egr valve MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 216 of 1839

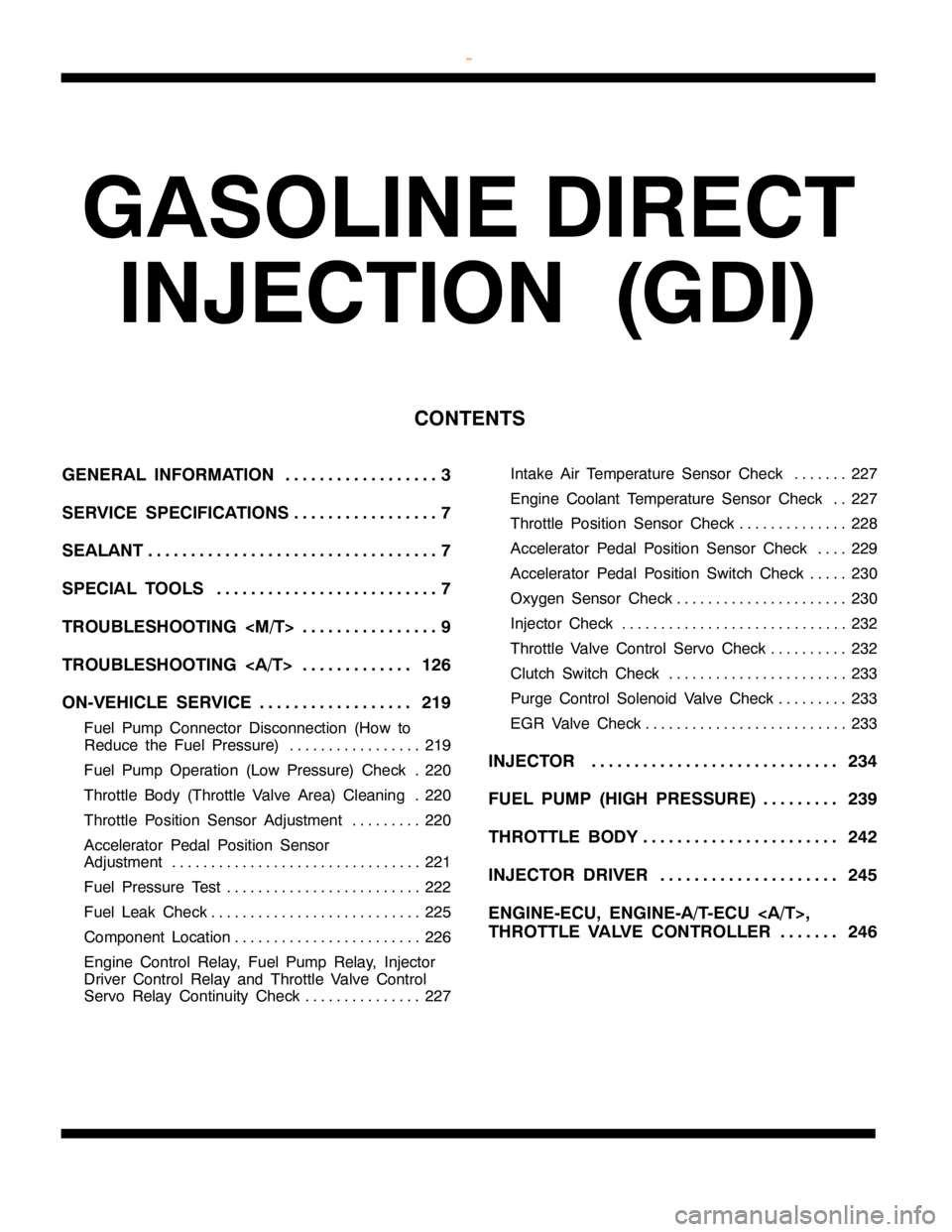

13A-2

GASOLINE DIRECT

INJECTION (GDI)

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 7.................

SEALANT 7..................................

SPECIAL TOOLS 7..........................

TROUBLESHOOTING

TROUBLESHOOTING 126.............

ON-VEHICLE SERVICE 219..................

Fuel Pump Connector Disconnection (How to

Reduce the Fuel Pressure) 219.................

Fuel Pump Operation (Low Pressure) Check 220.

Throttle Body (Throttle Valve Area) Cleaning 220.

Throttle Position Sensor Adjustment 220.........

Accelerator Pedal Position Sensor

Adjustment 221................................

Fuel Pressure Test 222.........................

Fuel Leak Check 225...........................

Component Location 226........................

Engine Control Relay, Fuel Pump Relay, Injector

Driver Control Relay and Throttle Valve Control

Servo Relay Continuity Check 227...............Intake Air Temperature Sensor Check 227.......

Engine Coolant Temperature Sensor Check 227..

Throttle Position Sensor Check 228..............

Accelerator Pedal Position Sensor Check 229....

Accelerator Pedal Position Switch Check 230.....

Oxygen Sensor Check 230......................

Injector Check 232.............................

Throttle Valve Control Servo Check 232..........

Clutch Switch Check 233.......................

Purge Control Solenoid Valve Check 233.........

EGR Valve Check 233..........................

INJECTOR 234.............................

FUEL PUMP (HIGH PRESSURE) 239.........

THROTTLE BODY 242.......................

INJECTOR DRIVER 245.....................

ENGINE-ECU, ENGINE-A/T-ECU ,

THROTTLE VALVE CONTROLLER 246.......

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 218 of 1839

GDI -General Information13A-4

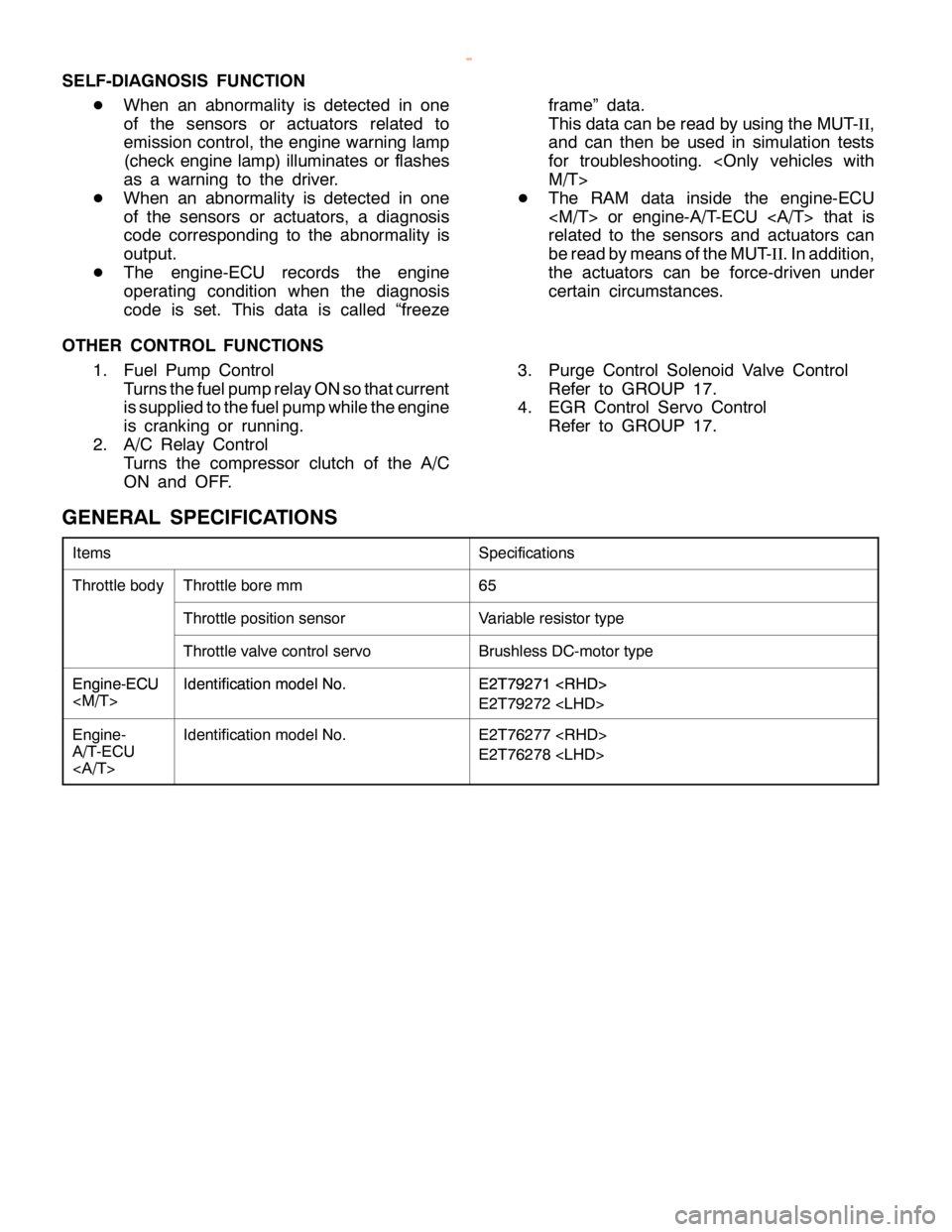

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in one

of the sensors or actuators related to

emission control, the engine warning lamp

(check engine lamp) illuminates or flashes

as a warning to the driver.

DWhen an abnormality is detected in one

of the sensors or actuators, a diagnosis

code corresponding to the abnormality is

output.

DThe engine-ECU records the engine

operating condition when the diagnosis

code is set. This data is called “freezeframe” data.

This data can be read by using the MUT-II,

and can then be used in simulation tests

for troubleshooting.

DThe RAM data inside the engine-ECU

related to the sensors and actuators can

be read by means of the MUT-II. In addition,

the actuators can be force-driven under

certain circumstances.

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Relay Control

Turns the compressor clutch of the A/C

ON and OFF.3. Purge Control Solenoid Valve Control

Refer to GROUP 17.

4. EGR Control Servo Control

Refer to GROUP 17.

GENERAL SPECIFICATIONS

ItemsSpecifications

Throttle bodyThrottle bore mm65

Throttle position sensorVariable resistor type

Throttle valve control servoBrushless DC-motor type

Engine-ECUIdentification model No.E2T79271

E2T79272

Engine-Identification model No.E2T76277

A/T-ECU

E2T76278

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 219 of 1839

GDI -General Information13A-5

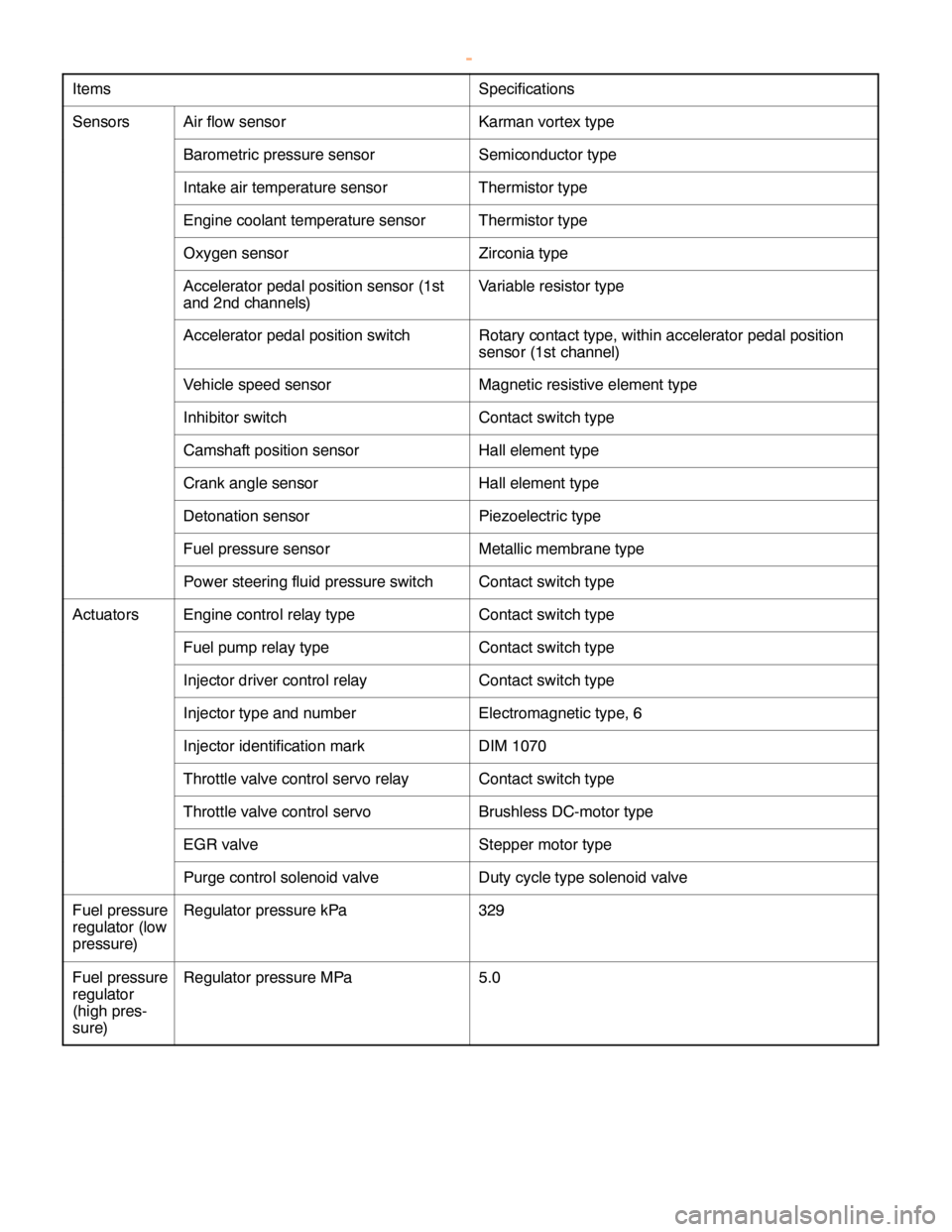

Items Specifications

SensorsAir flow sensorKarman vortex type

Barometric pressure sensorSemiconductor type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Accelerator pedal position sensor (1st

and 2nd channels)Variable resistor type

Accelerator pedal position switchRotary contact type, within accelerator pedal position

sensor (1st channel)

Vehicle speed sensorMagnetic resistive element type

Inhibitor switchContact switch type

Camshaft position sensorHall element type

Crank angle sensorHall element type

Detonation sensorPiezoelectric type

Fuel pressure sensorMetallic membrane type

Power steering fluid pressure switchContact switch type

ActuatorsEngine control relay typeContact switch type

Fuel pump relay typeContact switch type

Injector driver control relayContact switch type

Injector type and numberElectromagnetic type, 6

Injector identification markDIM 1070

Throttle valve control servo relayContact switch type

Throttle valve control servoBrushless DC-motor type

EGR valveStepper motor type

Purge control solenoid valveDuty cycle type solenoid valve

Fuel pressure

regulator (low

pressure)Regulator pressure kPa329

Fuel pressure

regulator

(high pres-

sure)Regulator pressure MPa5.0

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 224 of 1839

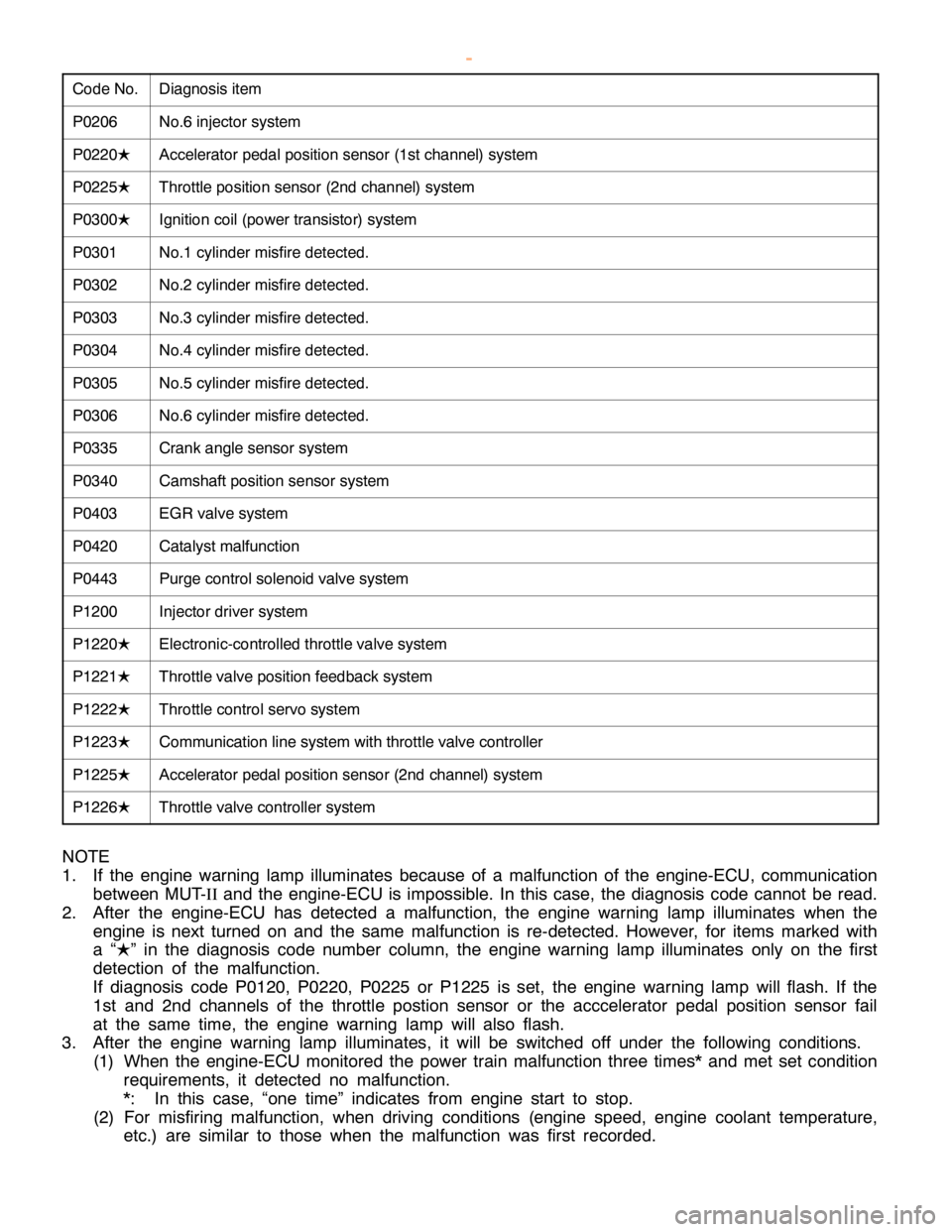

GDI -Troubleshooting

Code No. Diagnosis item

P0206No.6 injector system

P0220LAccelerator pedal position sensor (1st channel) system

P0225LThrottle position sensor (2nd channel) system

P0300LIgnition coil (power transistor) system

P0301No.1 cylinder misfire detected.

P0302No.2 cylinder misfire detected.

P0303No.3 cylinder misfire detected.

P0304No.4 cylinder misfire detected.

P0305No.5 cylinder misfire detected.

P0306No.6 cylinder misfire detected.

P0335Crank angle sensor system

P0340Camshaft position sensor system

P0403EGR valve system

P0420Catalyst malfunction

P0443Purge control solenoid valve system

P1200Injector driver system

P1220LElectronic-controlled throttle valve system

P1221LThrottle valve position feedback system

P1222LThrottle control servo system

P1223LCommunication line system with throttle valve controller

P1225LAccelerator pedal position sensor (2nd channel) system

P1226LThrottle valve controller system

NOTE

1. If the engine warning lamp illuminates because of a malfunction of the engine-ECU, communication

between MUT-

IIand the engine-ECU is impossible. In this case, the diagnosis code cannot be read.

2. After the engine-ECU has detected a malfunction, the engine warning lamp illuminates when the

engine is next turned on and the same malfunction is re-detected. However, for items marked with

a“

L” in the diagnosis code number column, the engine warning lamp illuminates only on the first

detection of the malfunction.

If diagnosis code P0120, P0220, P0225 or P1225 is set, the engine warning lamp will flash. If the

1st and 2nd channels of the throttle postion sensor or the acccelerator pedal position sensor fail

at the same time, the engine warning lamp will also flash.

3. After the engine warning lamp illuminates, it will be switched off under the following conditions.

(1) When the engine-ECU monitored the power train malfunction three times* and met set condition

requirements, it detected no malfunction.

*: In this case, “one time” indicates from engine start to stop.

(2) For misfiring malfunction, when driving conditions (engine speed, engine coolant temperature,

etc.) are similar to those when the malfunction was first recorded.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 229 of 1839

GDI -Troubleshooting

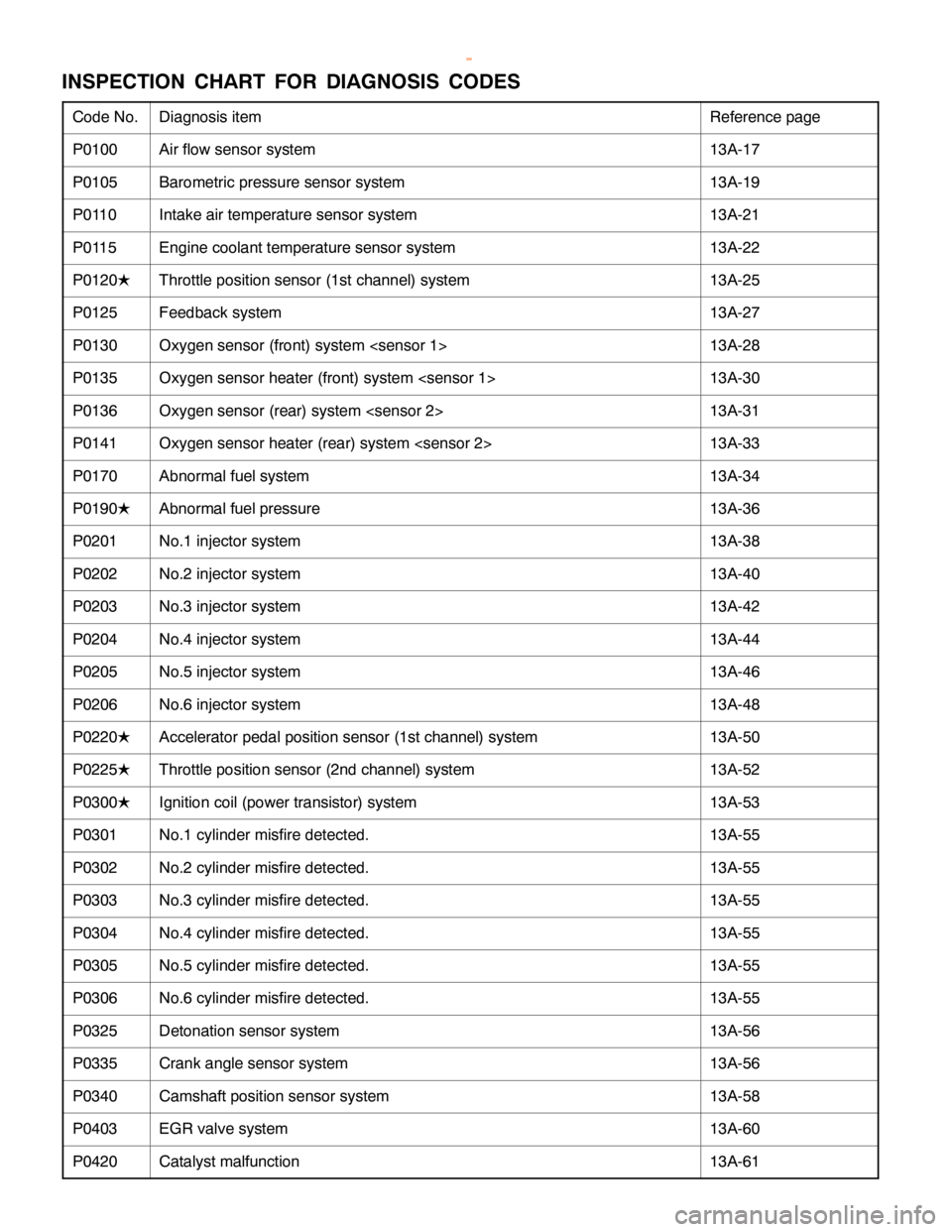

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference page

P0100Air flow sensor system13A-17

P0105Barometric pressure sensor system13A-19

P0110Intake air temperature sensor system13A-21

P0115Engine coolant temperature sensor system13A-22

P0120LThrottle position sensor (1st channel) system13A-25

P0125Feedback system13A-27

P0130Oxygen sensor (front) system

P0135Oxygen sensor heater (front) system

P0136Oxygen sensor (rear) system

P0141Oxygen sensor heater (rear) system

P0170Abnormal fuel system13A-34

P0190LAbnormal fuel pressure13A-36

P0201No.1 injector system13A-38

P0202No.2 injector system13A-40

P0203No.3 injector system13A-42

P0204No.4 injector system13A-44

P0205No.5 injector system13A-46

P0206No.6 injector system13A-48

P0220LAccelerator pedal position sensor (1st channel) system13A-50

P0225LThrottle position sensor (2nd channel) system13A-52

P0300LIgnition coil (power transistor) system13A-53

P0301No.1 cylinder misfire detected.13A-55

P0302No.2 cylinder misfire detected.13A-55

P0303No.3 cylinder misfire detected.13A-55

P0304No.4 cylinder misfire detected.13A-55

P0305No.5 cylinder misfire detected.13A-55

P0306No.6 cylinder misfire detected.13A-55

P0325Detonation sensor system13A-56

P0335Crank angle sensor system13A-56

P0340Camshaft position sensor system13A-58

P0403EGR valve system13A-60

P0420Catalyst malfunction13A-61

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 249 of 1839

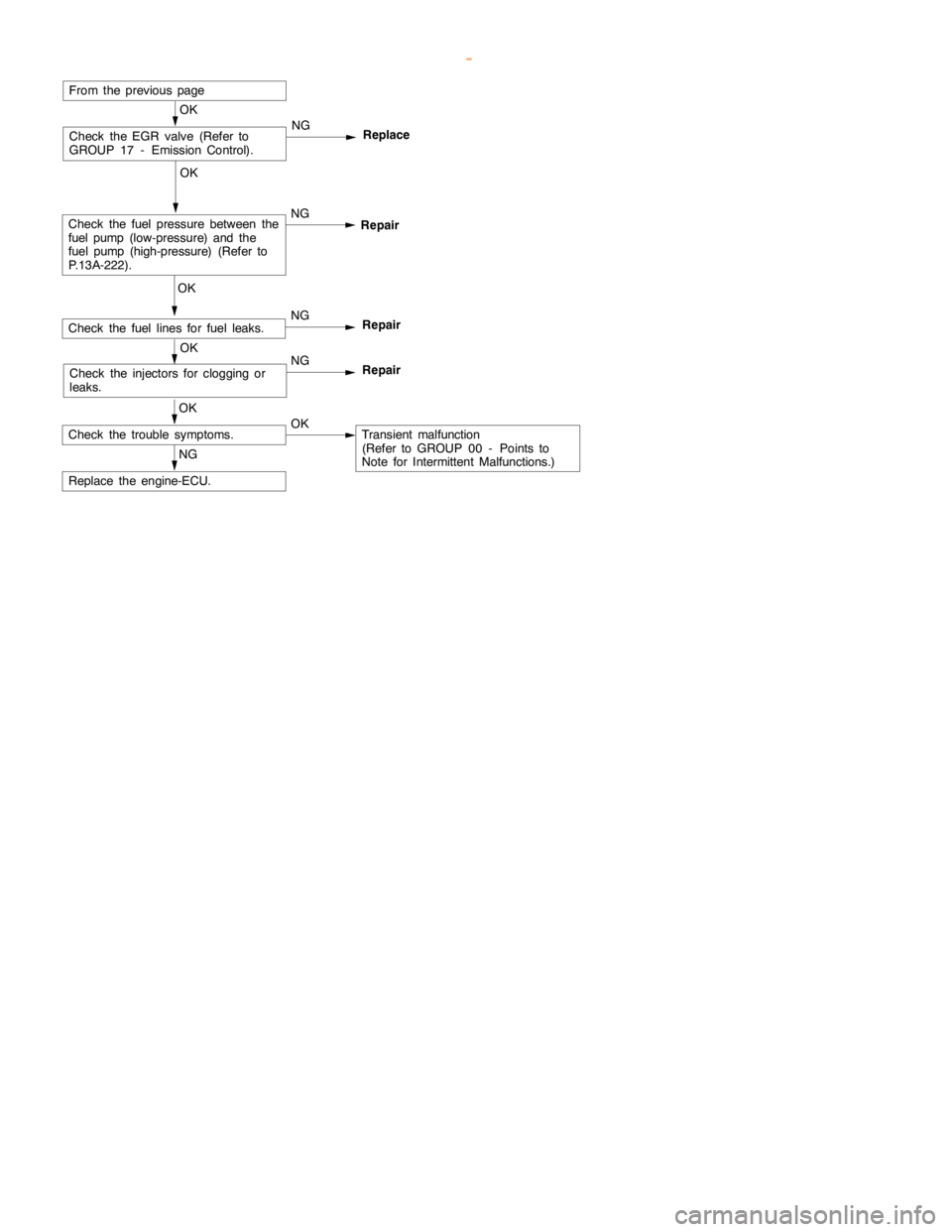

GDI -Troubleshooting

OK

Check the injectors for clogging or

leaks.NG

Repair

OK

Check the fuel lines for fuel leaks.NG

Repair

OK

Check the fuel pressure between the

fuel pump(low-pressure) and the

fuel pump (high-pressure)(Refer to

P.13A-222).NG

From the previouspage

OK

Check the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the engine-ECU.

OK

Check the EGR valve (Refer to

GROUP 17 - Emission Control).NG

Replace

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 274 of 1839

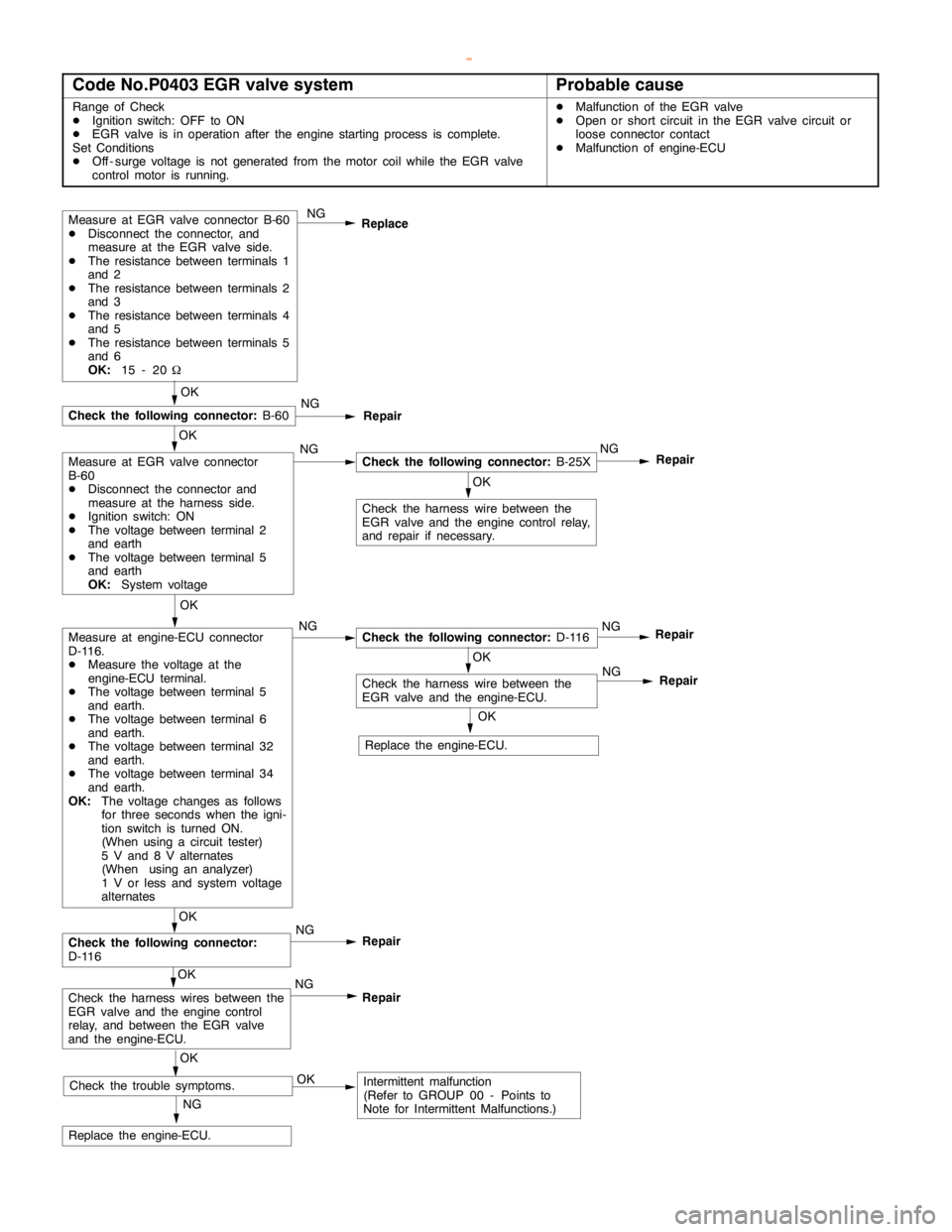

GDI -Troubleshooting

Code No.P0403 EGR valve systemProbable cause

Range of Check

DIgnition switch: OFF to ON

DEGR valve is in operation after theengine startingprocess is complete.

Set Conditions

DOff - surge voltage is not generated from the motor coil while the EGR valve

control motor is running.DMalfunction of the EGR valve

DOpen or short circuit in the EGR valve circuit or

loose connector contact

DMalfunction of engine-ECU

Measure at EGR valve connector B-60

DDisconnect the connector, and

measure at the EGR valve side.

DThe resistance between terminals 1

and 2

DThe resistance between terminals 2

and 3

DThe resistance between terminals 4

and 5

DThe resistance between terminals 5

and 6

OK:

15 - 20WNG

Replace

OK

Check the harness wire between the

EGR valve and theengine controlrelay,

and repair if necessary.

NG

Replace the engine-ECU.

OK

NG

Check the following connector:

B-25XNG

Repair

OK

Check the following connector:

B-60NG

Repair

OK

Measure at engine-ECU connector

D-116.

DMeasure the voltage at the

engine-ECU terminal.

DThe voltage between terminal 5

and earth.

DThe voltage between terminal 6

and earth.

DThe voltage between terminal 32

and earth.

DThe voltage between terminal 34

and earth.

OK:

The voltage changes as follows

for three seconds when the igni-

tion switch is turned ON.

(When using a circuit tester)

5 V and 8 V alternates

(When using an analyzer)

1 V or less and system voltage

alternatesNGCheck the following connector:

D-116NG

Repair

OK

Check the harness wire between the

EGR valve and the engine-ECU.

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wires between the

EGR valve and theengine control

relay, and between the EGR valve

and the engine-ECU.NG

Repair

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)NG

Repair

OK

Replace the engine-ECU.

Measure at EGR valve connector

B-60

DDisconnect the connector and

measure at the harness side.

DIgnition switch: ON

DThe voltage between terminal 2

and earth

DThe voltage between terminal 5

and earth

OK:

System voltage

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

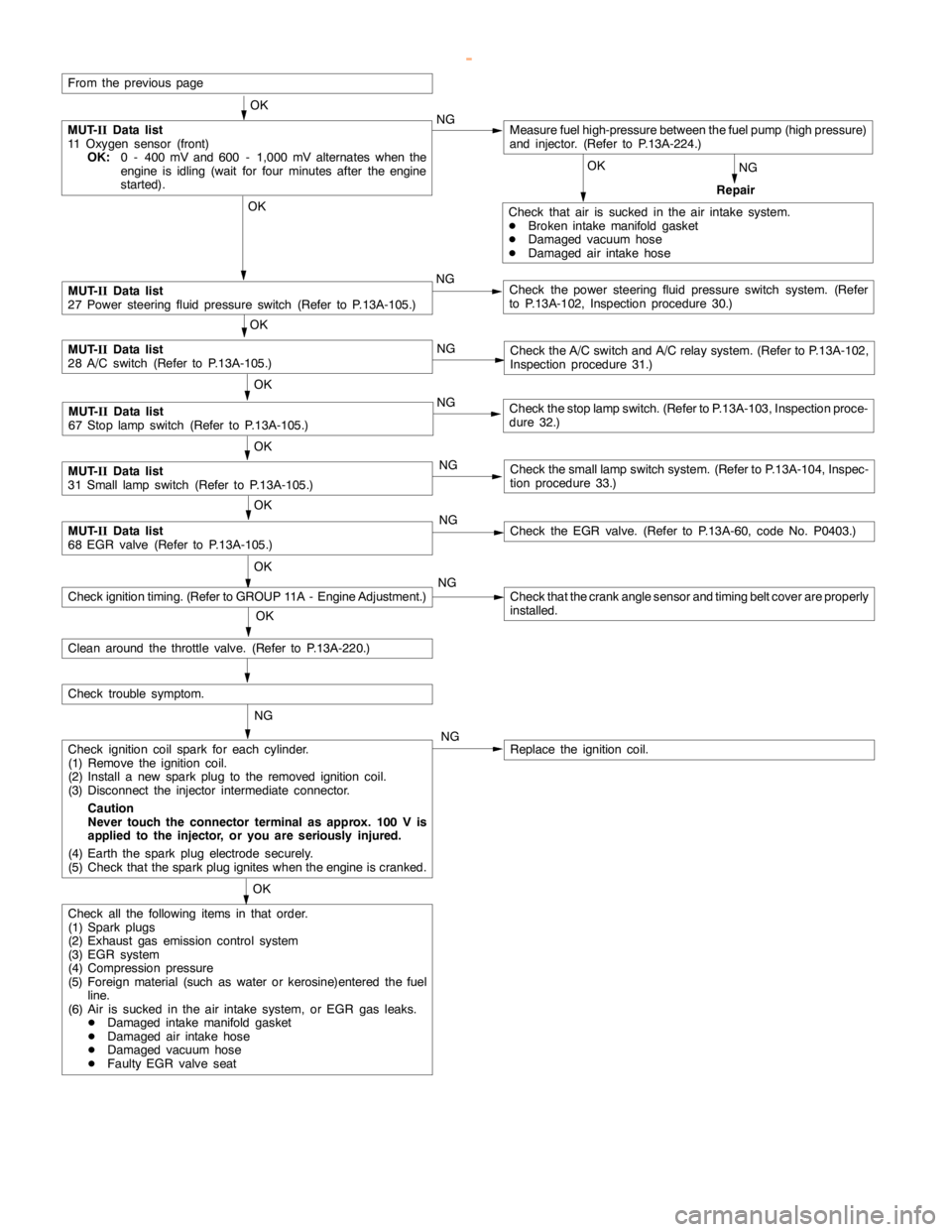

Page 296 of 1839

GDI -Troubleshooting

OK

Check that air is sucked in the air intake system.

DBroken intake manifold gasket

DDamaged vacuum hose

DDamaged air intake hose

From the previouspage

OK

MUT-

IIData list

27 Power steering fluid pressure switch (Refer to P.13A-105.)NGCheck the power steering fluid pressure switch system. (Refer

to P.13A-102, Inspection procedure 30.)

OK

MUT-

IIData list

28 A/C switch (Refer to P.13A-105.)NGCheck the A/C switch and A/C relay system. (Refer to P.13A-102,

Inspection procedure 31.)

OK

MUT-

IIData list

67 Stoplampswitch (Refer to P.13A-105.)NGCheck the stoplampswitch. (Refer to P.13A-103, Inspection proce-

dure 32.)

OK

MUT-

IIData list

31 Small lampswitch (Refer to P.13A-105.)NGCheck the smalllampswitch system. (Refer to P.13A-104, Inspec-

tion procedure 33.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve. (Refer to P.13A-60, code No. P0403.)

OK

NG

Check that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check trouble symptom.

Check all the following items in that order.

(1) Spark plugs

(2) Exhaust gas emission control system

(3) EGR system

(4) Compression pressure

(5) Foreign material (such as water or kerosine)entered the fuel

line.

(6) Air is sucked in the air intake system, or EGR gas leaks.

DDamaged intake manifoldgasket

DDamaged air intake hose

DDamaged vacuum hose

DFaulty EGR valve seat

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

0 - 400 mV and 600 - 1,000 mV alternates when the

engine is idling(wait for four minutes after theengine

started).NG

NG

Repair

Measure fuel high-pressure between the fuel pump (highpressure)

and injector. (Refer to P.13A-224.)

Clean around the throttle valve. (Refer to P.13A-220.)

NG

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 298 of 1839

GDI -Troubleshooting

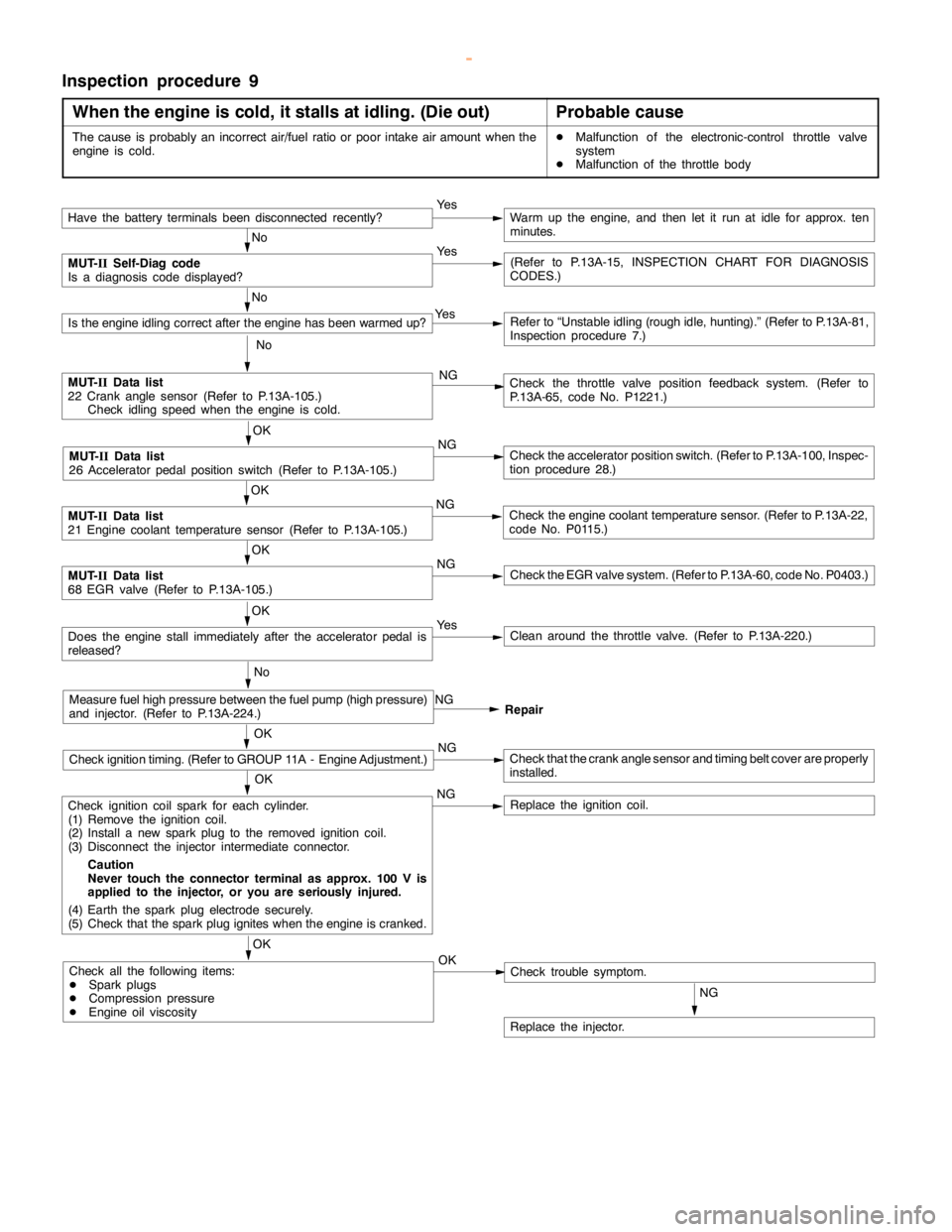

Inspection procedure 9

When the engine is cold, it stalls at idling. (Die out)

Probable cause

The cause is probably an incorrect air/fuel ratio or poor intake airamountwhen the

engine iscold.DMalfunction of the electronic-control throttle valve

system

DMalfunction of the throttle body

Have the battery terminalsbeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

Is the engine idlingcorrect after theengine has been warmed up?Ye sRefer to “Unstableidling (rough idle, hunting).”(Refer to P.13A-81,

Inspection procedure 7.)

No

MUT-

IIData list

22 Crankanglesensor (Refer to P.13A-105.)

Checkidlingspeed when theengine iscold.NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the accelerator position switch. (Refer to P.13A-100, Inspec-

tion procedure 28.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve system. (Refer to P.13A-60, code No. P0403.)

OK

Does theenginestall immediately after the acceleratorpedal is

released?Ye sClean around the throttle valve. (Refer to P.13A-220.)

No

Measure fuel highpressure between the fuelpump (highpressure)

and injector. (Refer to P.13A-224.)NG

Repair

OK

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)NGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check all the following items:

DSpark plugs

DCompression pressure

DEngine oilviscosityNGCheck trouble symptom. OK

Replace the injector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 300 of 1839

GDI -Troubleshooting

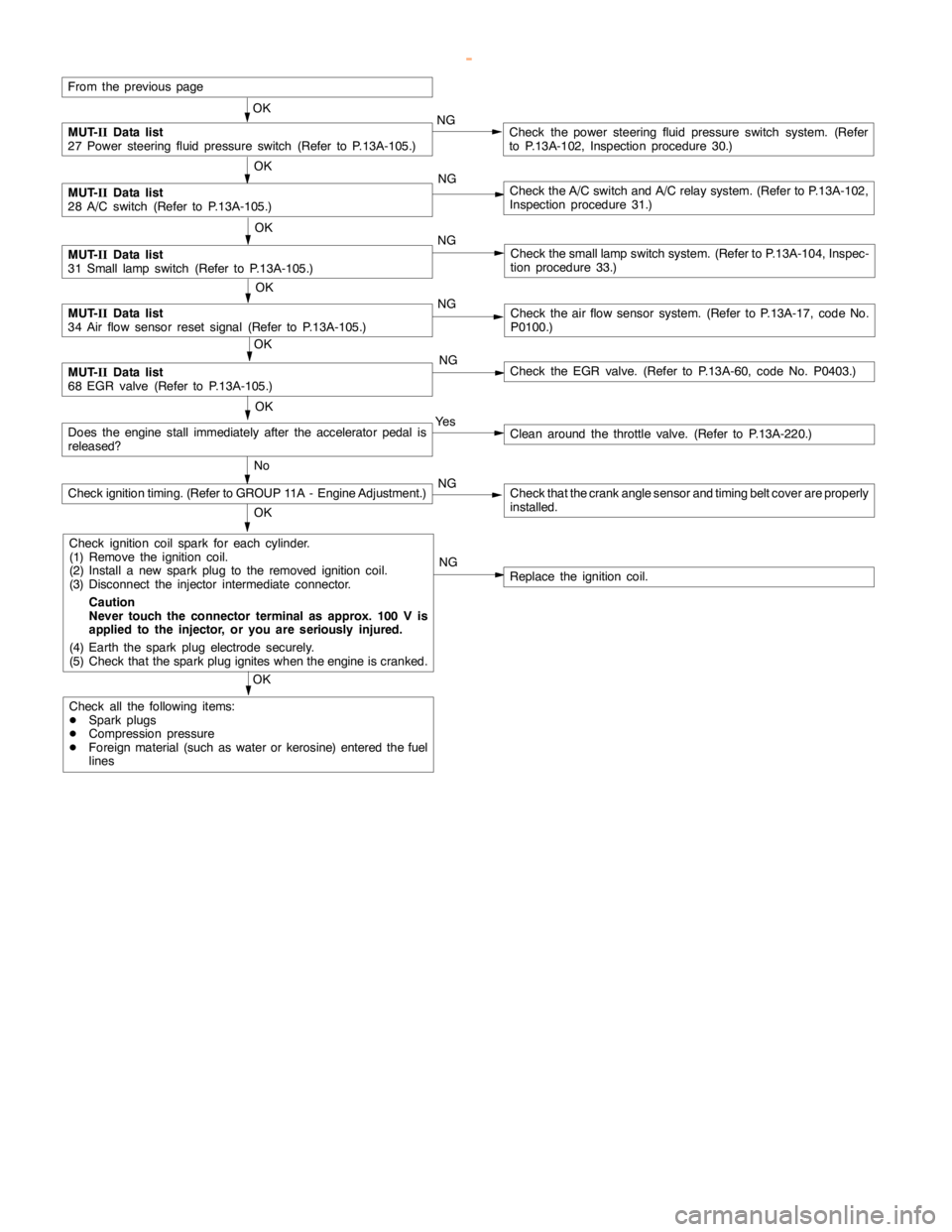

From the previouspage

OK

MUT-

IIData list

27 Power steering fluid pressure switch (Refer to P.13A-105.)NGCheck the power steering fluid pressure switch system. (Refer

to P.13A-102, Inspection procedure 30.)

OK

MUT-

IIData list

28 A/C switch (Refer to P.13A-105.)NGCheck the A/C switch and A/C relay system. (Refer to P.13A-102,

Inspection procedure 31.)

MUT-

IIData list

31 Small lampswitch (Refer to P.13A-105.)NGCheck the smalllampswitch system. (Refer to P.13A-104, Inspec-

tion procedure 33.)

OK

MUT-

IIData list

34 Air flow sensor reset signal (Refer to P.13A-105.)NGCheck the air flow sensor system. (Refer to P.13A-17, code No.

P0100.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve. (Refer to P.13A-60, code No. P0403.)

OK

Ye s

Clean around the throttle valve. (Refer to P.13A-220.)

No

NG

Check that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NG

Replace the ignition coil.

OK

Check all the following items:

DSpark plugs

DCompression pressure

DForeign material (such as water or kerosine) entered the fuel

linesOK

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)

Does theenginestall immediately after the acceleratorpedal is

released?

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk