radiator MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 173 of 1839

ENGINE <4M4> -Cylinder Head Gasket11C-32

"

DA

RADIATOR LOWER HOSE/RADIATOR UPPER

HOSE CONNECTION

1. Insert the hose up to the convex part of the thermostat

cover and water outlet pipe.

2. Align the mating marks on the radiator hose and the

hose clamp, and then install the hose.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 284 of 1839

GDI -Troubleshooting

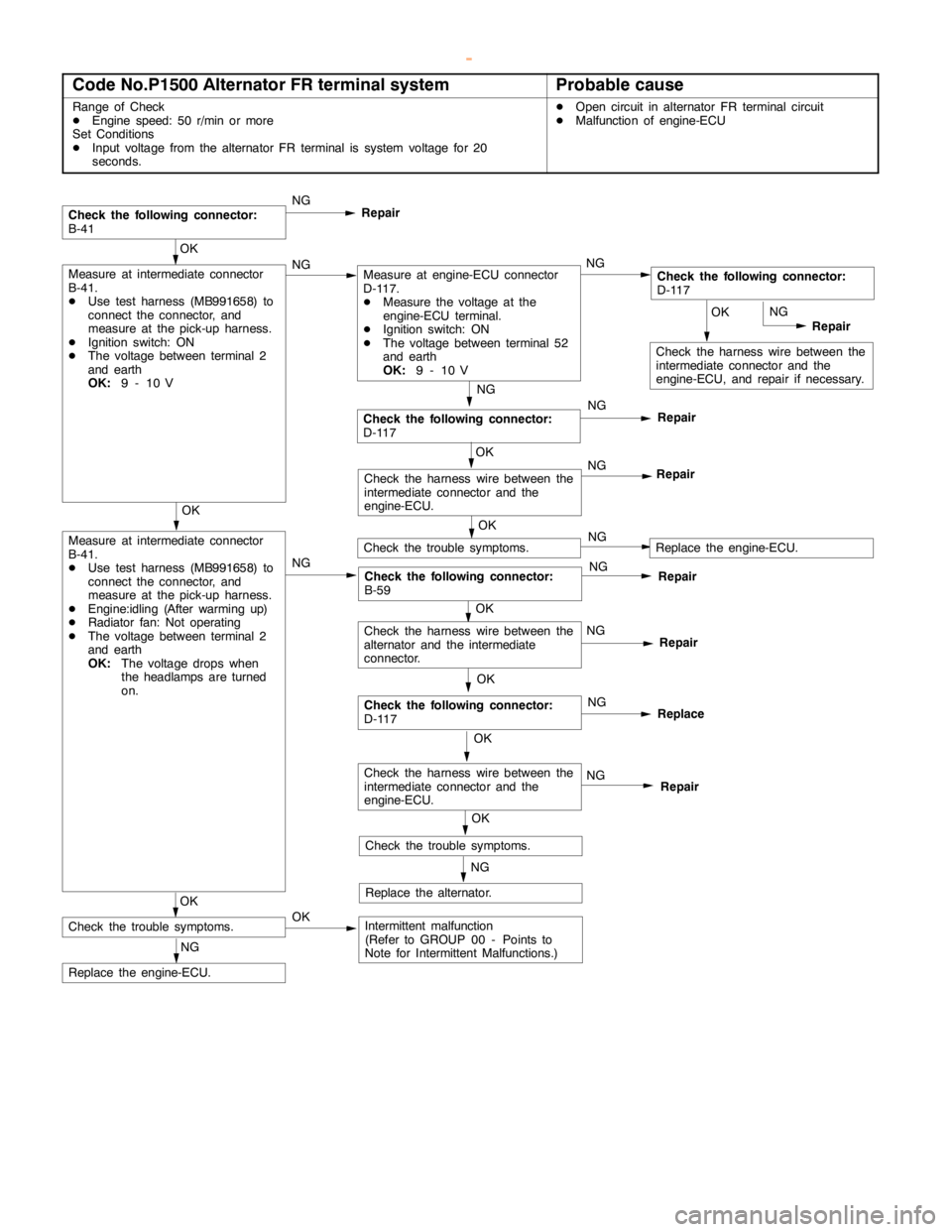

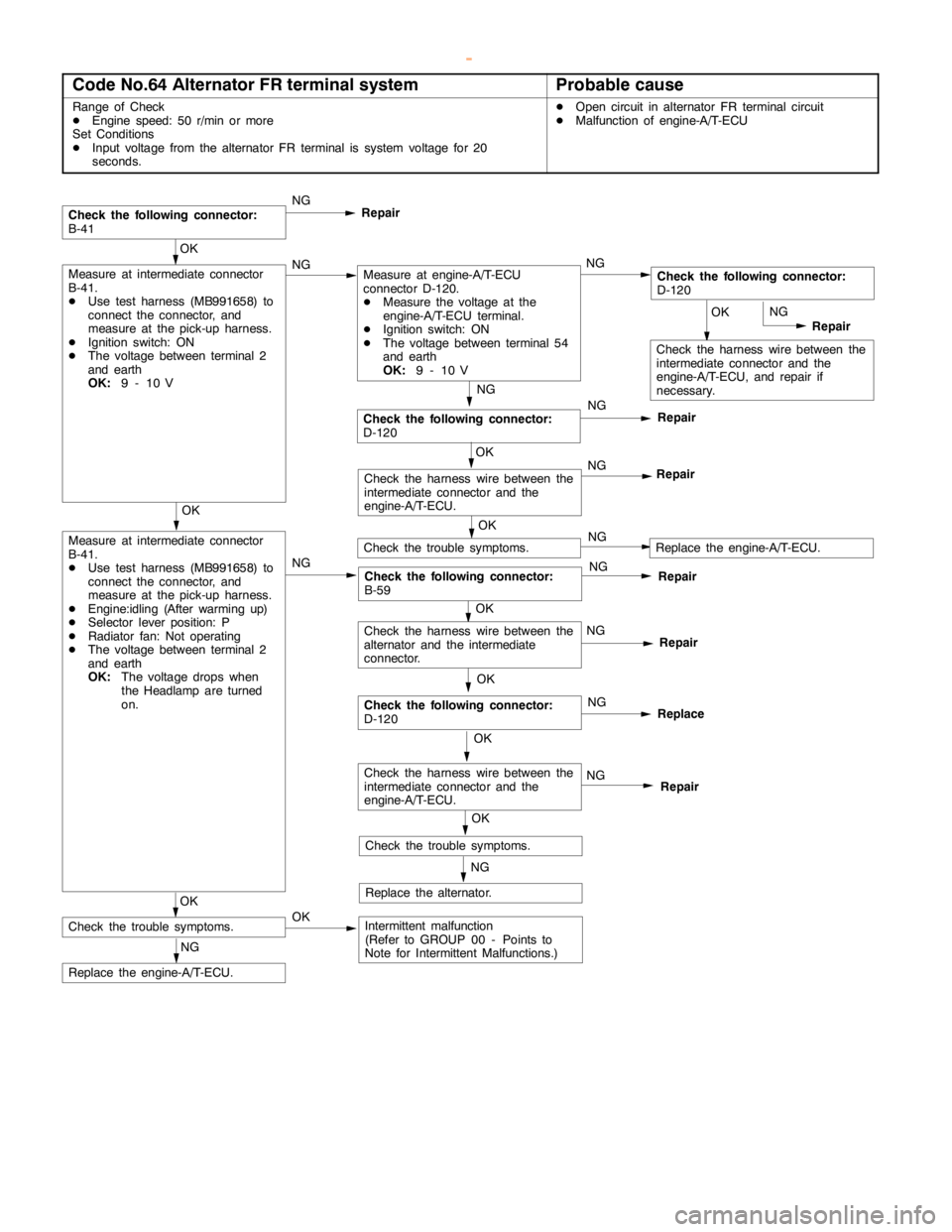

Code No.P1500 Alternator FR terminal systemProbable cause

Range of Check

DEngine speed: 50 r/min or more

Set Conditions

DInput voltage from the alternator FR terminal is system voltage for 20

seconds.DOpen circuit in alternator FR terminal circuit

DMalfunction of engine-ECU

OK

Check the harness wire between the

intermediate connector and the

engine-ECU, and repair if necessary.NG

Repair

NG

Check the following connector:

D-117NG

Repair

Check the following connector:

B-41NG

Repair

OK

Measure at intermediate connector

B-41.

DUse test harness (MB991658) to

connect the connector, and

measure at the pick-up harness.

DEngine:idling (After warming up)

DRadiator fan: Not operating

DThe voltage between terminal 2

and earth

OK:

The voltage drops when

the headlamps are turned

on.NG

Check the following connector:

B-59NG

Repair

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

OK

Check the harness wire between the

intermediate connector and the

engine-ECU.NG

Repair

OK

Measure at intermediate connector

B-41.

DUse test harness (MB991658) to

connect the connector, and

measure at the pick-up harness.

DIgnition switch: ON

DThe voltage between terminal 2

and earth

OK:

9 - 10 VNGMeasure at engine-ECU connector

D-117.

DMeasure the voltage at the

engine-ECU terminal.

DIgnition switch: ON

DThe voltage between terminal 52

and earth

OK:

9 - 10 VNGCheck the following connector:

D-117

OK

NG

Repair

OK

Check the following connector:

D-117NG

Replace

OK

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Check the harness wire between the

intermediate connector and the

engine-ECU.NG

Repair

NG

Replace the alternator.OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

Check the harness wire between the

alternator and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

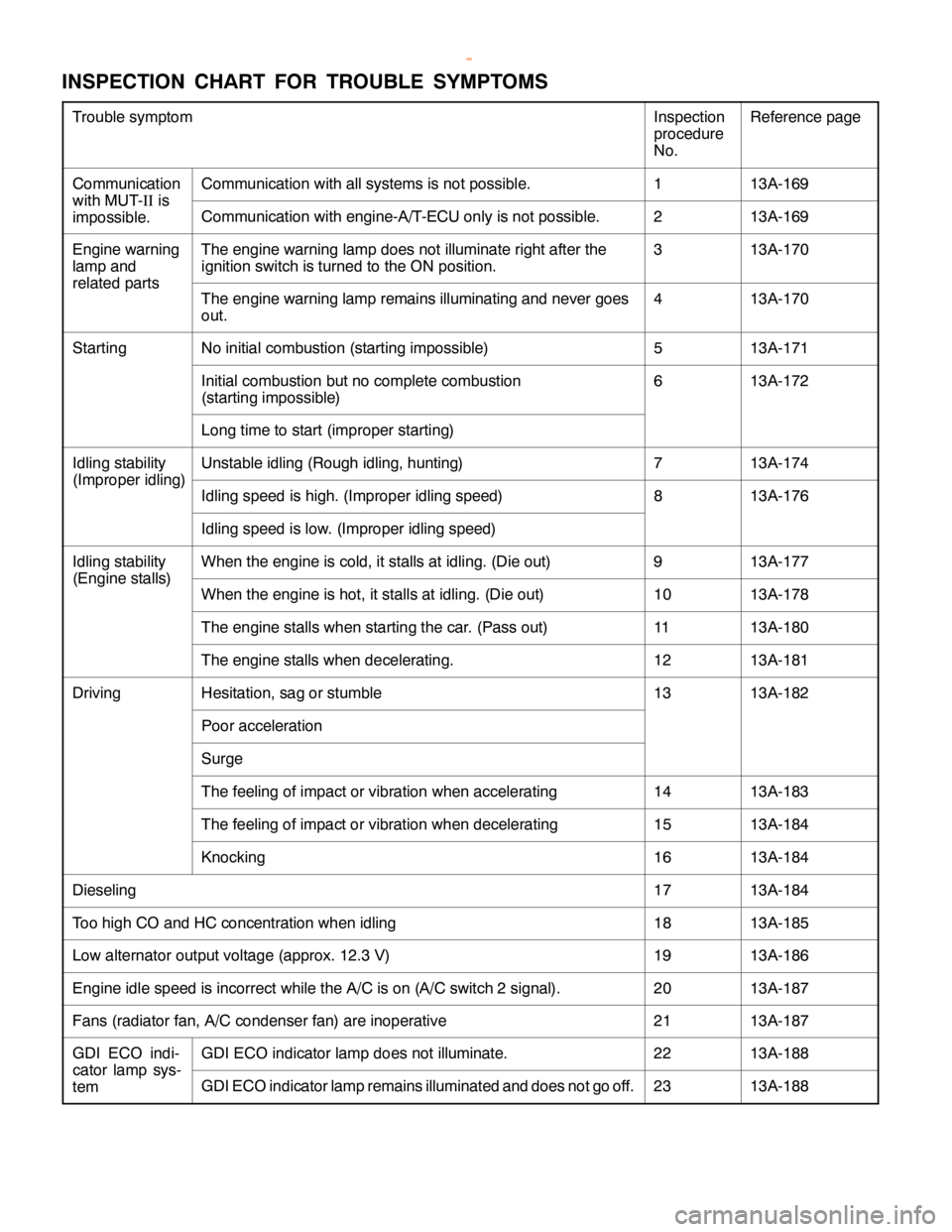

Page 308 of 1839

GDI -Troubleshooting

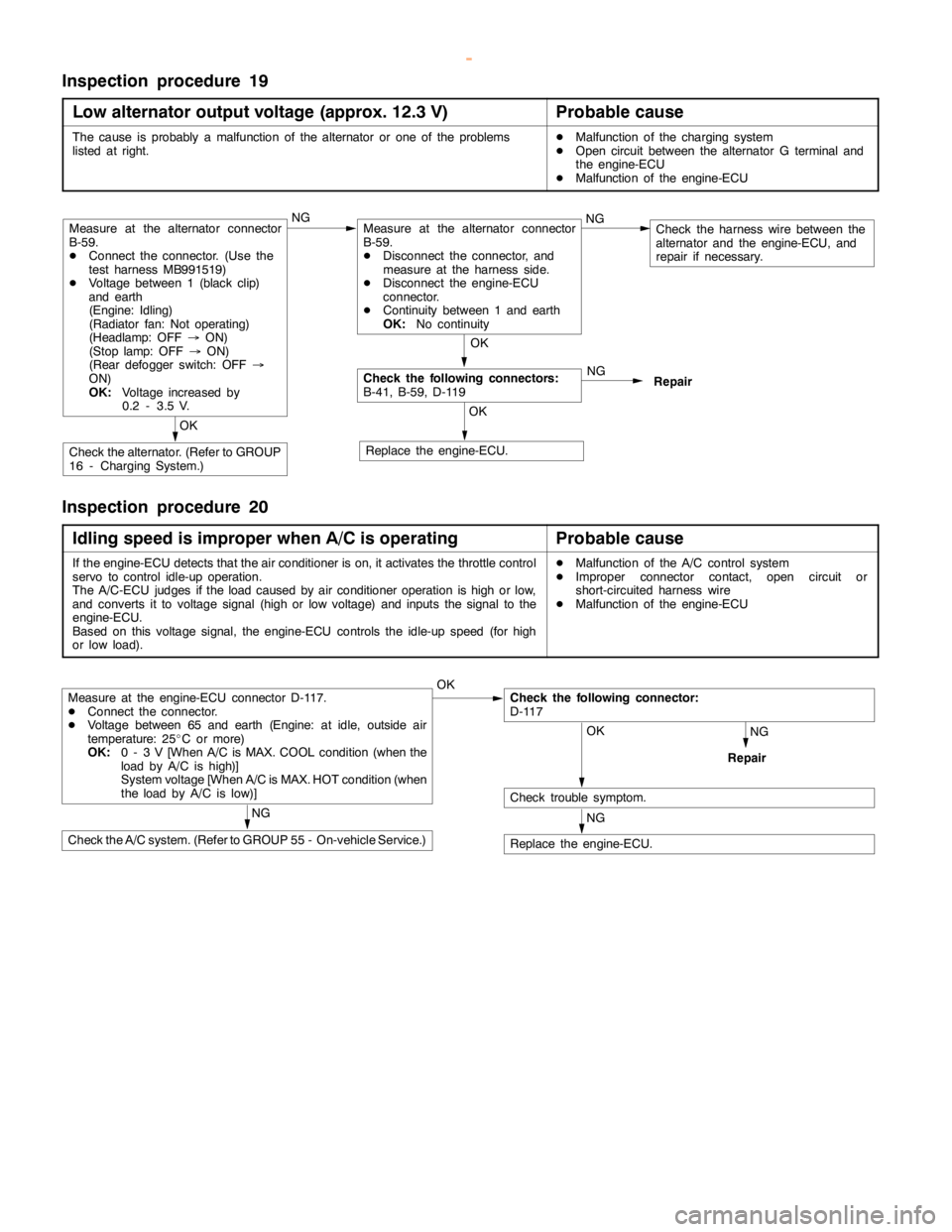

Inspection procedure 19

Low alternator output voltage (approx.12.3 V)

Probable cause

The cause is probably a malfunction of the alternator or one of the problems

listed at right.DMalfunction of the charging system

DOpen circuit between the alternator G terminal and

the engine-ECU

DMalfunction of the engine-ECU

NG

Repair

OK

Replace the engine-ECU.

OK

Check the alternator. (Refer to GROUP

16 - Charging System.)

OK

Check the following connectors:

B-41, B-59, D-119

Measure at the alternator connector

B-59.

DConnect the connector. (Use the

test harness MB991519)

DVoltage between 1 (black clip)

and earth

(Engine: Idling)

(Radiator fan: Not operating)

(Headlamp: OFF®ON)

(Stoplamp: OFF®ON)

(Rear defogger switch: OFF®

ON)

OK:

Voltage increased by

0.2 - 3.5 V.NGMeasure at the alternator connector

B-59.

DDisconnect the connector, and

measure at the harness side.

DDisconnect the engine-ECU

connector.

DContinuity between 1 and earth

OK:

No continuityNGCheck the harness wire between the

alternator and the engine-ECU, and

repair if necessary.

Inspection procedure 20

Idling speed is improper when A/C is operating

Probable cause

If the engine-ECU detects that the air conditioner is on, it activates the throttle control

servo to control idle-up operation.

The A/C-ECU judges if theloadcaused by air conditioner operation ishigh or low,

and converts it to voltage signal (high or low voltage) and inputs the signal to the

engine-ECU.

Based on this voltage signal, the engine-ECU controls the idle-up speed (forhigh

or low load).DMalfunction of the A/C control system

DImproper connector contact,opencircuit or

short-circuited harness wire

DMalfunction of the engine-ECU

NG

Repair

Measure at the engine-ECU connector D-117.

DConnect the connector.

DVoltage between 65 and earth (Engine: at idle, outside air

temperature: 25_C or more)

OK:

0 - 3 V [When A/C is MAX. COOL condition (when the

load by A/C is high)]

System voltage [When A/C is MAX. HOT condition (when

the load by A/C islow)]OKCheck the following connector:

D-117

OK

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Check the A/C system. (Refer to GROUP 55 - On-vehicle Service.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 327 of 1839

GDI -Troubleshooting

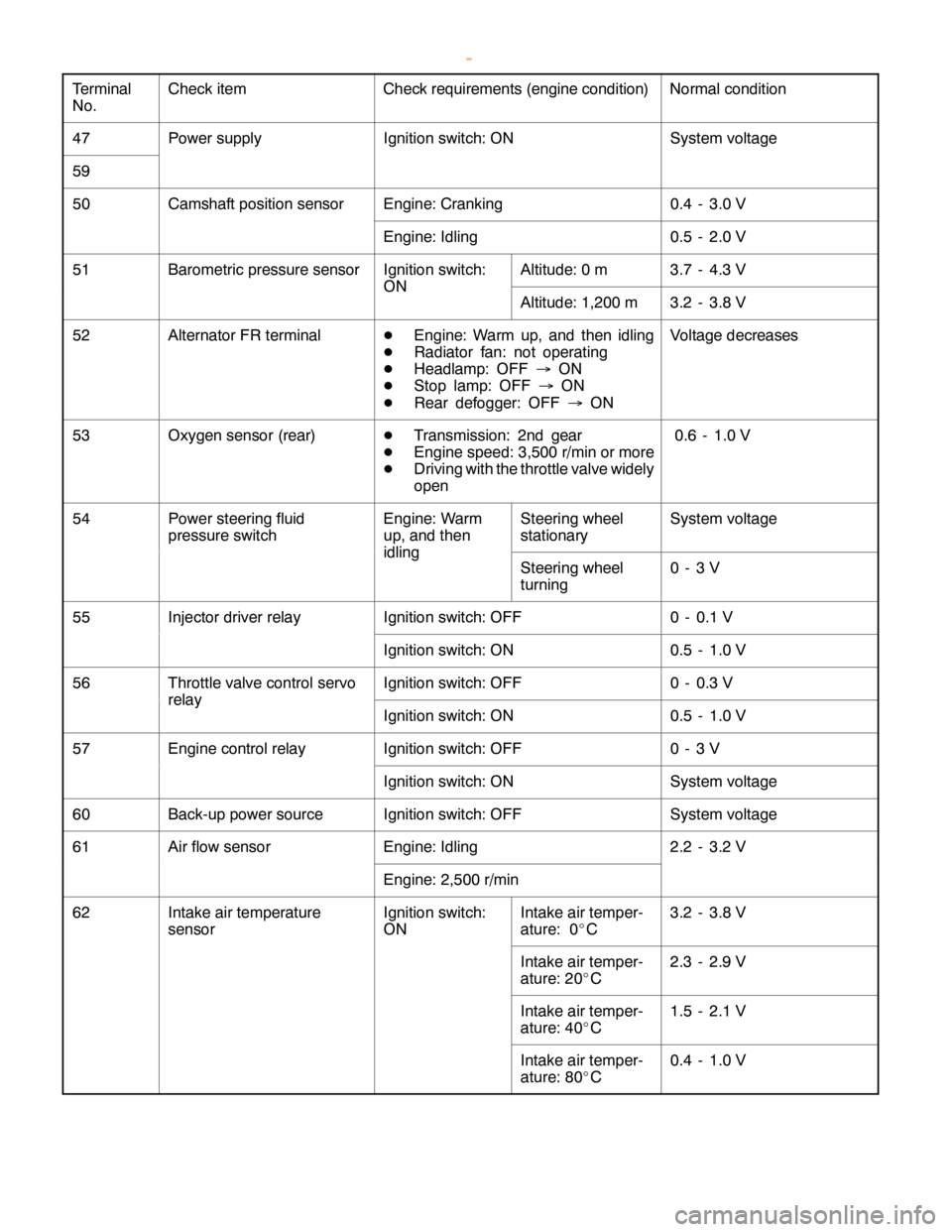

Terminal

No.Normal condition Check requirements (engine condition) Check item

47Power supplyIgnition switch: ONSystem voltage

59

50Camshaft position sensorEngine: Cranking0.4 - 3.0 V

Engine: Idling0.5 - 2.0 V

51Barometric pressure sensorIgnition switch:Altitude: 0 m3.7 - 4.3 V

ON

Altitude: 1,200 m3.2 - 3.8 V

52Alternator FR terminalDEngine: Warm up, and then idling

DRadiator fan: not operating

DHeadlamp: OFF®ON

DStop lamp: OFF®ON

DRear defogger: OFF®ONVoltage decreases

53Oxygen sensor (rear)DTransmission: 2nd gear

DEngine speed: 3,500 r/min or more

DDriving with the throttle valve widely

open0.6 - 1.0 V

54Power steering fluid

pressure switchEngine: Warm

up, and thenSteering wheel

stationarySystem voltage

idling

Steering wheel

turning0-3V

55Injector driver relayIgnition switch: OFF0 - 0.1 V

Ignition switch: ON0.5 - 1.0 V

56Throttle valve control servoIgnition switch: OFF0 - 0.3 V

relay

Ignition switch: ON0.5 - 1.0 V

57Engine control relayIgnition switch: OFF0-3V

Ignition switch: ONSystem voltage

60Back-up power sourceIgnition switch: OFFSystem voltage

61Air flow sensorEngine: Idling2.2 - 3.2 V

Engine: 2,500 r/min

62Intake air temperature

sensorIgnition switch:

ONIntake air temper-

ature: 0_C3.2 - 3.8 V

Intake air temper-

ature: 20_C2.3 - 2.9 V

Intake air temper-

ature: 40_C1.5 - 2.1 V

Intake air temper-

ature: 80_C0.4 - 1.0 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 367 of 1839

Page 380 of 1839

Page 493 of 1839

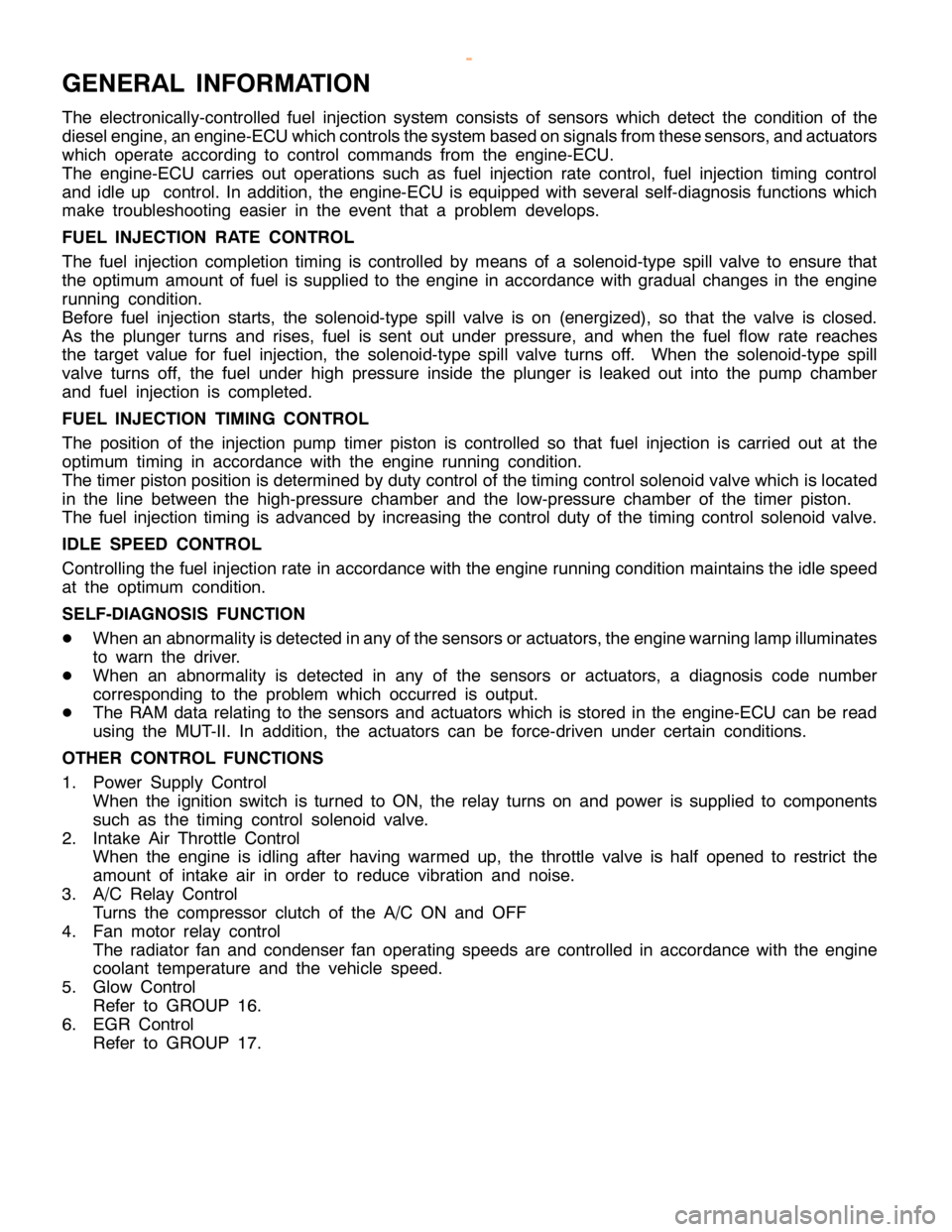

DIESEL FUEL <4M4> -General Information13C-2

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine is idling after having warmed up, the throttle valve is half opened to restrict the

amount of intake air in order to reduce vibration and noise.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Fan motor relay control

The radiator fan and condenser fan operating speeds are controlled in accordance with the engine

coolant temperature and the vehicle speed.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

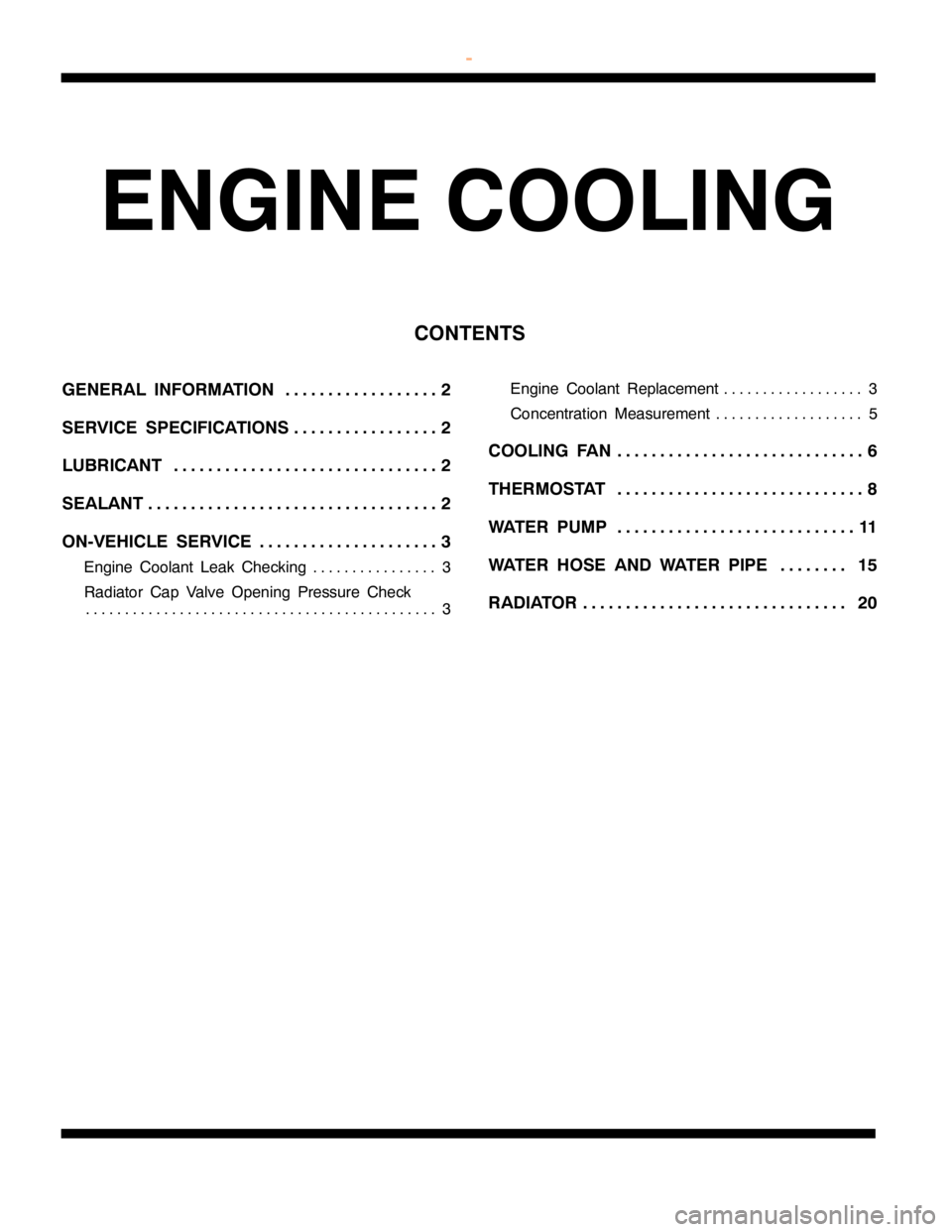

Page 678 of 1839

14-1

ENGINE COOLING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

LUBRICANT 2...............................

SEALANT 2..................................

ON-VEHICLE SERVICE 3.....................

Engine Coolant Leak Checking 3................

Radiator Cap Valve Opening Pressure Check

3 .............................................Engine Coolant Replacement 3..................

Concentration Measurement 5...................

COOLING FAN 6.............................

THERMOSTAT 8.............................

WATER PUMP 11............................

WATER HOSE AND WATER PIPE 15........

RADIATOR 20...............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 679 of 1839

ENGINE COOLING -General Information/

Service Specifications/Lubricant/Sealant14-2

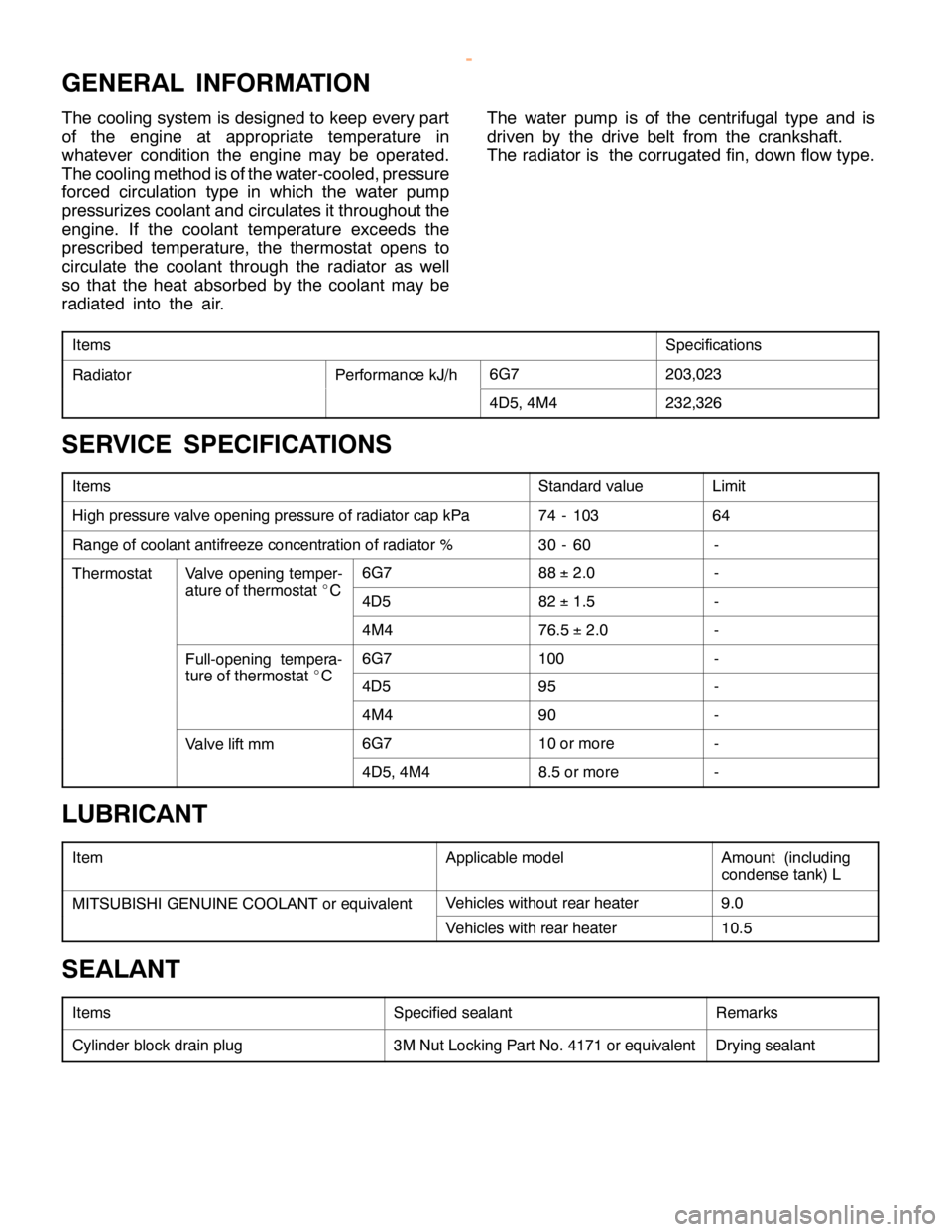

GENERAL INFORMATION

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.The water pump is of the centrifugal type and is

driven by the drive belt from the crankshaft.

The radiator is the corrugated fin, down flow type.

ItemsSpecifications

RadiatorPerformance kJ/h6G7203,023

4D5, 4M4232,326

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

High pressure valve opening pressure of radiator cap kPa74 - 10364

Range of coolant antifreeze concentration of radiator %30 - 60-

ThermostatValve opening temper-6G788±

2.0-

ature of thermostat_

C4D582±

1.5-

4M476.5±

2.0-

Full-opening tempera-6G7100-

ture of thermostat_

C4D595-

4M490-

Valve lift mm6G710 or more-

4D5, 4M48.5 or more-

LUBRICANT

ItemApplicable modelAmount (including

condense tank) L

MITSUBISHI GENUINE COOLANT or equivalentVehicles without rear heater9.0

Vehicles with rear heater10.5

SEALANT

ItemsSpecified sealantRemarks

Cylinder block drain plug3M Nut Locking Part No. 4171 or equivalentDrying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1165 of 1839

POWER PLANT MOUNT - No.1 Crossmember32-7

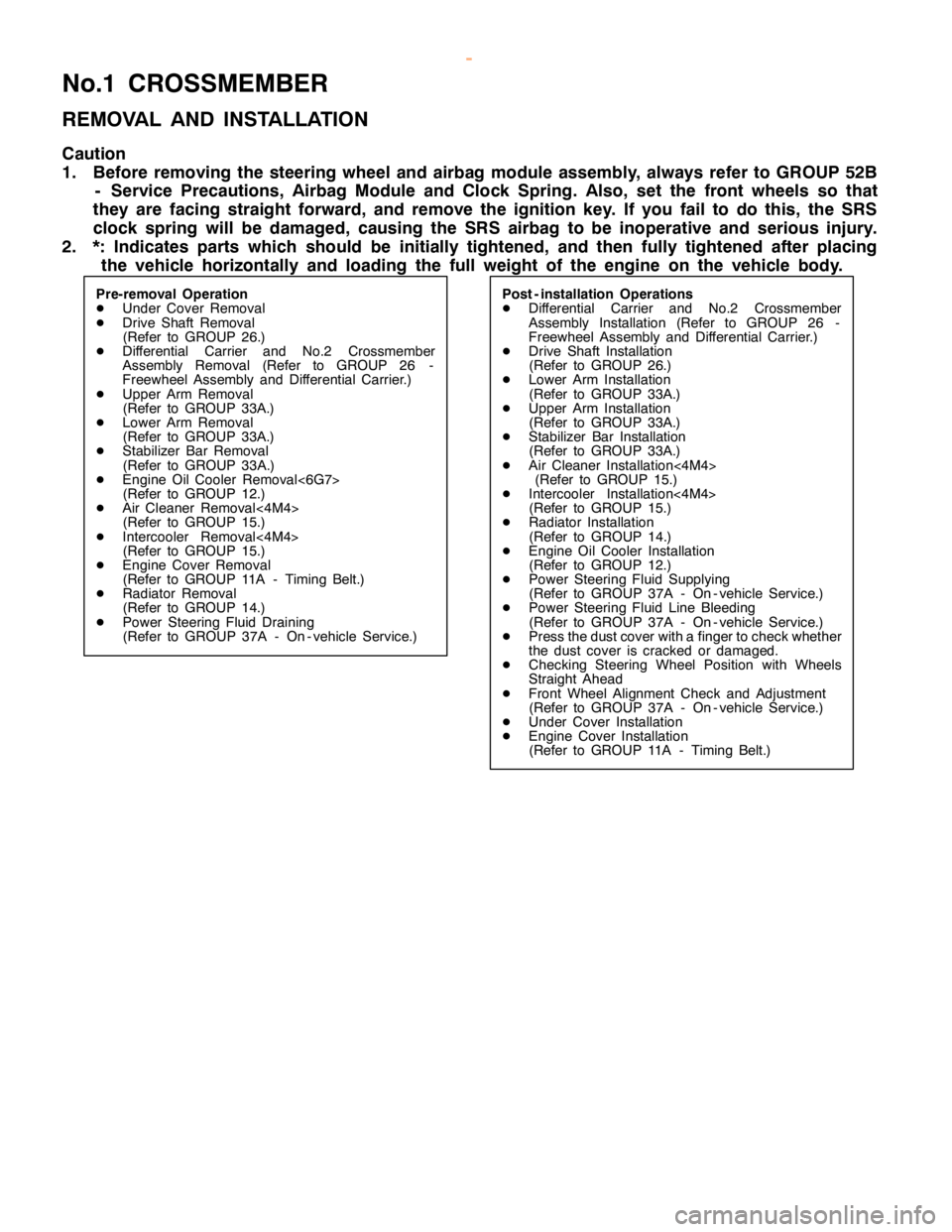

No.1 CROSSMEMBER

REMOVAL AND INSTALLATION

Caution

1. Before removing the steering wheel and airbag module assembly, always refer to GROUP 52B

- Service Precautions, Airbag Module and Clock Spring. Also, set the front wheels so that

they are facing straight forward, and remove the ignition key. If you fail to do this, the SRS

clock spring will be damaged, causing the SRS airbag to be inoperative and serious injury.

2. *: Indicates parts which should be initially tightened, and then fully tightened after placing

the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

DUnder Cover Removal

DDrive Shaft Removal

(Refer to GROUP 26.)

DDifferential Carrier and No.2 Crossmember

Assembly Removal (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DUpper Arm Removal

(Refer to GROUP 33A.)

DLower Arm Removal

(Refer to GROUP 33A.)

DStabilizer Bar Removal

(Refer to GROUP 33A.)

DEngine Oil Cooler Removal<6G7>

(Refer to GROUP 12.)

DAir Cleaner Removal<4M4>

(Refer to GROUP 15.)

DIntercooler Removal<4M4>

(Refer to GROUP 15.)

DEngine Cover Removal

(Refer to GROUP 11A - Timing Belt.)

DRadiator Removal

(Refer to GROUP 14.)

DPower Steering Fluid Draining

(Refer to GROUP 37A - On - vehicle Service.)Post - installation Operations

DDifferential Carrier and No.2 Crossmember

Assembly Installation (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DDrive Shaft Installation

(Refer to GROUP 26.)

DLower Arm Installation

(Refer to GROUP 33A.)

DUpper Arm Installation

(Refer to GROUP 33A.)

DStabilizer Bar Installation

(Refer to GROUP 33A.)

DAir Cleaner Installation<4M4>

(Refer to GROUP 15.)

DIntercooler Installation<4M4>

(Refer to GROUP 15.)

DRadiator Installation

(Refer to GROUP 14.)

DEngine Oil Cooler Installation

(Refer to GROUP 12.)

DPower Steering Fluid Supplying

(Refer to GROUP 37A - On - vehicle Service.)

DPower Steering Fluid Line Bleeding

(Refer to GROUP 37A - On - vehicle Service.)

DPress the dust cover with a finger tocheck whether

the dust cover is cracked or damaged.

DChecking Steering Wheel Position with Wheels

StraightAhead

DFront Wheel AlignmentCheck and Adjustment

(Refer to GROUP 37A - On - vehicle Service.)

DUnder Cover Installation

DEngine Cover Installation

(Refer to GROUP 11A - Timing Belt.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk