sensor MITSUBISHI SPYDER 1990 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 133 of 2103

ENGINE OVERHAUL Exhaust Manifold

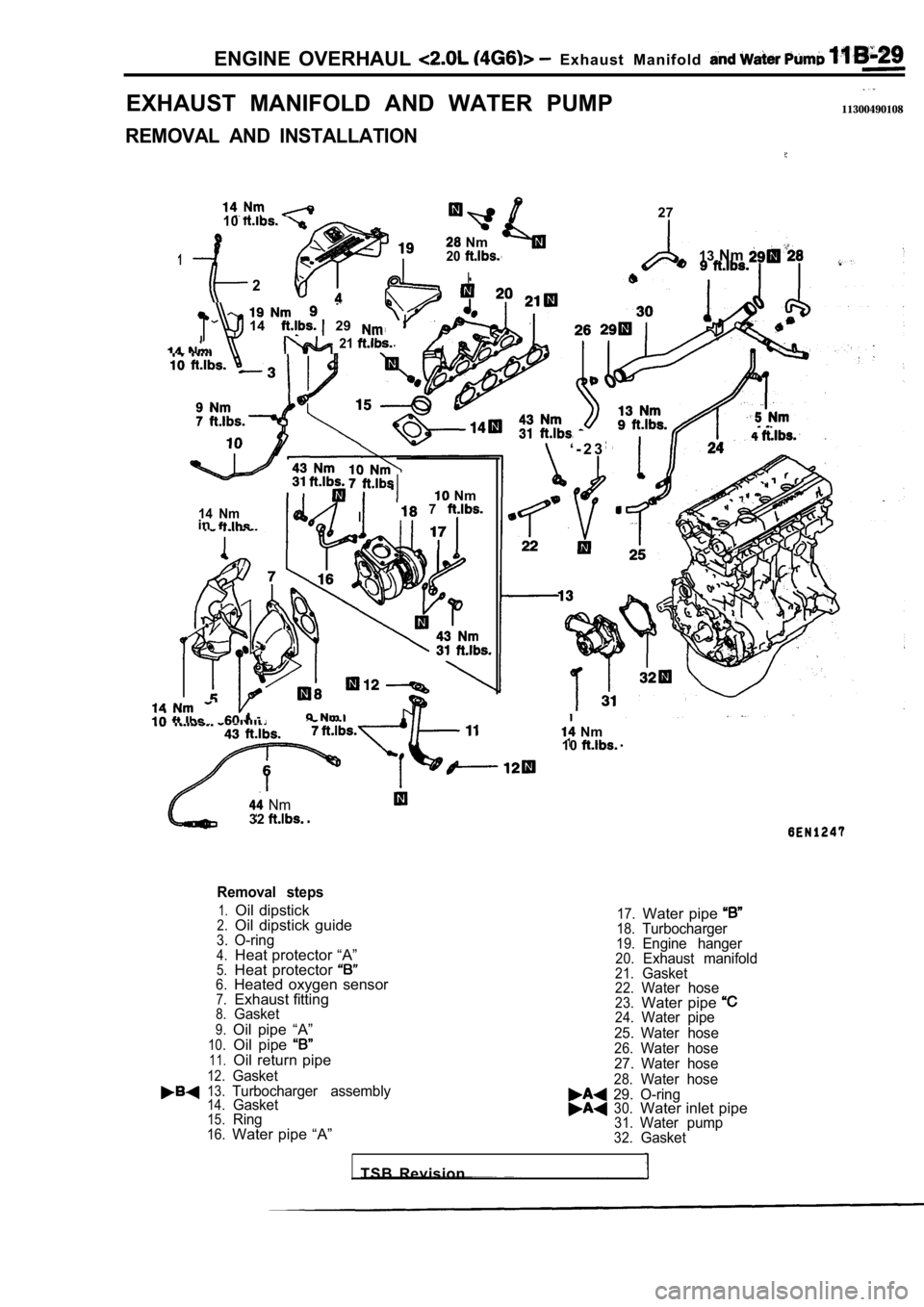

EXHAUST MANIFOLD AND WATER PUMP

REMOVAL AND INSTALLATION

11300490108

. .

10

Nm

120

2I

27

14 29

21

14 Nmin

Nm

I 7

I - Nm

13 Nm

‘ - 2 3

Nm

10

Nm32

Removal steps

1.Oil dipstick17.Water pipe 2.Oil dipstick guide18.Turbocharger3.O-ring19.Engine hanger4.Heat protector “A”20.Exhaust manifold5.Heat protector 21.Gasket6.Heated oxygen sensor22.Water hose7.Exhaust fitting23.Water pipe 8.Gasket24.Water pipe9.Oil pipe “A”25. Water hose10.Oil pipe 26.Water hose11.Oil return pipe27. Water hose12.Gasket28.Water hose13.Turbocharger assembly29. O-ring14.Gasket30.Water inlet pipe15.Ring31.Water pump16.Water pipe “A”32.Gasket

TSB Revision

Page 136 of 2103

ENGINE OVERHAUL Rocker, Arms

Camshaft sprocket side

sidecamshaft

Dowel pin

n0

Cap number

Symbol identifying

intake or exhaust

0

Camshaft sprocket side1197 810 12

2 6

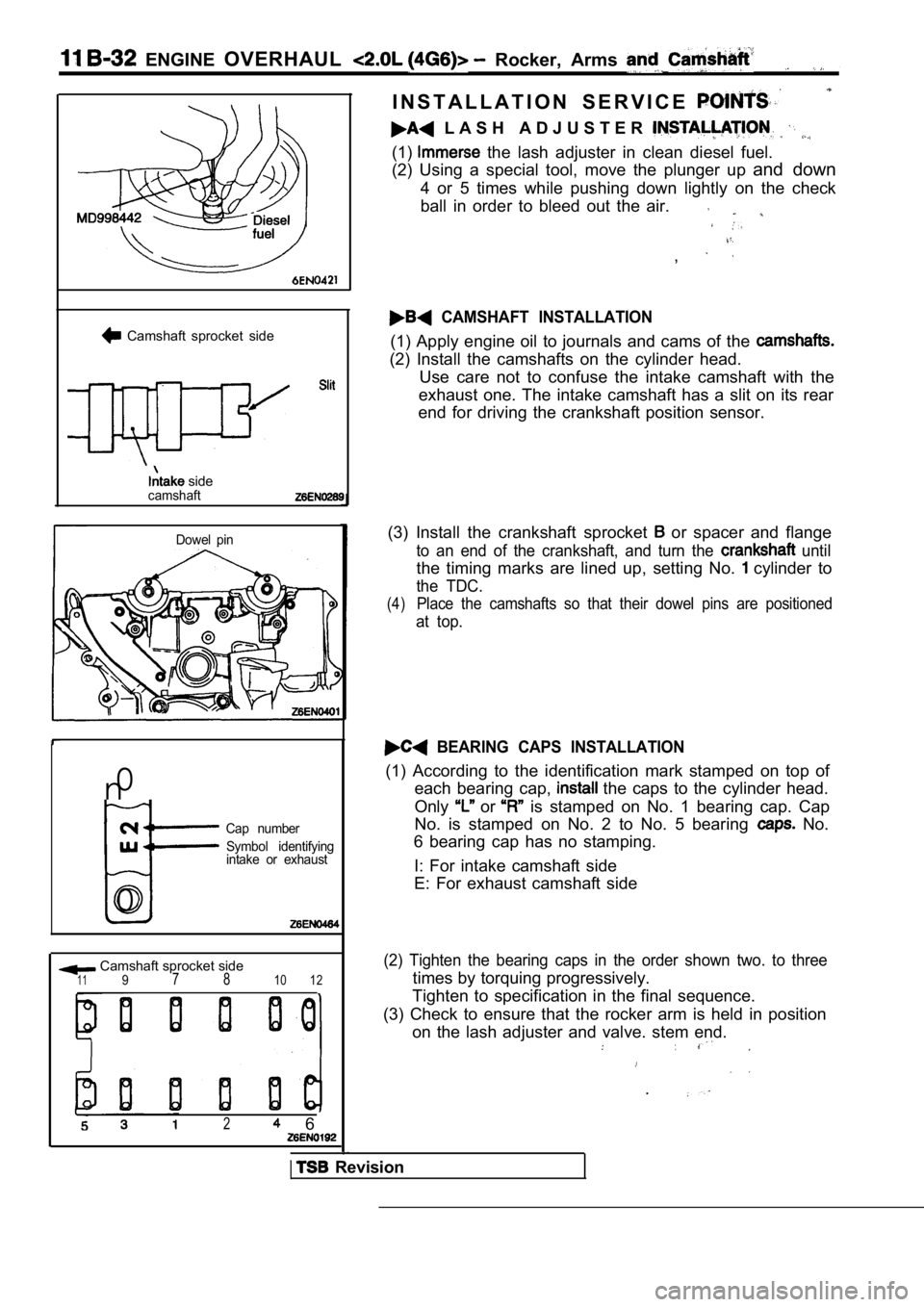

I N S T A L L A T I O N S E R V I C E

L A S H A D J U S T E R

(1) the lash adjuster in clean diesel fuel.

(2) Using a special tool, move the plunger up and down

4 or 5 times while pushing down lightly on the chec k

ball in order to bleed out the air.

,

CAMSHAFT INSTALLATION

(1) Apply engine oil to journals and cams of the

(2) Install the camshafts on the cylinder head. Use care not to confuse the intake camshaft with th e

exhaust one. The intake camshaft has a slit on its rear

end for driving the crankshaft position sensor.

(3) Install the crankshaft sprocket

or spacer and flange

to an end of the crankshaft, and turn the until

the timing marks are lined up, setting No. cylinder to

the TDC.

(4)Place the camshafts so that their dowel pins are po sitioned

at top.

BEARING CAPS INSTALLATION

(1) According to the identification mark stamped on top of

each bearing cap,

the caps to the cylinder head.

Only

or is stamped on No. 1 bearing cap. Cap

No. is stamped on No. 2 to No. 5 bearing

No.

6 bearing cap has no stamping.

I: For intake camshaft side

E: For exhaust camshaft side

(2) Tighten the bearing caps in the order shown two . to three

times by torquing progressively.

Tighten to specification in the final sequence.

(3) Check to ensure that the rocker arm is held in position

on the lash adjuster and valve. stem end.

.

Revision

Page 181 of 2103

ENGINE On-vehicle Service

IDLE MIXTURE CHECK

11100210081

1.Before inspection, set vehicles in the following co ndition:

lEngine coolant temperature:

l Lights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2.After turning the ignition switch to OFF, connect t he scan

tool to the data link connector.

3.Start the engine and run it at 2,500 for 2 minutes.

4. Set the CO, HC tester.

5. Check the CO contents and the HC contents at idl e.

Standard value:

CO contents: 0.5% or less

HC contents: 100 ppm or less

6. If the idle speed is outside the standard value, check

the following items: l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the h eated

oxygen sensor repeats between and

,000 at idle.)

l Fuel pressure

I n j e c t o r

lIgnition coil, spark plug cable, spark plug

lEGR system and the EGR valve leak

l Evaporative emission control system

Compression pressure

NOTE

Replace the three-way catalyst whenever the CO and

HC contents do not remain inside the standard value .

(even though the result of the inspection is normal on

all items.)

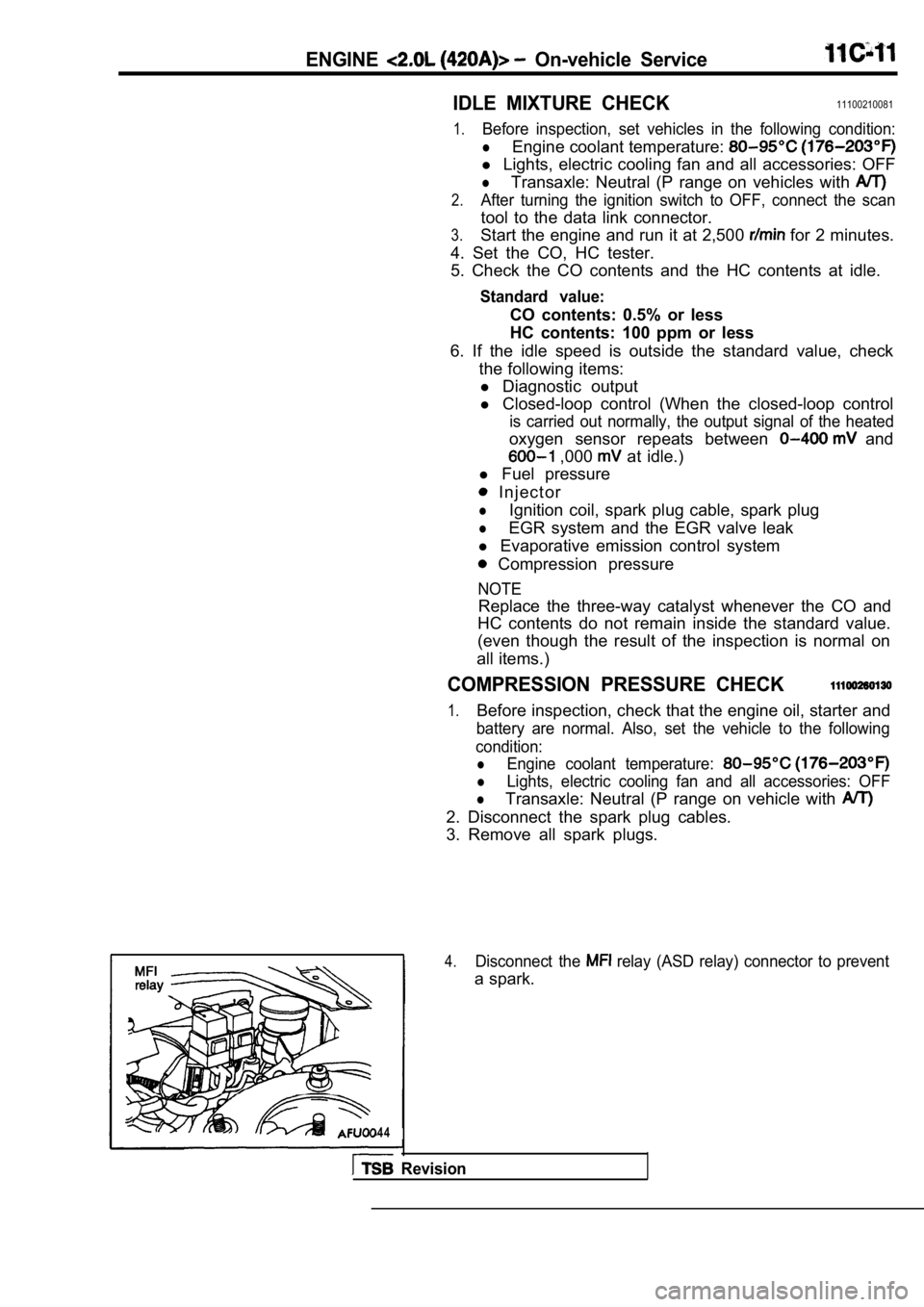

COMPRESSION PRESSURE CHECK

1.Before inspection, check that the engine oil, start er and

battery are normal. Also, set the vehicle to the fo llowing

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicle with

2. Disconnect the spark plug cables.

3. Remove all spark plugs.

4.Disconnect the relay (ASD relay) connector to prevent

a spark.

4 4

Revision

Page 184 of 2103

ENGINE Engine

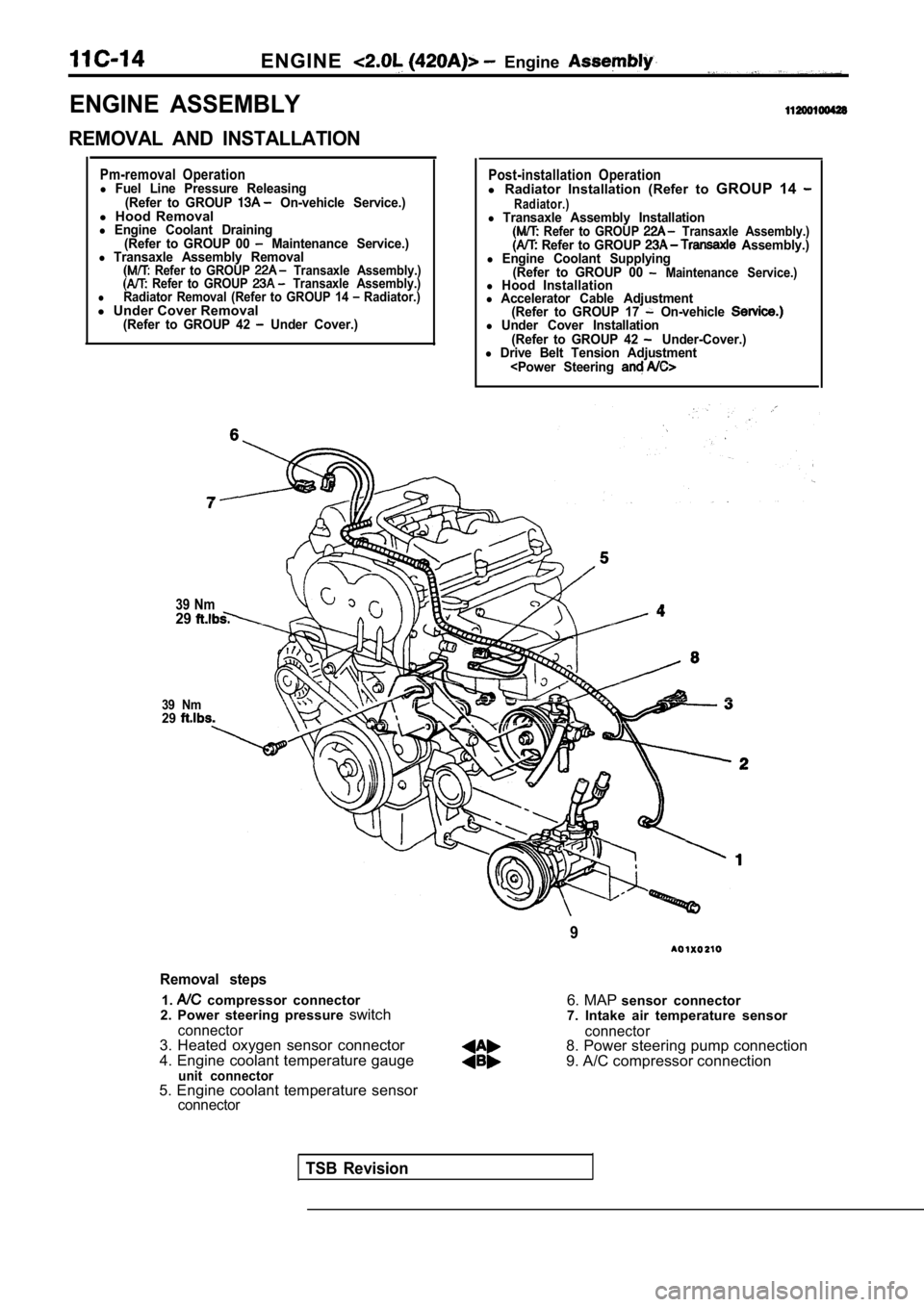

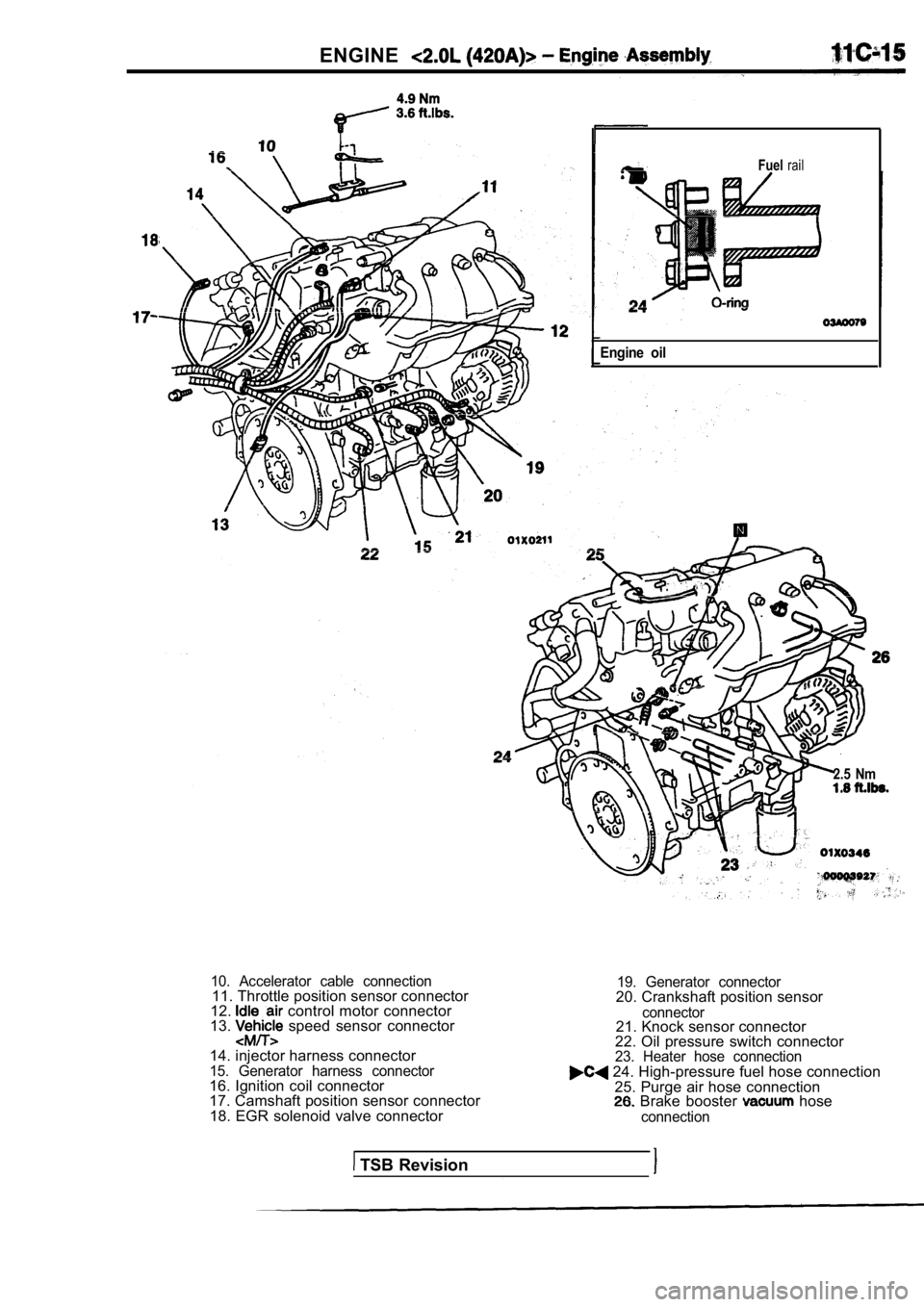

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Pm-removal Operationl Fuel Line Pressure Releasing(Refer to GROUP On-vehicle Service.)l Hood Removall Engine Coolant Draining

(Refer to GROUP 00 Maintenance Service.)l Transaxle Assembly Removal Refer to GROUP Transaxle Assembly.) Refer to GROUP Transaxle Assembly.)lRadiator Removal (Refer to GROUP 14 Radiator.)l Under Cover Removal(Refer to GROUP 42 Under Cover.)

39 Nm29

39 Nm29

Post-installation Operationl Radiator Installation (Refer to GROUP 14 Radiator.)l Transaxle Assembly Installation Refer to GROUP Transaxle Assembly.) Refer to GROUP Assembly.)l Engine Coolant Supplying

(Refer to GROUP 00 Maintenance Service.)l Hood Installationl Accelerator Cable Adjustment(Refer to GROUP 17 On-vehicle l Under Cover Installation

(Refer to GROUP 42 Under-Cover.)l Drive Belt Tension Adjustment

Removal steps

1. compressor connector

2. Power steering pressure switch

connector3. Heated oxygen sensor connector

4. Engine coolant temperature gauge

unit connector

6. MAP sensor connector

7. Intake air temperature sensor

connector8. Power steering pump connection

9. A/C compressor connection

5. Engine coolant temperature sensor

connector

TSB Revision

Page 185 of 2103

ENGINE

Fuelrail

Engine oil

2.5 Nm

10. Accelerator cable connection11. Throttle position sensor connector

12. control motor connector

13. speed sensor connector

14. injector harness connector

15. Generator harness connector16. Ignition coil connector

17. Camshaft position sensor connector 18. EGR solenoid valve connector

19. Generator connector20. Crankshaft position sensor

connector21. Knock sensor connector

22. Oil pressure switch connector

23. Heater hose connection 24. High-pressure fuel hose connection

25. Purge air hose connection

Brake booster hose

connection

TSB Revision

Page 191 of 2103

ENGINECamshaft and Camshaft Seal

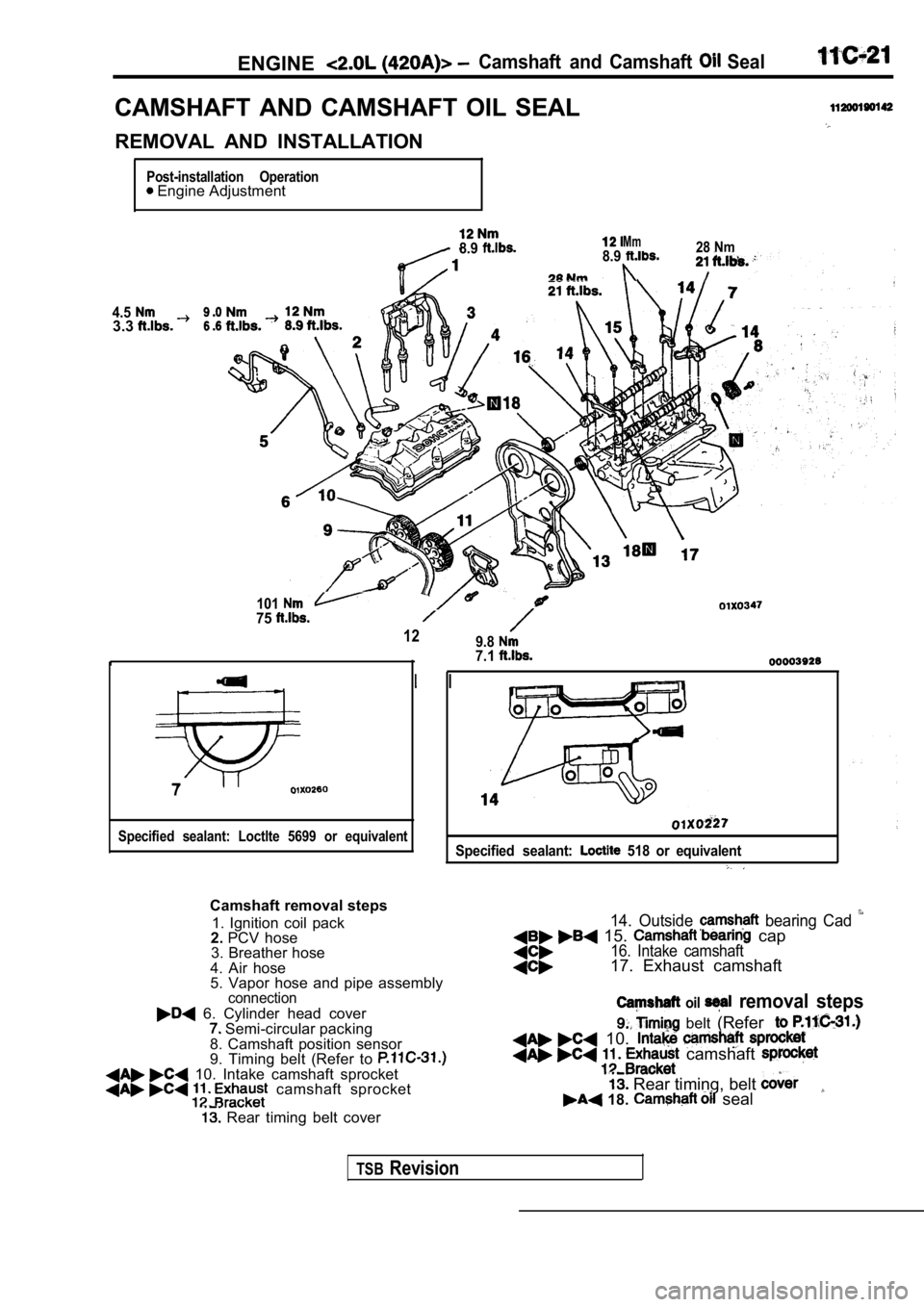

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Post-installation Operation Engine Adjustment

4.53.3

8.9Mm8.928 Nm

10175

129.8

7

Specified sealant: Loctlte 5699 or equivalent

7.1

Specified sealant: 518 or equivalent

Camshaft removal steps1. Ignition coil pack

2. PCV hose

3. Breather hose

4. Air hose

5. Vapor hose and pipe assembly

connection

6. Cylinder head cover Semi-circular packing

8. Camshaft position sensor

9. Timing belt (Refer to

10. Intake camshaft sprocket camshaft sprocket

Rear timing belt cover

14. Outside bearing Cad 15. cap16. Intake camshaft17. Exhaust camshaft

oil removal steps

belt (Refer

10. camshaft

Rear timing, belt 18. seal

TSBRevision

Page 199 of 2103

Cylinder Head

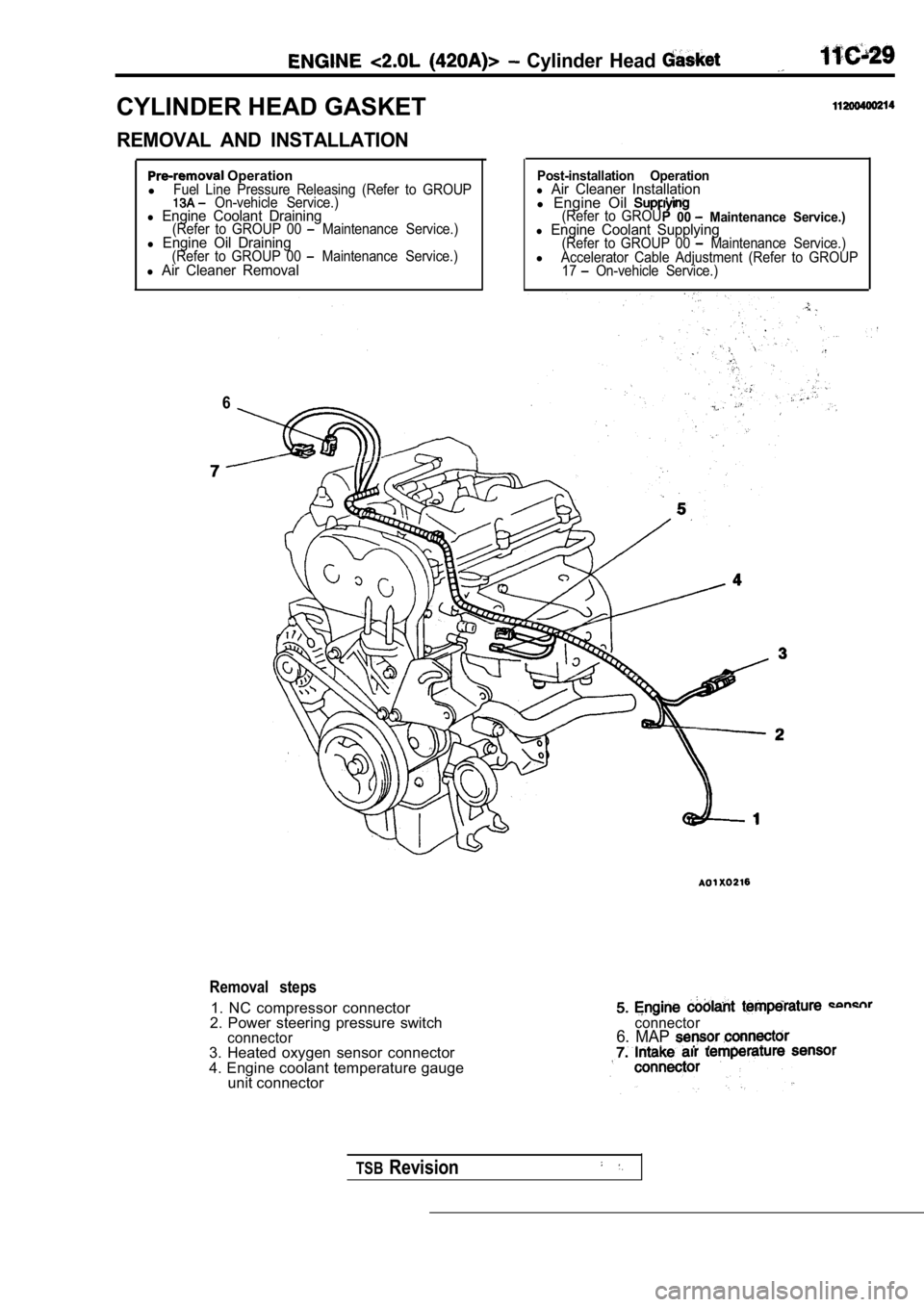

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Operation

lFuel Line Pressure Releasing (Refer to GROUP On-vehicle Service.)l Engine Coolant Draining(Refer to GROUP 00 Maintenance Service.)l Engine Oil Draining(Refer to GROUP 00 Maintenance Service.)l Air Cleaner Removal

6

Post-installation Operationl Air Cleaner Installationl Engine Oil (Refer to GROU00 Maintenance Service.)l Engine Coolant Supplying(Refer to GROUP 00 Maintenance Service.)lAccelerator Cable Adjustment (Refer to GROUP

17 On-vehicle Service.)

Removal steps

1. NC compressor connector

2. Power steering pressure switch

connector3. Heated oxygen sensor connector

4. Engine coolant temperature gauge unit connector

connector6. MAP

TSBRevision

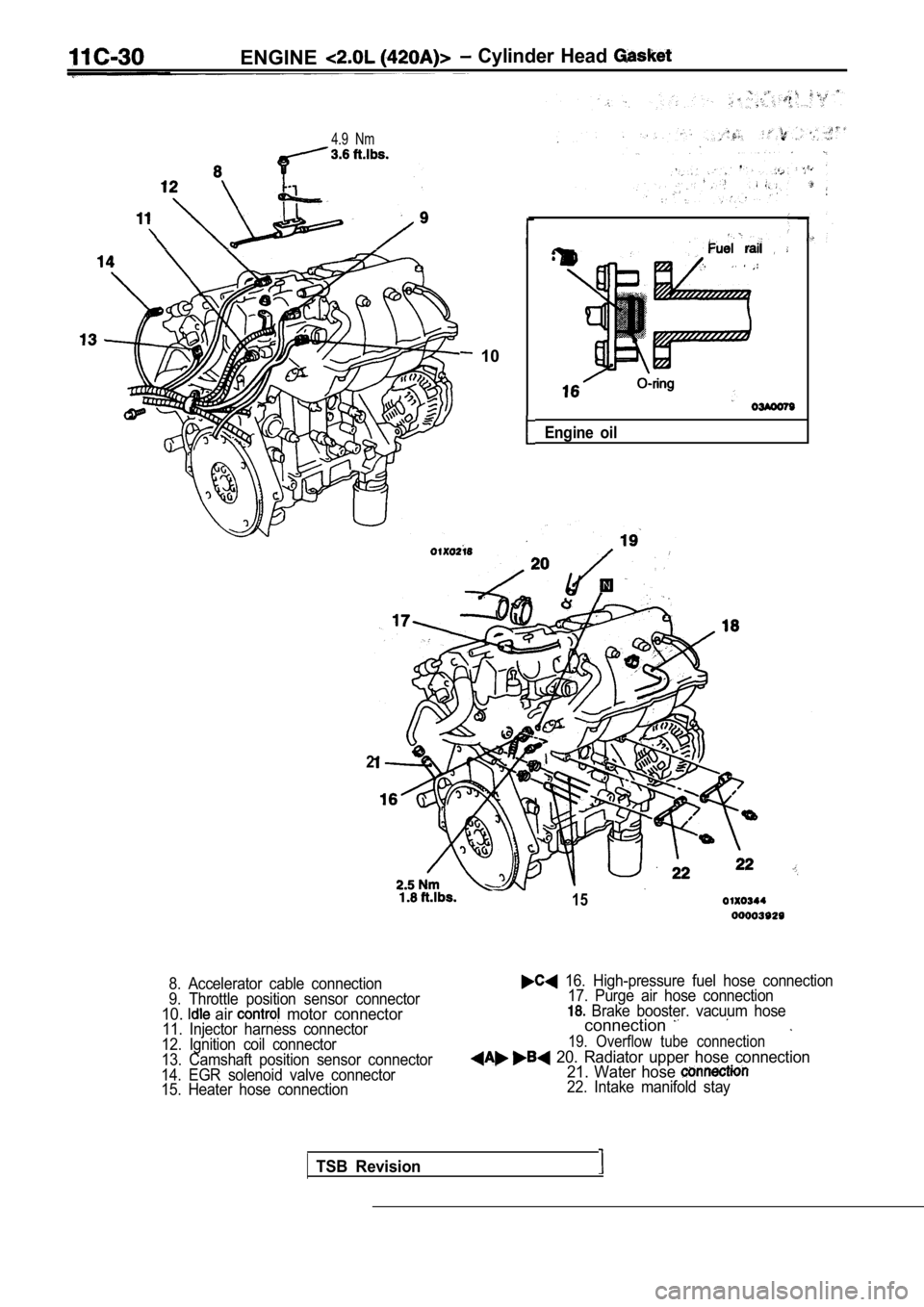

Page 200 of 2103

ENGINE Cylinder Head

4.9 Nm

10

Engine oil

TSB Revision

2

15

8. Accelerator cable connection

9. Throttle position sensor connector

10. air motor connector11. Injector harness connector

12. Ignition coil connector

13. Camshaft position sensor connector

14. EGR solenoid valve connector

15. Heater hose connection

16. High-pressure fuel hose connection 17. Purge air hose connection

Brake booster. vacuum hoseconnection

19. Overflow tube connection

20. Radiator upper hose connection 21. Water hose

22. Intake manifold stay

Page 212 of 2103

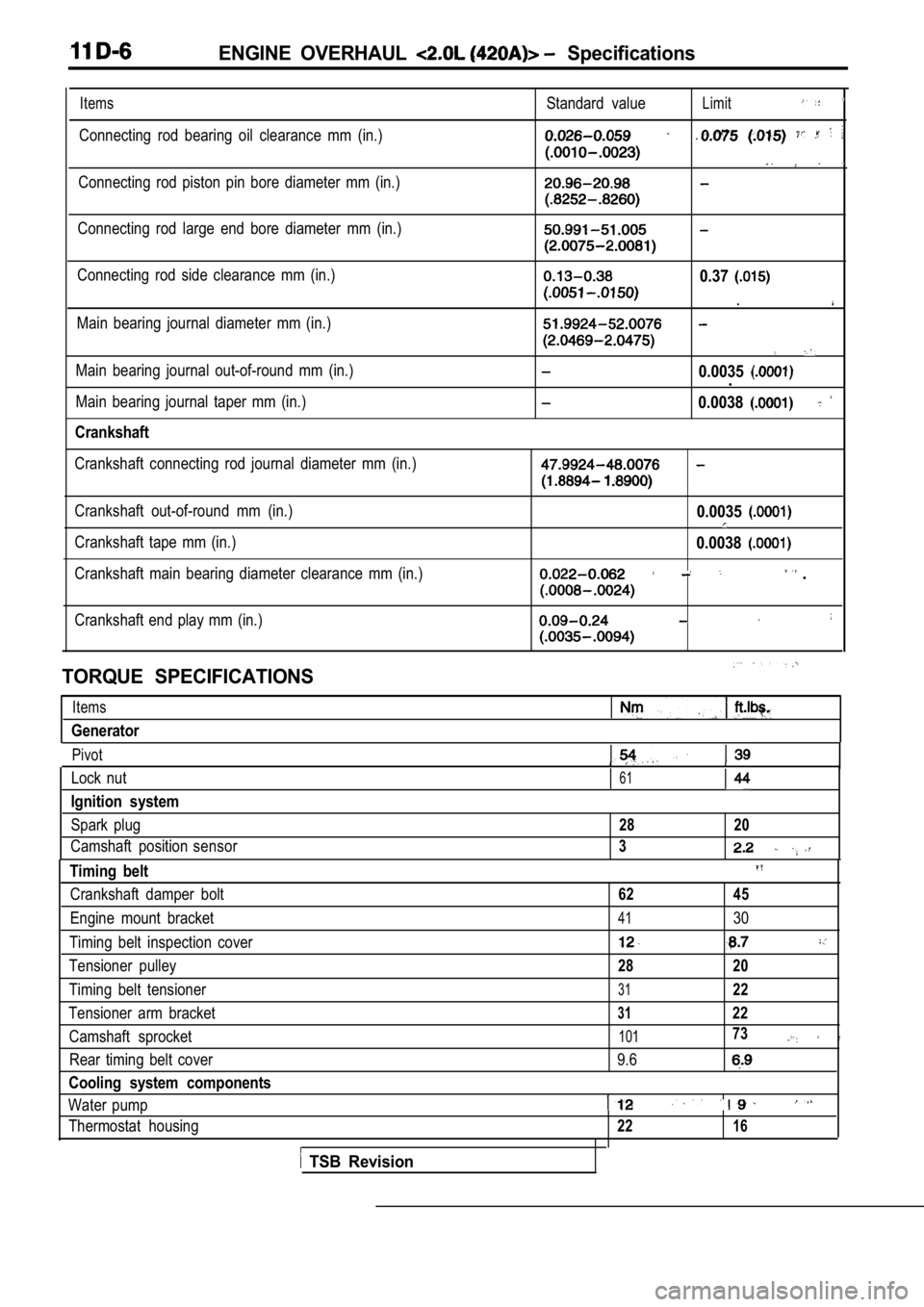

ENGINE OVERHAUL Specifications

Items

Connecting rod bearing oil clearance mm (in.)Standard value

Limit

Connecting rod piston pin bore diameter mm (in.)

Connecting rod large end bore diameter mm (in.)

Connecting rod side clearance mm (in.)

Main bearing journal diameter mm (in.)0.37

.

Main bearing journal out-of-round mm (in.)

Main bearing journal taper mm (in.)

Crankshaft

0.0035.

0.0038

Crankshaft connecting rod journal diameter mm (in.)

Crankshaft out-of-round mm (in.)

Crankshaft tape mm (in.)

Crankshaft main bearing diameter clearance mm (in.)0.0035

0.0038

.

Crankshaft end play mm (in.)

TORQUE SPECIFICATIONS

Items

Generator

Pivot

Lock nut61

Ignition system

Spark plug28 20

Camshaft position sensor3

Timing belt

Crankshaft damper bolt62 45

Engine mount bracket4130

Timing belt inspection cover

Tensioner pulley28 20

Timing belt tensioner3122

Tensioner arm bracket3122

Camshaft sprocket10173

Rear timing belt cover 9.6

Cooling system components

Water pump

Thermostat housing2216

TSB Revision

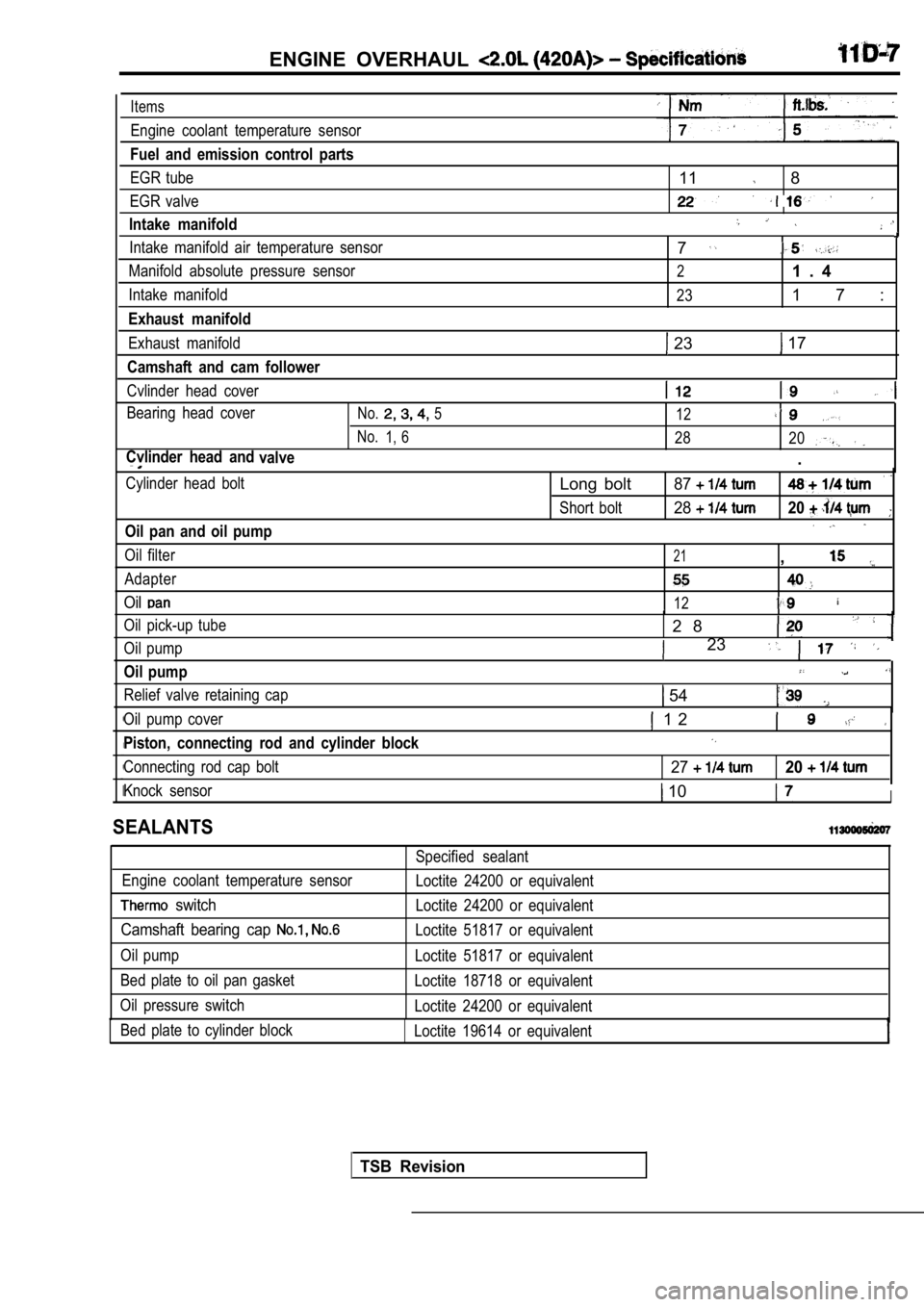

Page 213 of 2103

ENGINE OVERHAUL

Items

Engine coolant temperature sensor

Fuel and emission control parts

EGR tube

EGR valve

Intake manifold

11 8

Intake manifold air temperature sensor

Manifold absolute pressure sensor

Intake manifold

Exhaust manifold

Exhaust manifold

Camshaft and cam follower

Cvlinder head cover

Bearing head cover

No.5 12

No.1, 628 20

Cvlinder head and

valve.

7

21 . 4

231 7 :

23 17

Cylinder head bolt

Oil pan and oil pump

Oil filter

Adapter

Oil

Oil pick-up tube

Oil pump

Oil pump

Relief valve retaining cap

Long bolt87

Short bolt2820

21,

12

2 8

23

54

Oil pump cover

Piston, connecting rod and cylinder block

Connecting rod cap bolt

1 2

2720

Knock sensor 10I

SEALANTS

Engine coolant temperature sensor

switch

Camshaft bearing cap

Oil pump

Bed plate to oil pan gasket

Oil pressure switch Bed plate to cylinder block Specified sealant

Loctite 24200 or equivalent

Loctite 24200 or equivalent

Loctite 51817 or equivalent

Loctite 51817 or equivalent

Loctite 18718 or equivalent

Loctite 24200 or equivalent

Loctite 19614 or equivalent

TSB Revision