ABS MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1176 of 1839

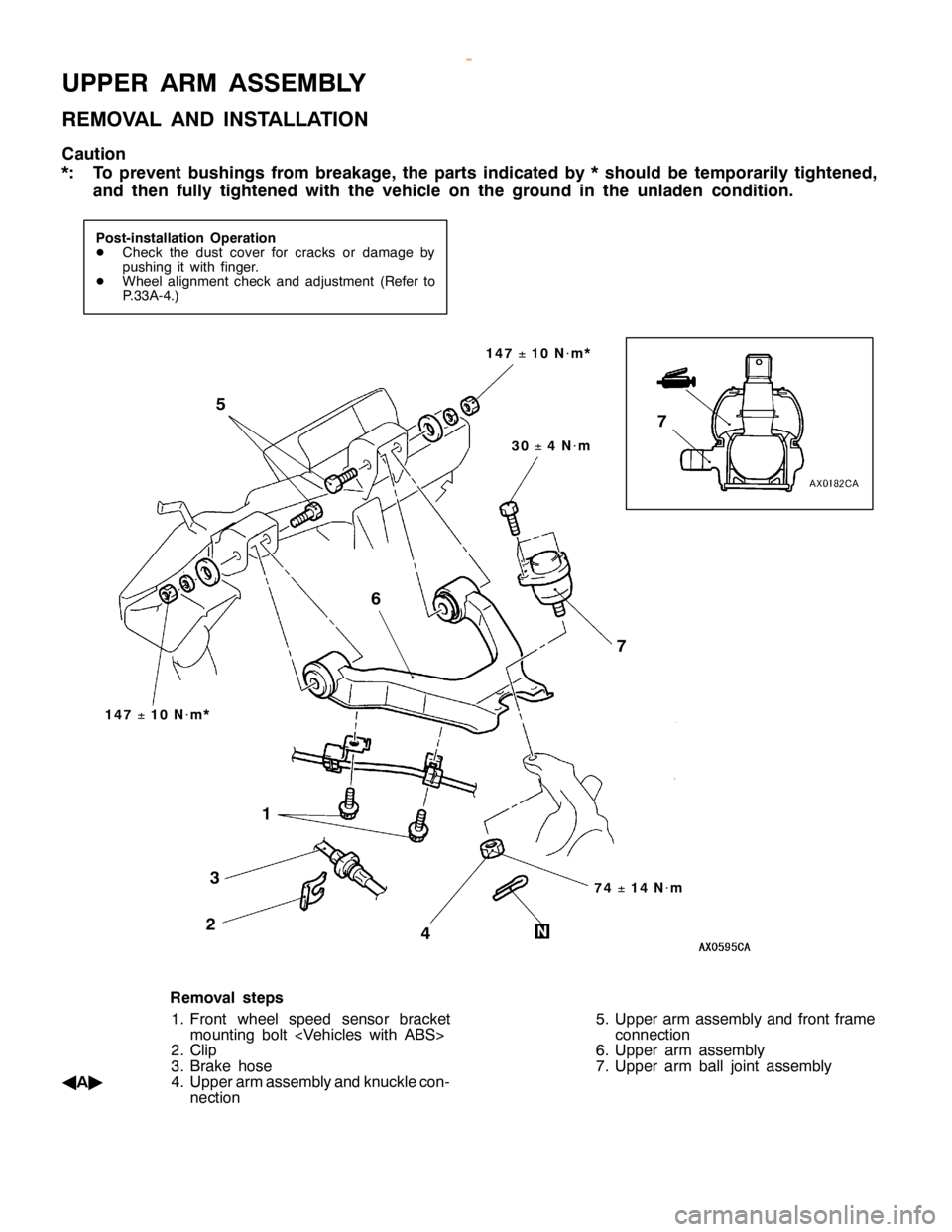

U

PPER ARM ASSEM BLY

R EM OVA L AND IN STA LLA TIO N

C au tio n

* : To pre ven t bush in gs fr o m bre akag e, th e parts in dic ate d by *sh ould be te m pora rily tig hte n ed ,

a n d th en fu lly tig hte n ed wit h th e veh ic le on th e gro und in th e unla d en co ndit io n. 3

2 15

6

71

47 ±

10 N×

m * 3

0 ±

4 N×

m

R em oval ste p s

1 . Fro nt wheel sp eed se nso r bra cke t

m ountin g bolt

2 . C lip

3 . B ra ke hose

A A"

4. U ppera rm asse m bly and kn uckle co n-

n ectio n 5

. U pper arm asse m bly and fr o nt fr a m e

c o nnectio n

6 . U pper arm asse m bly

7 . U pper arm ball jo in t asse m bly

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1179 of 1839

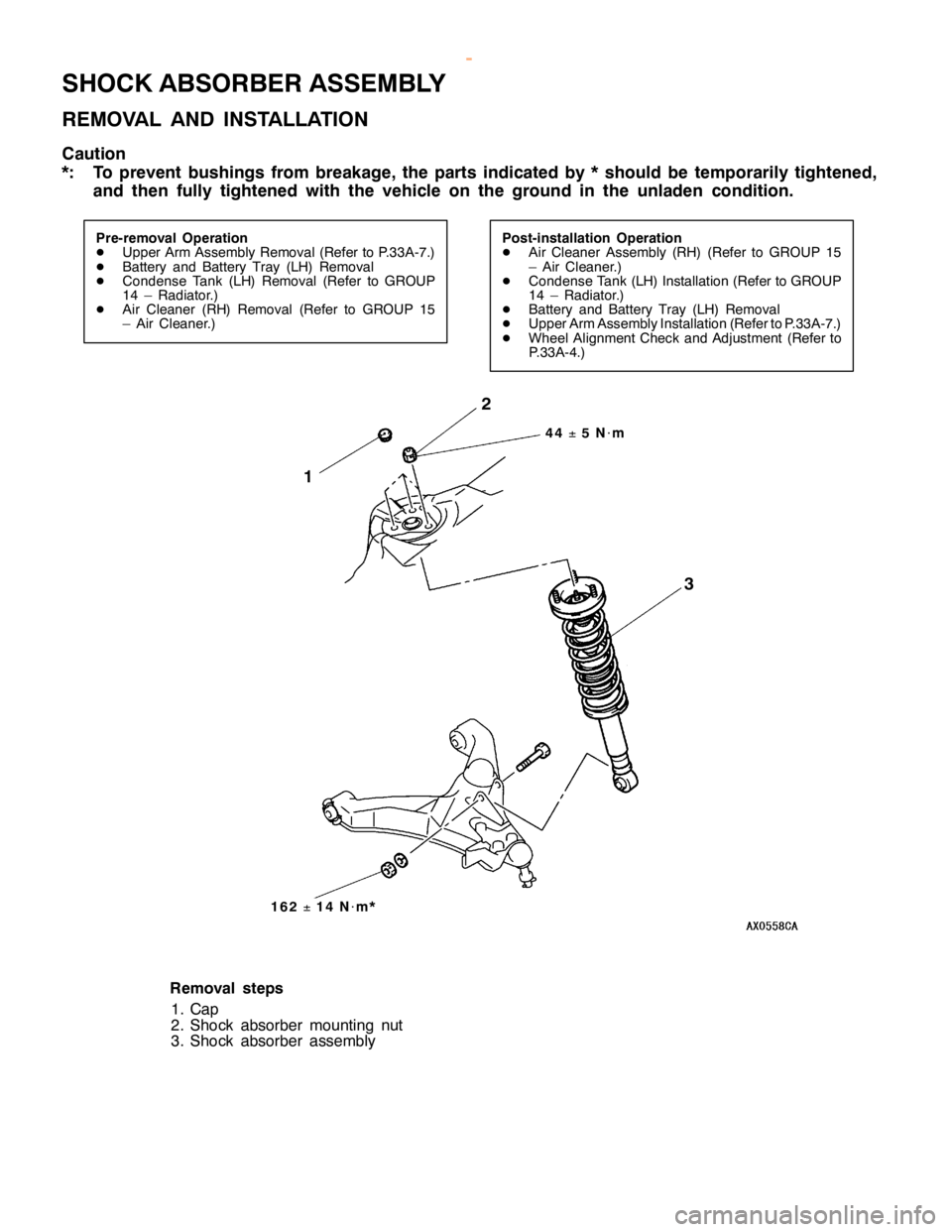

S

H O CK ABSO RBER ASSEM BLY

R EM OVA L AND IN STA LLA TIO N

C au tio n

* : To pre ven t bush in gs fr o m bre akag e, th e parts in dic ate d by *sh ould be te m pora rily tig hte n ed ,

a n d th en fu lly tig hte n ed wit h th e veh ic le on th e gro und in th e unla d en co ndit io n. 2

1

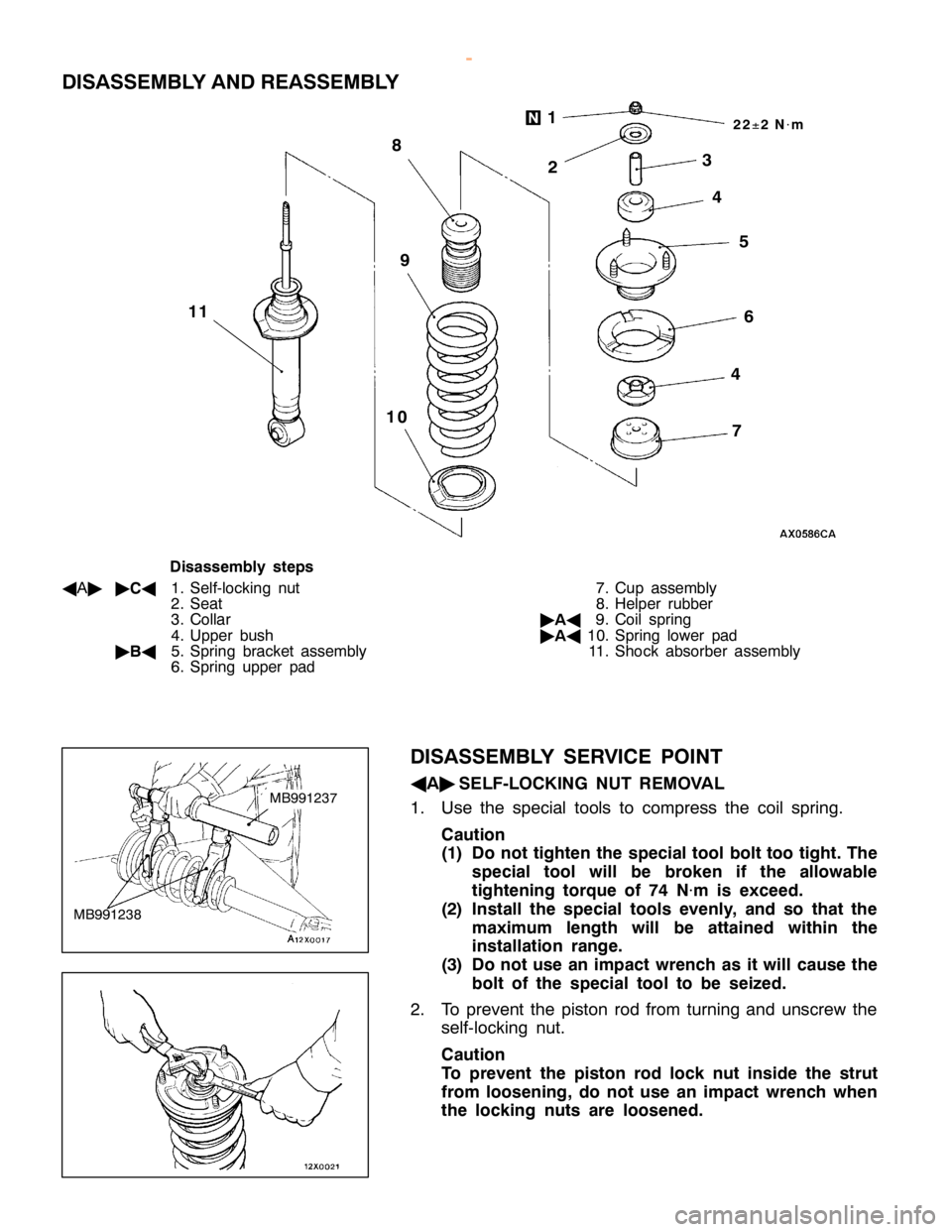

Page 1180 of 1839

3

21

5

6

78

9

1

0 1

1 4

D is assem bly ste p s

A A" "

CA

1. S elf - lo ckin g nut

2 . S eat

3 . C olla r

4 . U pper bush

" BA

5. S prin g bra cke t asse m bly

6 . S prin g upper pad 7

. C up asse m bly

8 . H elp er ru bber

" AA

9. C oil sp rin g

" AA

10. S prin g lo w er pad

1 1 . S hock abso rb er asse m bly

D IS A SSEM BLY SER VIC E PO IN T

A A"

SELF-L O CKIN G NUT REM OVA L

1 . Use th e sp ecia l to ols to co m pre ss th e co il sp rin g.

C au tio n

( 1 ) Do not tig hte n th e sp ecia l to ol bolt to o tig ht. T he

s p ecia l to ol will be bro ken if th e allo w ab le

t ig hte n in g to rq ue of 74 N×

m is exceed .

( 2 ) In sta ll th e sp ecia l to ols even ly , an d so th at th e

m axim um le n gth will be atta in ed wit h in th e

i n sta lla tio n ra n ge.

( 3 ) Do not use an im pact w re n ch as it w ill cau se th e

b olt of th e sp ecia l to ol to be seiz e d .

2 . To pre ve nt th e pis to n ro d fr o m tu rn in g and unscre w th e

s e lf - lo ckin g nut.

C au tio n

T o pre ven t th e pis to n ro d lo ck nut in sid e th e str u t

f r o m lo osen in g, do not use an im pact w re n ch when

t h e lo ckin g nuts are lo osen ed . M

B991237

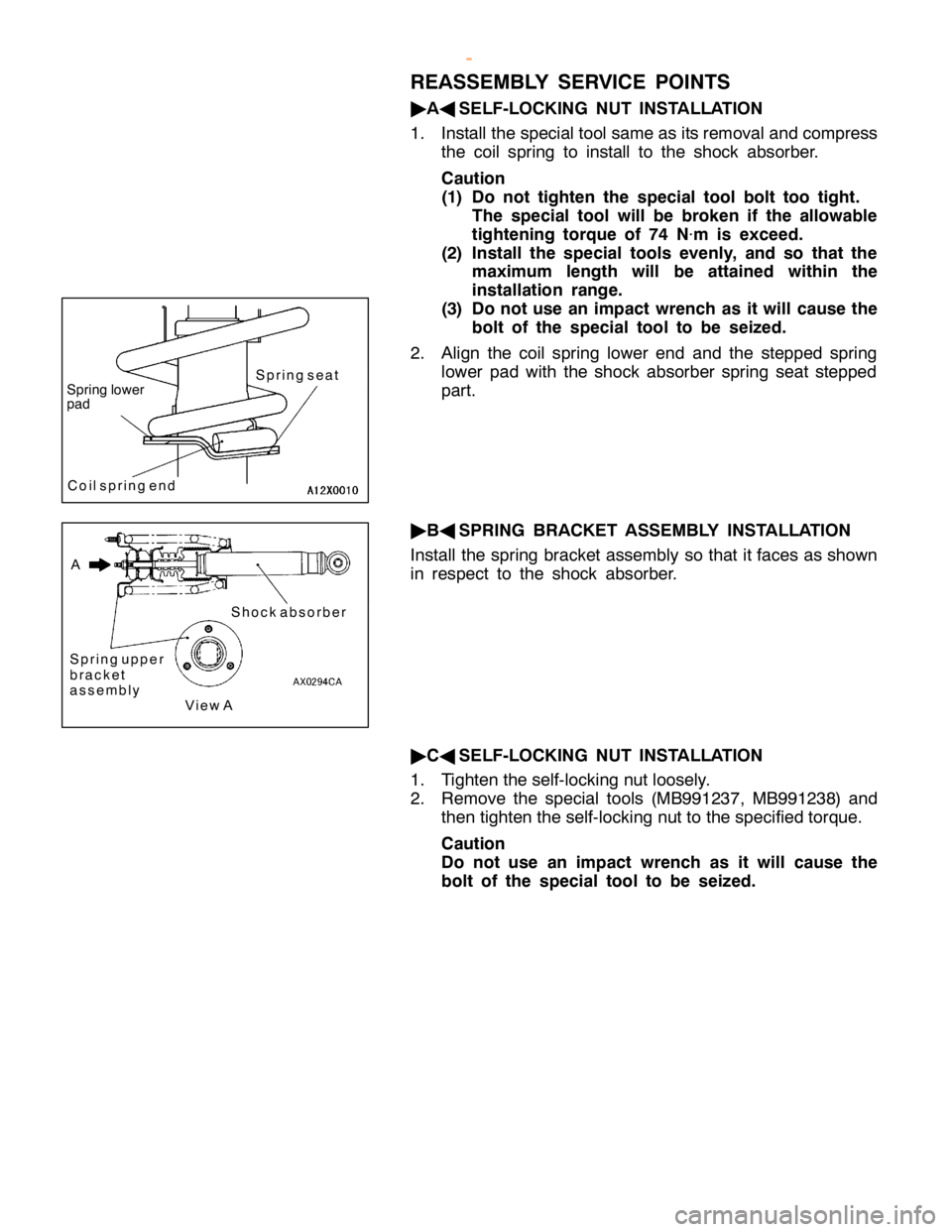

Page 1181 of 1839

S

prin g lo w er

p ad C

oil s p rin g end S

prin g upper

b ra cke t

a sse m bly V

ie w A A

S

hock abso rb er

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1182 of 1839

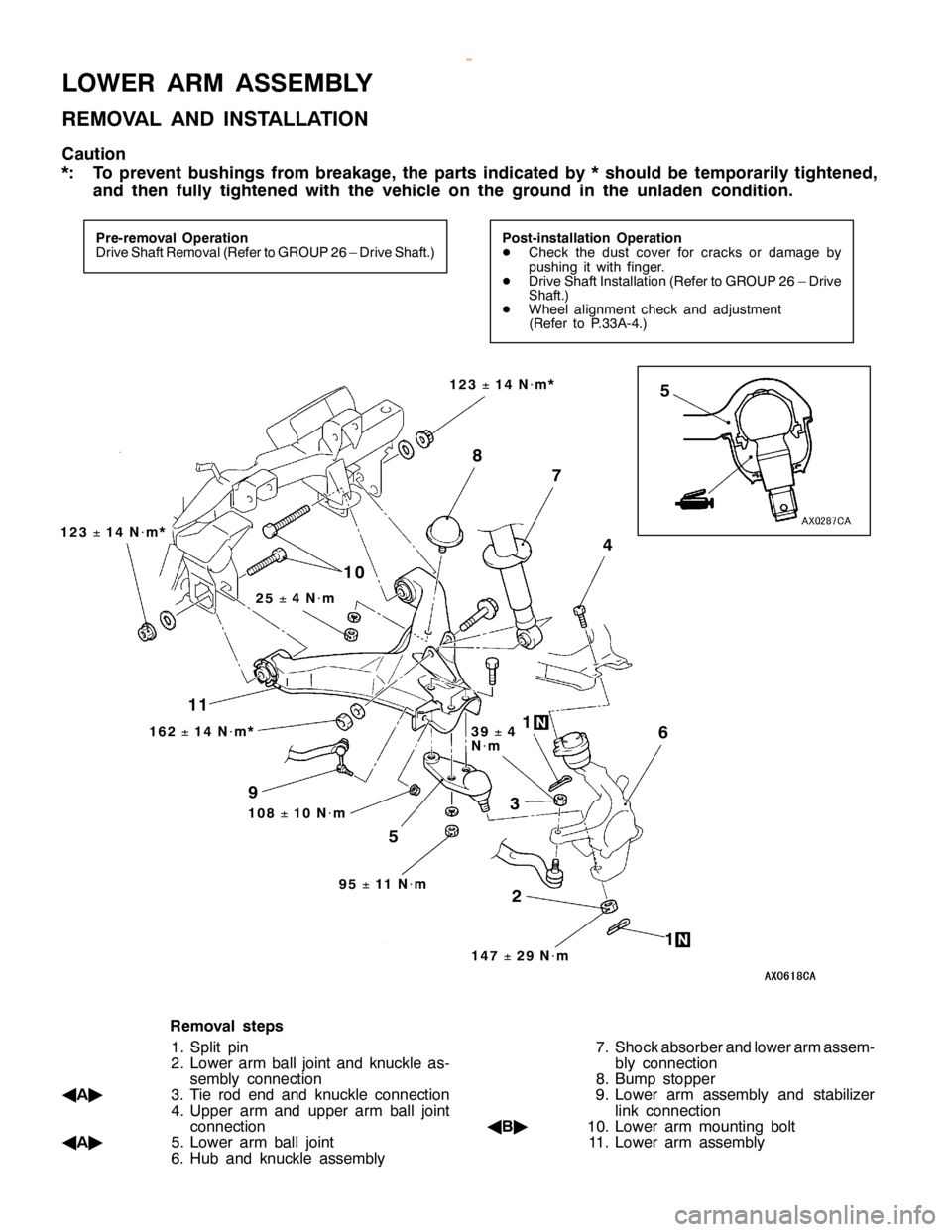

L

O W ER ARM ASSEM BLY

R EM OVA L AND IN STA LLA TIO N

C au tio n

* : To pre ven t bush in gs fr o m bre akag e, th e parts in dic ate d by *sh ould be te m pora rily tig hte n ed ,

a n d th en fu lly tig hte n ed wit h th e veh ic le on th e gro und in th e unla d en co ndit io n. 7

4

2

5

±4

N

×m 1

0 5 6

2 5

R em oval ste p s

1 . S plit pin

2 . Low er arm ball jo in t and kn uckle as-

s e m bly co nnectio n

A A"

3. Tie ro d end and kn uckle co nnectio n

4 . U pper arm and upper arm ball jo in t

c o nnectio n

A A"

5. Low er arm ball jo in t

6 . H ub and kn uckle asse m bly 7

. S hock abso rb era nd lo w era rm asse m -

b ly co nnectio n

8 . B um p sto pper

9 . Low er arm asse m bly and sta biliz e r

l in k co nnectio n

A B"

10. Low er arm mountin g bolt

1 1 . Low er arm asse m bly

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

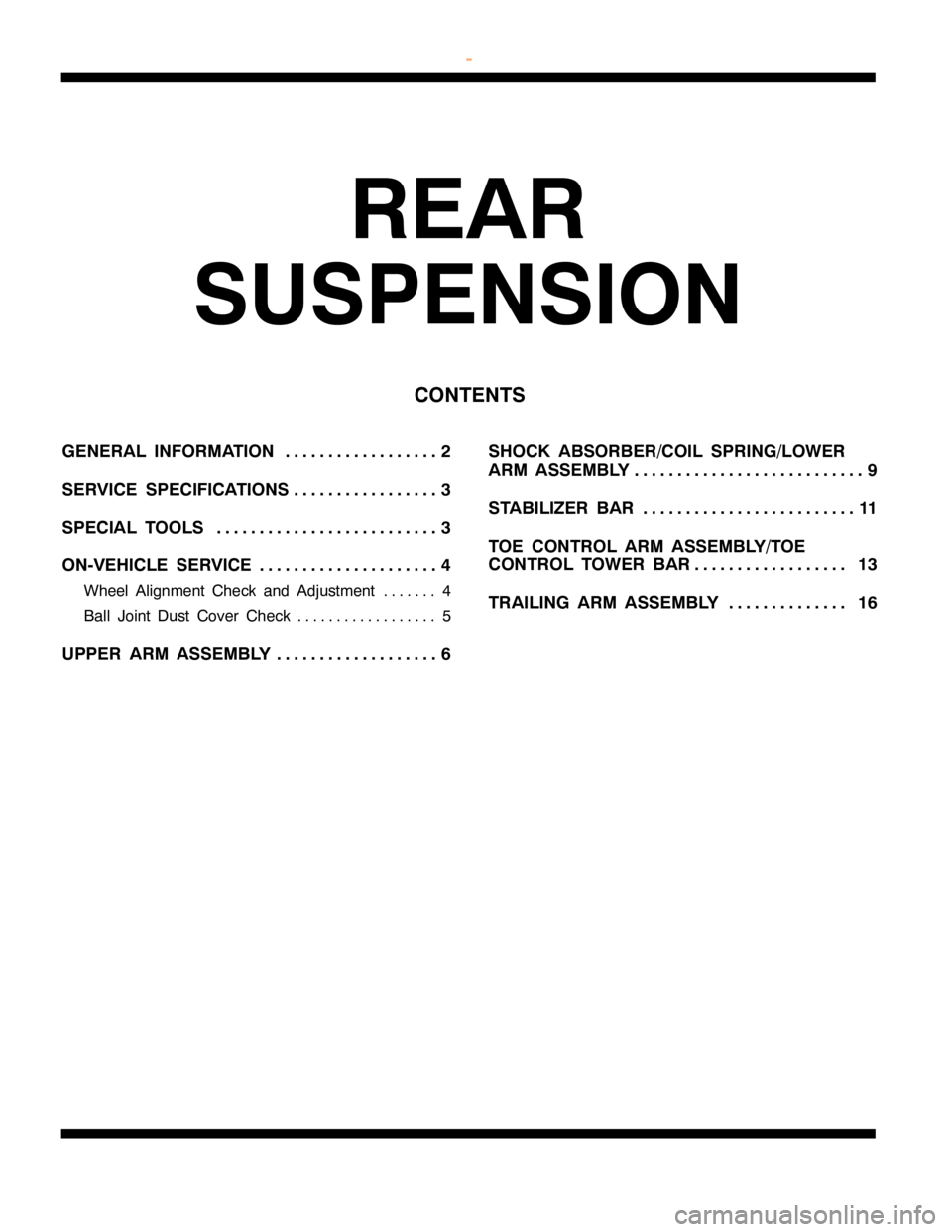

Page 1189 of 1839

34-1

REAR

SUSPENSION

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 4.....................

Wheel Alignment Check and Adjustment 4.......

Ball Joint Dust Cover Check 5..................

UPPER ARM ASSEMBLY 6...................SHOCK ABSORBER/COIL SPRING/LOWER

ARM ASSEMBLY 9...........................

STABILIZER BAR 11.........................

TOE CONTROL ARM ASSEMBLY/TOE

CONTROL TOWER BAR 13..................

TRAILING ARM ASSEMBLY 16..............

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1197 of 1839

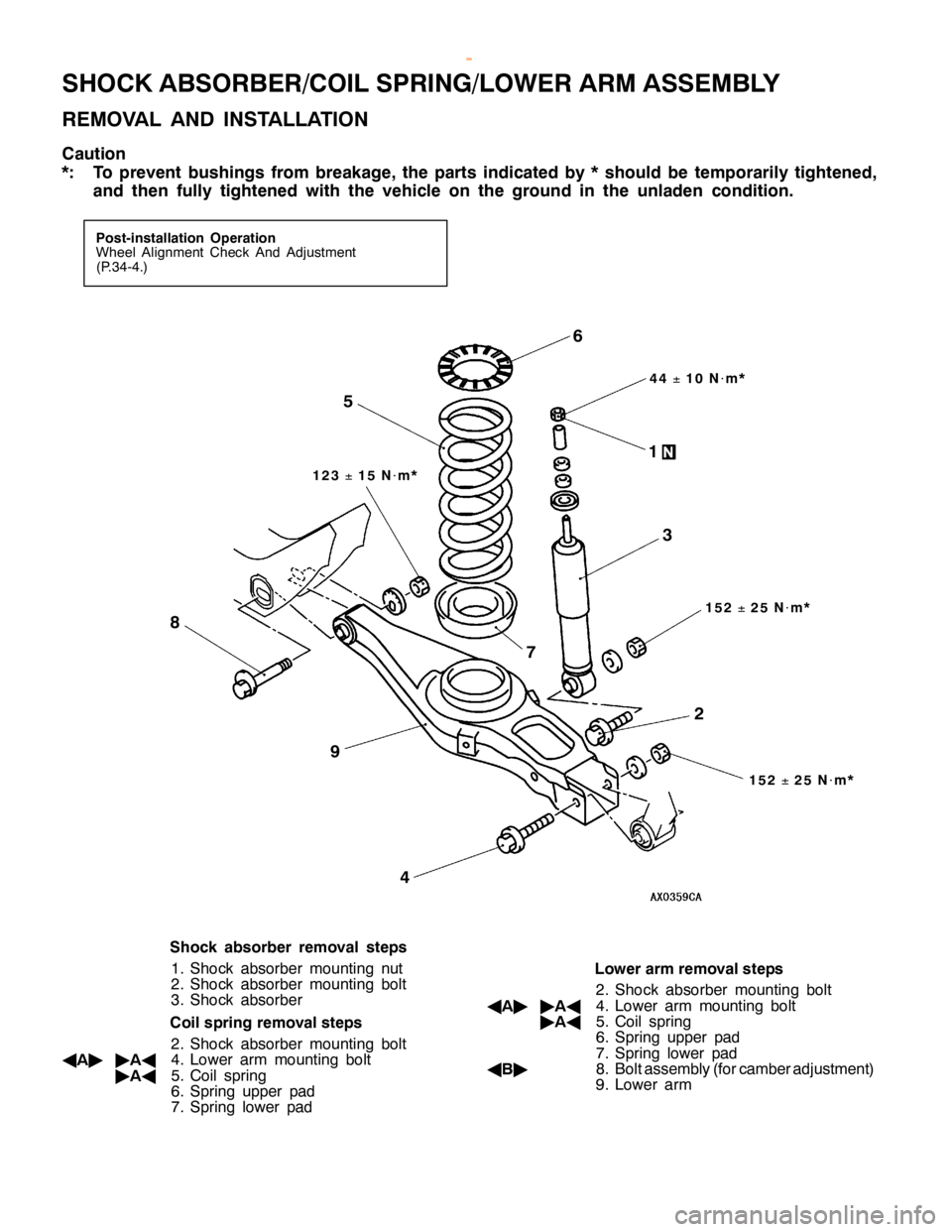

S

H O CK ABSO RBER /C O IL SPR IN G /L O W ER ARM ASSEM BLY

R EM OVA L AND IN STA LLA TIO N

C au tio n

* : To pre ven t bush in gs fr o m bre akag e, th e parts in dic ate d by *sh ould be te m pora rily tig hte n ed ,

a n d th en fu lly tig hte n ed wit h th e veh ic le on th e gro und in th e unla d en co ndit io n. 15

1

52 ±

25 N×

m * 9

48

7

S hock ab so rb er re m oval ste p s

1 . S hock abso rb er m ountin g nut

2 . S hock abso rb er m ountin g bolt

3 . S hock abso rb er

C oil sp rin g re m oval ste p s

2 . S hock abso rb er m ountin g bolt

A A"

"

AA

4. Low er arm mountin g bolt

" AA

5. C oil sp rin g

6 . S prin g upper pad

7 . S prin g lo w er pad L

ow er arm re m oval ste p s

2 . S hock abso rb er m ountin g bolt

A A"

"

AA

4. Low er arm mountin g bolt

" AA

5. C oil sp rin g

6 . S prin g upper pad

7 . S prin g lo w er pad

A B"

8. B olt a sse m bly (fo rca m bera dju stm ent)

9 . Low er arm

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

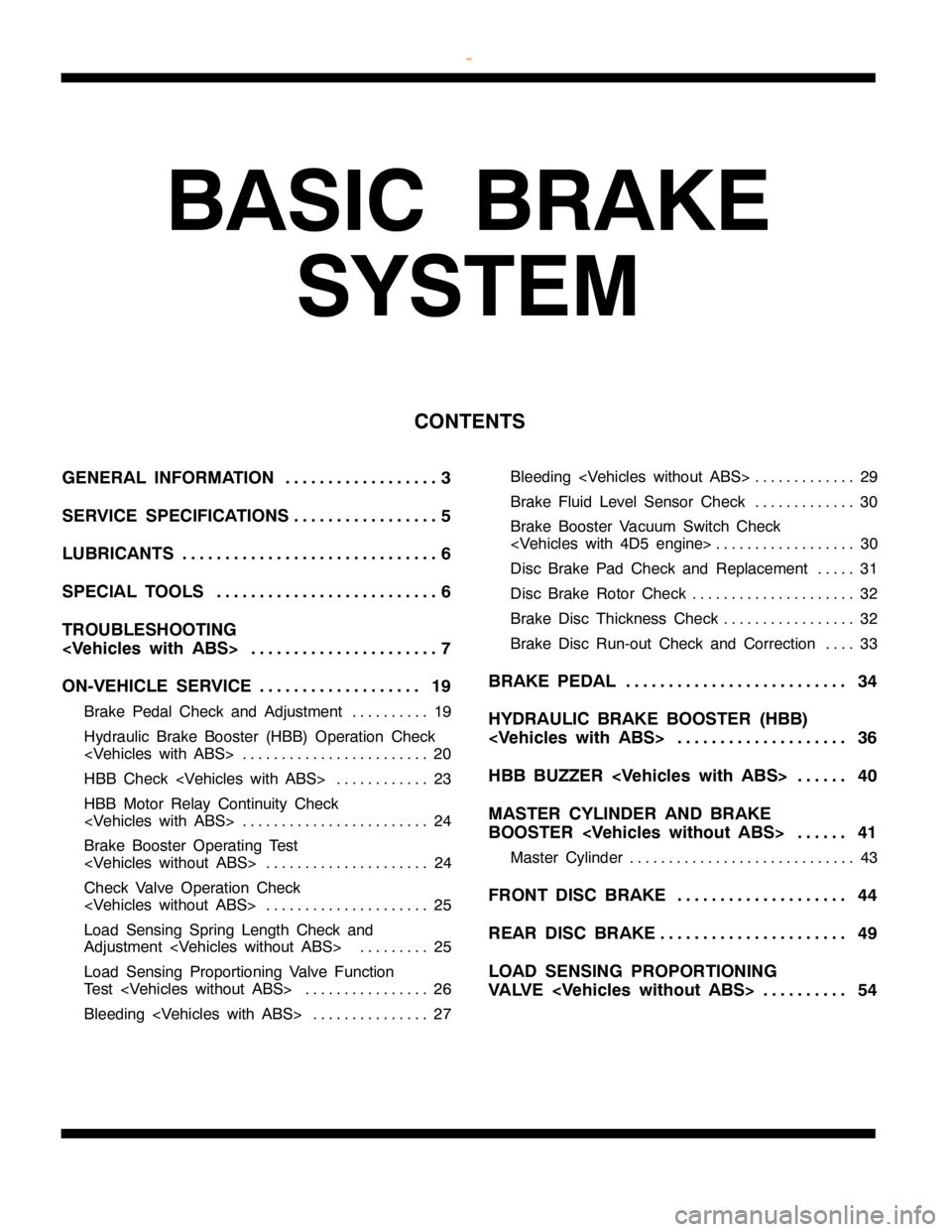

Page 1210 of 1839

35A-2

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 6..............................

SPECIAL TOOLS 6..........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 19...................

Brake Pedal Check and Adjustment 19..........

Hydraulic Brake Booster (HBB) Operation Check

HBB Check

HBB Motor Relay Continuity Check

Brake Booster Operating Test

Check Valve Operation Check

Load Sensing Spring Length Check and

Adjustment

Load Sensing Proportioning Valve Function

Test

Bleeding

Brake Fluid Level Sensor Check 30.............

Brake Booster Vacuum Switch Check

Disc Brake Pad Check and Replacement 31.....

Disc Brake Rotor Check 32.....................

Brake Disc Thickness Check 32.................

Brake Disc Run-out Check and Correction 33....

BRAKE PEDAL 34..........................

HYDRAULIC BRAKE BOOSTER (HBB)

HBB BUZZER

MASTER CYLINDER AND BRAKE

BOOSTER

Master Cylinder 43.............................

FRONT DISC BRAKE 44....................

REAR DISC BRAKE 49......................

LOAD SENSING PROPORTIONING

VALVE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1211 of 1839

BASIC BRAKE SYSTEM -General Information35A-3

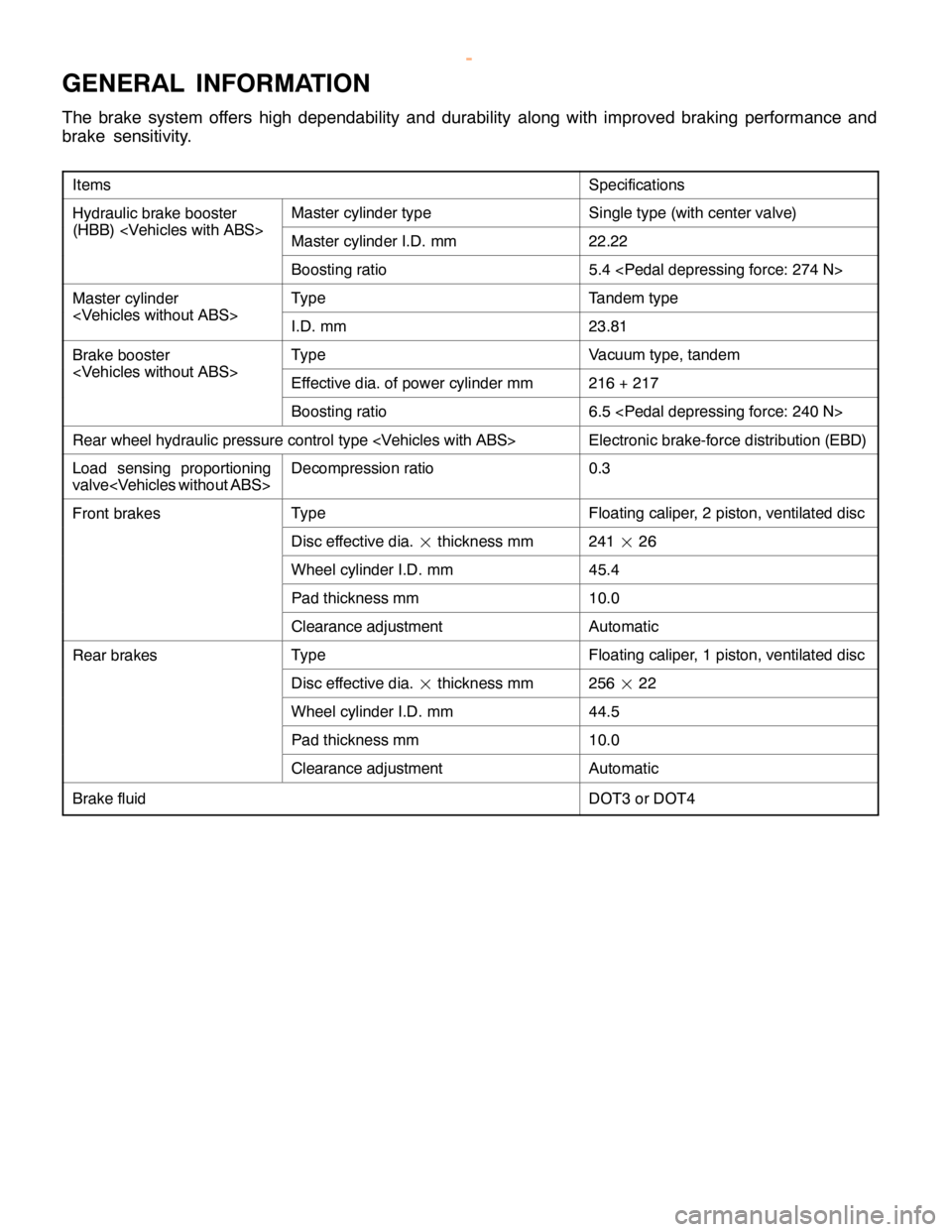

GENERAL INFORMATION

The brake system offers high dependability and durability along with improved braking performance and

brake sensitivity.

ItemsSpecifications

Hydraulic brake boosterMaster cylinder typeSingle type (with center valve)

(HBB)

Boosting ratio5.4

Master cylinderTypeTandem type

Brake boosterTypeVacuum type, tandem

Boosting ratio6.5

Rear wheel hydraulic pressure control type

Load sensing proportioning

valve

Front brakesTypeFloating caliper, 2 piston, ventilated disc

Disc effective dia.¢

thickness mm241¢

26

Wheel cylinder I.D. mm45.4

Pad thickness mm10.0

Clearance adjustmentAutomatic

Rear brakesTypeFloating caliper, 1 piston, ventilated disc

Disc effective dia.¢

thickness mm256¢

22

Wheel cylinder I.D. mm44.5

Pad thickness mm10.0

Clearance adjustmentAutomatic

Brake fluidDOT3 or DOT4

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1213 of 1839

BASIC BRAKE SYSTEM -Service Specifications35A-5

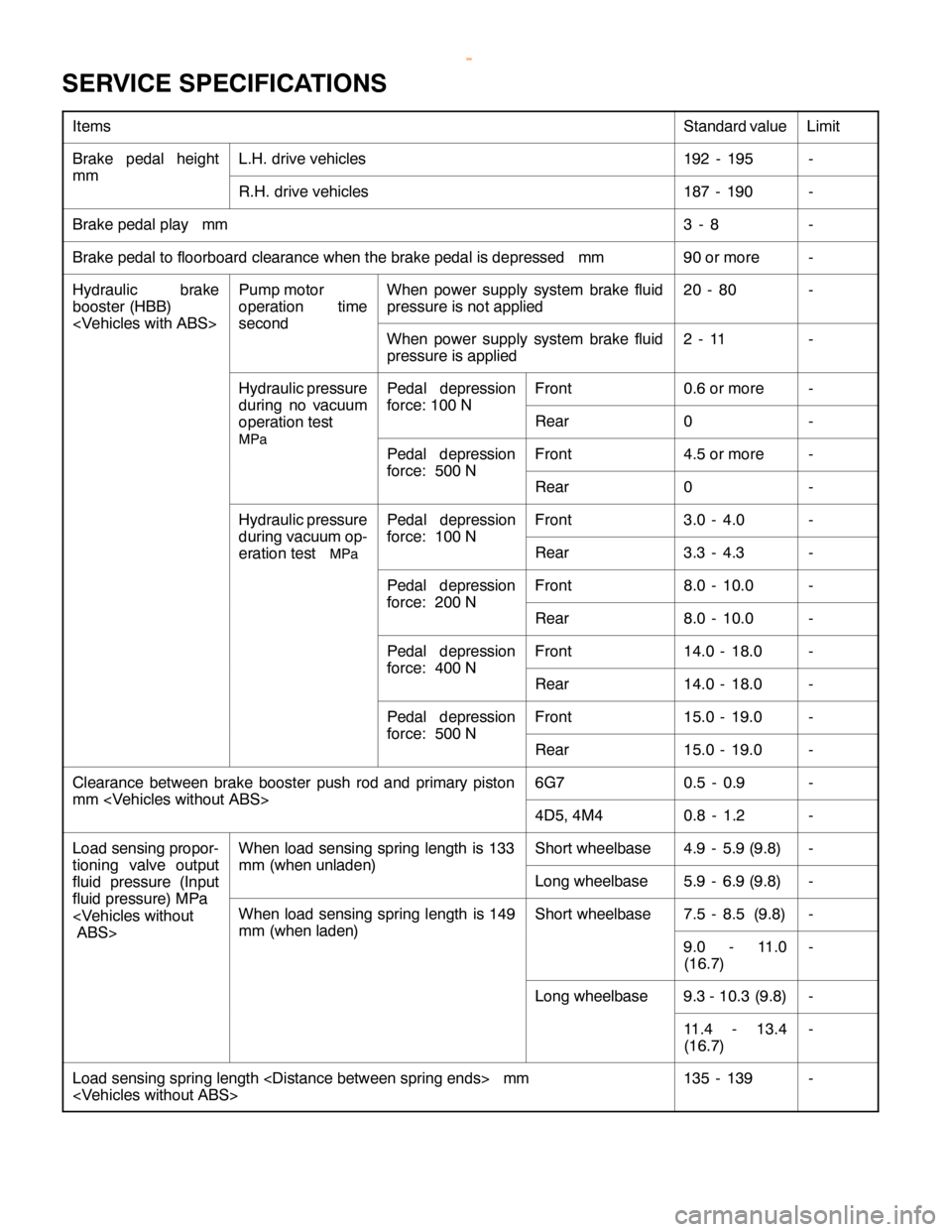

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Brake pedal heightL.H. drive vehicles192 - 195-

mm

R.H. drive vehicles187 - 190-

Brake pedal play mm3-8-

Brake pedal to floorboard clearance when the brake pedal is depressed mm90 or more-

Hydraulic brake

booster (HBB)Pump motor

operation timeWhen power supply system brake fluid

pressure is not applied20 - 80-

When power supply system brake fluid

pressure is applied2-11-

Hydraulic pressurePedal depressionFront0.6 or more-

during no vacuum

operation testforce: 100 N

Rear0-

MPa

Pedal depressionFront4.5 or more-

force: 500 N

Rear0-

Hydraulic pressurePedal depressionFront3.0 - 4.0-

during vacuum op-

eration test

MPa

force: 100 N

Rear3.3 - 4.3-

Pedal depressionFront8.0 - 10.0-

force: 200 N

Rear8.0 - 10.0-

Pedal depressionFront14.0 - 18.0-

force: 400 N

Rear14.0 - 18.0-

Pedal depressionFront15.0 - 19.0-

force: 500 N

Rear15.0 - 19.0-

Clearance between brake booster push rod and primary piston6G70.5 - 0.9-

mm

4D5, 4M40.8 - 1.2-

Load sensing propor-When load sensing spring length is 133Short wheelbase4.9 - 5.9 (9.8)-

tioning valve output

fluid pressure (Inputmm (when unladen)

Long wheelbase5.9 - 6.9 (9.8)-

fluid pressure) MPa

9.0 - 11.0

(16.7)-

Long wheelbase9.3 - 10.3 (9.8)-

11.4 - 13.4

(16.7)-

Load sensing spring length

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk