compression ratio MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 298 of 1839

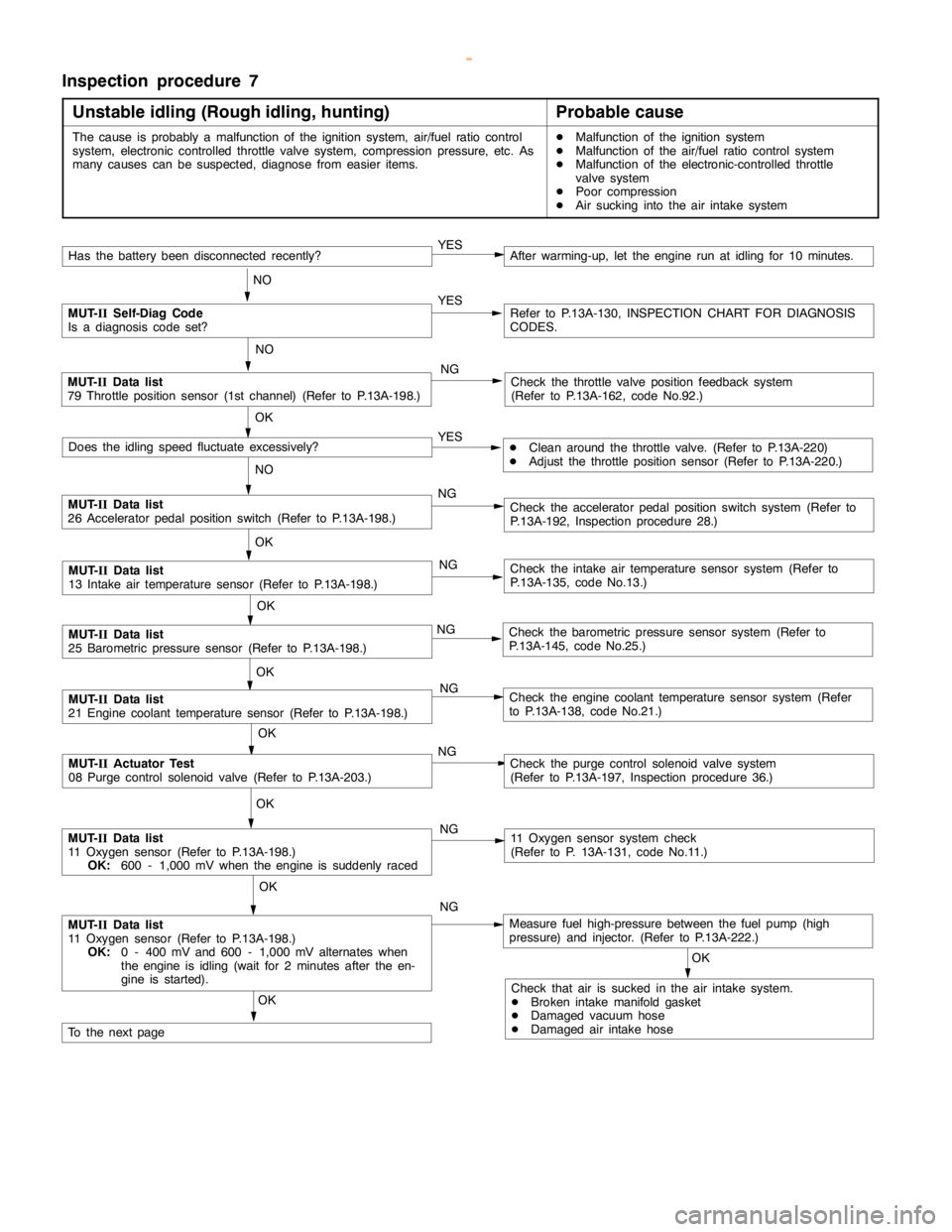

GDI -Troubleshooting

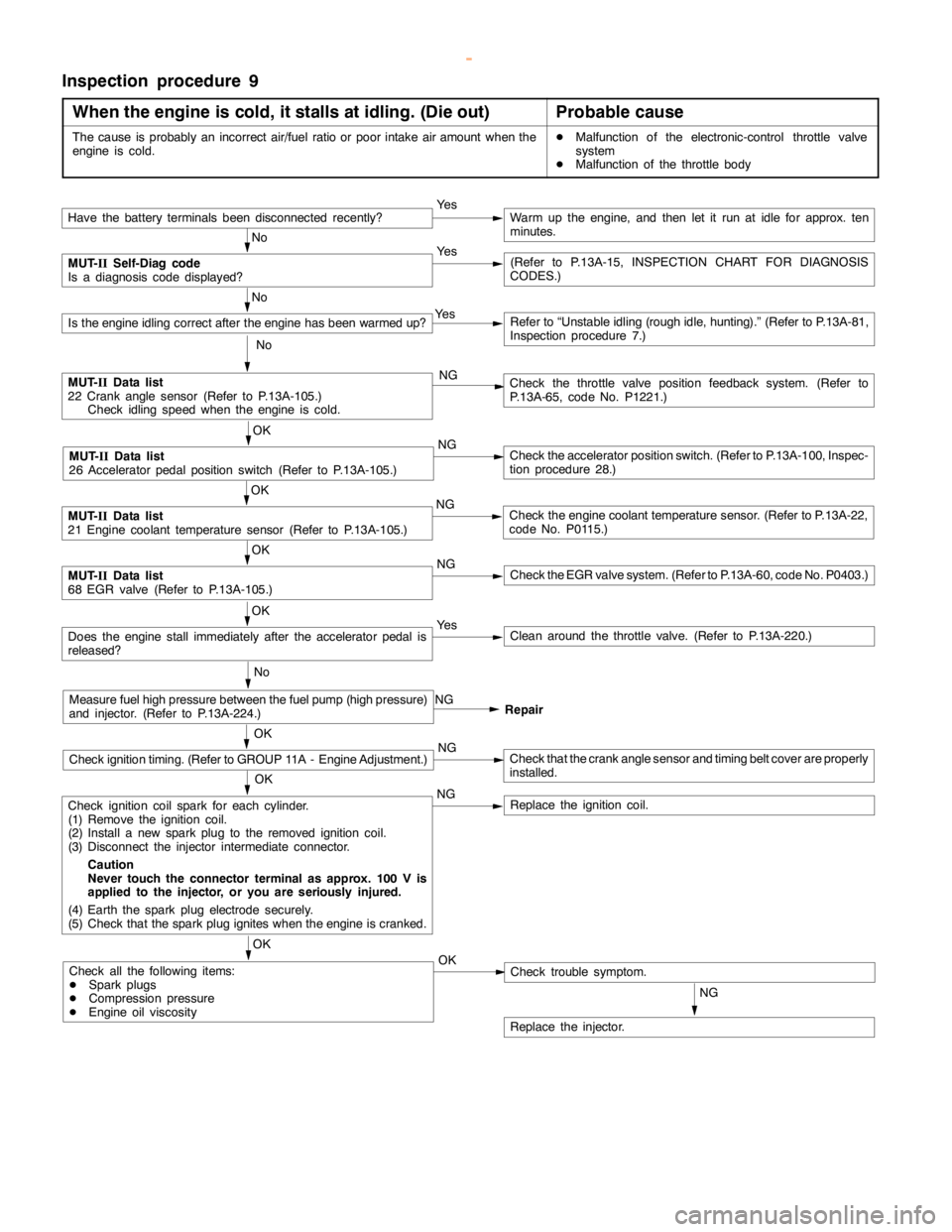

Inspection procedure 9

When the engine is cold, it stalls at idling. (Die out)

Probable cause

The cause is probably an incorrect air/fuel ratio or poor intake airamountwhen the

engine iscold.DMalfunction of the electronic-control throttle valve

system

DMalfunction of the throttle body

Have the battery terminalsbeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

Is the engine idlingcorrect after theengine has been warmed up?Ye sRefer to “Unstableidling (rough idle, hunting).”(Refer to P.13A-81,

Inspection procedure 7.)

No

MUT-

IIData list

22 Crankanglesensor (Refer to P.13A-105.)

Checkidlingspeed when theengine iscold.NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the accelerator position switch. (Refer to P.13A-100, Inspec-

tion procedure 28.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve system. (Refer to P.13A-60, code No. P0403.)

OK

Does theenginestall immediately after the acceleratorpedal is

released?Ye sClean around the throttle valve. (Refer to P.13A-220.)

No

Measure fuel highpressure between the fuelpump (highpressure)

and injector. (Refer to P.13A-224.)NG

Repair

OK

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)NGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check all the following items:

DSpark plugs

DCompression pressure

DEngine oilviscosityNGCheck trouble symptom. OK

Replace the injector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 299 of 1839

GDI -Troubleshooting

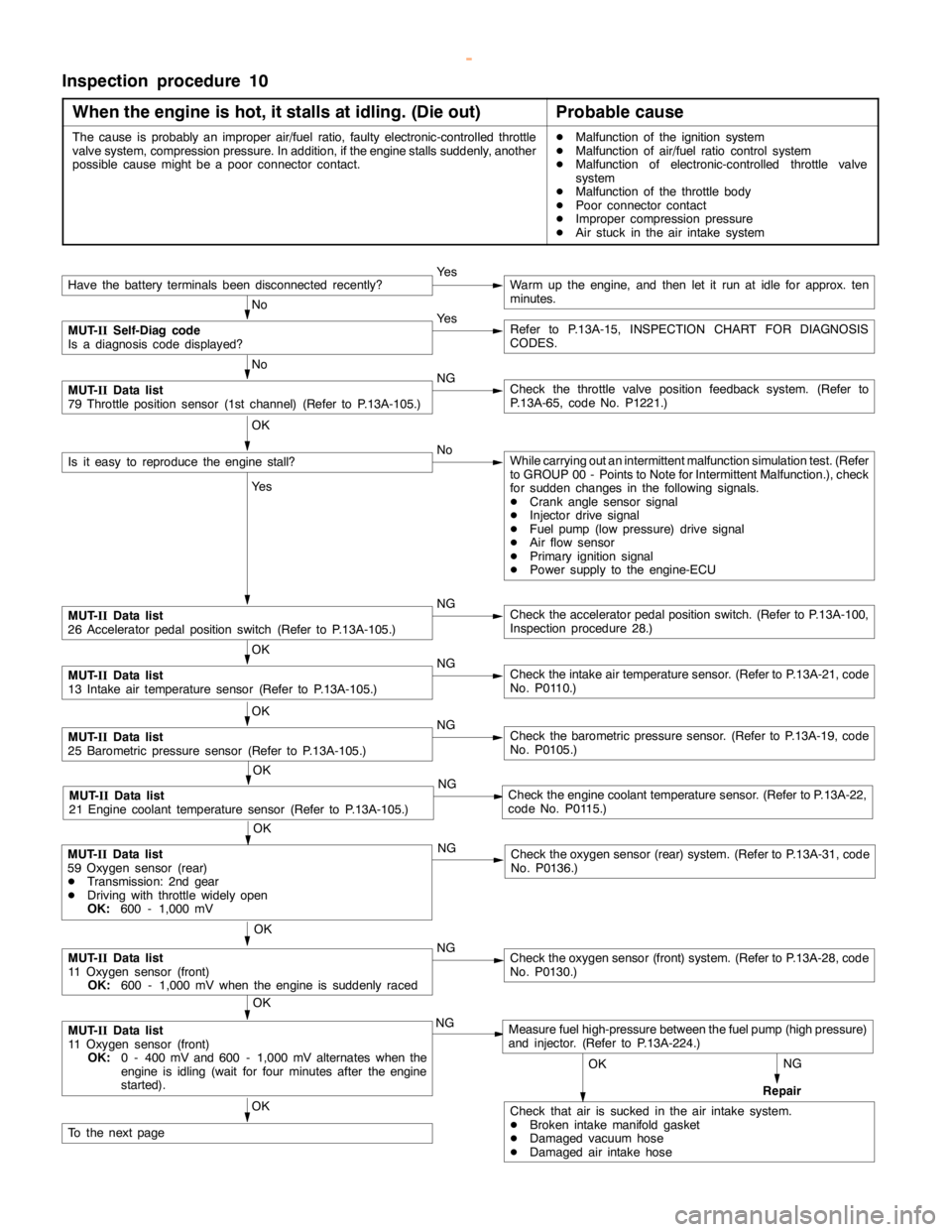

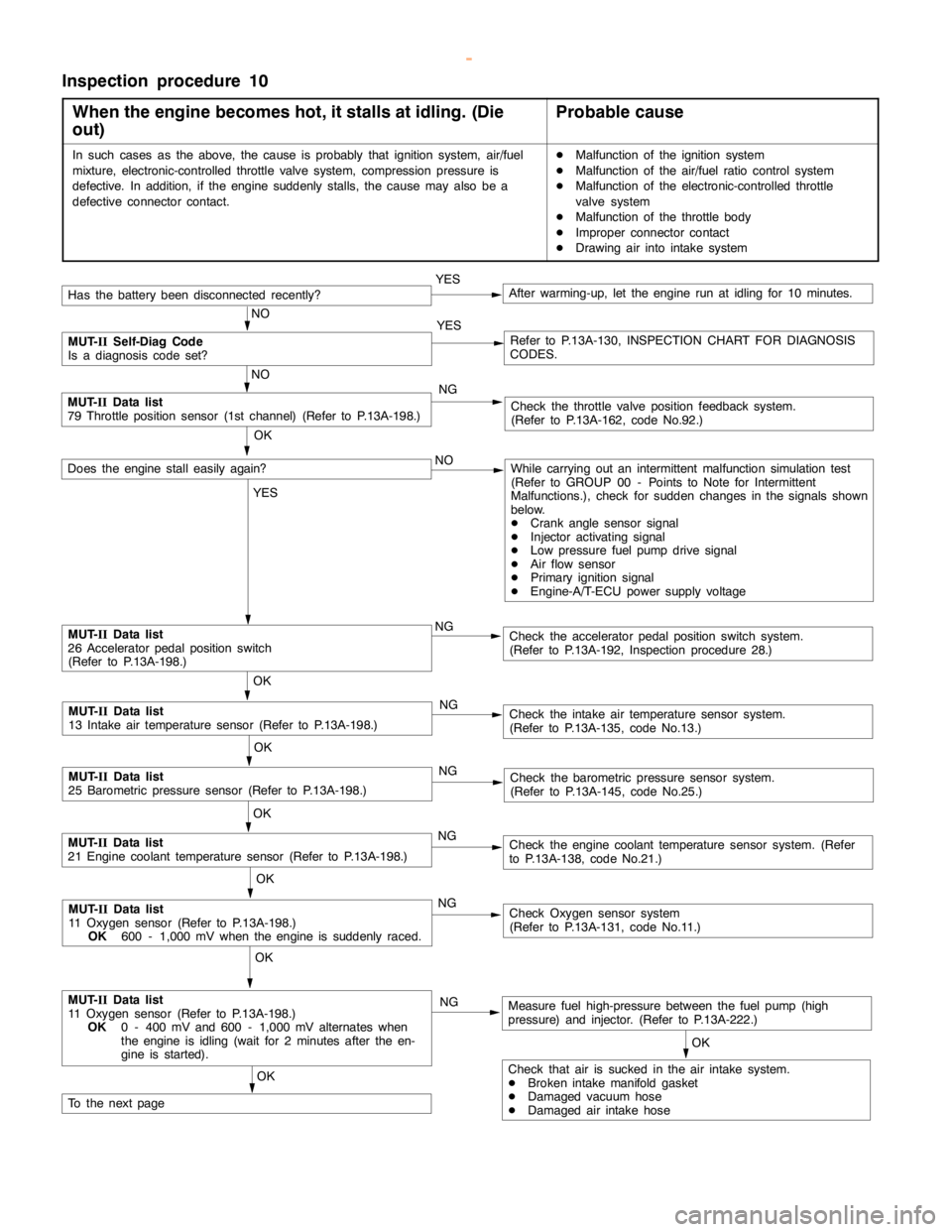

Inspection procedure 10

When the engine is hot, it stalls at idling. (Die out)

Probable cause

The cause is probably an improper air/fuel ratio, faulty electronic-controlled throttle

valve system, compression pressure. In addition, if theenginestalls suddenly, another

possible causemight be a poorconnector contact.DMalfunction of the ignition system

DMalfunction of air/fuel ratio control system

DMalfunction of electronic-controlled throttle valve

system

DMalfunction of the throttle body

DPoor connector contact

DImproper compression pressure

DAir stuck in the air intake system

NG

Repair

Have the battery terminalsbeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

Is it easy to reproduce theengine stall?NoWhile carrying out an intermittent malfunction simulation test. (Refer

to GROUP 00 - Points to Note for Intermittent Malfunction.), check

for sudden changes in the following signals.

DCrankanglesensor signal

DInjector drive signal

DFuel pump(low pressure) drive signal

DAir flow sensor

DPrimary ignition signal

DPower supply to the engine-ECU

Ye s

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the acceleratorpedal positionswitch. (Refer to P.13A-100,

Inspection procedure 28.)

OK

MUT-

IIData list

13 Intake air temperature sensor (Refer to P.13A-105.)NGCheck the intake air temperature sensor. (Refer to P.13A-21, code

No. P0110.)

OK

MUT-

IIData list

25 Barometric pressure sensor (Refer to P.13A-105.)NGCheck the barometric pressure sensor. (Refer to P.13A-19, code

No. P0105.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

600 - 1,000 mV when theengine is suddenlyracedNGCheck the oxygen sensor (front) system. (Refer to P.13A-28, code

No. P0130.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

0 - 400 mV and 600 - 1,000 mV alternates when the

engine is idling(wait for four minutes after theengine

started).NGMeasure fuel high-pressure between the fuel pump (highpressure)

and injector. (Refer to P.13A-224.)

OK

Check that air is sucked in the air intake system.

DBroken intakemanifoldgasket

DDamaged vacuum hose

DDamaged air intake hoseOK

To the nextpage

OK

MUT-

IIData list

59 Oxygen sensor (rear)

DTransmission: 2nd gear

DDriving with throttle widelyopen

OK:

600 - 1,000 mVNGCheck the oxygen sensor (rear) system. (Refer to P.13A-31, code

No. P0136.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 303 of 1839

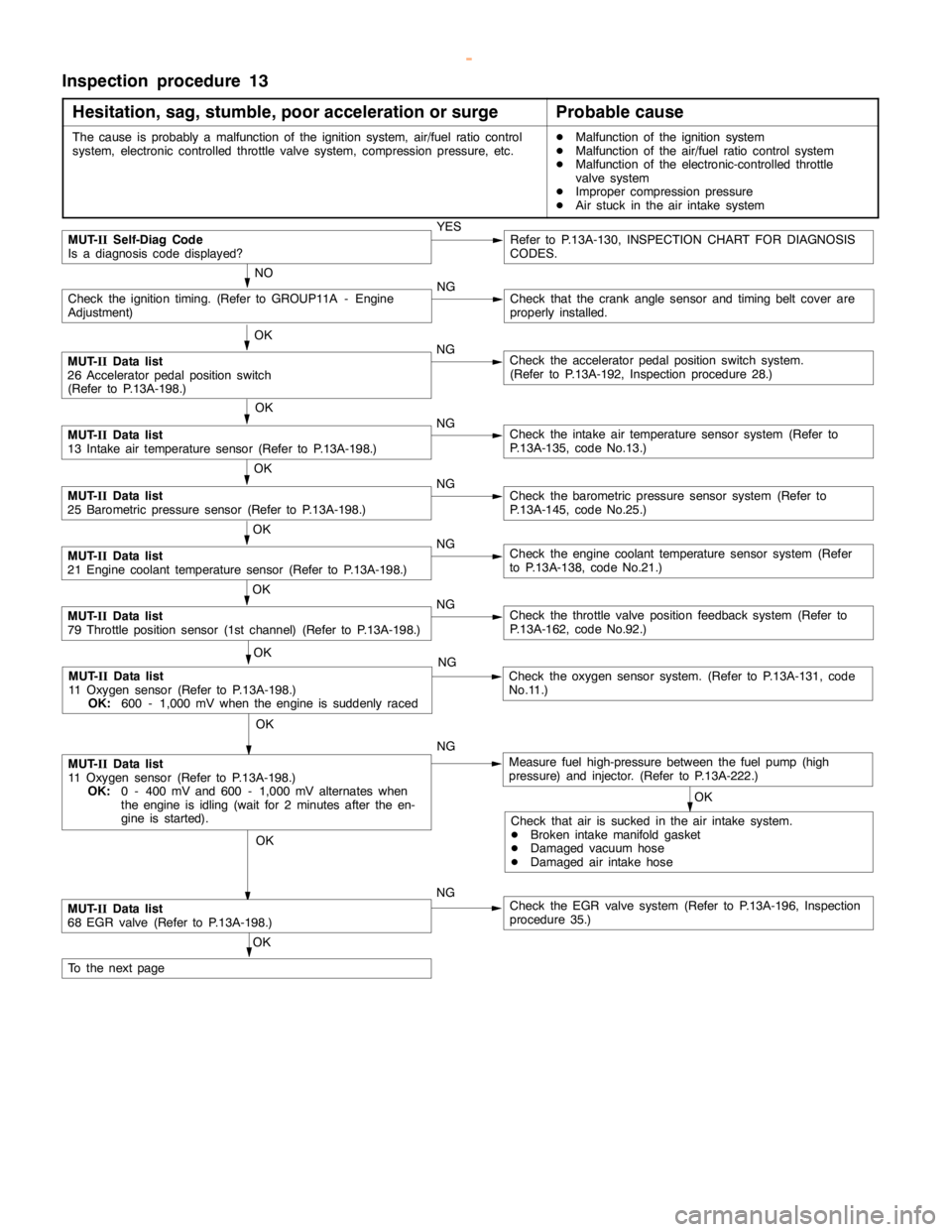

GDI -Troubleshooting

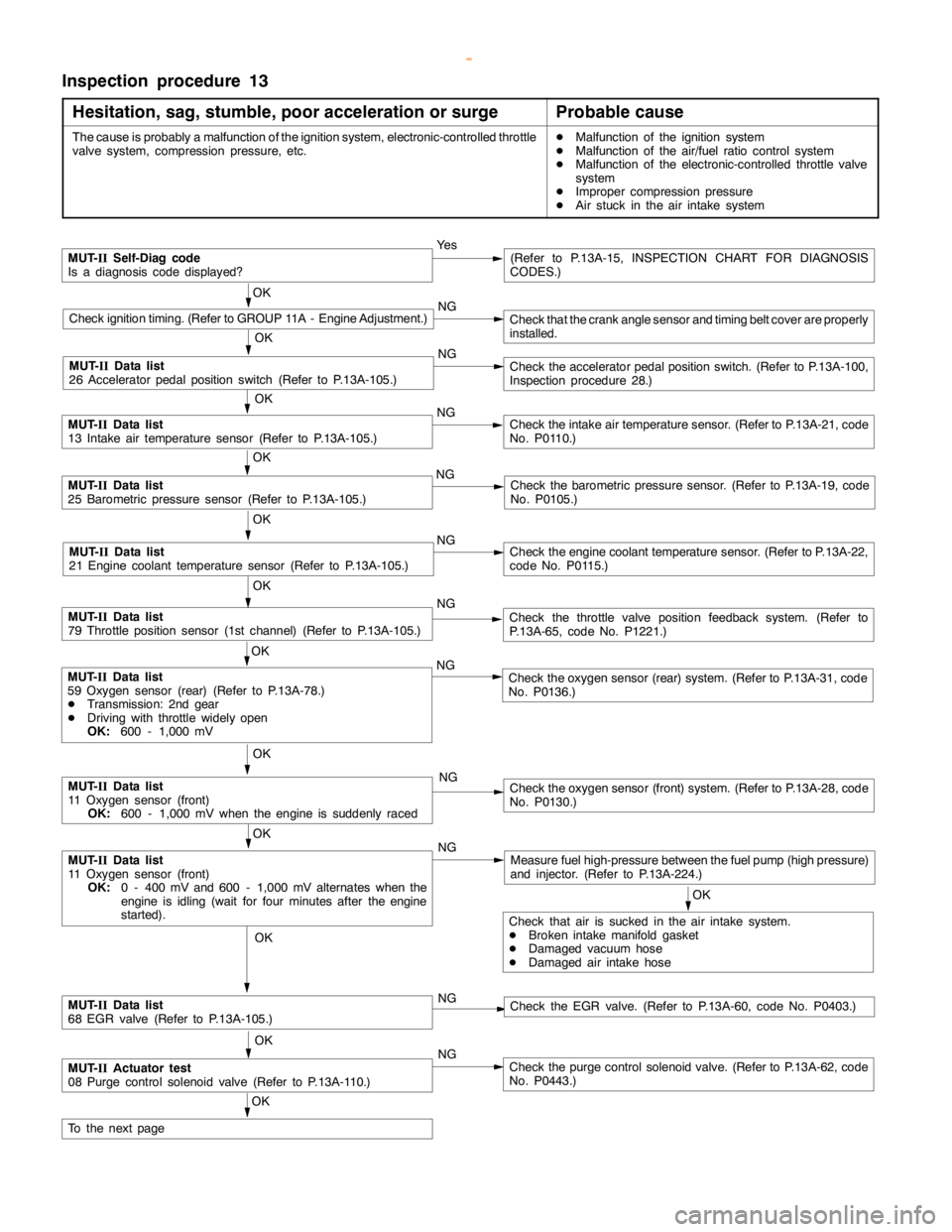

Inspection procedure 13

Hesitation, sag, stumble, poor acceleration or surge

Probable cause

The cause is probably a malfunction of the ignition system, electronic-controlled throttle

valve system, compression pressure, etc.DMalfunction of the ignition system

DMalfunction of the air/fuel ratio control system

DMalfunction of the electronic-controlled throttle valve

system

DImproper compression pressure

DAir stuck in the air intake system

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

OK

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)NGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

NG

Check the acceleratorpedal positionswitch. (Refer to P.13A-100,

Inspection procedure 28.)

OK

MUT-

IIData list

13 Intake air temperature sensor (Refer to P.13A-105.)NGCheck the intake air temperature sensor. (Refer to P.13A-21, code

No. P0110.)

OK

MUT-

IIData list

25 Barometric pressure sensor (Refer to P.13A-105.)NGCheck the barometric pressure sensor. (Refer to P.13A-19, code

No. P0105.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

0 - 400 mV and 600 - 1,000 mV alternates when the

engine is idling(wait for four minutes after theengine

started).NGMeasure fuel high-pressure between the fuel pump (highpressure)

and injector. (Refer to P.13A-224.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

600 - 1,000 mV when theengine is suddenlyracedNGCheck the oxygen sensor (front) system. (Refer to P.13A-28, code

No. P0130.)

OK

Check that air is sucked in the air intake system.

DBroken intake manifold gasket

DDamaged vacuum hose

DDamaged air intake hose

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve. (Refer to P.13A-60, code No. P0403.)

OK

MUT-

IIActuator test

08 Purge control solenoid valve (Refer to P.13A-110.)NGCheck the purge control solenoid valve. (Refer to P.13A-62, code

No. P0443.)

OK

To the nextpage

OK

MUT-

IIData list

59 Oxygen sensor (rear) (Refer to P.13A-78.)

DTransmission: 2nd gear

DDriving with throttle widelyopen

OK:

600 - 1,000 mVNGCheck the oxygen sensor (rear) system. (Refer to P.13A-31, code

No. P0136.)

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 304 of 1839

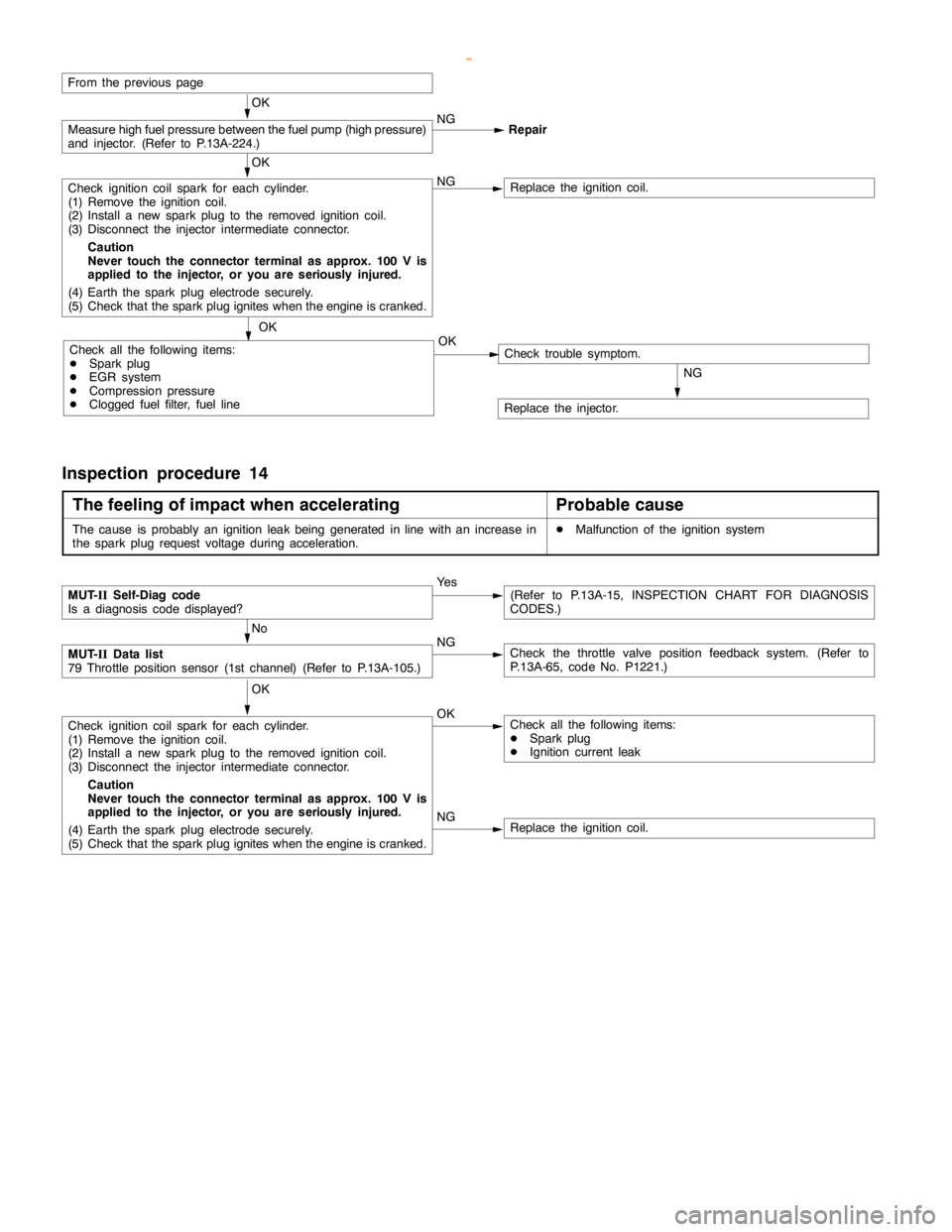

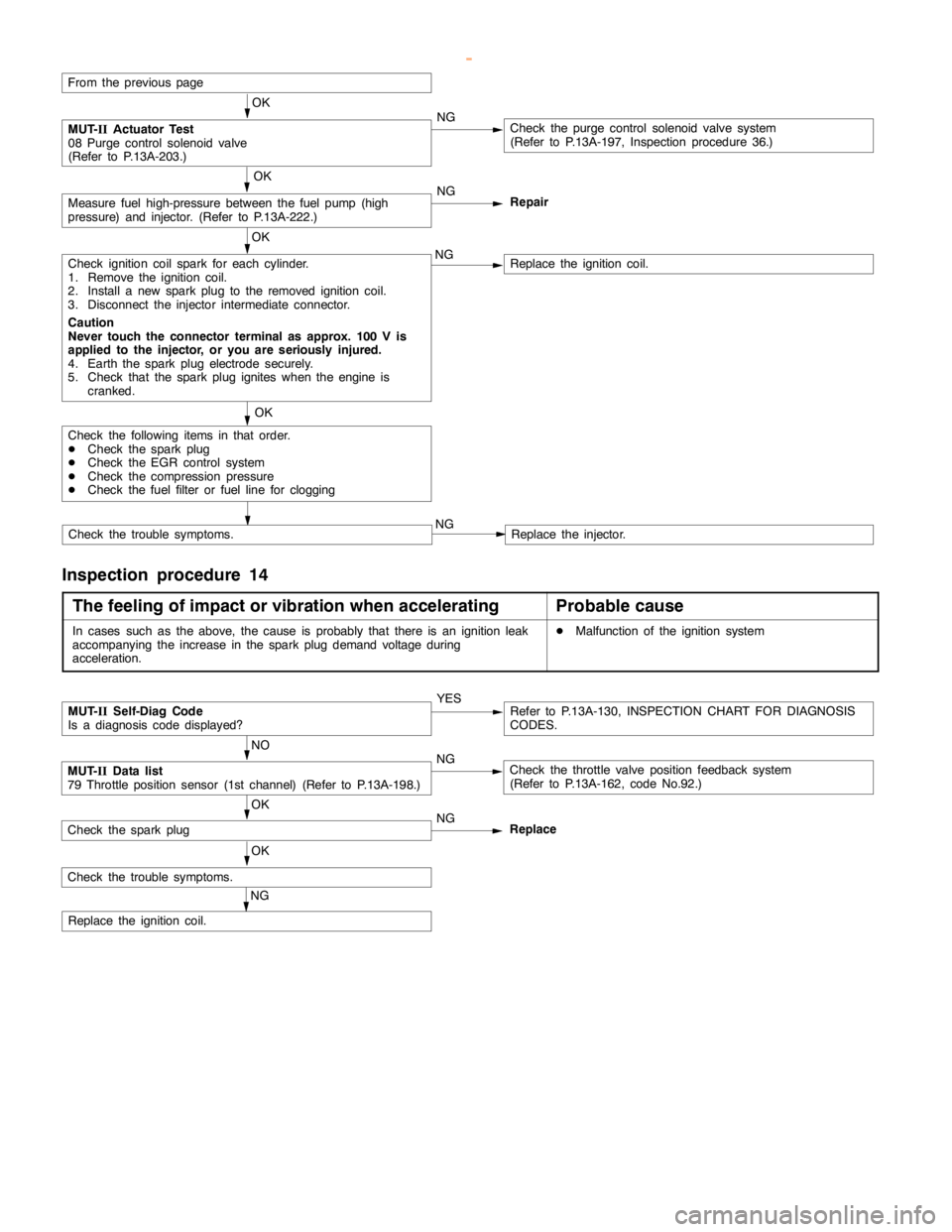

GDI -Troubleshooting

From the previouspage

OK

Measure high fuelpressure between the fuelpump (highpressure)

and injector. (Refer to P.13A-224.)NG

Repair

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check all the following items:

DSparkplug

DEGR system

DCompression pressure

DClogged fuel filter, fuel lineNGCheck trouble symptom.

Replace the injector.

OK

Inspection procedure 14

The feeling of impact when accelerating

Probable cause

The cause is probably an ignition leakbeing generated in linewith an increase in

the sparkplug request voltage during acceleration.DMalfunction of the ignition system

NGReplace the ignition coil.

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.OKCheck all the following items:

DSparkplug

DIgnition current leak

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 306 of 1839

GDI -Troubleshooting

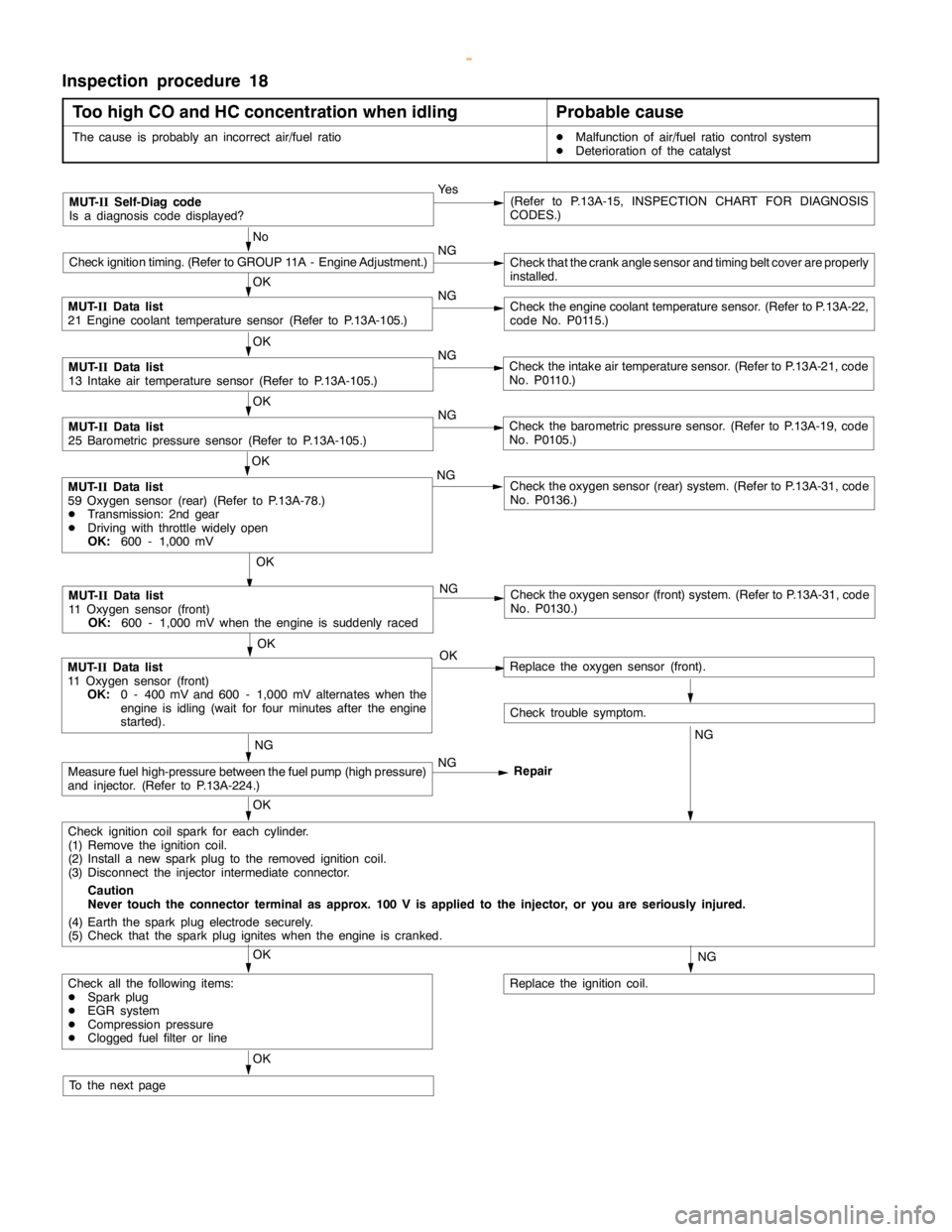

Inspection procedure 18

Too high CO and HC concentration when idling

Probable cause

The cause is probably an incorrect air/fuel ratioDMalfunction of air/fuel ratio control system

DDeterioration of the catalyst

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)NGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

13 Intake air temperature sensor (Refer to P.13A-105.)NGCheck the intake air temperature sensor. (Refer to P.13A-21, code

No. P0110.)

OK

MUT-

IIData list

25 Barometric pressure sensor (Refer to P.13A-105.)NGCheck the barometric pressure sensor. (Refer to P.13A-19, code

No. P0105.)

OK

NG

Check the oxygen sensor (front) system. (Refer to P.13A-31, code

No. P0130.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

0 - 400 mV and 600 - 1,000 mV alternates when the

engine is idling(wait for four minutes after theengine

started).OKReplace the oxygen sensor (front).

Check trouble symptom.

NGNG

Measure fuel high-pressure between the fuel pump (highpressure)

and injector. (Refer to P.13A-224.)NG

Repair

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.

NG

Replace the ignition coil.

OK

Check all the following items:

DSparkplug

DEGR system

DCompression pressure

DClogged fuel filter or line

OK

To the nextpage

OK

MUT-

IIData list

59 Oxygen sensor (rear) (Refer to P.13A-78.)

DTransmission: 2nd gear

DDriving with throttle widelyopen

OK:

600 - 1,000 mVNGCheck the oxygen sensor (rear) system. (Refer to P.13A-31, code

No. P0136.)

MUT-

IIData list

11 Oxygen sensor (front)

OK:

600 - 1,000 mV when theengine is suddenlyraced

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 388 of 1839

Page 392 of 1839

Page 396 of 1839

Page 397 of 1839

Page 1211 of 1839

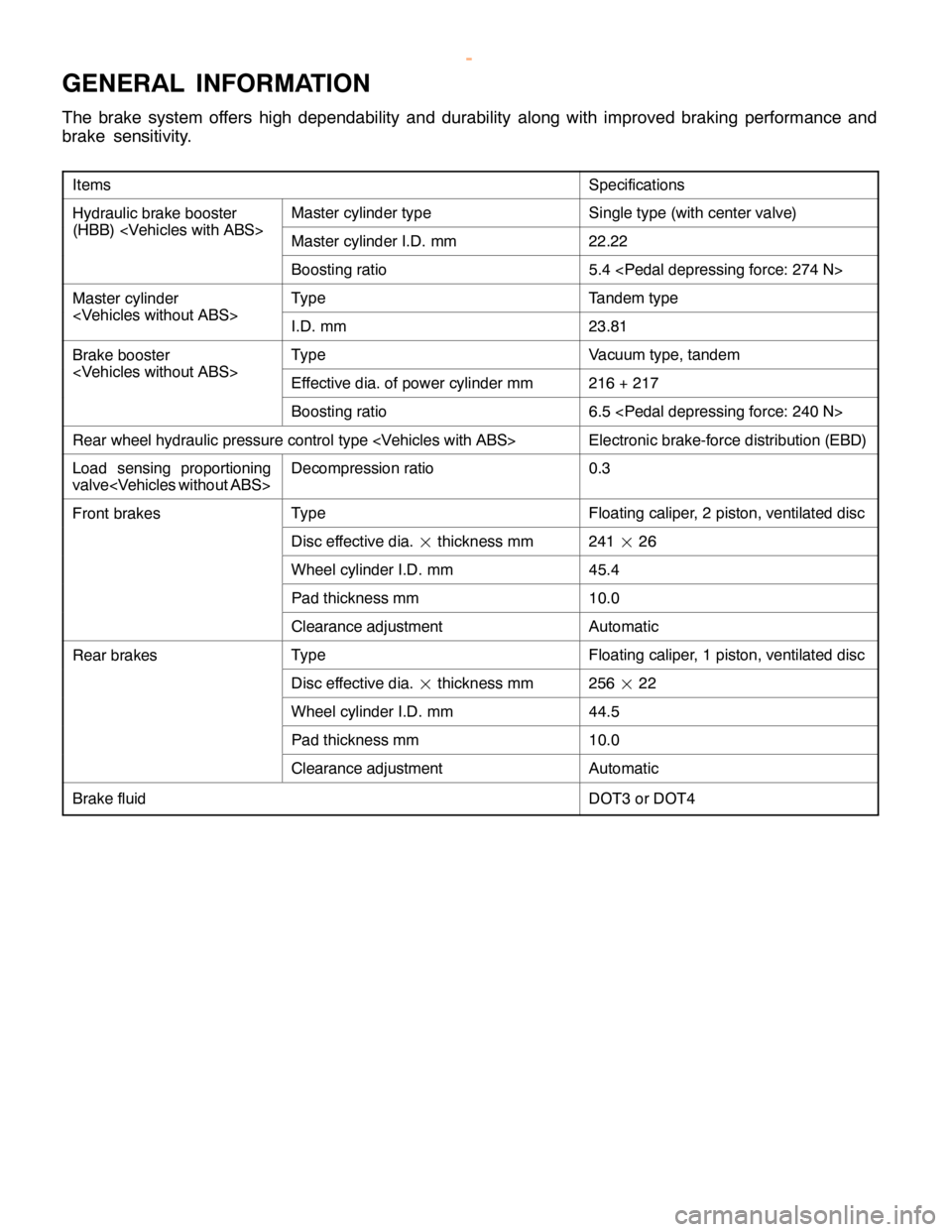

BASIC BRAKE SYSTEM -General Information35A-3

GENERAL INFORMATION

The brake system offers high dependability and durability along with improved braking performance and

brake sensitivity.

ItemsSpecifications

Hydraulic brake boosterMaster cylinder typeSingle type (with center valve)

(HBB)

Boosting ratio5.4

Master cylinderTypeTandem type

Brake boosterTypeVacuum type, tandem

Boosting ratio6.5

Rear wheel hydraulic pressure control type

Load sensing proportioning

valve

Front brakesTypeFloating caliper, 2 piston, ventilated disc

Disc effective dia.¢

thickness mm241¢

26

Wheel cylinder I.D. mm45.4

Pad thickness mm10.0

Clearance adjustmentAutomatic

Rear brakesTypeFloating caliper, 1 piston, ventilated disc

Disc effective dia.¢

thickness mm256¢

22

Wheel cylinder I.D. mm44.5

Pad thickness mm10.0

Clearance adjustmentAutomatic

Brake fluidDOT3 or DOT4

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk