sensor MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 528 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

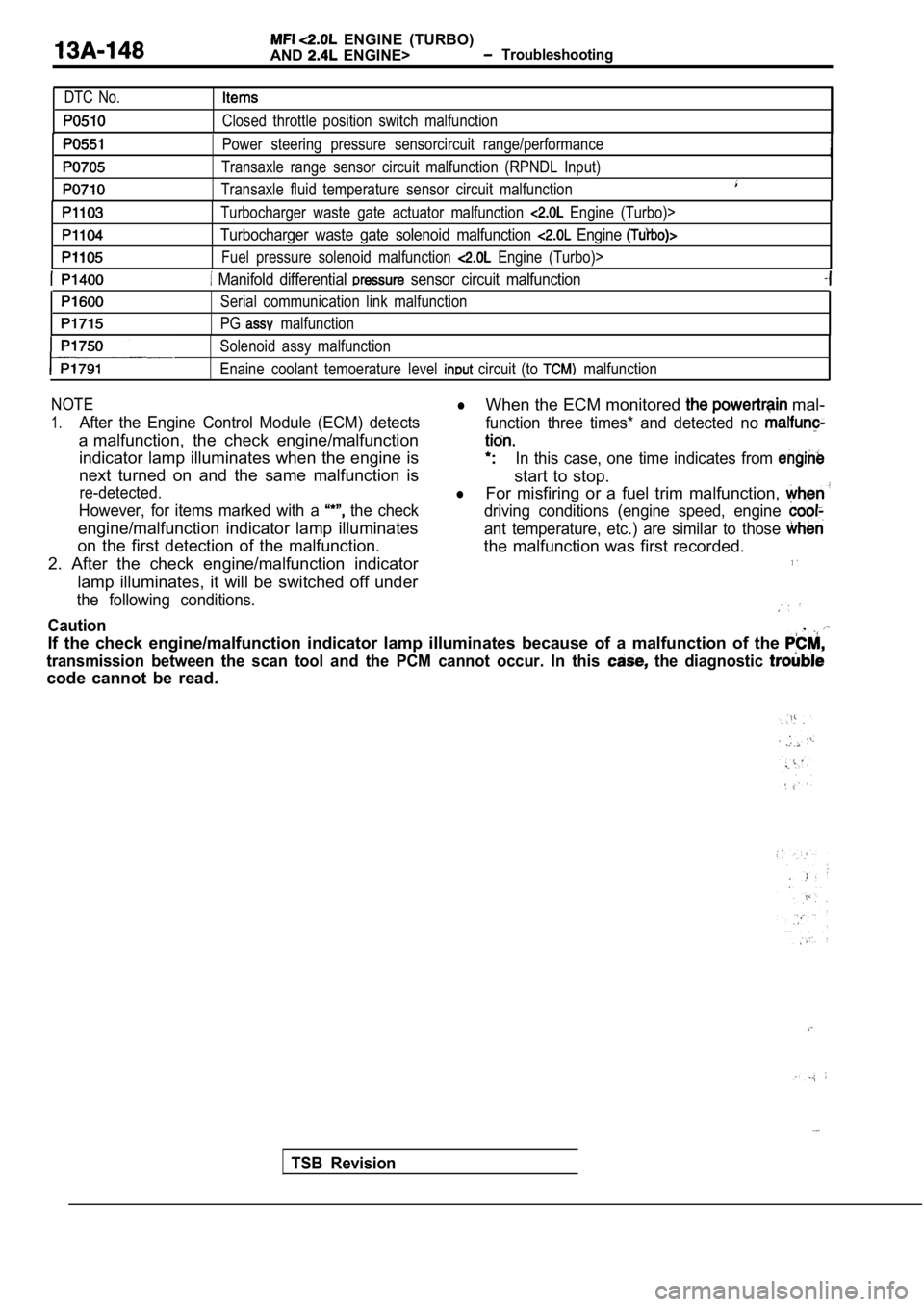

DTC No.

Closed throttle position switch malfunction

Power steering pressure sensorcircuit range/perfor mance

Transaxle range sensor circuit malfunction (RPNDL Input)

Transaxle fluid temperature sensor circuit malfunct ion

Turbocharger waste gate actuator malfunction Engine (Turbo)>

Turbocharger waste gate solenoid malfunction Engine

Fuel pressure solenoid malfunction Engine (Turbo)>

Manifold differential sensor circuit malfunction

Serial communication link malfunction

PG

malfunction

Solenoid assy malfunction

Enaine coolant temoerature level

circuit (to malfunction

NOTElWhen the ECM monitored mal-

1.After the Engine Control Module (ECM) detects function three times* and detected no

a malfunction, the check engine/malfunction

indicator lamp illuminates when the engine isIn this case, one time indicates from

next turned on and the same malfunction is

start to stop.

re-detected.lFor misfiring or a fuel trim malfunction,

However, for items marked with a the checkdriving conditions (engine speed, engine

engine/malfunction indicator lamp illuminatesant temperature, etc.) are similar to those

on the first detection of the malfunction. the malfunction was first recorded.

2. After the check engine/malfunction indicator

lamp illuminates, it will be switched off under

the following conditions.

Caution,

If the check engine/malfunction indicator lamp illu minates because of a malfunction of the

transmission between the scan tool and the PCM cann ot occur. In this the diagnostic

code cannot be read.

TSB Revision

Page 529 of 2103

E N G I N E

AND ENGINE>

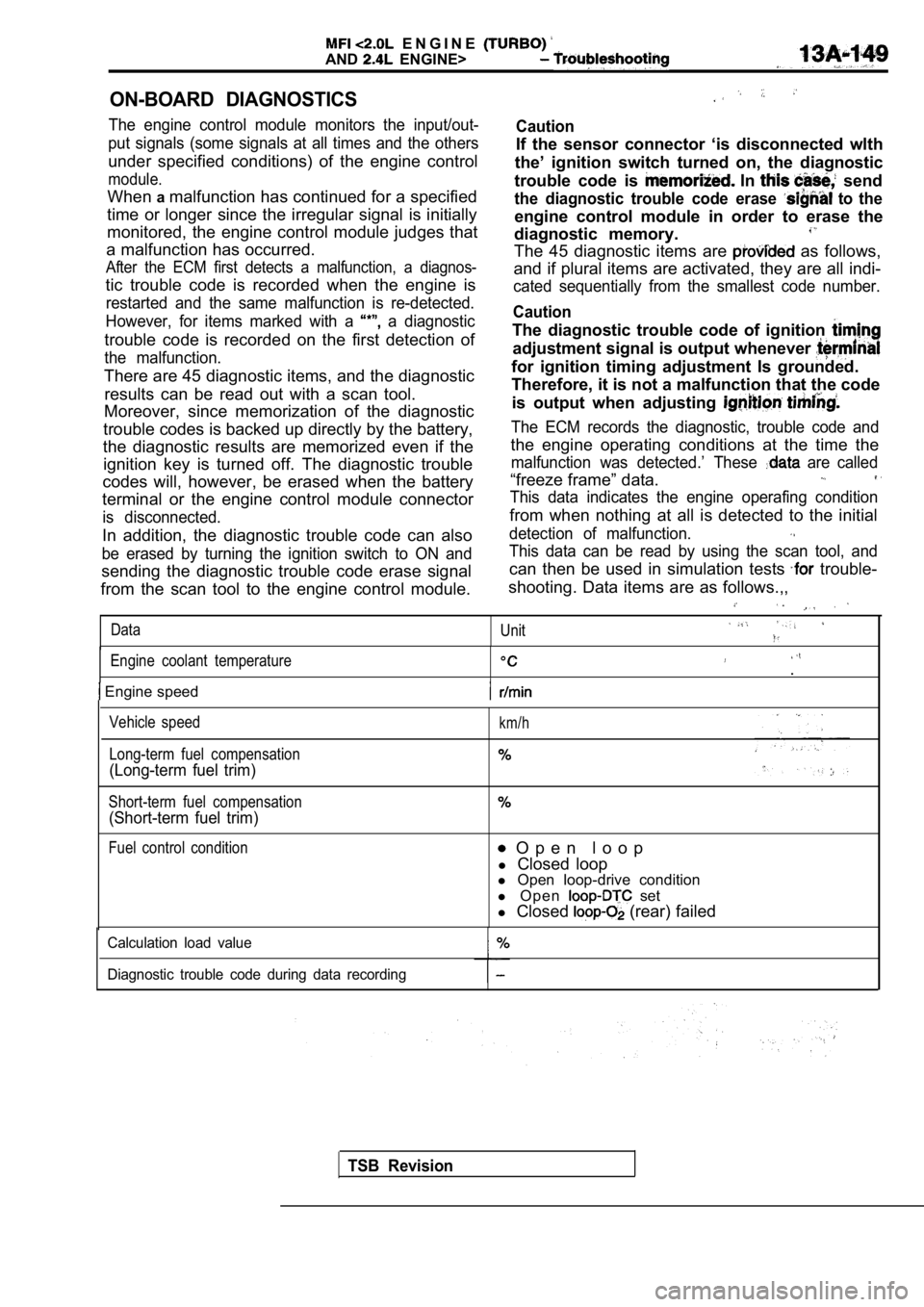

ON-BOARD DIAGNOSTICS

The engine control module monitors the input/out-

put signals (some signals at all times and the othe rs

under specified conditions) of the engine control

module.

Whenamalfunction has continued for a specified

time or longer since the irregular signal is initia lly

monitored, the engine control module judges that

a malfunction has occurred.

After the ECM first detects a malfunction, a diagno s-

tic trouble code is recorded when the engine is

restarted and the same malfunction is re-detected.

However, for items marked with a

a diagnostic

trouble code is recorded on the first detection of

the malfunction.

There are 45 diagnostic items, and the diagnostic results can be read out with a scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ignition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery

terminal or the engine control module connector

is disconnected.

In addition, the diagnostic trouble code can also

be erased by turning the ignition switch to ON and

sending the diagnostic trouble code erase signal

from the scan tool to the engine control module.

Caution

If the sensor connector ‘is disconnected wlth

the’ ignition switch turned on, the diagnostic

trouble code is

In send

the diagnostic trouble code erase to the

engine control module in order to erase the

diagnostic memory.

The 45 diagnostic items are as follows,

and if plural items are activated, they are all ind i-

cated sequentially from the smallest code number.

Caution

The diagnostic trouble code of ignition

adjustment signal is output whenever

for ignition timing adjustment Is grounded.

Therefore, it is not a malfunction that the code

is output when adjusting

The ECM records the diagnostic, trouble code and

the engine operating conditions at the time the

malfunction was detected.’ These are called

“freeze frame” data.

This data indicates the engine operafing condition

from when nothing at all is detected to the initial

detection of malfunction.

This data can be read by using the scan tool, and

can then be used in simulation tests trouble-

shooting. Data items are as follows.,,

Data Unit

Engine coolant temperature.

Engine speed

Vehicle speed

Long-term fuel compensation

(Long-term fuel trim)

Short-term fuel compensation

(Short-term fuel trim)

km/h

Fuel control condition O p e n l o o p

l Closed loop

l Open loop-drive condition

l O p e n

set

l Closed

(rear) failed

Calculation load value

Diagnostic trouble code during data recording

TSB Revision

Page 535 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting .

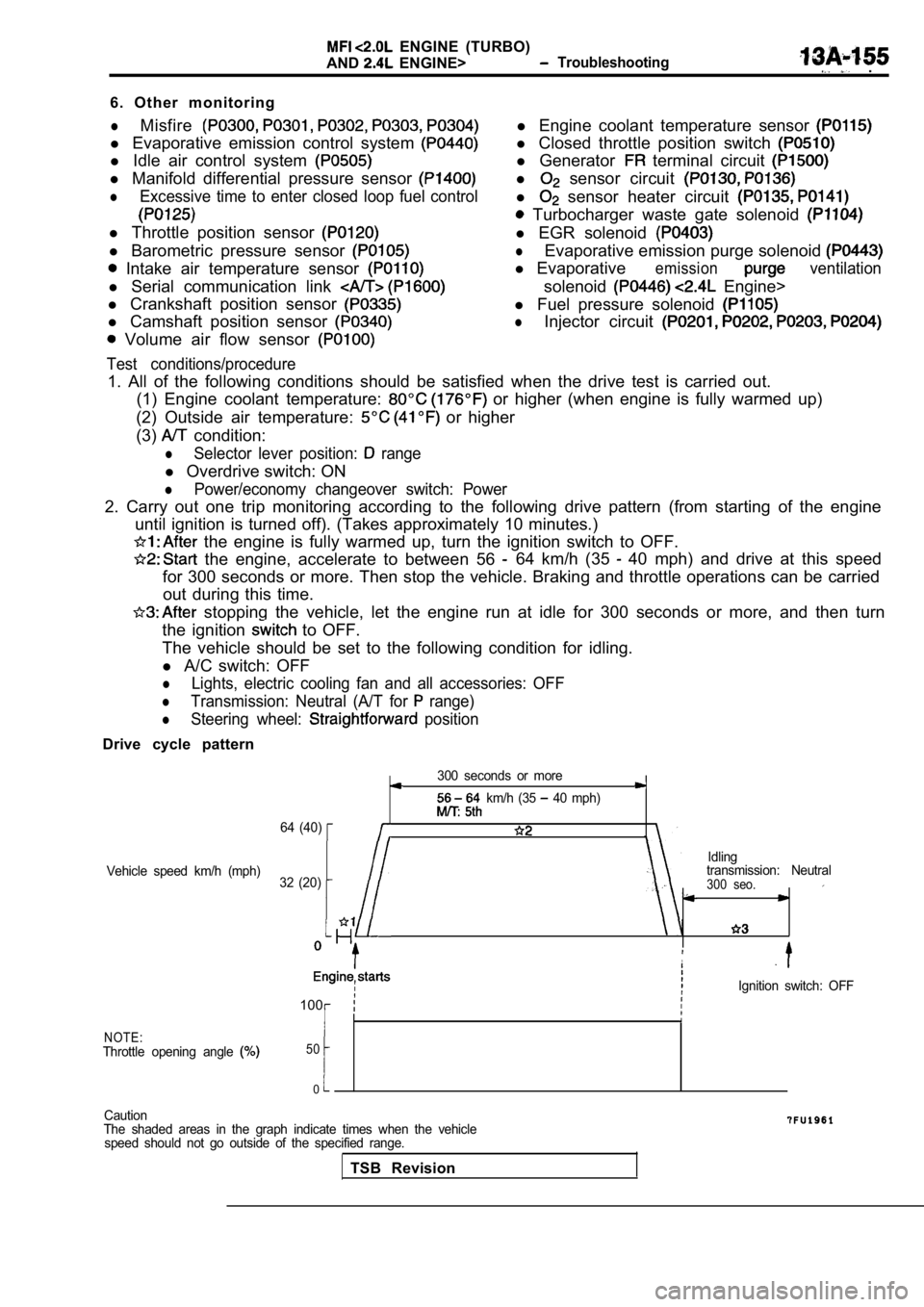

6. Other monitoring

lMisfire

l Evaporative emission control system

l Idle air control system

l Manifold differential pressure sensor

lExcessive time to enter closed loop fuel control

l Throttle position sensor

l Barometric pressure sensor

Intake air temperature sensor

l Serial communication link

l Crankshaft position sensor

l Camshaft position sensor

Volume air flow sensor

Test conditions/procedure

l Engine coolant temperature sensor

l Closed throttle position switch

l Generator terminal circuit

l sensor circuit

l sensor heater circuit

Turbocharger waste gate solenoid

l EGR solenoid

lEvaporative emission purge solenoid

l Evaporativeemissionventilation

solenoid Engine>

l Fuel pressure solenoid

lInjector circuit

1. All of the following conditions should be satisf ied when the drive test is carried out.

(1) Engine coolant temperature:

or higher (when engine is fully warmed up)

(2) Outside air temperature:

or higher

(3)

condition:

lSelector lever position: range

l Overdrive switch: ON

lPower/economy changeover switch: Power

2. Carry out one trip monitoring according to the f ollowing drive pattern (from starting of the engine

until ignition is turned off). (Takes approximately 10 minutes.)

the engine is fully warmed up, turn the ignition s witch to OFF.

the engine, accelerate to between 56 64 km/h (35 40 mph) and drive at this speed

for 300 seconds or more. Then stop the vehicle. Bra king and throttle operations can be carried

out during this time.

stopping the vehicle, let the engine run at idle f or 300 seconds or more, and then turn

the ignition

to OFF.

The vehicle should be set to the following conditio n for idling.

l A/C switch: OFF

lLights, electric cooling fan and all accessories: O FF

lTransmission: Neutral (A/T for range)

lSteering wheel: position

Drive cycle pattern

300 seconds or more

km/h (35 40 mph)

64 (40)

Idling

Vehicle speed km/h (mph) transmission: Neutral

32 (20)

300 seo.

,

Ignition switch: OFF

100

NOTE:Throttle opening angle 50

0

Caution

The shaded areas in the graph indicate times when t he vehicle

speed should not go outside of the specified range.

TSB Revision

Page 538 of 2103

ENGINE

A N D E N G I N E > .

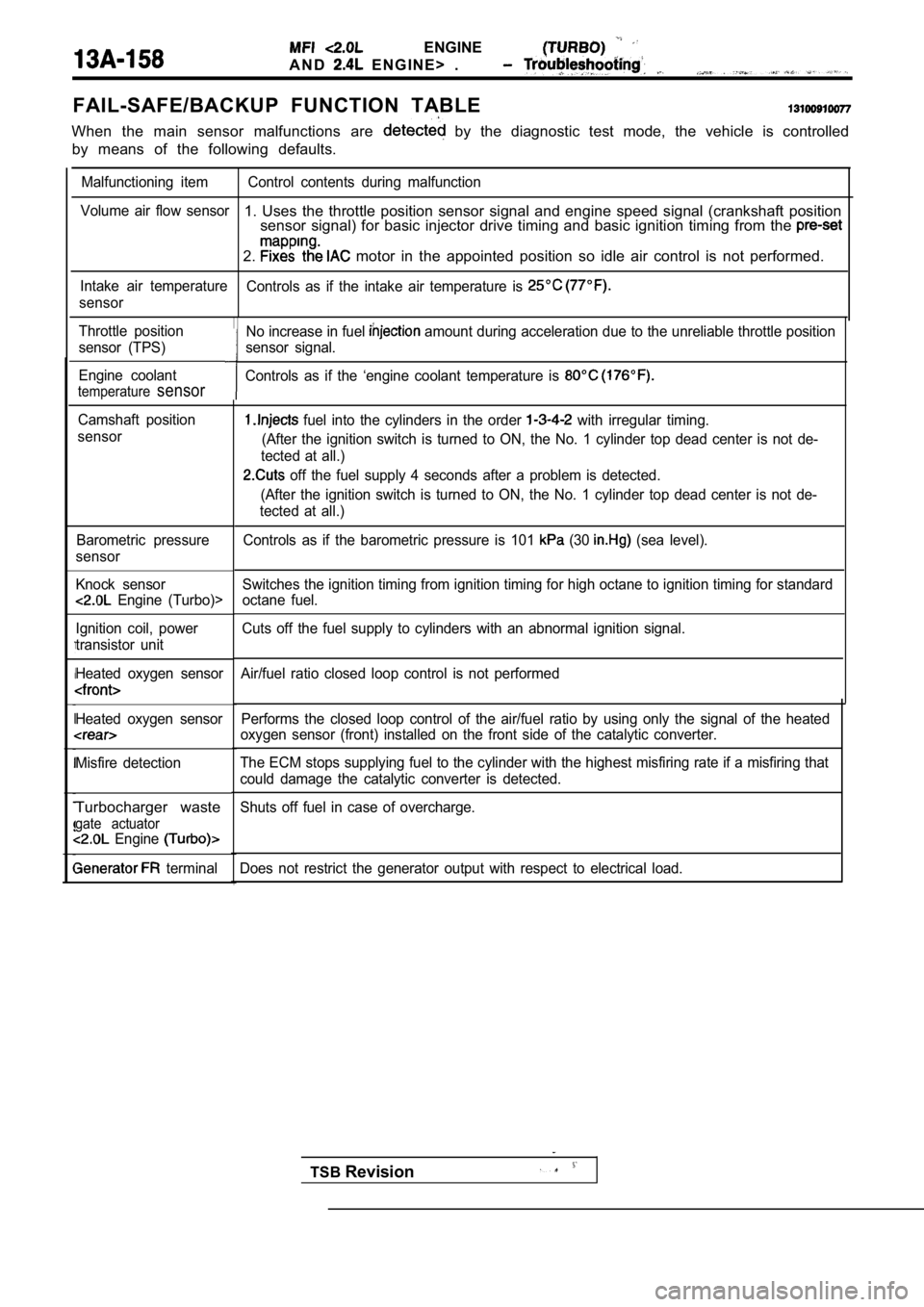

FAIL-SAFE/BACKUP FUNCTION TABLE

When the main sensor malfunctions are by the diagnostic test mode, the vehicle is controlled

by means of the following defaults.

Malfunctioning item Control contents during malfunct ion

Volume air flow sensor

1. Uses the throttle position sensor signal and eng ine speed signal (crankshaft position

sensor signal) for basic injector drive timing and basic ignition timing from the

2. motor in the appointed position so idle air contro l is not performed.

Intake air temperature

Controls as if the intake air temperature is

sensor

Throttle position

sensor (TPS)

Engine coolant

temperaturesensor

Camshaft position

sensor

Barometric pressure

sensor

Knock sensor

Engine (Turbo)>

Ignition coil, power

transistor unit

Heated oxygen sensor

Heated oxygen sensor

Misfire detection

Turbocharger waste

gate actuator Engine

terminal Performs the closed loop control of the air/fuel ra

tio by using only the signal of the heated

oxygen sensor (front) installed on the front side o f the catalytic converter.

The ECM stops supplying fuel to the cylinder with t he highest misfiring rate if a misfiring that

could damage the catalytic converter is detected.

Shuts off fuel in case of overcharge.

Does not restrict the generator output with respect to electrical load.

No increase in fuel amount during acceleration due to the unreliable throttle position

sensor signal.

Controls as if the ‘engine coolant temperature is

fuel into the cylinders in the order with irregular timing.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

off the fuel supply 4 seconds after a problem is d etected.

(After the ignition switch is turned to ON, the No. 1 cylinder top dead center is not de-

tected at all.)

Controls as if the barometric pressure is 101

(30 (sea level).

Switches the ignition timing from ignition timing f or high octane to ignition timing for standard

octane fuel.

Cuts off the fuel supply to cylinders with an abnor mal ignition signal.

Air/fuel ratio closed loop control is not performed

TSB Revision

Page 539 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

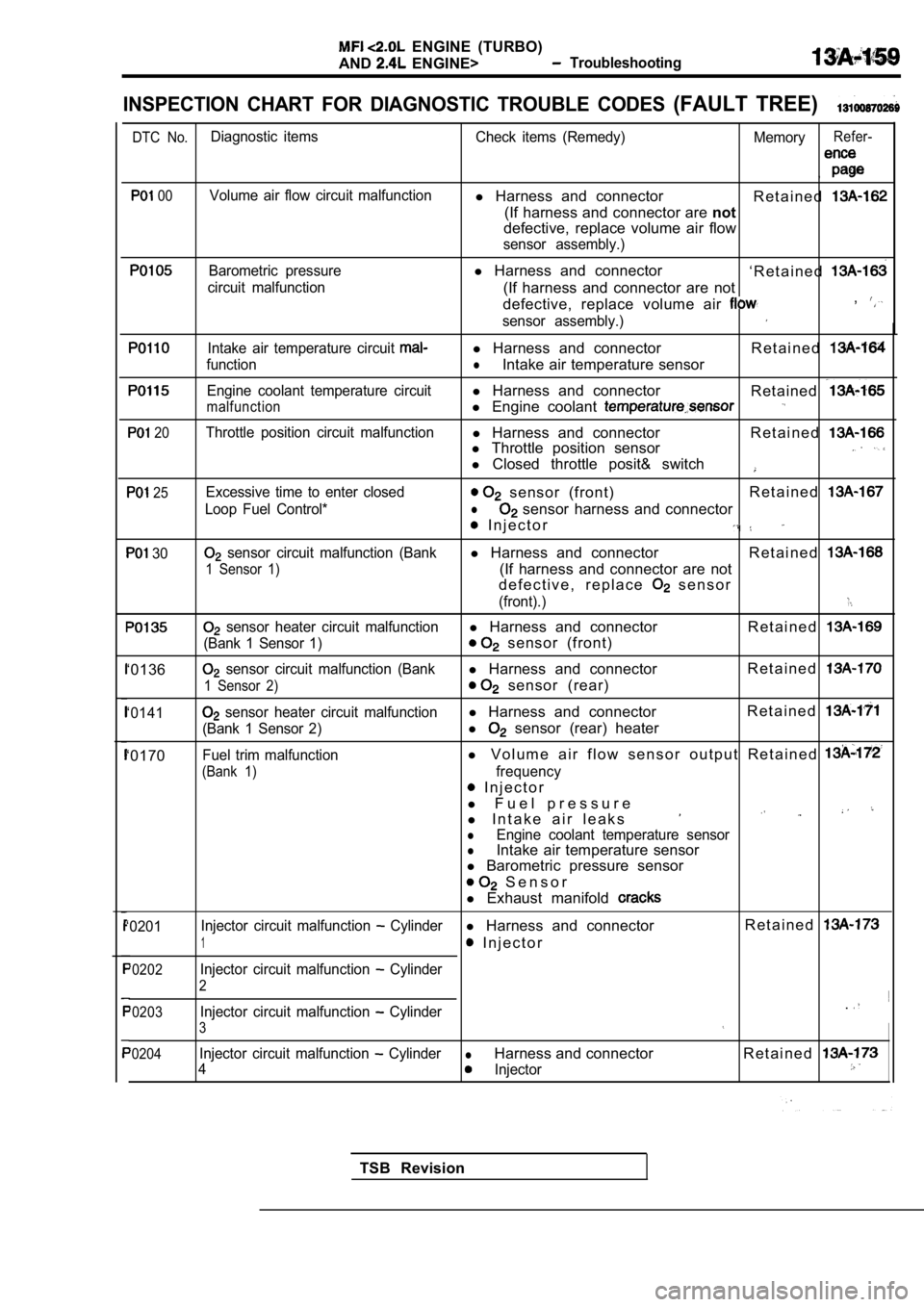

INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES (FAULT TREE)

DTC No.Diagnostic items Check items (Remedy) MemoryRefer-

,

00Volume air flow circuit malfunctionl Harness and connector

R e t a i n e d

(If harness and connector are not

defective, replace volume air flow

sensor assembly.)

Barometric pressurel Harness and connector

‘ R e t a i n e d

circuit malfunction(If harness and connector are not

defective, replace volume air ,

sensor assembly.)

Intake air temperature circuit l Harness and connector R e t a i n e d

functionlIntake air temperature sensor

Engine coolant temperature circuitl Harness and connector

Retained

malfunctionl Engine coolant

20Throttle position circuit malfunctionl Harness and connector R e t a i n e dl Throttle position sensor

l Closed throttle posit& switch

25

30

‘0136

‘0141

‘0170

Excessive time to enter closed sensor (front) R e t a i n e d

Loop Fuel Control*l sensor harness and connector

I n j e c t o r

sensor circuit malfunction (Bankl

Harness and connector R e t a i n e d

1 Sensor 1)(If harness and connector are not

d e f e c t i v e , r e p l a c e

s e n s o r

(front).)

sensor heater circuit malfunctionl Harness and connector R e t a i n e d

(Bank 1 Sensor 1) sensor (front)

sensor circuit malfunction (Bankl Harness and connector R e t a i n e d

1 Sensor 2) sensor (rear)

sensor heater circuit malfunctionl

Harness and connector R e t a i n e d

(Bank 1 Sensor 2)l sensor (rear) heater

Fuel trim malfunctionl

V o l u m e a i r f l o w s e n s o r o u t p u t R e t a i n e d

(Bank 1)frequency

I n j e c t o r

l F u e l p r e s s u r e

l I n t a k e a i r l e a k s

lEngine coolant temperature sensorlIntake air temperature sensor

l Barometric pressure sensor

S e n s o r

l Exhaust manifold

‘0201 Injector circuit malfunction Cylinderl

Harness and connector R e t a i n e d

1 I n j e c t o r

‘0202Injector circuit malfunction Cylinder

2

‘0203Injector circuit malfunction Cylinder.

3

‘0204Injector circuit malfunction CylinderlHarness and connector R e t a i n e d

4Injector

TSB Revision

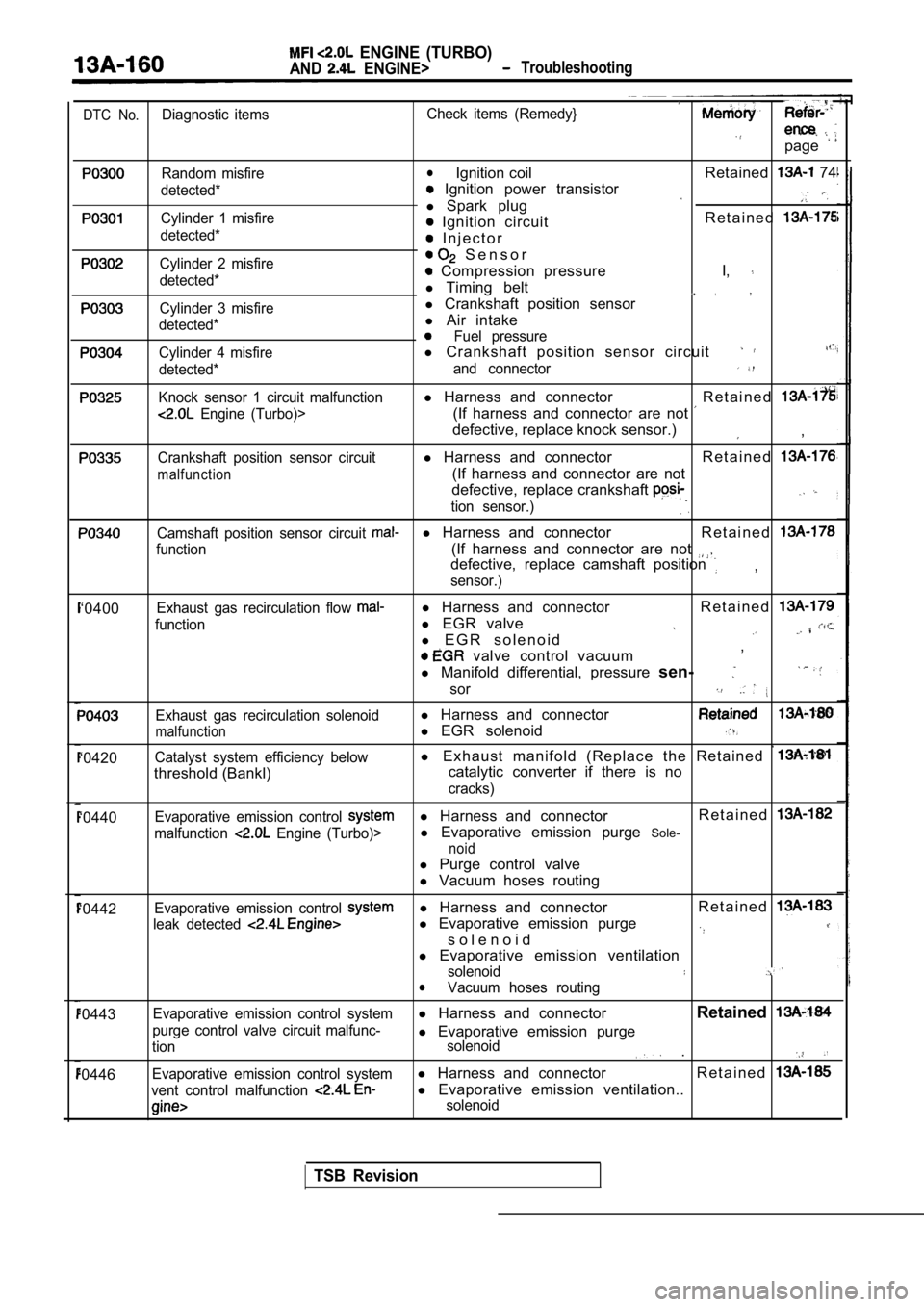

Page 540 of 2103

ENGINE (TURBO)

AND ENGINE> Troubleshooting

DTC No.Diagnostic itemsCheck items (Remedy}

page

Random misfire

detected*

Cylinder 1 misfire

detected*

Cylinder 2 misfire

detected*

Cylinder 3 misfire

detected*

Cylinder 4 misfire

detected*

Knock sensor 1 circuit malfunction

Engine (Turbo)>

Crankshaft position sensor circuit

malfunction

lIgnition coil Retained 74

Ignition power transistor

l Spark plug

R e t a i n e d Ignition circuit

I n j e c t o r

S e n s o r

Compression pressure I,

l

Timing belt

l Crankshaft position sensor

l Air intake

Fuel pressure

l Crankshaft position sensor circuit

and connector

l Harness and connector R e t a i n e d

(If harness and connector are not

defective, replace knock sensor.),

l Harness and connector R e t a i n e d

(If harness and connector are not

defective, replace crankshaft

tion sensor.)

Camshaft position sensor circuit l Harness and connector R e t a i n e d

function(If harness and connector are not defective, replace camshaft position

sensor.),

‘0400

‘0420

Exhaust gas recirculation flow

function

Exhaust gas recirculation solenoid

malfunction

Catalyst system efficiency below

threshold (Bankl) l

Harness and connector R e t a i n e d

l

EGR valve

l E G R s o l e n o i d

valve control vacuum ,

l Manifold differential, pressure sen-

sor

l Harness and connector

l EGR solenoid

l E x h a u s t m a n i f o l d ( R e p l a c e t h e R e t a i n e d

catalytic converter if there is no

cracks)

‘0440Evaporative emission control l Harness and connector R e t a i n e d

malfunction Engine (Turbo)>l

Evaporative emission purge Sole-

noid

l Purge control valve

l Vacuum hoses routing

‘0442

‘0443

‘0446

Evaporative emission control l Harness and connector R e t a i n e d

leak detected l

Evaporative emission purge

s o l e n o i d

l Evaporative emission ventilation

solenoidlVacuum hoses routing

Evaporative emission control system

l Harness and connector Retained

purge control valve circuit malfunc-l

Evaporative emission purgetion solenoid .

Evaporative emission control systeml

Harness and connector R e t a i n e d

vent control malfunction l

Evaporative emission ventilation..

solenoid

TSB Revision

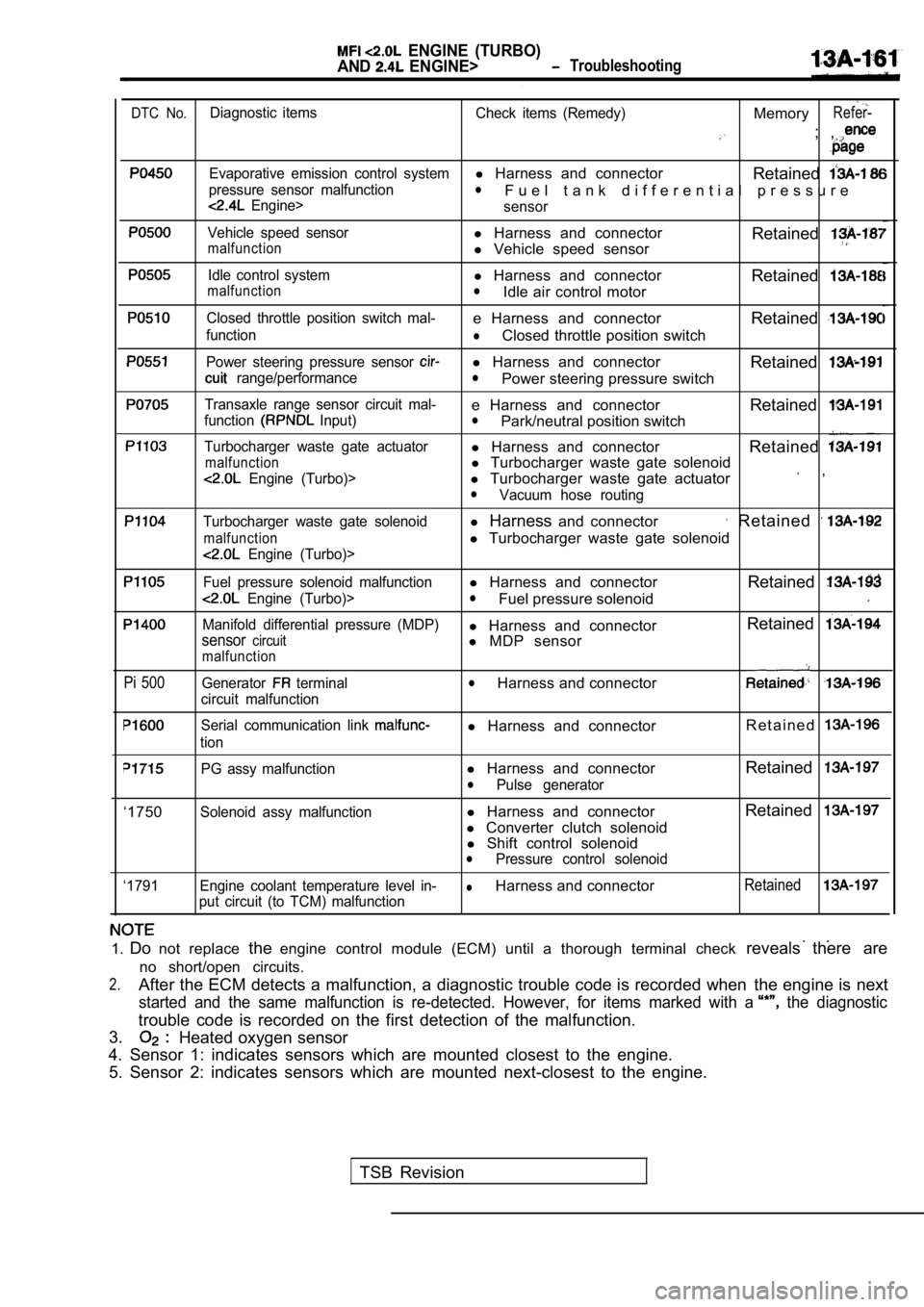

Page 541 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

DTC No.Diagnostic items Check items (Remedy)MemoryRefer-

; ,

Evaporative emission control systeml Harness and connector

Retained

pressure sensor malfunctionl

Engine>F u e l t a n k d i f f e r e n t i a l p r e s s u r e

sensor

Vehicle speed sensorl Harness and connectormalfunctionl Vehicle speed sensor Retained

Idle control systeml

Harness and connector

RetainedmalfunctionlIdle air control motor

Closed throttle position switch mal-e Harness and connector Retained

functionlClosed throttle position switch

Power steering pressure sensor l Harness and connector

Retained

range/performancelPower steering pressure switch

Transaxle range sensor circuit mal-e Harness and connector Retainedfunction Input)lPark/neutral position switch

Turbocharger waste gate actuatorl Harness and connector

Retained

malfunctionl Turbocharger waste gate solenoid

Engine (Turbo)>l Turbocharger waste gate actuator ,

lVacuum hose routing

Turbocharger waste gate solenoidl Harness and connector Retained

malfunctionl Turbocharger waste gate solenoid

Engine (Turbo)>

Fuel pressure solenoid malfunctionl Harness and connector

Retained

Engine (Turbo)>lFuel pressure solenoid

Manifold differential pressure (MDP)l Harness and connector Retainedsensorcircuitl

MDP sensormalfunction

Pi 500Generator terminal

circuit malfunctionlHarness and connector

Serial communication link

tion

l Harness and connector R e t a i n e d

‘1750

‘1791PG assy malfunction

l

Harness and connector RetainedlPulse generator

Solenoid assy malfunction

l Harness and connector Retained

l

Converter clutch solenoid

l Shift control solenoid

lPressure control solenoid

Engine coolant temperature level in-

lHarness and connectorRetained

put circuit (to TCM) malfunction

1. Do not replace theengine control module (ECM) until a thorough termin al check reveals there are

no short/open circuits.

2.After the ECM detects a malfunction, a diagnostic t rouble code is recorded when the engine is next

started and the same malfunction is re-detected. Ho wever, for items marked with a the diagnostic

trouble code is recorded on the first detection of the malfunction.

3.

Heated oxygen sensor

4. Sensor 1: indicates sensors which are mounted cl osest to the engine.

5. Sensor 2: indicates sensors which are mounted ne xt-closest to the engine.

TSB Revision

Page 542 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Volume Air Flow Circuit Malfunction

[Comment]Background

lWhile the engine is running, the volume air flow se nsor outputs a MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Volume Air Flow Circuit Malfunction

[Comment]Background

lWhile the engine is running, the volume air flow se nsor outputs a](/img/19/57345/w960_57345-541.png)

ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Volume Air Flow Circuit Malfunction

[Comment]Background

lWhile the engine is running, the volume air flow se nsor outputs a signal which

corresponds to the volume of air flow.

lThe engine control module checks whether the freque ncy of this signal output by the

volume air flow sensor while the engine is running is at or above the set value.

Check Area, Judgement Criteria

1. Check Area

Engine is not lower than 500

Judgement CriterialSensor output frequency has continued to be 3.3 Hz or lower for 4 sec.

2. Check Area l Throttle position sensor voltage is 2

or lower. Engine speed is not higher than 2000

Judgement CriterialSensor freauencv has continued to be 1000 Hz or hiaher fo r 4 sec. EnginelSensor output frequency has continued to be 800 Hz or higher for 4 sec. Engine>

3. Check Area

l Throttle position sensor voltage is 1.5 or higher.

l Engine speed is 2000 or higher.

Judgement CriterialSensor output frequency is Hz or lower for 4 seconds.

Measure at the volume air flow Check the volume air flow sensor

sensor connector A-l 02. circuit. (Refer to

l Connect the connector. (Use PROCEDURE 47.)

the test harness:

1. Voltage between 3 and ground(Engine: idling)OK: 2.2-3.2 2. Voltage between 7 and ground OK: (Engine: idling)

6 - 9

OK

Replace the ECM.

(Ignition switch: ON)

O K : 6 - 9

TSB Revision

Check the following connector

Probable cause

lVolume air, flow lOpen or shorted sensor or loose connector Engine control module failed

Check trouble symptom.

N G

Repair

Replacethevolumeairflowsensor.

, Check trouble

Repair

Replace the ECM.

Page 543 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE ( T U R B O )

AND ENGINE> Troubleshooting

Code No. Barometric Pressure Malfunction Probable cause ,

[ C o m m e n t ]BackgroundlThe barometric pressure sensor outputs a voltage wh

ich MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE ( T U R B O )

AND ENGINE> Troubleshooting

Code No. Barometric Pressure Malfunction Probable cause ,

[ C o m m e n t ]BackgroundlThe barometric pressure sensor outputs a voltage wh

ich](/img/19/57345/w960_57345-542.png)

ENGINE ( T U R B O )

AND ENGINE> Troubleshooting

Code No. Barometric Pressure Malfunction Probable cause ,

[ C o m m e n t ]BackgroundlThe barometric pressure sensor outputs a voltage wh

ich corresponds to the barometricpressure.

Barometric pressure sensor failedlOpen or shorted barometric or loose connectorl Engine control module failedl The engine control module checks whether this volta ge is within a specified range.

Check Area l 60

or more have passed since the starting sequence wa s completed.

l Battery voltage is not lower than 8 V.

Judgement CriterialSensor output voltage has continued to be 4.5 or higher [corresponding to a barometricpressure of 114 (17 psi) or higher] for 4 sec. ,

or

lSensor output voltage has continued to be 1.95 or lower a barometricpressure of 50 (7.4 psi) or lower] for 4 sec.

theECM and the barometric

NGMeasure at the volume air flow

sensor connector

lDisconnect the connector, andmeasure at the harness side.lVoltage between 1 and ground(Ignition switch: ON)

O K :

l Continuity between 5 andground

sor connector l Connect the connector. (Use

the test harness:

lVoltage between 2 and ground(Ignition switch: ON)

OK: 3.7-4.3

[Altitude: 0 (0 ft.)]

[Altitude: 1,200 (3,937

OK

at the ECM 3-56. Connect the connector. Voltage between 85 and ground (Ignition switch: ON)

OK: 3.7-4.3

[Altitude: 0 (0 ft.)]

I

[(Altitude: 1,200 (3,937ii.)]

Continuity

OKsure sensor connector.I

Check the following connector: Repair

A-i

OK

OK

Check trouble symptom.

NG

Replace the ECM.

N GCheck the harness wire between Repairthe ECM and the barometric pres-sure sensor connector.

OKOK

the ECM and the barometric pres- harness wire

sure sensor connector.

Repair

OK

the ECM.

TSB Revision1

Page 544 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting,

Code No. Intake Air Temperature Circuit

[Comment]

Background

lThe intake air temperature sensor converts the intake air temperature to a voltag MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting,

Code No. Intake Air Temperature Circuit

[Comment]

Background

lThe intake air temperature sensor converts the intake air temperature to a voltag](/img/19/57345/w960_57345-543.png)

ENGINE (TURBO)

AND ENGINE> Troubleshooting,

Code No. Intake Air Temperature Circuit

[Comment]

Background

lThe intake air temperature sensor converts the intake air temperature to a voltage and

outputs it.

l The engine control module checks whether the voltag e is within a specified range.

Check Area

l 60

or more have passed since the starting sequence wa s completed.

Judgement CriterialSensor output voltage has continued to be 4.6 or higher [corresponding to an intake

air temperature of or lower] for 4 sec.

or

lSensor output voltage has continued to be 0.2 or lower [corresponding to an intake

air temperature of or higher] for 4 sec.

l Intake air temperature lOpen or shorted intake circuit, or loose l Engine control

Check the intake air temperature sor. (Refer to Replace the volume air flow sensor.

Measure at the volume air flow sensor

l

l a n d g r o u n d Check the wire between the RepairECM and the intake air temperaturesensor connector.

Replace the ECM.

Revision