sensor MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 474 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 16 . ,

Acceleration shock ,

[Comment] Malfunction of the ignition systemIn cases such as the above, the cause is probably that there is an ignition leak ac MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 16 . ,

Acceleration shock ,

[Comment] Malfunction of the ignition systemIn cases such as the above, the cause is probably that there is an ignition leak ac](/img/19/57345/w960_57345-473.png)

E N G I N E

INSPECTION PROCEDURE 16 . ,

Acceleration shock ,

[Comment] Malfunction of the ignition systemIn cases such as the above, the cause is probably that there is an ignition leak accompanyinglthe increase in the spark plug demand voltage durin g acceleration.Improper control of reduction stiifting.

Are diagnostic trouble codes output

NO YES

Refer to INSPECTION CHART D I A G N O S T I CTROUBLE CODES.

Check the following items.

l

Check the ignition coil, spark plugs, spark plug ca bles.

l Check for occurrence of ignition leak.

l Check the torque reduction link (wire) between the PCM and TCM.

INSPECTION PROCEDURE 17

Deceleration shock Probable cause

[Comment]Malfunction of the system is suspected.l Malfunction of ‘system

III

Are diagnostic trouble codes output

NO

YESR e f e r t o C H A R T F O R TROUBLE CODES.

SCAN TOOL Actuator test

07 motor. (Refer to PROCEDURE FOR DIAGNOSTIC TROUBLE CODES

SCAN TOOL Special function“Reset

Check trouble I

N G

TSB Revision

Check the throttle body minimum air flow.

(Refer to

SCAN TOOL SENS

07 Throttle position (Refer to NGl Check the throttle position sensor

(Refer to INSPECTION PROCEDURE 43.)

Page 476 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting

INSPECTION PROCEDURE 20

Knocking

[Comment]l Defective knock sensorIn cases such as the above, the cause is probably t hat the detonation control is defecti MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting

INSPECTION PROCEDURE 20

Knocking

[Comment]l Defective knock sensorIn cases such as the above, the cause is probably t hat the detonation control is defecti](/img/19/57345/w960_57345-475.png)

ENGINE Troubleshooting

INSPECTION PROCEDURE 20

Knocking

[Comment]l Defective knock sensorIn cases such as the above, the cause is probably t hat the detonation control is defective or l

the heat value of the spark plug is inappropriate. Inappropriate value of the

YES

Are

diagnostic troublecodesRefer to INSPECTION CHART FOR DIAGNOSTIC

outputTROUBLE CODES.

NO

SCAN TOOL SENSORNG

09 Knock sensor volts (Refer toCheck the knock sensor circuit (Refer to INSPECTION

PROCEDURE FOR DIAGNOSTIC TROUBLE

OK

Check the following items. l heat ranae

l Check ‘if (water, alcohol, etc.) got into fuel.

Dieseling cause

[Comment]Fuel leakage from injectors is suspected. l

Fuel leakage from injectors

Check the injectors for fuel leakage.

R e v i s i o n

Page 477 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 22

Too high CO and HC concentration when idling

[Comment]Abnormal air-fuel ratio is suspected.

cause

of the air-fuel ratio control system.l MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

INSPECTION PROCEDURE 22

Too high CO and HC concentration when idling

[Comment]Abnormal air-fuel ratio is suspected.

cause

of the air-fuel ratio control system.l](/img/19/57345/w960_57345-476.png)

E N G I N E

INSPECTION PROCEDURE 22

Too high CO and HC concentration when idling

[Comment]Abnormal air-fuel ratio is suspected.

cause

of the air-fuel ratio control system.l Deteriorated catalyst .

SCAN TOOL DTC

Are diagnostic trouble codes output Refer to INSPECTION CHART FOR DIAGNOSTICTROUBLE CODES.

NG

27 Intake air temperature sensor. (Refer to Check the intake air temperature sensor circuit.

( R e f e r t o 3 9 . ) .

N G Check the MAP sensor circuit11MAP sensor reading. (Refer to (Refer to INSPECTION PROCEDURE 40.)IOK

SCAN TOOL SENSOR READ TESTS (Data list)

83 sensor volts (rear) (Refer to l Transaxle gear range l Driving with the throttle wide open

O K :

OK

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to OK: 1 when suddenlv

N G Check the heated oxygensensor (rear) circuit.

(Refer to INSPECTION PROCEDURE 41.)

NG

02 sensor volts (front) (Refer to

Check the fuel pressure. (Refer to

OK

Check the following items.

l Check the injectors for operation sound.

l Check the injectors for fuel leakage.

l Check the ignition coil, spark plugs, spark plug ca bles.

l Check the compression pressure.

l Check the positive crankcase ventilation system.

l Check the evaporative emission control system.

l Check the EGR system.

NG

Check trouble symptom.

N G

Replace the three-way catalytic converter.

TSB Revisiqn

Page 479 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE ( N O N - T U R B O ) >

INSPECTION PROCEDURE 25

Transaxle range sensor circuit

[Comment]The transaxle range sensor inputs the condition of the selector lever, i.e. whether it MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE ( N O N - T U R B O ) >

INSPECTION PROCEDURE 25

Transaxle range sensor circuit

[Comment]The transaxle range sensor inputs the condition of the selector lever, i.e. whether it](/img/19/57345/w960_57345-478.png)

ENGINE ( N O N - T U R B O ) >

INSPECTION PROCEDURE 25

Transaxle range sensor circuit

[Comment]The transaxle range sensor inputs the condition of the selector lever, i.e. whether it is in or range or in some other range, to the PCM.

The PCM controls the idle air control motor based o n this input.Improper connector contact, open circuit

Check the transaxle range sensor. (Refer to GROUP On-vehicle Service.) Replace.

lDisconnect the connector,and measure atthe harness

A-l

OK

Check trouble symptom.

OK

Replace the PCM.

Check harness wire betweenN G

PCM transaxle rangesensor connector.

O K

Replace the PCM.

,

INSPECTION PROCEDURE 26

A/C switch and A/C compressor clutch relay system

motor, and also operates the A/C compressor magneti c clutch.Probable cause

l Malfunction of A/C control l Malfunction of A/C switch Improper connector open short-circuited harness wire

l Malfunction of PCM

NG

OKCheck the A/C compressor clutch relay.

Measure at the PCM

l

(Refer to GROUP 55 On-vehicle Service.)

Disconnect the connector, and measure at the harnes s

Replace

Check the

system. (Refer to GROUP 55

side.lVoltage between 64 and ground, and 38 and ground(Ignition switch: ON)

(A/C switch: ON)

OK: Battery positive voltage

l Connect a jumper wire between 64 and ground.

(Ignition switch: ON)

(A/C switch: ON)

OK: A/C compressor clutch turns ON.

OK1NG RepairA-l 06,A-l 07

OK

Check trouble symptom.

Replace the PCM.

NG

TSB Revision

Page 481 of 2103

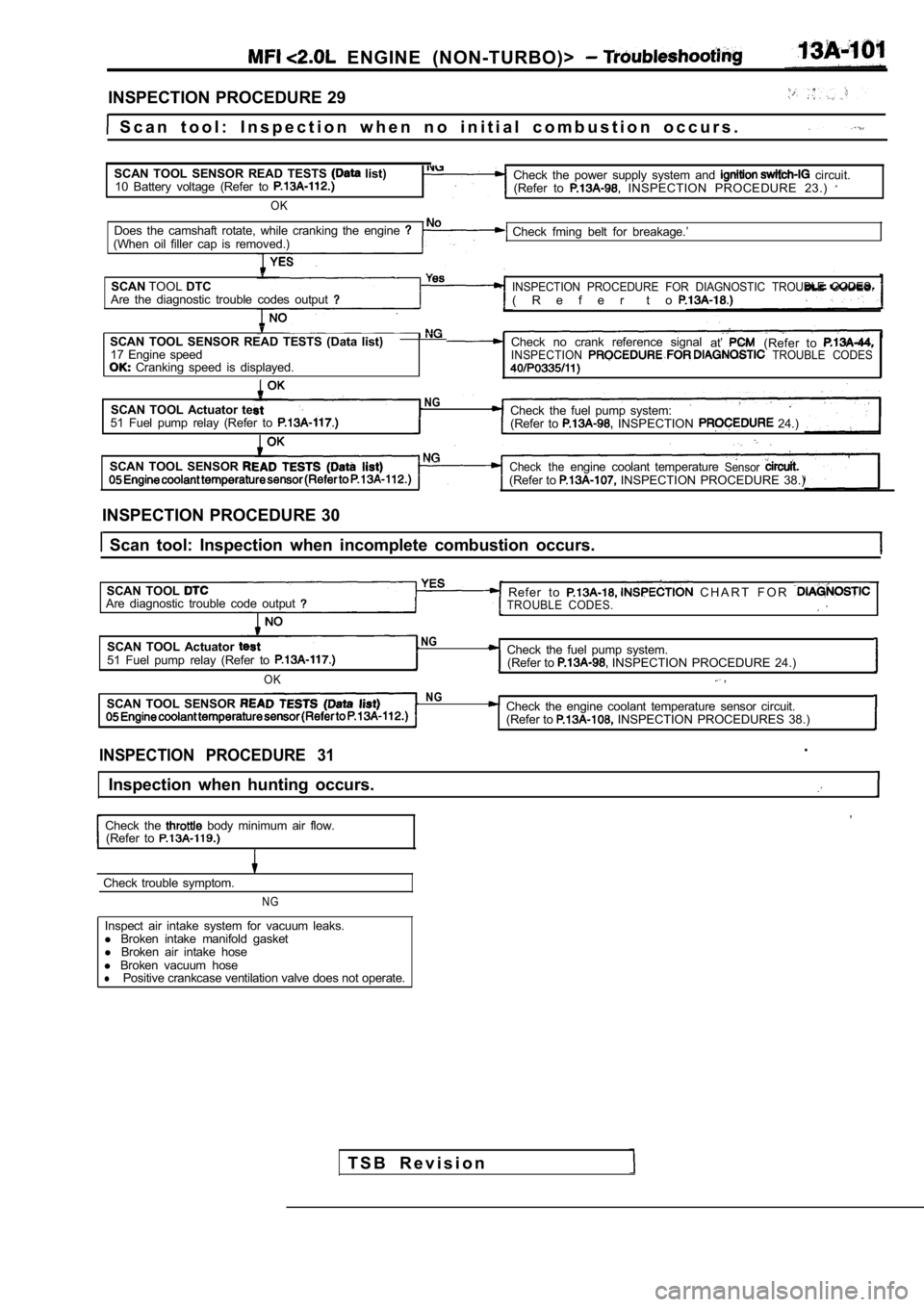

ENGINE (NON-TURBO)>

INSPECTION PROCEDURE 29

S c a n t o o l : I n s p e c t i o n w h e n n o i n i t i a l c o m b u s t i o n oc c u r s .

SCAN TOOL SENSOR READ TESTS

list)

10 Battery voltage (Refer to

OK

Check the power supply system and circuit.

(Refer to INSPECTION PROCEDURE 23.)

Does the camshaft rotate, while cranking the engine (When oil filler cap is removed.) Check fming belt for breakage.’

SCAN TOOLDTC

INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODES.Are the diagnostic trouble codes output( R e f e r t o

SCAN TOOL SENSOR READ TESTS (Data list) Check no crank reference signal

at’(Refer to 17 Engine speedINSPECTION TROUBLE CODES Cranking speed is displayed.

SCAN TOOL Actuator teNGCheck the fuel pump system:51 Fuel pump relay (Refer to (Refer to INSPECTION 24.)

SCAN TOOL SENSOR

Check theengine coolant temperatureSensor(Refer to INSPECTION PROCEDURE 38.)

INSPECTION PROCEDURE 30

Scan tool: Inspection when incomplete combustion o ccurs.

SCAN TOOL

Refer to C H A R T F O R Are diagnostic trouble code outputTROUBLE CODES.

SCAN TOOL Actuator NG

51 Fuel pump relay (Refer to Check the fuel pump system. (Refer to INSPECTION PROCEDURE 24.)

OK ,

SCAN TOOL SENSOR NGCheck the engine coolant temperature sensor circuit .

(Refer to INSPECTION PROCEDURES 38.)

INSPECTION PROCEDURE 31.

Inspection when hunting occurs.

,

Check the body minimum air flow.

(Refer to

Check trouble symptom.

NG

Inspect air intake system for vacuum leaks.

l Broken intake manifold gasket

l Broken air intake hose

l Broken vacuum hose

lPositive crankcase ventilation valve does not opera te.

T S B R e v i s i o n

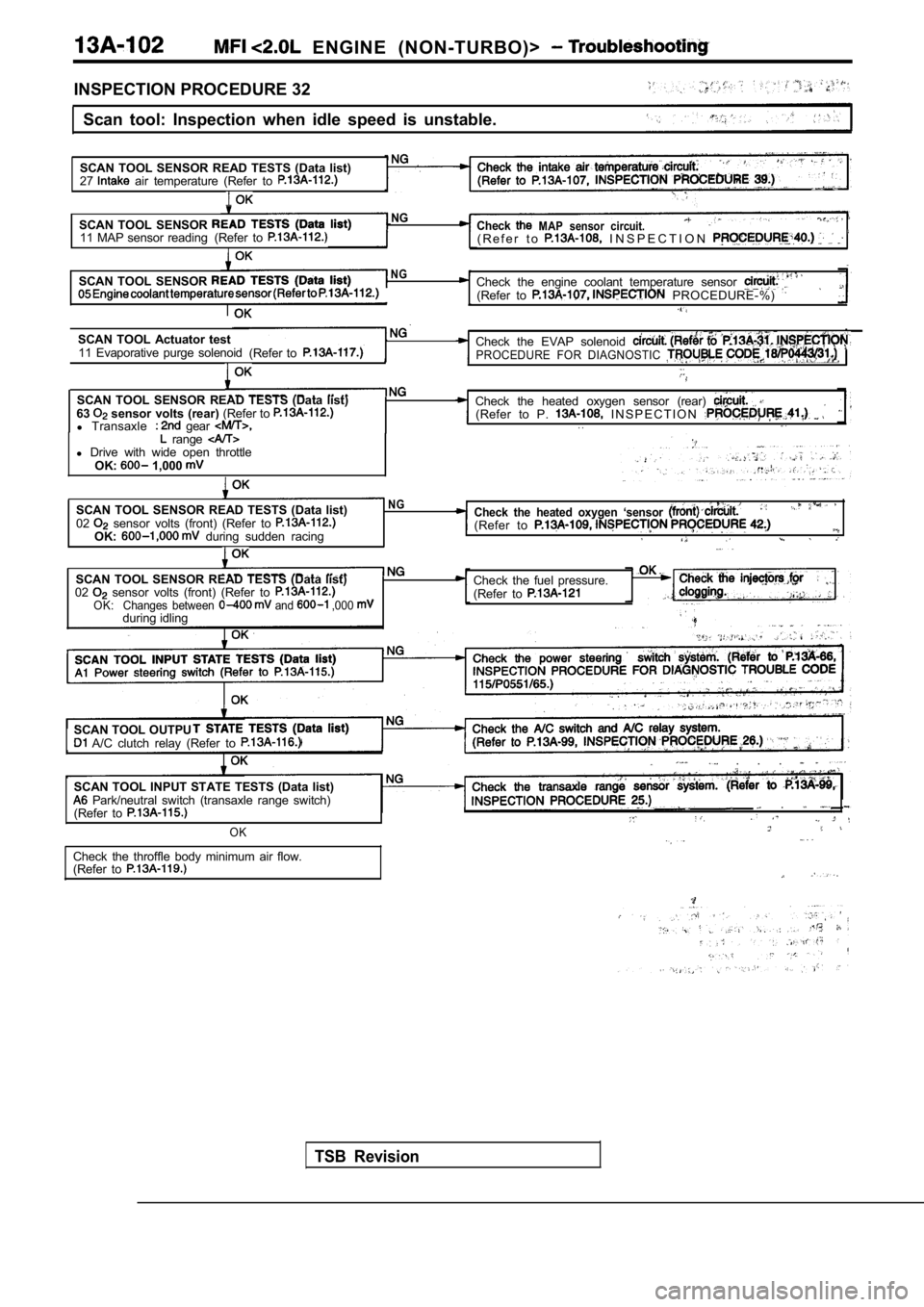

Page 482 of 2103

ENGINE (NON-TURBO)>

INSPECTION PROCEDURE 32Scan tool: Inspection when idle speed is unstable.

SCAN TOOL SENSOR READ TESTS (Data list)

27

air temperature (Refer to . .

SCAN TOOL SENSOR 11 MAP sensor reading (Refer to

NG CheckMAP sensor circuit.( R e f e r t o I N S P E C T I O N

SCAN TOOL SENSOR NGCheck the engine coolant temperature sensor (Refer to PROCEDURE-%)

SCAN TOOL Actuator test11 Evaporative purge solenoid (Refer toCheck the EVAP solenoid PROCEDURE FOR DIAGNOSTIC

SCAN TOOL SENSOR READ TESTS (Data list)

63 sensor volts (rear) (Refer to l Transaxle gear

Check the heated oxygen sensor (rear) (Refer to P. I N S P E C T I O N . . range l Drive with wide open throttle

OK: 1,000

SCAN TOOL SENSOR READ TESTS (Data list)NG

02 sensor volts (front) (Refer to Check the heated oxygen ‘sensor

OK: during sudden racing (Refer to

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to Changes between and ,000 OK:during idling Check the fuel pressure.

(Refer to

SCAN TOOL OUTPU A/C clutch relay (Refer to

SCAN TOOL INPUT STATE TESTS (Data list) Park/neutral switch (transaxle range switch)

(Refer to

OK

Check the throffle body minimum air flow.

(Refer to

. . .

. .

TSB Revision

Page 483 of 2103

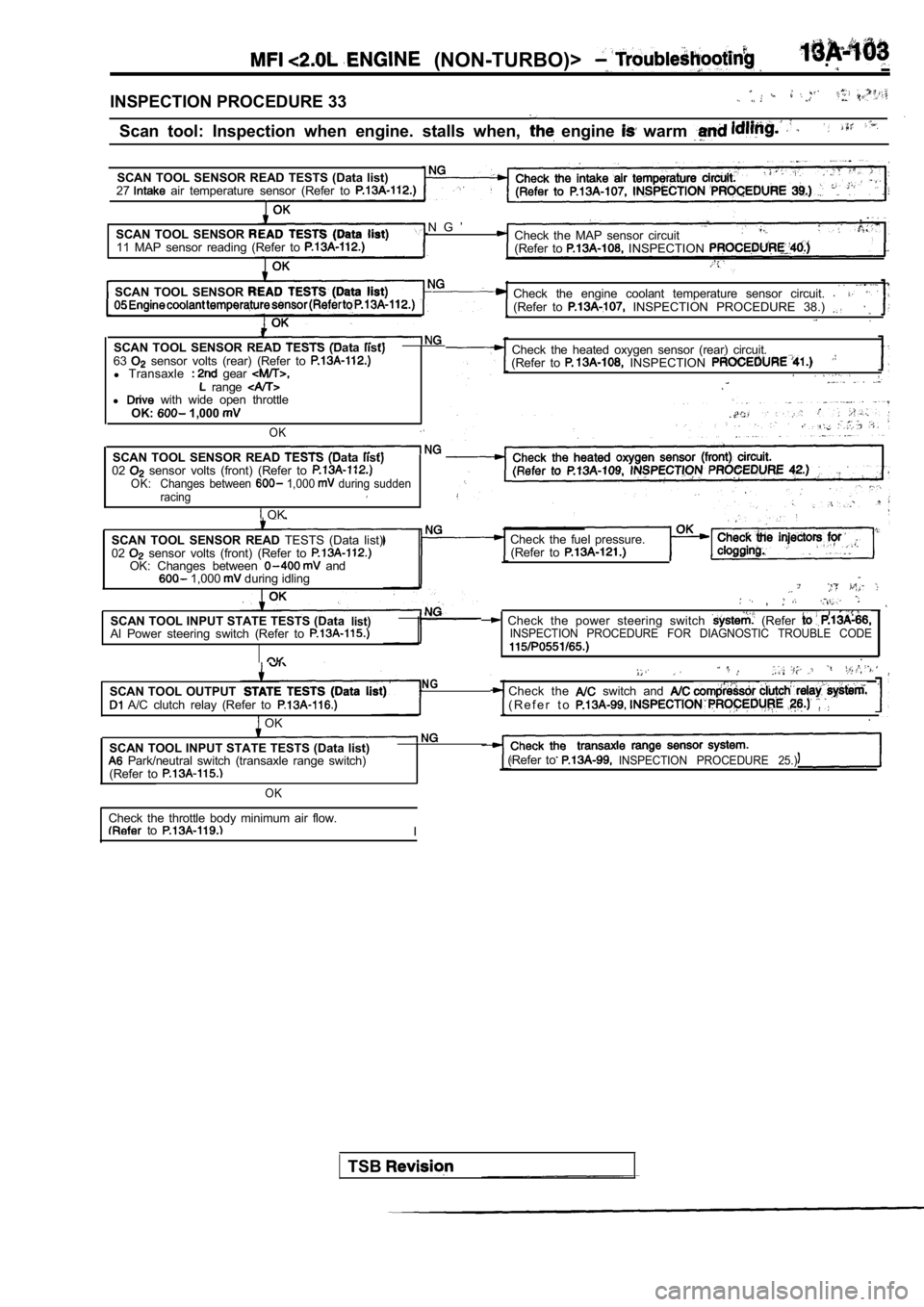

(NON-TURBO)> .

INSPECTION PROCEDURE 33

Scan tool: Inspection when engine. stalls when, engine warm

SCAN TOOL SENSOR READ TESTS (Data list)

27 air temperature sensor (Refer to

.

SCAN TOOL SENSOR N G ’ Check the MAP sensor circuit

11 MAP sensor reading (Refer to

(Refer to INSPECTION

SCAN TOOL SENSOR Check the engine coolant temperature sensor circuit . (Refer to INSPECTION PROCEDURE 38.) .

SCAN TOOL SENSOR READ TESTS (Data list)

63 sensor volts (rear) (Refer to l Transaxle gear range l with wide open throttle

OK: 1,000

OK

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to OK: Changes between 1,000 during sudden

racing

OK Check the heated oxygen sensor (rear) circuit.

(Refer to

INSPECTION ,

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to OK: Changes between and 1,000 during idling

SCAN TOOL INPUT STATE TESTS (Data

list)Al Power steering switch (Refer to

Check the fuel pressure. (Refer to

,

Check the power steering switch (Refer INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODE

.

SCAN TOOL OUTPUT

A/C clutch relay (Refer to

OK

NGCheck the switch and ( R e f e r t o .

SCAN TOOL INPUT STATE TESTS (Data list) Park/neutral switch (transaxle range switch)

(Refer to (Refer toINSPECTION PROCEDURE 25.)

OK

Check the throttle body minimum air flow. to I

TSB

Page 484 of 2103

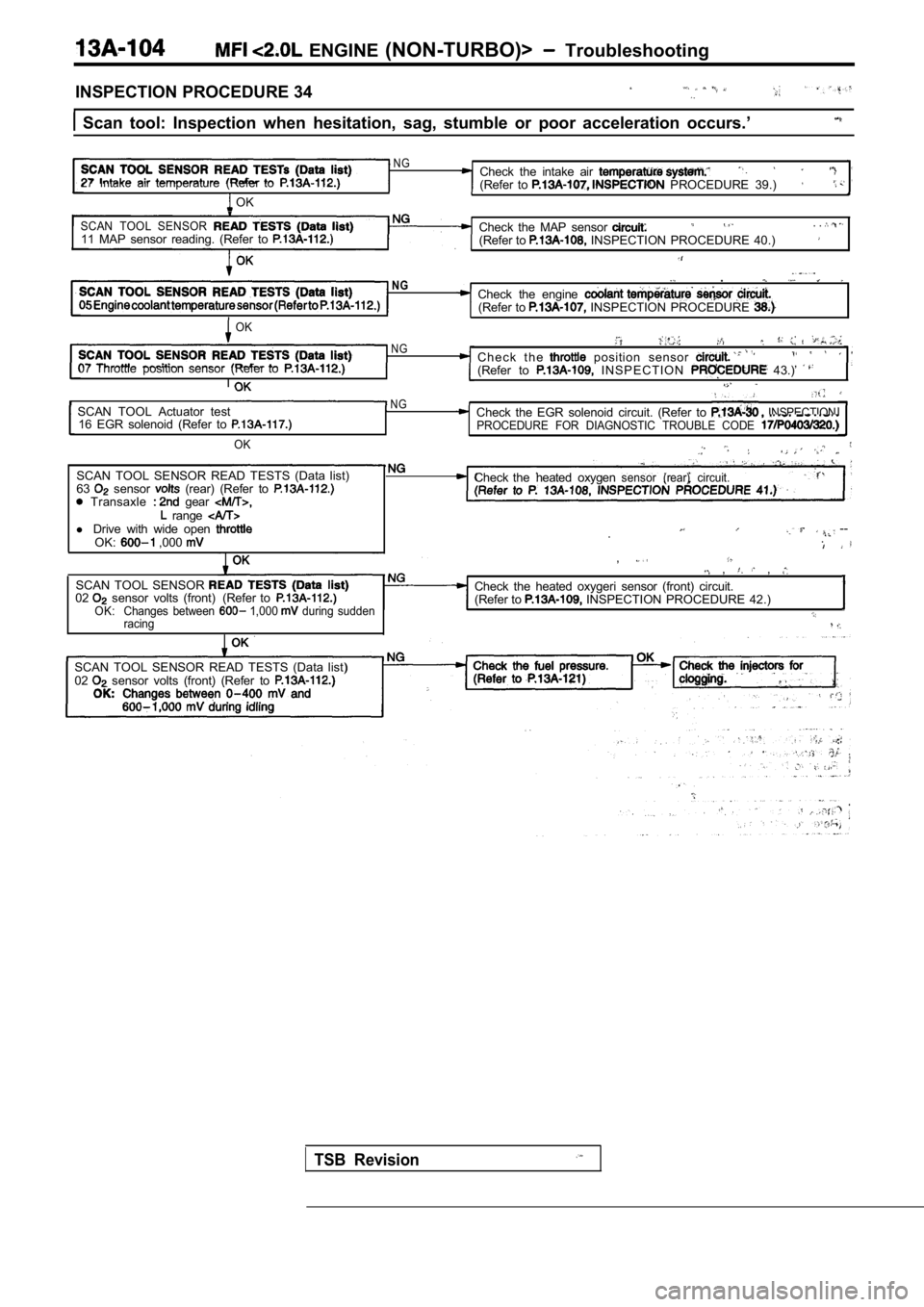

ENGINE (NON-TURBO)> Troubleshooting

INSPECTION PROCEDURE 34

Scan tool: Inspection when hesitation, sag, stumbl e or poor acceleration occurs.’

N G

27 Intakeair temperature (Refer toCheck the intake air (Refer to PROCEDURE 39.)

OK

SCAN TOOL SENSOR11 MAP sensor reading. (Refer to Check the MAP sensor . .

(Refer to INSPECTION PROCEDURE 40.)

NG.

Check the engine (Refer to INSPECTION PROCEDURE

OK

N G

07 Throttle position sensor (Refer toC h e c k t h e position sensor (Refer to I N S P E C T I O N 43.)’ I

SCAN TOOL Actuator testN GINSPECTION16 EGR solenoid (Refer to

OK

SCAN TOOL SENSOR READ TESTS (Data list)

63 sensor (rear) (Refer to Transaxle gear range l Drive with wide open OK: ,000

Check the EGR solenoid circuit. (Refer to PROCEDURE FOR DIAGNOSTIC TROUBLE CODE

Check thesensor circuit.heated oxygen(rear)

. --.

SCAN TOOL SENSOR 02 sensor volts (front) (Refer toOK: Changes between 1,000 during sudden

racing

, , ,

Check the heated oxygeri sensor (front) circuit.

(Refer to INSPECTION PROCEDURE 42.)

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to

TSB Revision

Page 485 of 2103

E N G I N E

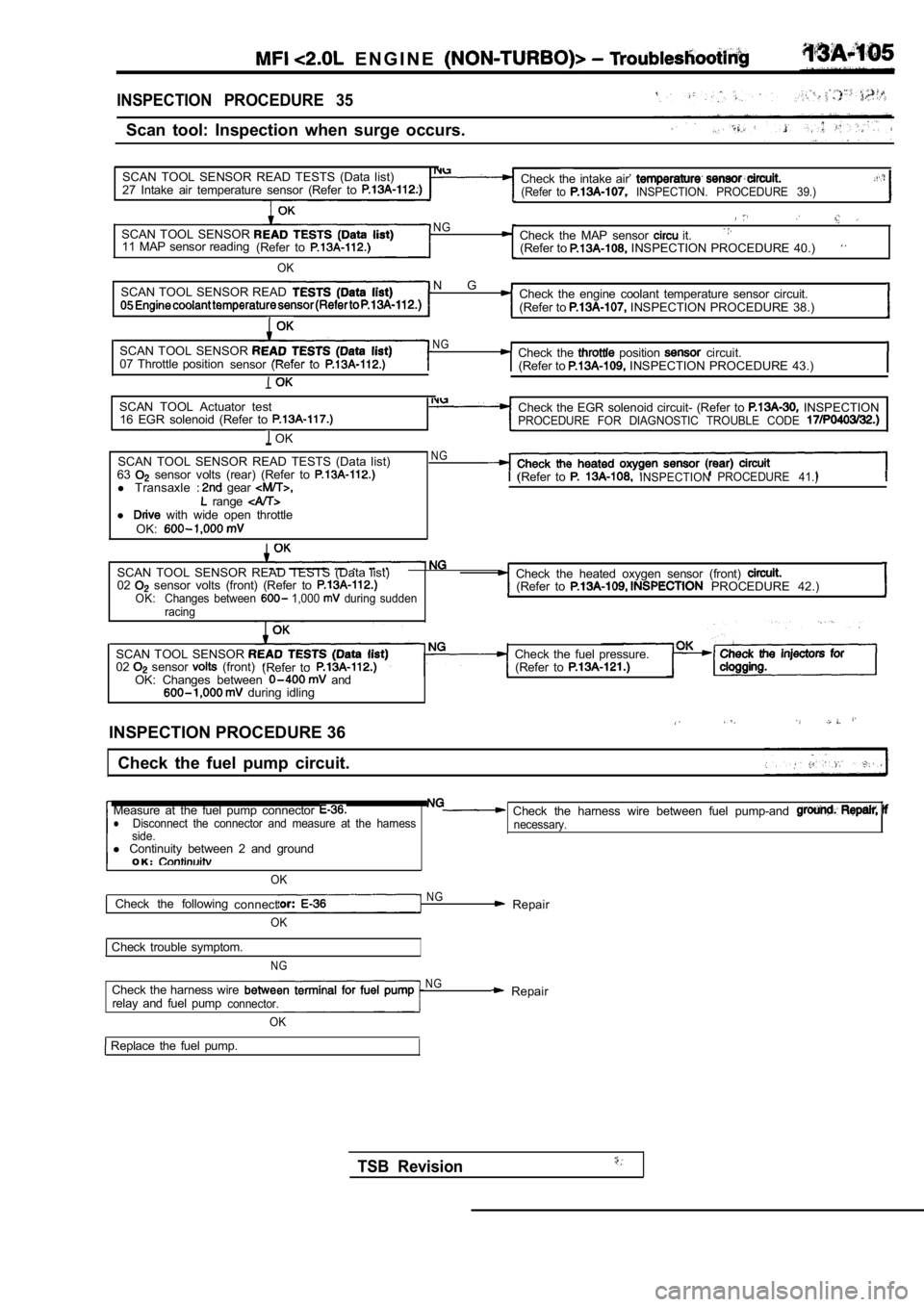

INSPECTION PROCEDURE 35

Scan tool: Inspection when surge occurs.

SCAN TOOL SENSOR READ TESTS (Data list)

27 Intake air temperature sensor (Refer to

Check the intake air’ (Refer to INSPECTION. PROCEDURE 39.)

SCAN TOOL SENSOR 11 MAP sensor reading (Refer to

OK NG

Check the MAP sensor it.(Refer to INSPECTION PROCEDURE 40.)

SCAN TOOL SENSOR READ

N GCheck the engine coolant temperature sensor circuit

.

(Refer to INSPECTION PROCEDURE 38.)

SCAN TOOL SENSOR NGCheck the position circuit.

07 Throttle position sensor (Refer to(Refer to INSPECTION PROCEDURE 43.)

SCAN TOOL Actuator test

16 EGR solenoid (Refer to

OK Check the EGR solenoid circuit- (Refer to

INSPECTIONPROCEDURE FOR DIAGNOSTIC TROUBLE CODE

SCAN TOOL SENSOR READ TESTS (Data list)

63 sensor volts (rear) (Refer to l Transaxle gear range l with wide open throttle

OK:

NG

(Refer to INSPECTION PROCEDURE 41.)

SCAN TOOL SENSOR READ TESTS (Data list)

02 sensor volts (front) (Refer to OK: Changes between 1,000 during sudden

racing

Check the heated oxygen sensor (front) (Refer to PROCEDURE 42.)

SCAN TOOL SENSOR 02 sensor (front) (Refer toOK: Changes between and during idling Check the fuel pressure.

(Refer to

INSPECTION PROCEDURE 36

Check the fuel pump circuit.

Measure at the fuel pump connector

Check the harness wire between fuel pump-and lDisconnect the connector and measure at the harness necessary.

side.

l Continuity between 2 and ground

O K :

OK

Check the following connectNG Repair

OK

Check trouble symptom.

NG

Check the harness wirerelay and fuel pumpconnector.

OK

N G Repair

Replace the fuel pump.

TSB Revision

Page 487 of 2103

E N G I N E

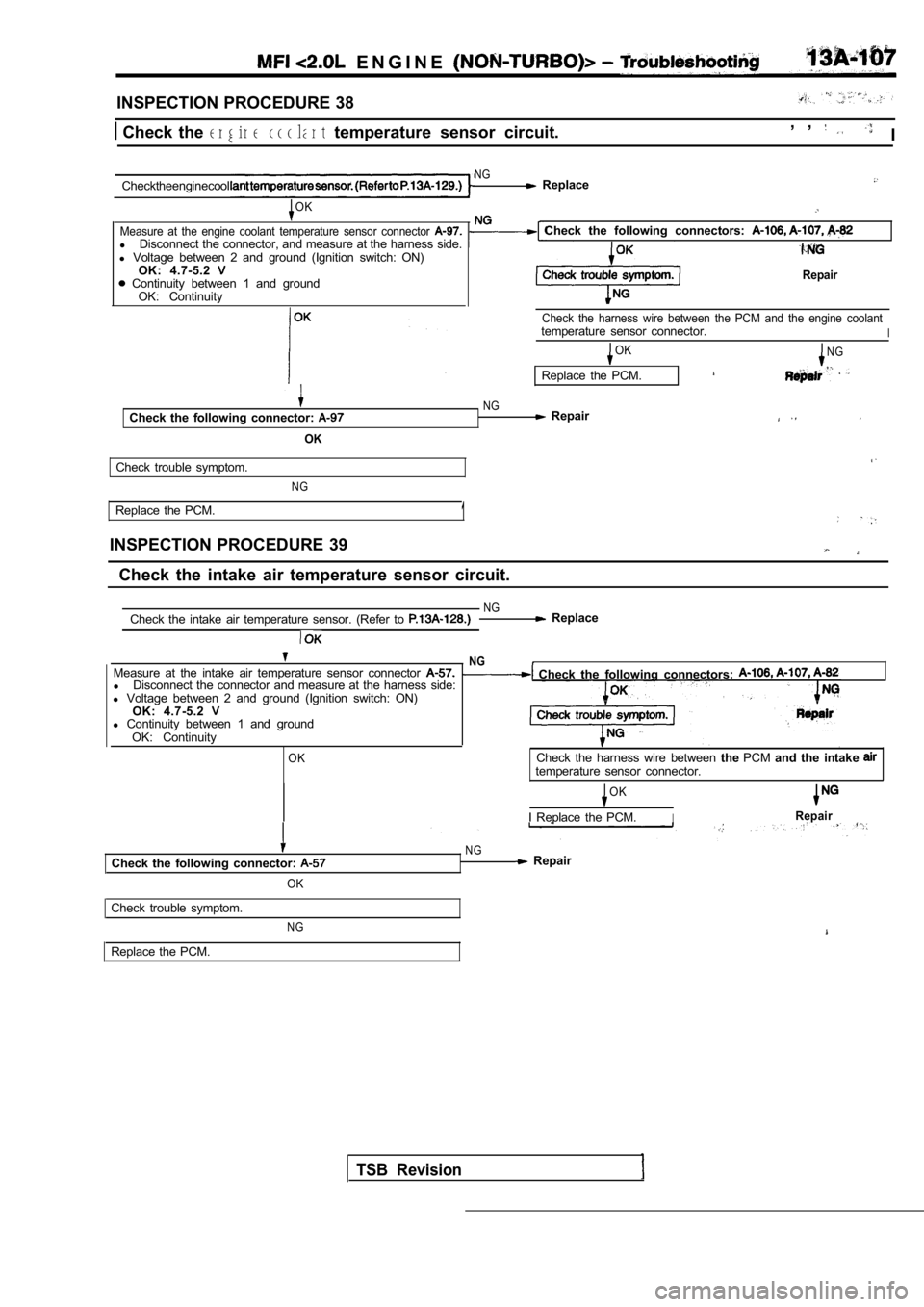

INSPECTION PROCEDURE 38

Check the engine coolant temperature sensor circuit. , , I

Checktheenginecool

NG Replace

OK

Measure at the engine coolant temperature sensor co nnector

lDisconnect the connector, and measure at the harnes s side.

l Voltage between 2 and ground (Ignition switch: ON)

OK: 4.7-5.2

Continuity between 1 and ground OK: Continuity

Check the following connectors:

Repair

Check the harness wire between the PCM and the engi ne coolanttemperature sensor connector.I

Check the following connector:

OK

OKN G

Replace the PCM.

NG Repair

Check trouble symptom.

N G

Replace the PCM.

INSPECTION PROCEDURE 391

Check the intake air temperature sensor circuit.

NGCheck the intake air temperature sensor. (Refer to Replace

NGMeasure at the intake air temperature sensor connec tor Check the following connectors: lDisconnect the connector and measure at the harness side:

l Voltage between 2 and ground (Ignition switch: ON)

OK: 4.7-5.2

l Continuity between 1 and ground

OK: Continuity

OKCheck the harness wire between thePCM and the intake temperature sensor connector.

OK

I Replace the PCM.IRepair

Check the following connector:

OK

NG Repair

Check trouble symptom.

Replace the PCM.

NG

TSB Revision