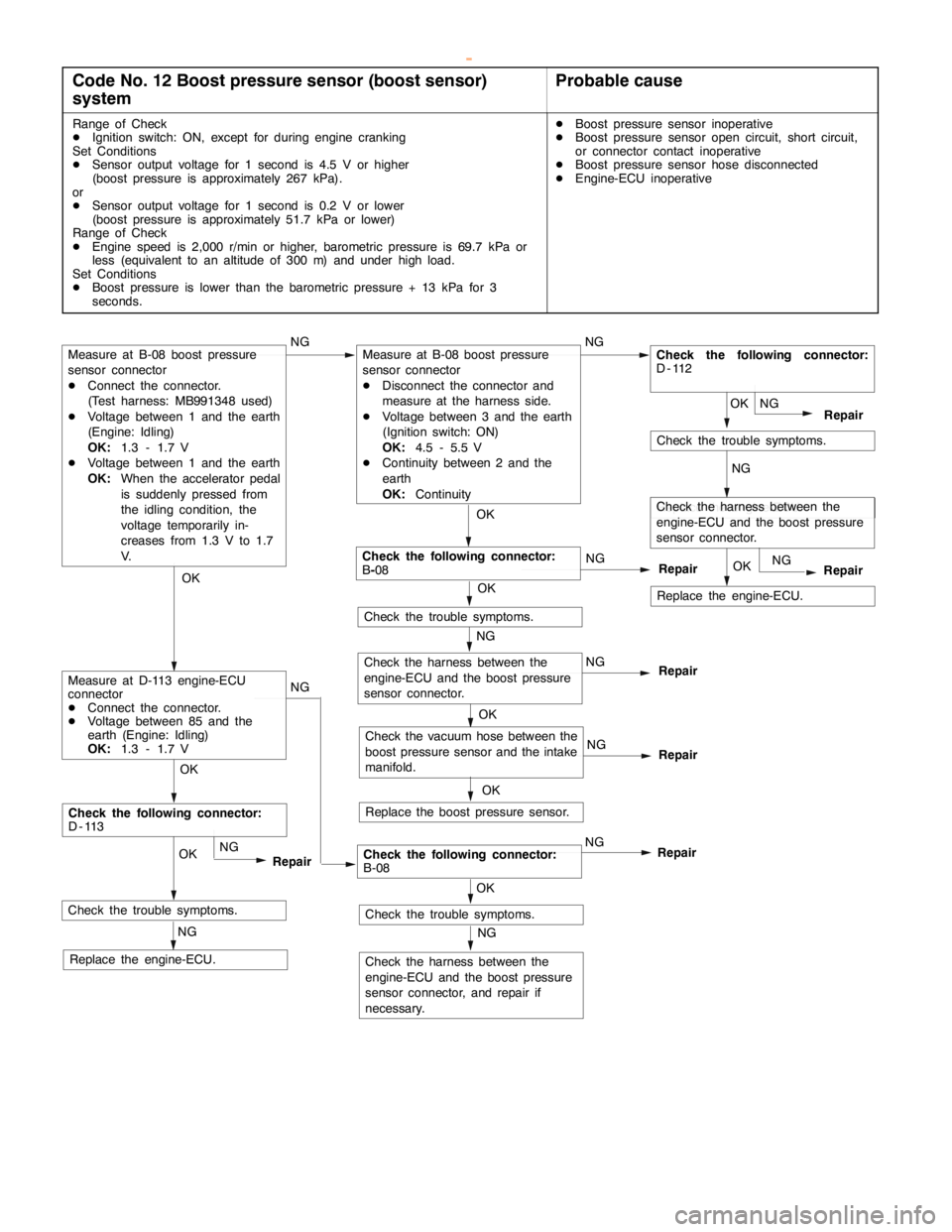

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-10

Code No. 12 Boost pressure sensor (boost sensor)

systemProbable cause

Range of Check

DIgnition switch: ON, except for during engine cranking

Set Conditions

DSensor output voltage for 1 second is 4.5 V or higher

(boost pressure is approximately 267 kPa).

or

DSensor output voltage for 1 second is 0.2 V or lower

(boost pressure is approximately 51.7 kPa or lower)

Range of Check

DEngine speed is 2,000 r/min or higher, barometric pressure is 69.7 kPa or

less (equivalent to an altitude of 300 m) and under high load.

Set Conditions

DBoost pressure is lower than the barometric pressure + 13 kPa for 3

seconds.DBoost pressure sensor inoperative

DBoost pressure sensor open circuit, short circuit,

or connector contact inoperative

DBoost pressure sensor hose disconnected

DEngine-ECU inoperative

NG

Check the trouble symptoms.

Replace the engine-ECU.

Check the following connector:

D-113

NGOK

NG

Repair

RepairOK

NG

Check the trouble symptoms.

OKOK

OK

Check the following connector:

B-08NG

Check the trouble symptoms. NG

Repair

NG

NG

Check the vacuum hose between the

boost pressure sensor and the intake

manifold.

Replace the boost pressure sensor.

OK OK OK

Repair

NG

Repair

Check the trouble symptoms.

Check the harness between the

engine-ECU and the boost pressure

sensor connector, and repair if

necessary.

NG OK

NG

RepairCheck the following connector:

B-08NG

Measure at B-08 boost pressure

sensor connector

DConnect the connector.

(Test harness: MB991348 used)

DVoltage between 1 and the earth

(Engine: Idling)

OK:1.3 - 1.7 V

DVoltage between 1 and the earth

OK:When the accelerator pedal

is suddenly pressed from

the idling condition, the

voltage temporarily in-

creases from 1.3 V to 1.7

V.

Measure at D-113 engine-ECU

connector

DConnect the connector.

DVoltage between 85 and the

earth (Engine: Idling)

OK:1.3 - 1.7 V

Check the harness between the

engine-ECU and the boost pressure

sensor connector.

Measure at B-08 boost pressure

sensor connector

DDisconnect the connector and

measure at the harness side.

DVoltage between 3 and the earth

(Ignition switch: ON)

OK:4.5 - 5.5 V

DContinuity between 2 and the

earth

OK:Continuity

Replace the engine-ECU.NGCheck the harness between the

engine-ECU and the boost pressure

sensor connector.

Replace the engine-ECU.OK

NG

Repair

Check the following connector:

D-112

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 621 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-11

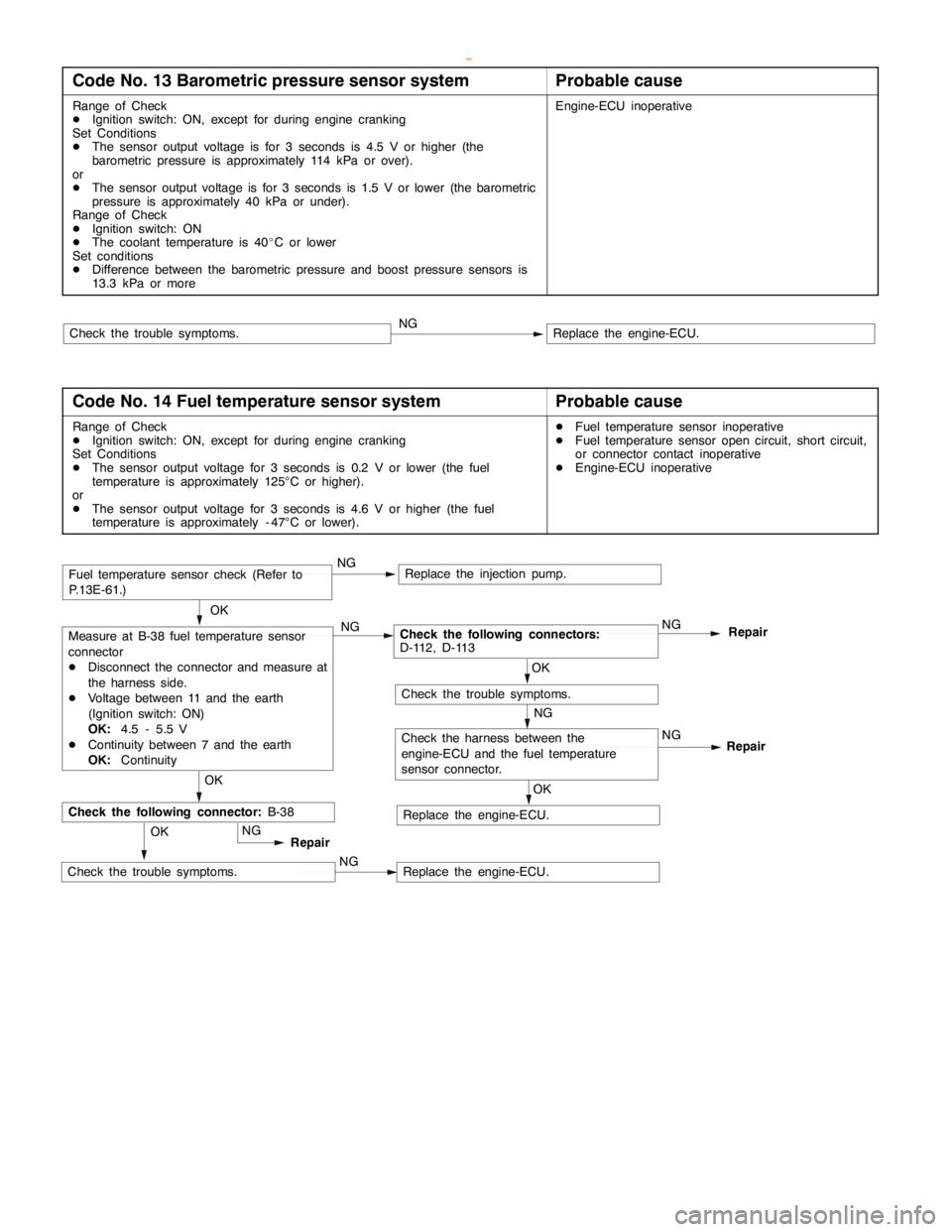

Code No. 13 Barometric pressure sensor systemProbable cause

Range of Check

DIgnition switch: ON, except for during engine cranking

Set Conditions

DThe sensor output voltage is for 3 seconds is 4.5 V or higher (the

barometric pressure is approximately 114 kPa or over).

or

DThe sensor output voltage is for 3 seconds is 1.5 V or lower (the barometric

pressure is approximately 40 kPa or under).

Range of Check

DIgnition switch: ON

DThe coolant temperature is 40_C or lower

Set conditions

DDifference between the barometric pressure and boost pressure sensors is

13.3 kPa or moreEngine-ECU inoperative

Replace the engine-ECU.NGCheck the trouble symptoms.

Code No. 14 Fuel temperature sensor systemProbable cause

Range of Check

DIgnition switch: ON, except for during engine cranking

Set Conditions

DThe sensor output voltage for 3 seconds is 0.2 V or lower (the fuel

temperature is approximately 125°C or higher).

or

DThe sensor output voltage for 3 seconds is 4.6 V or higher (the fuel

temperature is approximately - 47°C or lower).DFuel temperature sensor inoperative

DFuel temperature sensor open circuit, short circuit,

or connector contact inoperative

DEngine-ECU inoperative

OK

Measure at B-38 fuel temperature sensor

connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 11 and the earth

(Ignition switch: ON)

OK:4.5 - 5.5 V

DContinuity between 7 and the earth

OK:ContinuityNGCheck the following connectors:

D-112, D-113NG

Repair

OK

OK

Check the harness between the

engine-ECU and the fuel temperature

sensor connector.Repair

NG

Check the trouble symptoms.

Replace the engine-ECU.NG

Replace the engine-ECU.OKNG

Replace the injection pump.

OK

Repair

Check the following connector:B-38

NG

NGCheck the trouble symptoms.

Fuel temperature sensor check (Refer to

P.13E-61.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 622 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-12

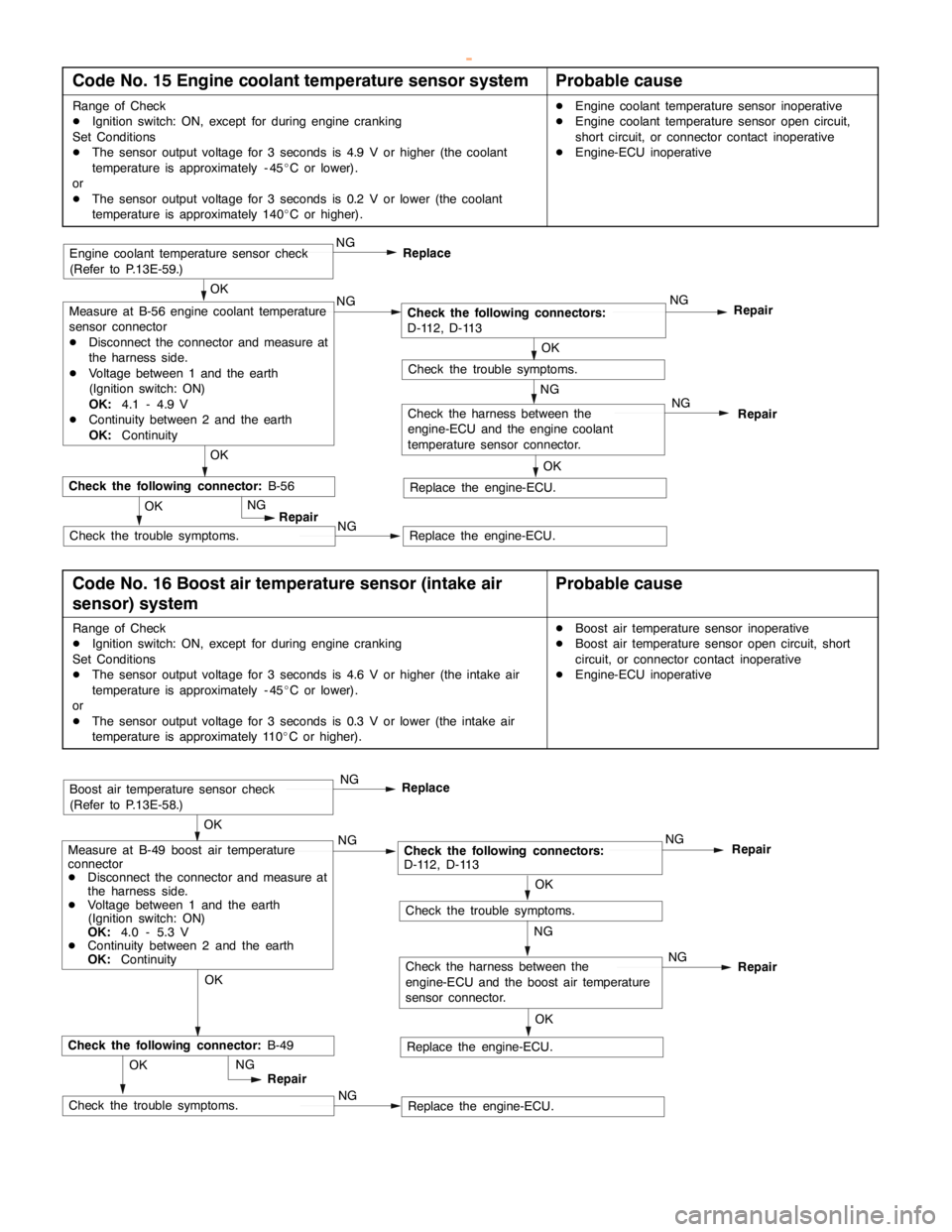

Code No. 15 Engine coolant temperature sensor systemProbable cause

Range of Check

DIgnition switch: ON, except for during engine cranking

Set Conditions

DThe sensor output voltage for 3 seconds is 4.9 V or higher (the coolant

temperature is approximately - 45_C or lower).

or

DThe sensor output voltage for 3 seconds is 0.2 V or lower (the coolant

temperature is approximately 140_C or higher).DEngine coolant temperature sensor inoperative

DEngine coolant temperature sensor open circuit,

short circuit, or connector contact inoperative

DEngine-ECU inoperative

OK

NGNG

Repair

OK

OKRepair

NGEngine coolant temperature sensor check

(Refer to P.13E-59.)

Replace the engine-ECU.NG

Replace the engine-ECU.OK NG

OK

Repair

Check the following connector:B-56

NGCheck the trouble symptoms.NG

Measure at B-56 engine coolant temperature

sensor connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:4.1 - 4.9 V

DContinuity between 2 and the earth

OK:ContinuityCheck the following connectors:

D-112, D-113

Check the harness between the

engine-ECU and the engine coolant

temperature sensor connector.

Check the trouble symptoms. Replace

Code No. 16 Boost air temperature sensor (intake air

sensor) systemProbable cause

Range of Check

DIgnition switch: ON, except for during engine cranking

Set Conditions

DThe sensor output voltage for 3 seconds is 4.6 V or higher (the intake air

temperature is approximately - 45_C or lower).

or

DThe sensor output voltage for 3 seconds is 0.3 V or lower (the intake air

temperature is approximately 110_C or higher).DBoost air temperature sensor inoperative

DBoost air temperature sensor open circuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

OK

Measure at B-49 boost air temperature

connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:4.0 - 5.3 V

DContinuity between 2 and the earth

OK:ContinuityNGCheck the following connectors:

D-112, D-113NG

Repair

OK

OKRepair

NGBoost air temperature sensor check

(Refer to P.13E-58.)

Check the trouble symptoms.

Replace the engine-ECU.NG

Replace the engine-ECU.OK NG

OK

Repair

Check the following connector:B-49Replace

NGCheck the trouble symptoms.NG

Check the harness between the

engine-ECU and the boost air temperature

sensor connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk