alternator MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 344 of 1839

Page 367 of 1839

Page 380 of 1839

Page 400 of 1839

Page 409 of 1839

Page 636 of 1839

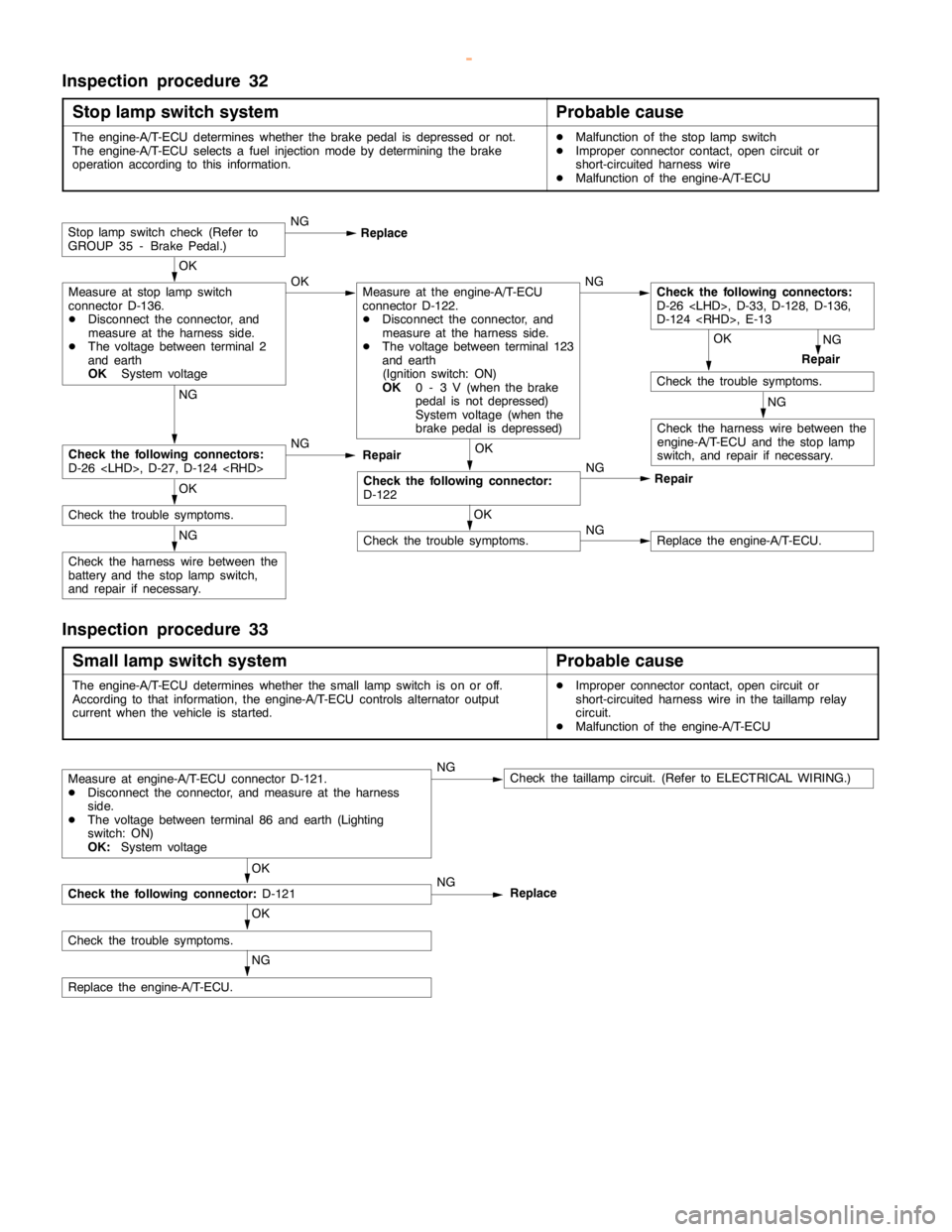

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-26

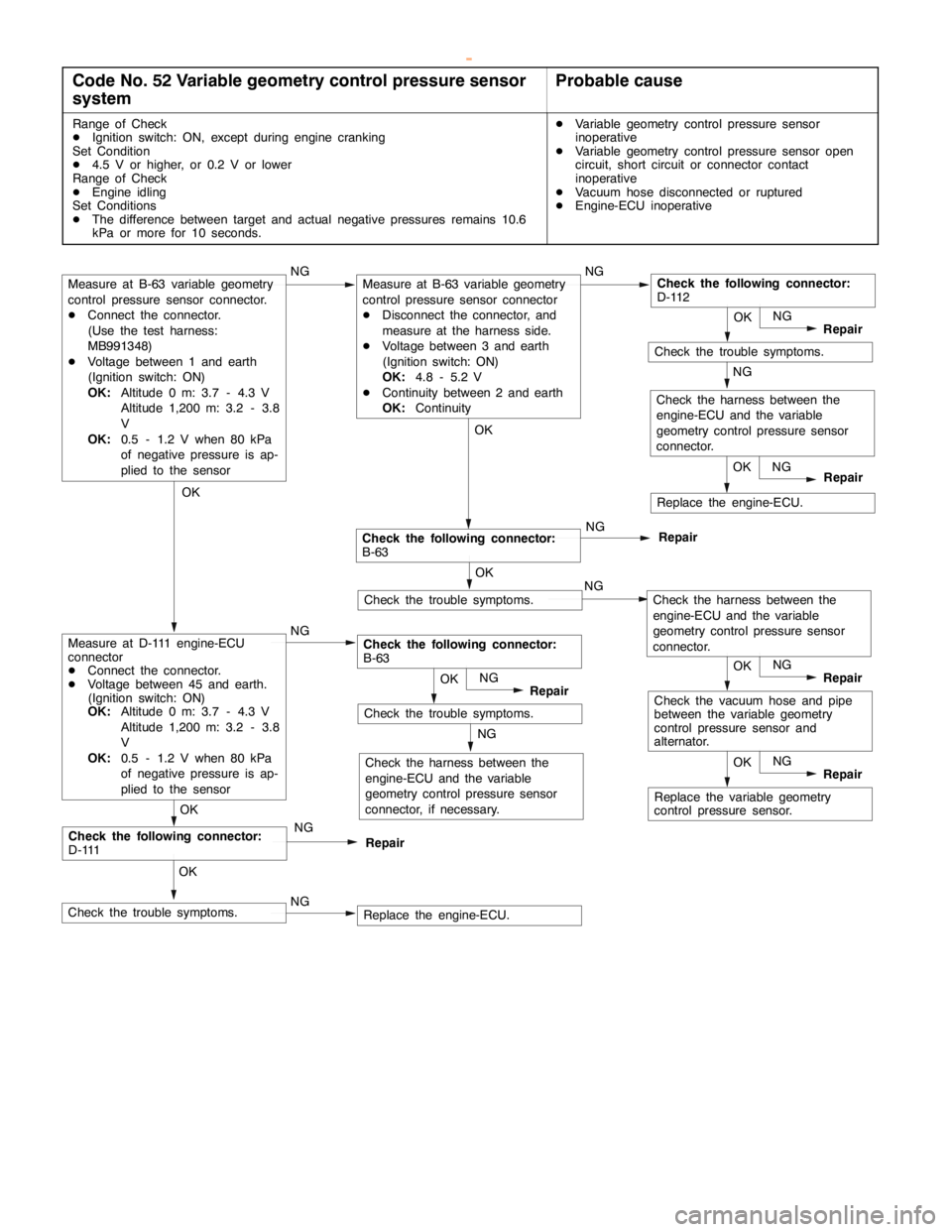

Code No. 52 Variable geometry control pressure sensor

systemProbable cause

Range of Check

DIgnition switch: ON, except during engine cranking

Set Condition

D4.5 V or higher, or 0.2 V or lower

Range of Check

DEngine idling

Set Conditions

DThe difference between target and actual negative pressures remains 10.6

kPa or more for 10 seconds.DVariable geometry control pressure sensor

inoperative

DVariable geometry control pressure sensor open

circuit, short circuit or connector contact

inoperative

DVacuum hose disconnected or ruptured

DEngine-ECU inoperative

NGReplace the engine-ECU.

Check the harness between the

engine-ECU and the variable

geometry control pressure sensor

connector, if necessary.

NG

Check the trouble symptoms.OK

NG

Repair

Replace the variable geometry

control pressure sensor.OK

NG

Repair

Check the vacuum hose and pipe

between the variable geometry

control pressure sensor and

alternator.OK

NG

Repair

NG

NG

Check the trouble symptoms.OK

Repair

Check the trouble symptoms.

OK

Replace the engine-ECU.OK

Repair NG NG

Check the harness between the

engine-ECU and the variable

geometry control pressure sensor

connector.

Check the trouble symptoms.OK

NG

Repair

Check the following connector:

D-111NG

Repair

OK

OKOK

Check the following connector:

B-63NG

NGNG

Check the following connector:

B-63

Measure at B-63 variable geometry

control pressure sensor connector.

DConnect the connector.

(Use the test harness:

MB991348)

DVoltage between 1 and earth

(Ignition switch: ON)

OK:Altitude 0 m: 3.7 - 4.3 V

Altitude 1,200 m: 3.2 - 3.8

V

OK:0.5 - 1.2 V when 80 kPa

of negative pressure is ap-

plied to the sensor

Measure at D-111 engine-ECU

connector

DConnect the connector.

DVoltage between 45 and earth.

(Ignition switch: ON)

OK:Altitude 0 m: 3.7 - 4.3 V

Altitude 1,200 m: 3.2 - 3.8

V

OK:0.5 - 1.2 V when 80 kPa

of negative pressure is ap-

plied to the sensor

Measure at B-63 variable geometry

control pressure sensor connector

DDisconnect the connector, and

measure at the harness side.

DVoltage between 3 and earth

(Ignition switch: ON)

OK:4.8 - 5.2 V

DContinuity between 2 and earth

OK:ContinuityCheck the following connector:

D-112

Check the harness between the

engine-ECU and the variable

geometry control pressure sensor

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 749 of 1839

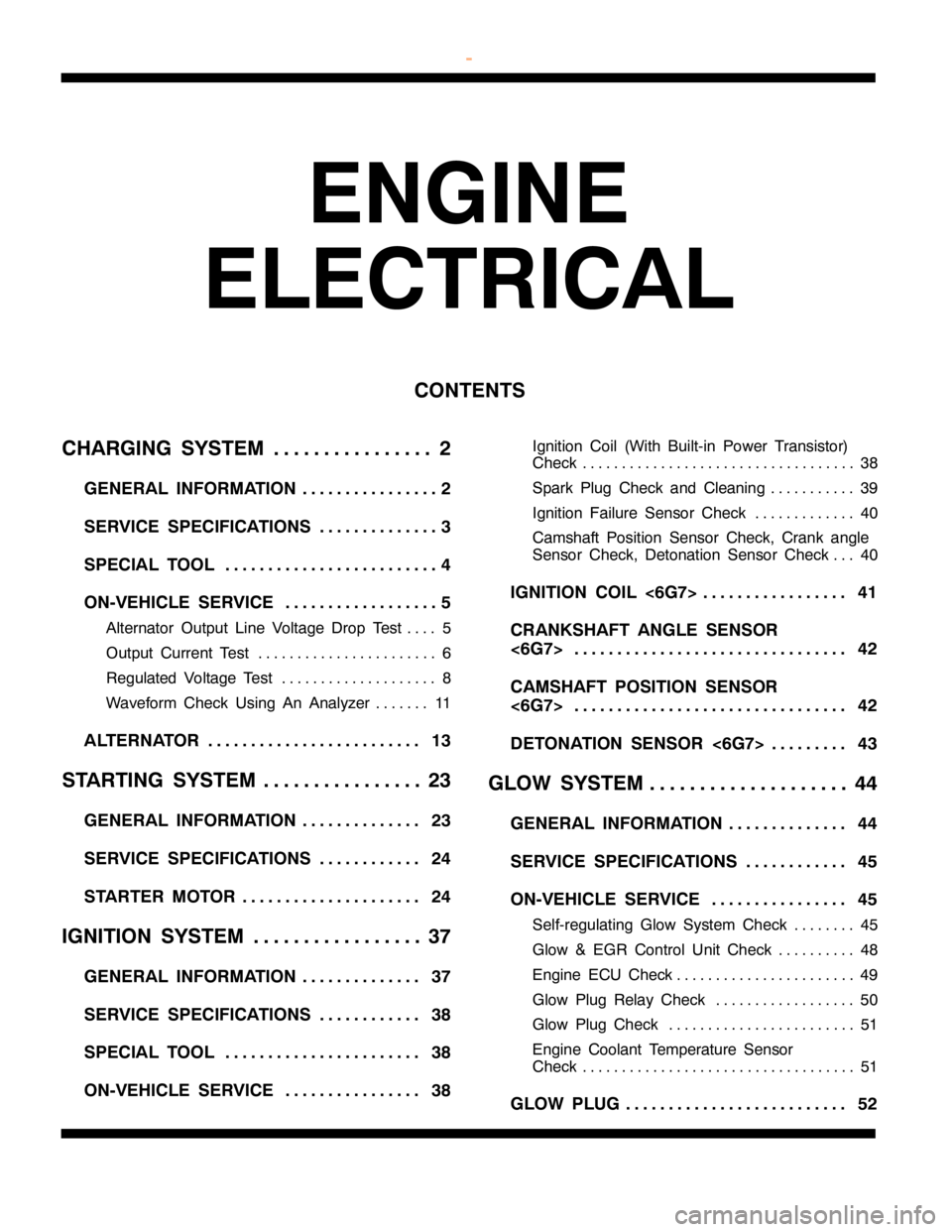

16-1

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3..............

SPECIAL TOOL 4.........................

ON-VEHICLE SERVICE 5..................

Alternator Output Line Voltage Drop Test 5....

Output Current Test 6.......................

Regulated Voltage Test 8....................

Waveform Check Using An Analyzer 11.......

ALTERNATOR 13.........................

STARTING SYSTEM 23................

GENERAL INFORMATION 23..............

SERVICE SPECIFICATIONS 24............

STARTER MOTOR 24.....................

IGNITION SYSTEM 37.................

GENERAL INFORMATION 37..............

SERVICE SPECIFICATIONS 38............

SPECIAL TOOL 38.......................

ON-VEHICLE SERVICE 38................

Ignition Coil (With Built-in Power Transistor)

Check 38...................................

Spark Plug Check and Cleaning 39...........

Ignition Failure Sensor Check 40.............

Camshaft Position Sensor Check, Crank angle

Sensor Check, Detonation Sensor Check 40...

IGNITION COIL <6G7> 41.................

CRANKSHAFT ANGLE SENSOR

<6G7> 42................................

CAMSHAFT POSITION SENSOR

<6G7> 42................................

DETONATION SENSOR <6G7> 43.........

GLOW SYSTEM 44....................

GENERAL INFORMATION 44..............

SERVICE SPECIFICATIONS 45............

ON-VEHICLE SERVICE 45................

Self-regulating Glow System Check 45........

Glow & EGR Control Unit Check 48..........

Engine ECU Check 49.......................

Glow Plug Relay Check 50..................

Glow Plug Check 51........................

Engine Coolant Temperature Sensor

Check 51...................................

GLOW PLUG 52..........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 758 of 1839

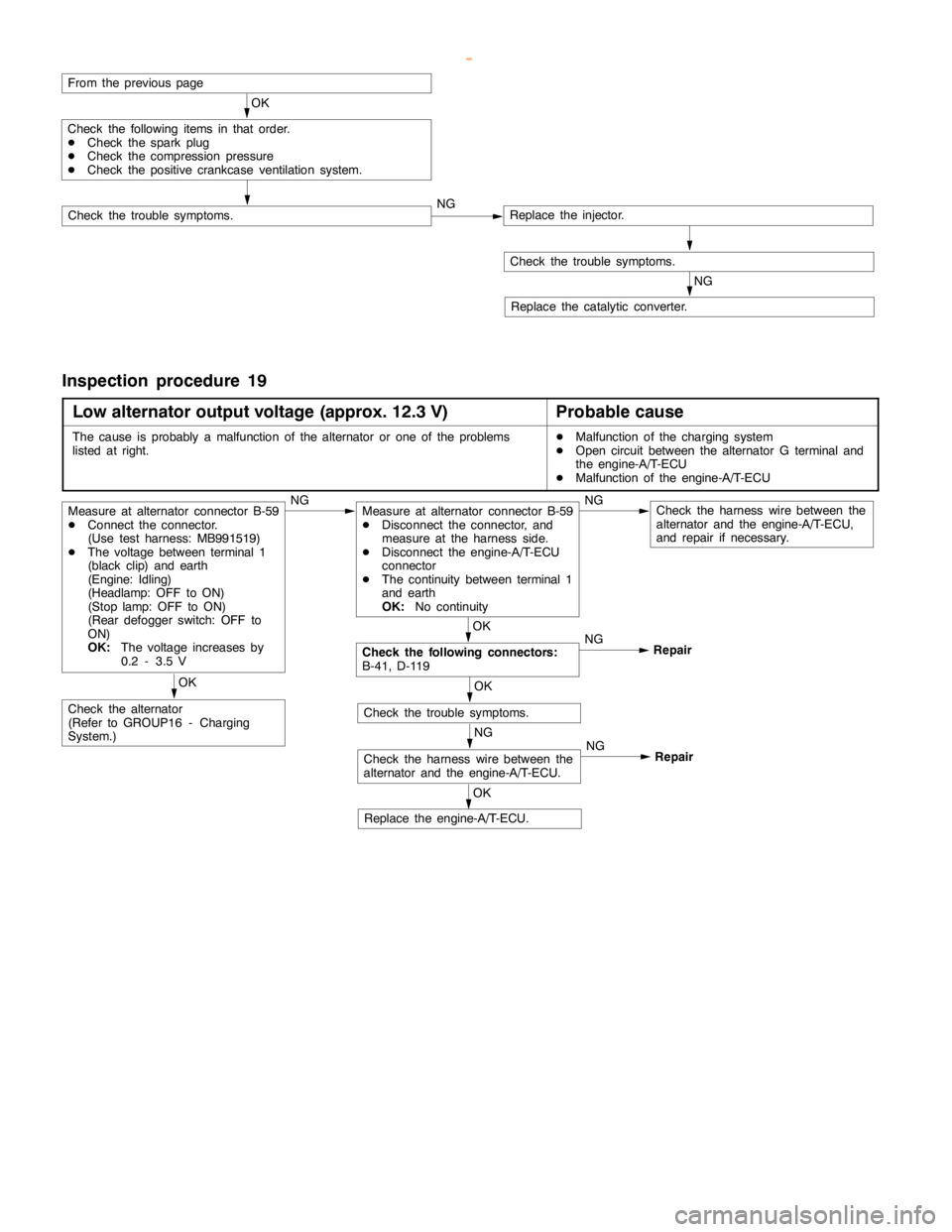

ENGINE ELECTRICAL -Charging System16-10

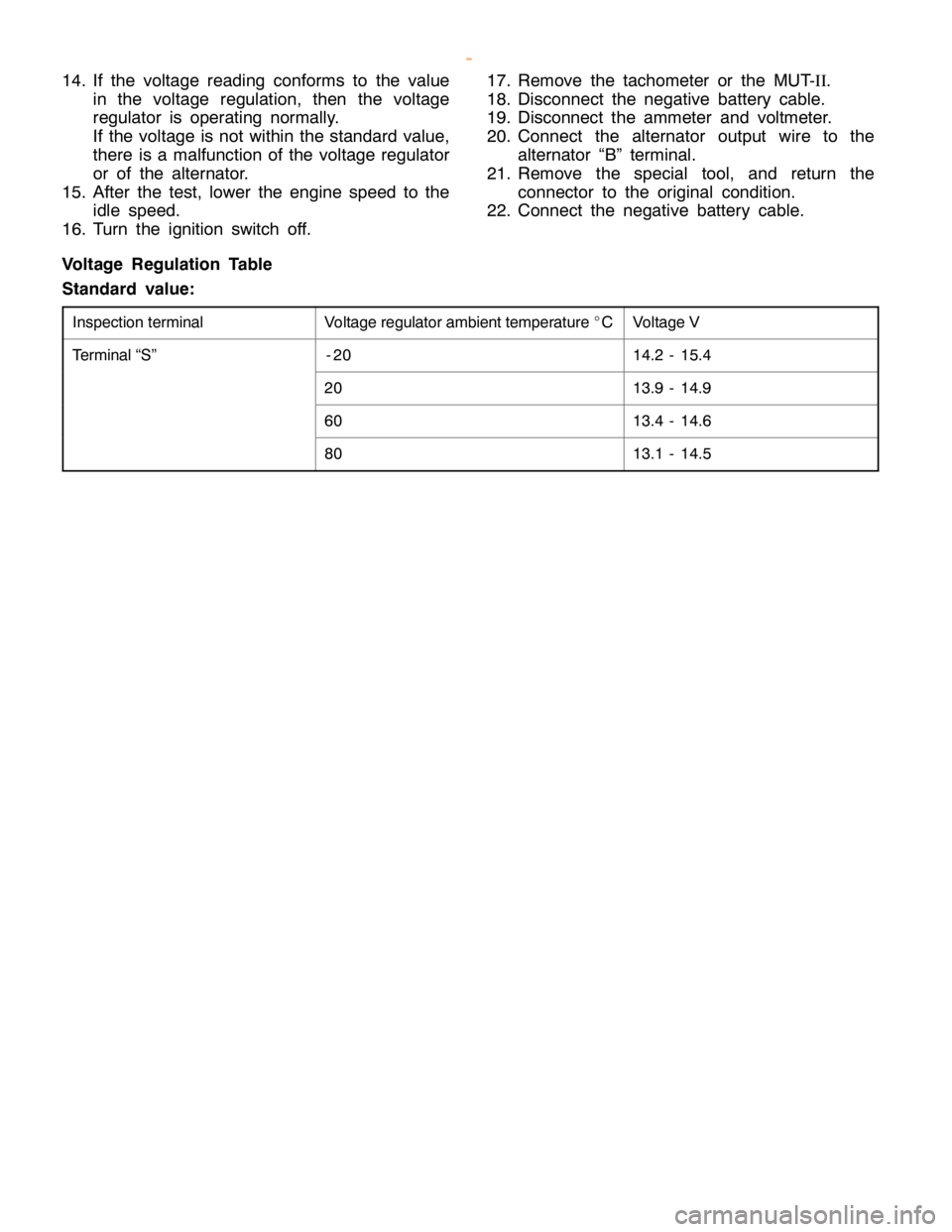

14. If the voltage reading conforms to the value

in the voltage regulation, then the voltage

regulator is operating normally.

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator

or of the alternator.

15. After the test, lower the engine speed to the

idle speed.

16. Turn the ignition switch off.17. Remove the tachometer or the MUT-II.

18. Disconnect the negative battery cable.

19. Disconnect the ammeter and voltmeter.

20. Connect the alternator output wire to the

alternator “B” terminal.

21. Remove the special tool, and return the

connector to the original condition.

22. Connect the negative battery cable.

Voltage Regulation Table

Standard value:

Inspection terminalVoltage regulator ambient temperature_

CVoltage V

Terminal “S”-2014.2 - 15.4

2013.9 - 14.9

6013.4 - 14.6

8013.1 - 14.5

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1640 of 1839

CHASSIS ELECTRICAL -Radio/Tape Player54A-70

A-2 Mixed with noise, only at night.

The following factors can be considered as possible

causes of noise appearing at night.

1. Factors due to signal conditions: Due to the

fact that long-distance signals are more easily

received at night, even stations that are

received without problem during the day may

experience interference in a general worsening

of reception conditions. The weaker a station

is the more susceptible it is to interference,and a change to a different station or the

appearance of a beating sound* may occur.

Beat sound*: Two signals close in frequency

interfere with each other, creating a repetitious

high-pitched sound. This sound is generated

not only by sound signals but by electrical

waves as well.

2. Factors due to vehicle noise: Alternator noise

may be a cause.

Is the noise still obvious even with

the lamps OFF?NO

YES

Do the following measures eliminate

the noise?

DTune to a station with a strong

signal.

DTune to a station with a strong

signal without completely

extending the antenna.YESOK

NO

Does the noise fade away when the

vehicle harness is moved away from

the radio chassis? (if the harness is

not in the proper position.)YESOK

NO

If there is more noise than other radios, consult a

service centre.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1763 of 1839

HEATER, AIR CONDITIONER AND VENTILATION - On-vehicle Service55A-17

REFRIGERANT LEAK REPAIR

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system. (See procedure.)

2. Charge the system with approximately one

pound of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

6. Replace receiver drier.

Caution

Replacement filter-drier units must be

sealed while in storage. The drier used in

these units will saturate water quickly upon

exposure to the atmosphere. When

installing a drier, have all tools and supplies

ready for quick reassembly to avoid keeping

the system open any longer than necessary.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are

produced in the system when it is operating.

Extreme care must be exercised to make sure that

all connections are pressure tight. Dirt and moisture

can enter the system when it is opened for repair

or replacement of lines or components. The

following precautions must be observed. The

system must be completely discharged before

opening any fitting of connection in the refrigeration

system. Open fittings with caution even after the

system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trapped

pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use

the correct line for the installation you are servicing.

A good rule for the flexible hose lines is keep the

radius of all bends at least 10 times the diameter

of the hose.

Sharper bends will reduce the flow of refrigerant.

The flexible hose lines should be routed so that

they are at least 80 mm from the exhaust manifold.

It is good practice to inspect all flexible hose lines

at least once a year to make sure they are in good

condition and properly routed.

Unified plumbing connections with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or

any other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets,

or a loose clutch assembly. Verify accessory drive

belt tension (power steering or alternator).

Improper accessory drive belt tension can cause

a misleading noise when the compressor is

engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure),

restrict air flow through condenser. Install

manifold gauge set to make sure discharge

pressure doesn’t exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt.

Check to assure clutch coil is tight (no rotation

or wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge. (See “Charging

System”.)

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retorque. Repeat Step 1.

7. If noise continues, replace compressor and

repeat Step 1.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk