sensor MITSUBISHI SPYDER 1990 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 390 of 2103

ENGINE (NON-TURBO)> Troubleshooting

DTC No. ItemsI

107

108

109

110

112

113

114

118

119

126 38)

Cylinder misfire

Cylinder

misfire

Cylinder

misfire

misfire

Catalytic

efficiency failure

EVAP purge flow monitor failure

Park/neutral position switch (transaxle range switc h) failure

Fuel system rich

Fuel system lean

Downstream

shorted to

128Closed loop temperature not reached

129

Downstream at center

132

133

TPS voltage does not agree with MAP

Timing belt skipped 1 tooth or more

135No 5 volts to MAP sensor

136No 5 volts to throttle position sensor

137EATX controller DTC present

138Taraet idle not reached

High speed radiator fan control relay

146 1496)

153

154

155

156

157

160

161

183

5 volts too low

Battery temperature sensor voltage too low

Battery temperature sensor voltage too high

Upstream

voltage grounded

Downstream

voltage grounded

Intermittent loss of CMP or CKP

EVAP leak monitor small leak detected

EVAP leak monitor large leak detected

Evaporative emission ventilation solenoid circuit

Evaporative emission ventilation solenoid switch or mechanical fault

EVAP leak monitor pinched hose found

NOTE

Following a detected malfunction of the Control Module (PCM), the check engine lamp

up the next time the engine is turned on if the mal function is still detected. However, for items

with an asterisk in the table above, the check engine lamp goes on’ the first time a malfundin is

detected.

Once the check engine lamp is lit, any one of the f ollowing

will turn it off.

lWhen the PCMhas found no malfunction after monitoring the power train times time

is from engine start to engine stop).

lA misfire of fuel abnormality when engine speed, coolant temperature, etc. are to those

when the malfunction was first recorded, and the PCM has detected no malfunction.

Caution

If the check engine lamp is turned on by a malfunct ion of the PCM, the scan tool communicate

with the PCM, and the diagnostic trouble code canno t be read.

,

TSB Revision

Page 392 of 2103

ENGINE (NON-TURBO)> Troubleshooting.

HOW TO READ AND ERASE DIAGNOSTIC

CODES

TSB Revision Caution

1. If battery voltage is diagnostic codes.

may not be output. Be sure to check the,

and charging system before

2.If the battery is disconnected or if the connector

is disconnected, the diagnostic trouble code

will be erased. Do not disconnect the battery or

until after the diagnostic are recorded.

3. Turn the ignition switch, off before

disconnecting the scan. tool.

When using the scan tool

NOTE

When carrying out inspection General ‘Scan Tool,

mode, the interface

cartridge) and

adaptor harness do not

need to be installed.

2.The following items cannot be checked in scan

mode; they can only be checked in General Scan

Tool mode.

SENSOR READ TEST

l term fuel trim

l Calculated load vlaue

FREEZ FRAME DATA

READINESS TESTS

3. When diagnostic trouble codes (DTC) are’ erased,

the freeze frame data and

test status will

be erased at the same time. Therefore,

should be recorded if necessary

4. If the automatic transaxle DTC

been stored, the DTC for the PCM should be

after the DTC for the TCM is erased:

1. Install the interface cartridge cartridge) to the scan

tool

2. Use the cartridge adapter harness to the

scan tool

to the data link

start the engine and on the

(if applicable). Shut off the engine.

3. Read the diagnostic trouble codes.

4.Repair the malfunction while referring to the

CHART FOR DIAGNOSTIC TROUBLE CODES.

5. Turn the ignition switch to OFF and then back to ON

6. the diagnostic trouble codes using the scan tool.

7. Check that the diagnostic trouble code is normal .

Page 395 of 2103

ENGINE (NON-TURBO)>

INSPECTION USING TOOL SENSOR

TEST, INPUT STATE TEST,, OUTPUT AND

T E S T

1.Carry out inspection by means:’ of the data list ‘and the

actuator test function.

If there is a malfunction, check and repair the cha ssis

harnesses and components.

2. Recheck using the scan tool and check that the

malfunction has been eliminated as a result of the repairs.

3. Erase the diagnostic trouble code from memory.

4. Remove the scan tool.

5.Start the engine again and carry out a road test to confirm.

that the problem

disappeared. . .

NOTE

Refer to for Sensor Read Tests.

Refer to

for Input State Tests.

Refer to

for Output State Tests.

Refer to -for Actuator Tests.

Caution

If in the following

F U N C T I O N to the IAC.

In the following case, reset the IAC.

lThe throttle body or motor has been replaced.

lThe motor related circuit has been opened during

engine running or motor operation test.

TSB Revision

Page 396 of 2103

ENGINE (NON-TURBO)> Troubleshooting

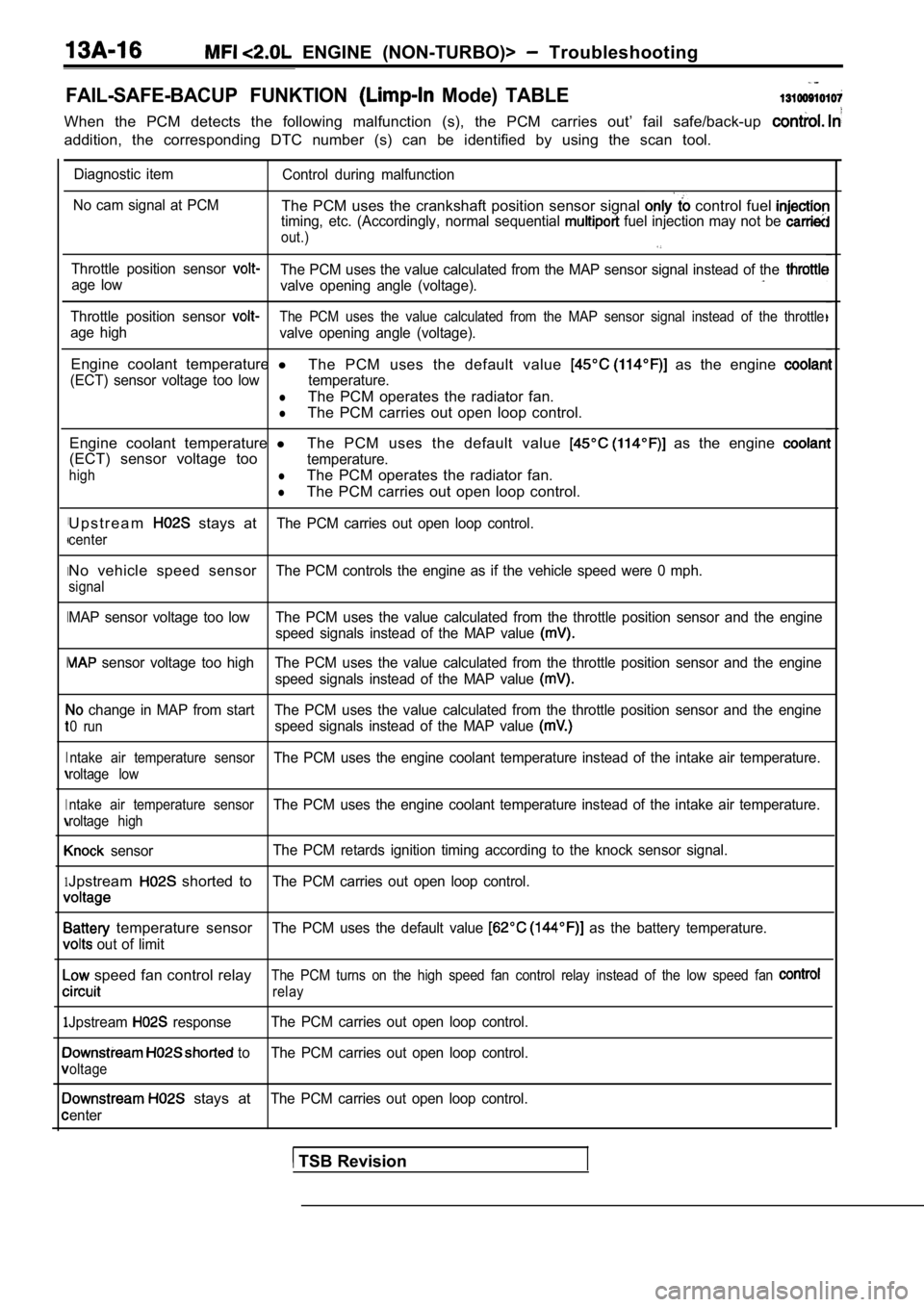

FAIL-SAFE-BACUP FUNKTION Mode) TABLE

When the PCM detects the following malfunction (s), the PCM carries out’ fail safe/back-up

addition, the corresponding DTC number (s) can be i dentified by using the scan tool.

I

I

I

I

I

1

1

Diagnostic item

Control during malfunction

No cam signal at PCM

The PCM uses the crankshaft position sensor signal control fuel timing, etc. (Accordingly, normal sequential fuel injection may not be

out.)

Throttle position sensor The PCM uses the value calculated from the MAP sens or signal instead of the age low

valve opening angle (voltage).

Throttle position sensor The PCM uses the value calculated from the MAP sens or signal instead of the throttle

age high

valve opening angle (voltage).

Engine coolant temperature l

The PCM uses the default value as the engine

(ECT) sensor voltage too low temperature.

lThe PCM operates the radiator fan.

lThe PCM carries out open loop control.

Engine coolant temperature lThe PCM uses the default value

as the engine

(ECT) sensor voltage tootemperature.

highlThe PCM operates the radiator fan.

lThe PCM carries out open loop control.

U p s t r e a m

stays atThe PCM carries out open loop control.

center

No vehicle speed sensorThe PCM controls the engine as if the vehicle speed were 0 mph.

signal

MAP sensor voltage too low The PCM uses the value ca lculated from the throttle position sensor and the engine

speed signals instead of the MAP value

sensor voltage too high The PCM uses the value calc ulated from the throttle position sensor and the engine

speed signals instead of the MAP value

change in MAP from start The PCM uses the value cal culated from the throttle position sensor and the engine

0 runspeed signals instead of the MAP value

ntake air temperature sensorThe PCM uses the engine coolant temperature instead of the intake air temperature.

roltage low

ntake air temperature sensor

The PCM uses the engine coolant temperature instead of the intake air temperature.

roltage high

sensorThe PCM retards ignition timing according to the kn

ock sensor signal.

Jpstream shorted toThe PCM carries out open loop control.

temperature sensorThe PCM uses the default value as the battery temperature.

out of limit

speed fan control relayThe PCM turns on the high speed fan control relay i nstead of the low speed fan

relay

Jpstream responseThe PCM carries out open loop control.

to The PCM carries out open loop control.

oltage

stays atThe PCM carries out open loop control.

enter

TSB Revision

Page 397 of 2103

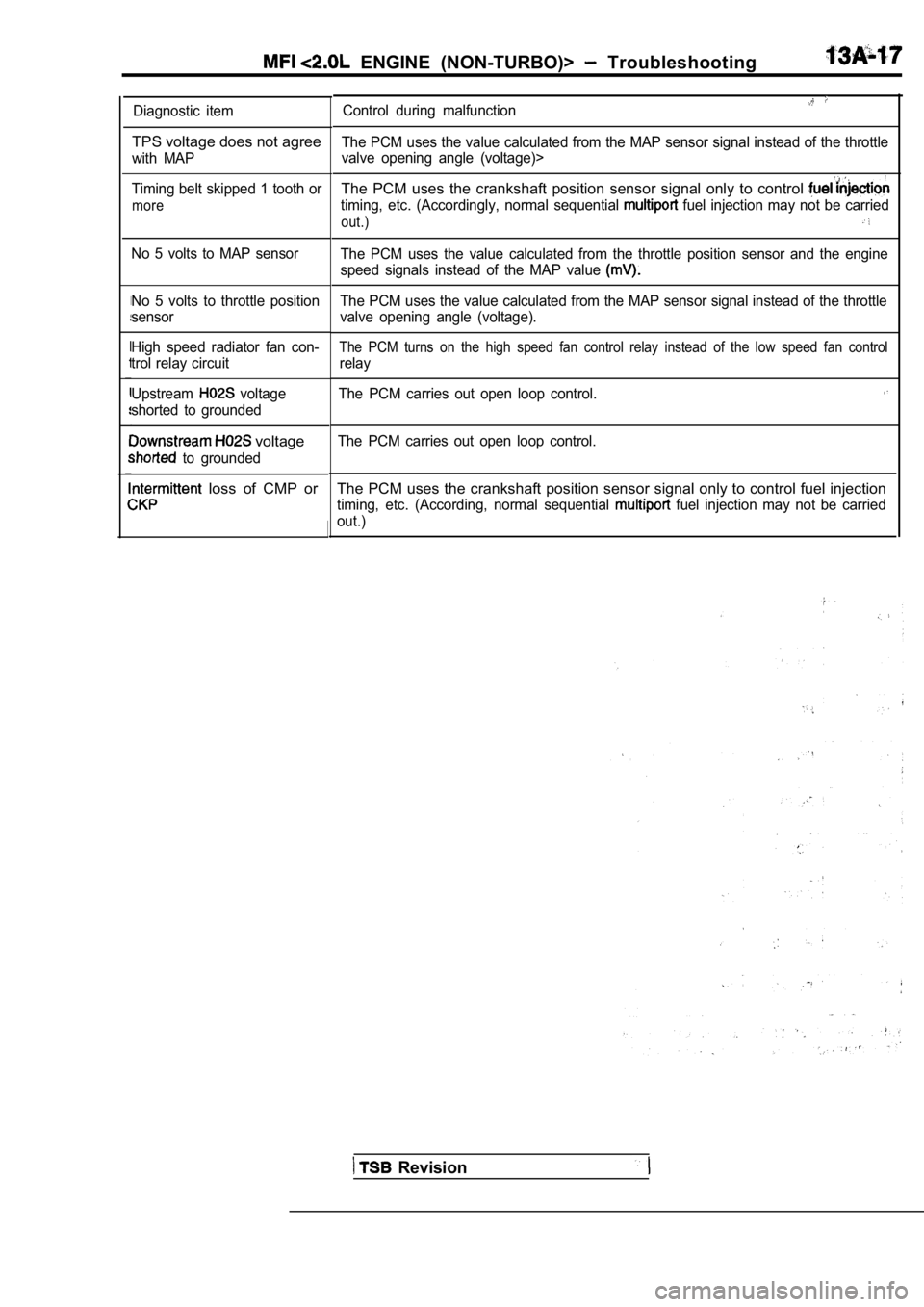

ENGINE (NON-TURBO)> Troubleshooting

Diagnostic item

TPS voltage does not agree

with MAP

Timing belt skipped 1 tooth or

more

No 5 volts to MAP sensor

No 5 volts to throttle position

sensor

High speed radiator fan con-

trol relay circuit

Upstream

voltage

shorted to grounded

voltage

to grounded

loss of CMP or

Control during malfunction

The PCM uses the value calculated from the MAP sens or signal instead of the throttle

valve opening angle (voltage)>

The PCM uses the crankshaft position sensor signal only to control

timing, etc. (Accordingly, normal sequential fuel injection may not be carried

out.)

The PCM uses the value calculated from the throttle position sensor and the engine

speed signals instead of the MAP value

The PCM uses the value calculated from the MAP sens or signal instead of the throttle

valve opening angle (voltage).

The PCM turns on the high speed fan control relay i nstead of the low speed fan control

relay

The PCM carries out open loop control.

The PCM carries out open loop control.

The PCM uses the crankshaft position sensor signal only to control fuel injection

timing, etc. (According, normal sequential fuel injection may not be carried

out.)

Revision

Page 398 of 2103

ENGINE (NON-TURBO)> Troubleshooting

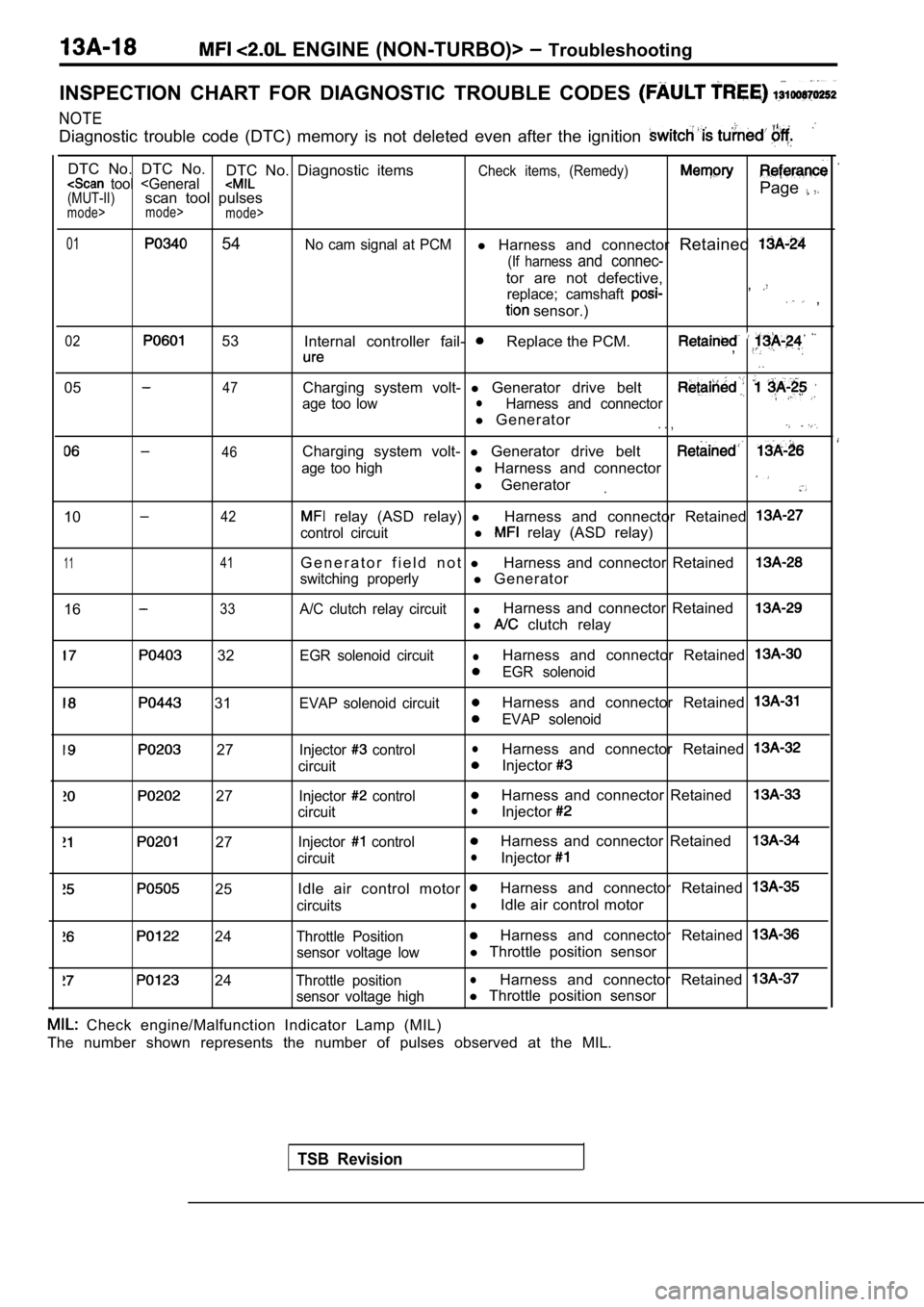

INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES

NOTE

Diagnostic trouble code (DTC) memory is not deleted even after the ignition

DTC No. DTC No.

DTC No. Diagnostic itemsCheck items, (Remedy) tool

mode>

mode>

01 54No cam signal at PCMl Harness and connector Retained

(If harness and connec-

tor are not defective,

replace; camshaft ,

sensor.) ,

02 53

Internal controller fail- Replace the PCM.,

. .

0547

46

Charging system volt- l Generator drive belt

age too lowlHarness and connector

l Generator. . ,

Charging system volt- l Generator drive belt

age too highl Harness and connector

l Generator

1042

1 141

1633

relay (ASD relay) lHarness and connector Retained

control circuitl relay (ASD relay)

G e n e r a t o r f i e l d n o t lHarness and connector Retained

switching properlyl Generator

A/C clutch relay circuitlHarness and connector Retained

l clutch relay

32

31

27

27

27

25

24

24

EGR solenoid circuitlHarness and connector Retained

EGR solenoid

EVAP solenoid circuit

Harness and connector Retained

EVAP solenoid

Injector

controllHarness and connector Retained

circuitInjector

Injector controlHarness and connector Retained

circuitlInjector

Injector controlHarness and connector Retained

circuitlInjector

Idle air control motor Harness and connector Retained

circuitslIdle air control motor

Throttle PositionHarness and connector Retained

sensor voltage lowl Throttle position sensor

Throttle positionlHarness and connector Retained

sensor voltage highl Throttle position sensor

TSB Revision

Check engine/Malfunction Indicator Lamp (MIL)

The number shown represents the number of pulses ob served at the MIL.

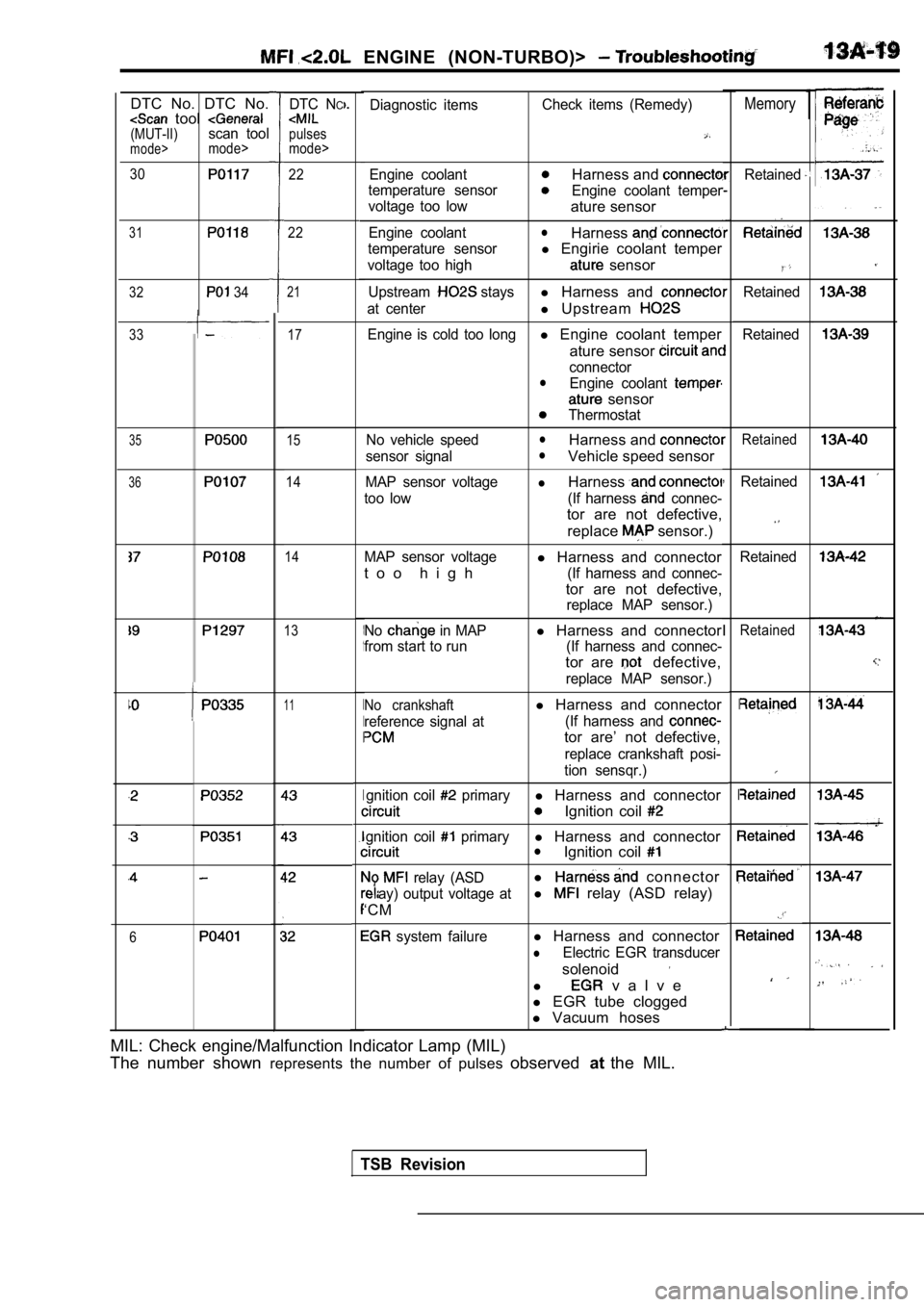

Page 399 of 2103

ENGINE (NON-TURBO)>

1MemoryDiagnostic itemsCheck items (Remedy)

Engine coolantHarness and

temperature sensorEngine coolant temper

voltage too low

ature sensor

Engine coolantlHarness

temperature sensorl Engirie coolant temper

voltage too high sensor

Upstream staysl Harness and

at centerl Upstream

Engine is cold too longl Engine coolant temper

ature sensor

connectorlEngine coolant

sensor

Thermostat

No vehicle speed

lHarness and

sensor signallVehicle speed sensor

MAP sensor voltagelHarness

too low (If harness connec-

tor are not defective, replace

sensor.)

MAP sensor voltagel Harness and connector

t o o h i g h

(If harness and connec-

tor are not defective,

replace MAP sensor.)

No

in MAPl Harness and connector

from start to run (If harness and connec-

tor are defective,

replace MAP sensor.)

No crankshaftl Harness and connector

reference signal at (If harness and

tor are’ not defective,

replace crankshaft posi-

tion sensqr.)

gnition coil

primaryl Harness and connector

Ignition coil

gnition coil primaryl Harness and connectorlIgnition coil

relay (ASDl connector

ay) output voltage atl relay (ASD relay)

‘CM

system failurel Harness and connector

lElectric EGR transducer

solenoid

l v a l v e

l EGR tube clogged

l Vacuum hoses

DTC NC

pulses

mode>

DTC No. DTC No. tool (MUT-II)scan toolmode>mode>

30

31

32 34

1

I

I

I

I

Retained22

22

,

I

I

I

Retained

Retained

21

17

15

14

14

33

35Retained

36Retained

Retained

13Retained

11

6

MIL: Check engine/Malfunction Indicator Lamp (MIL)

The number shown represents the number of pulses observedatthe MIL.

TSB Revision

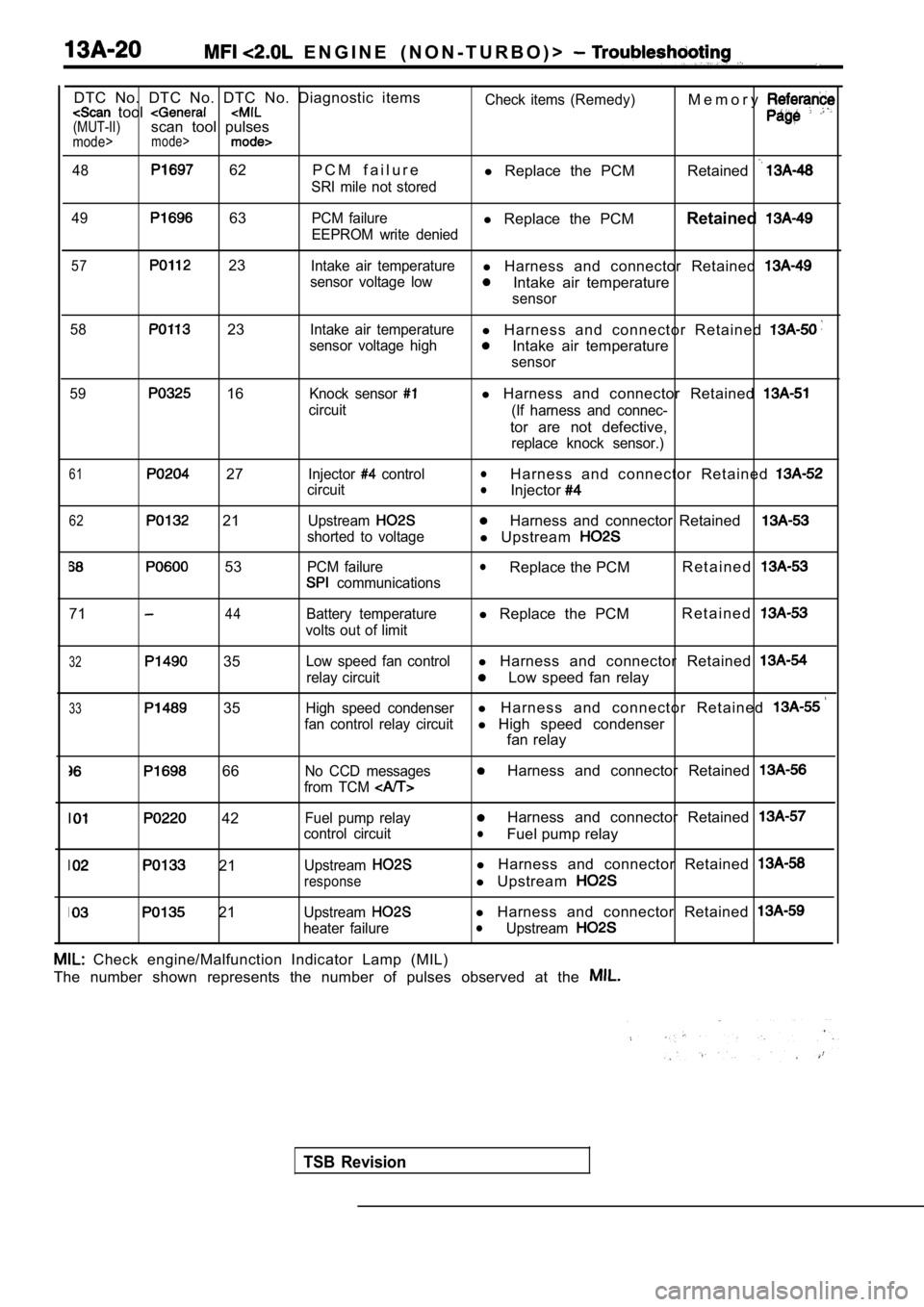

Page 400 of 2103

E N G I N E ( N O N - T U R B O ) >

DTC No. DTC No. DTC No. Diagnostic items tool (MUT-II)scan tool pulsesmode>mode>

48 62 P C M f a i l u r e

SRI mile not storedCheck items (Remedy)

l

Replace the PCM M e m o r yRetained

49 63PCM failurel

Replace the PCM Retained

EEPROM write denied

57 23Intake air temperaturel Harness and connector Retained

sensor voltage lowIntake air temperature

sensor

58

23Intake air temperaturel H a r n e s s a n d c o n n e c t o r R e t a i n e d

sensor voltage highIntake air temperature

sensor

59

16Knock sensor

circuit

l Harness and connector Retained

(If harness and connec-

tor are not defective,

replace knock sensor.)

61 27

62 21

53

Injector control

circuit

Upstream

shorted to voltage

PCM failure

communications

lH a r n e s s a n d c o n n e c t o r R e t a i n e d lInjector

Harness and connector Retained

l Upstream

lReplace the PCM R e t a i n e d

7144Battery temperature

volts out of limitl Replace the PCM R e t a i n e d

32 35

33 35

Low speed fan controll

Harness and connector Retained

relay circuitLow speed fan relay

High speed condenserl H a r n e s s a n d c o n n e c t o r R e t a i n e d

fan control relay circuitl High speed condenser

fan relay

66No CCD messages

from TCM Harness and connector Retained

42

21

21

Fuel pump relay

control circuit

Upstream

response

Upstream

heater failure

Harness and connector Retained

lFuel pump relay

l Harness and connector Retained

l Upstream

l Harness and connector Retained lUpstream

Check engine/Malfunction Indicator Lamp (MIL)

The number shown represents the number of pulses ob served at the

TSB Revision

Page 402 of 2103

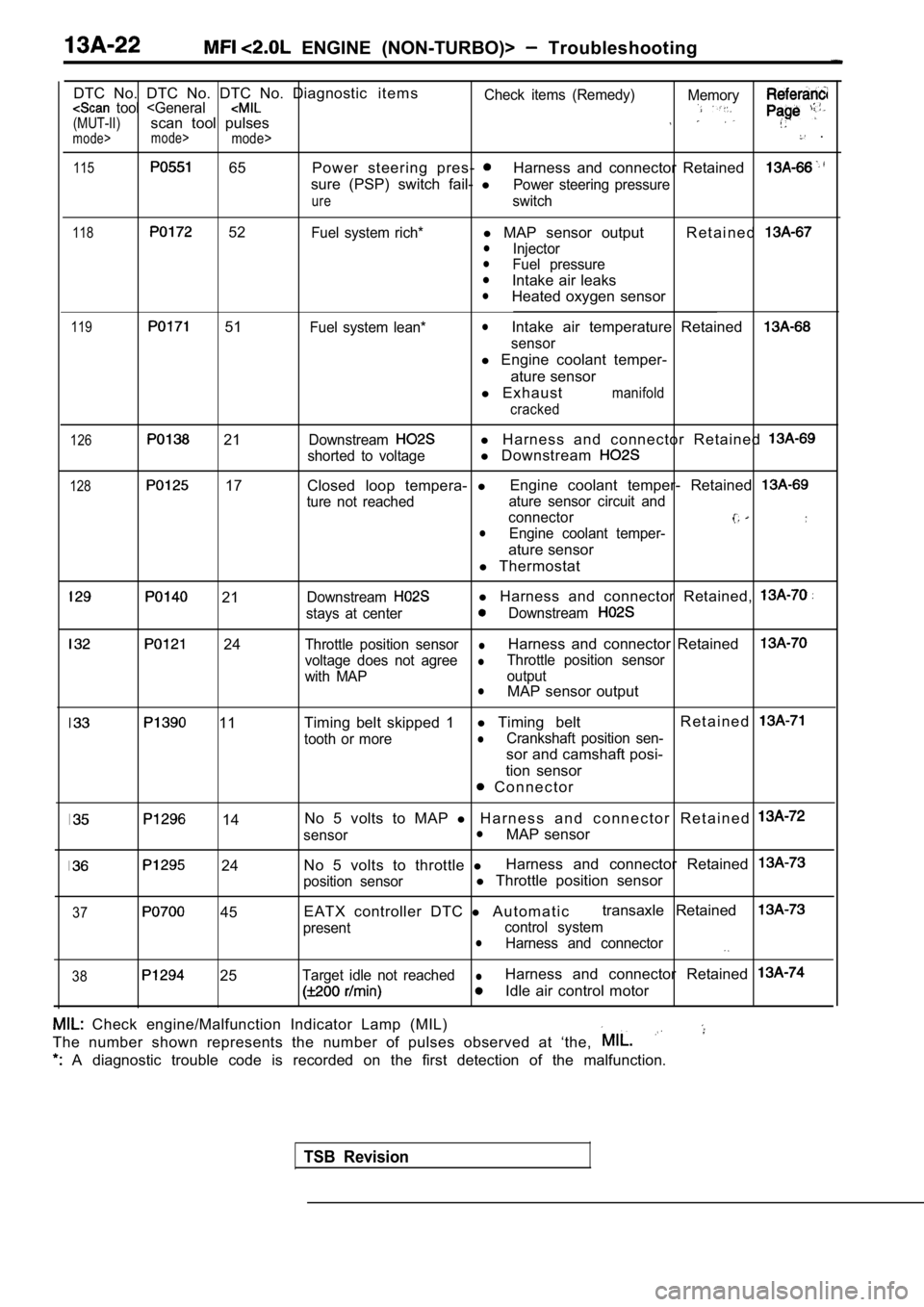

ENGINE (NON-TURBO)> Troubleshooting

DTC No. DTC No. DTC No. Diagnostic i t e m s

Check items (Remedy) Memory tool

115 65 Power steering pres- Harness and connector Retained

sure (PSP) switch fail-

lPower steering pressure

ureswitch

118 52Fuel system rich*l MAP sensor output R e t a i n e dlInjectorlFuel pressurelIntake air leakslHeated oxygen sensor

119 51Fuel system lean*lIntake air temperature Retained

sensor

l Engine coolant temper-

ature sensor

l E x h a u s t

manifold

cracked

126 21

128 17

Downstreaml H a r n e s s a n d c o n n e c t o r R e t a i n e d

shorted to voltagel Downstream

Closed loop tempera- lEngine coolant temper- Retained

ture not reached ature sensor circuit and

connector

lEngine coolant temper-

ature sensor

l Thermostat

21

24

11

Downstreaml Harness and connector Retained,

stays at centerDownstream

Throttle position sensorlHarness and connector Retained

voltage does not agreelThrottle position sensor

with MAP output

lMAP sensor output

Timing belt skipped 1 l

Timing belt R e t a i n e d

tooth or morelCrankshaft position sen-

sor and camshaft posi-

tion sensor

C o n n e c t o r

37

14

24

45 No 5 volts to MAP

l H a r n e s s a n d c o n n e c t o r R e t a i n e d

sensorlMAP sensor

No 5 volts to throttle lHarness and connector Retained

position sensorl

Throttle position sensor

EATX controller DTC l A u t o m a t i c transaxle Retained

present

control systemlHarness and connector

38 25Target idle not reachedlHarness and connector Retained

Idle air control motor

Check engine/Malfunction Indicator Lamp (MIL)

The number shown represents the number of pulses ob served at ‘the,

A diagnostic trouble code is recorded on the first detection of the malfunction.

TSB Revision

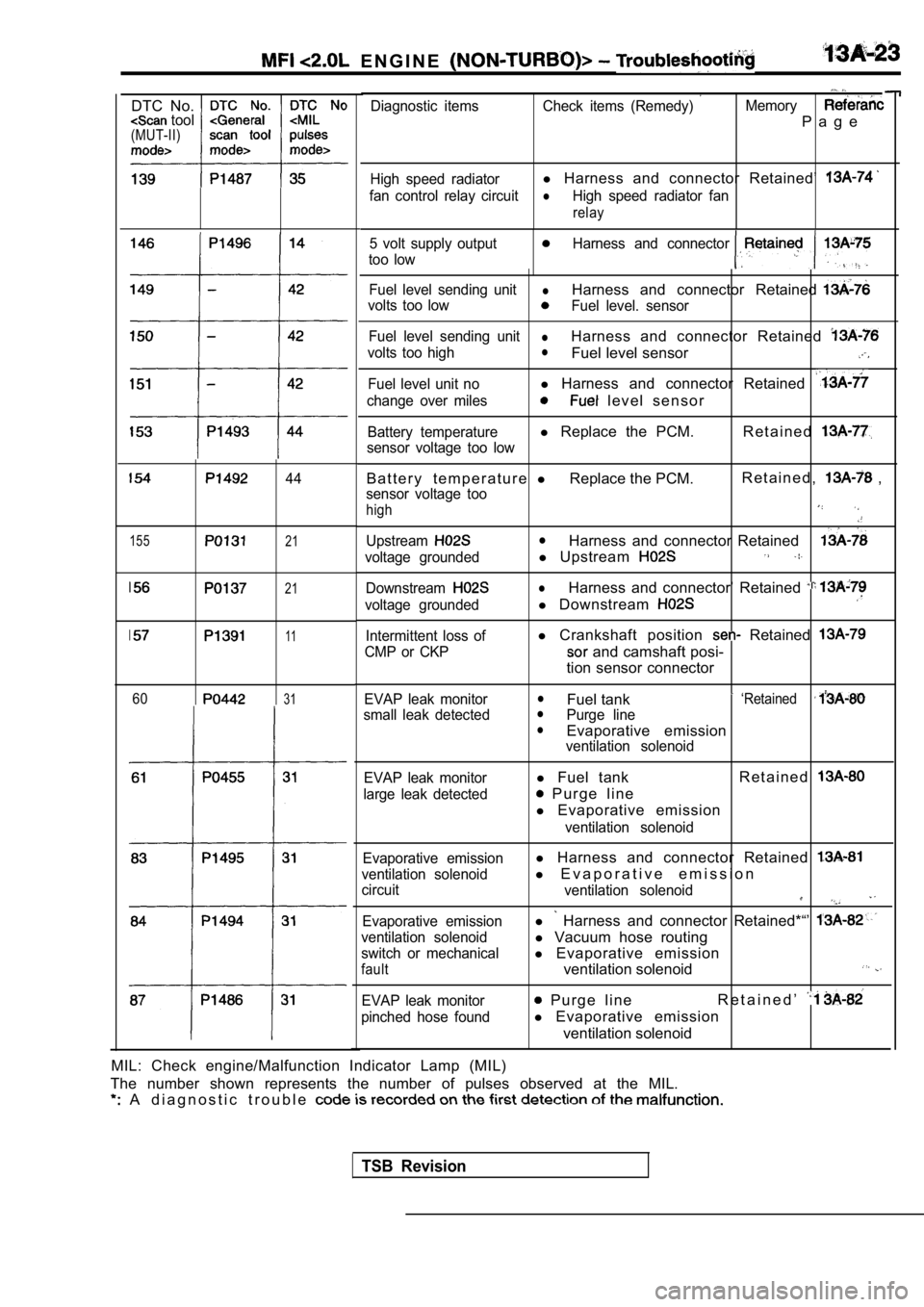

Page 403 of 2103

E N G I N E

DTC No. tool(MUT-II)

155

44

21

21

11

6031

Diagnostic items Check items (Remedy) Memory

P a g e

High speed radiatorl Harness and connector Retained’

fan control relay circuitlHigh speed radiator fan

relay

5 volt supply outputHarness and connector

too low

Fuel level sending unitlHarness and connector Retained

volts too lowFuel level. sensor

Fuel level sending unit

lHarness and connector Retained

volts too highlFuel level sensor

Fuel level unit nol Harness and connector Retained

change over miles l e v e l s e n s o r

Battery temperaturel Replace the PCM. R e t a i n e d

sensor voltage too low

B a t t e r y t e m p e r a t u r e lReplace the PCM. R e t a i n e d , ,

sensor voltage too

high

UpstreamlHarness and connector Retained

voltage groundedl

Upstream

DownstreamlHarness and connector’ Retained

voltage groundedl Downstream

Intermittent loss of

CMP or CKPl Crankshaft position Retained

and camshaft posi-

tion sensor connector

EVAP leak monitor

small leak detectedlFuel tank ‘RetainedlPurge linelEvaporative emissionventilation solenoid

EVAP leak monitor

large leak detected

l Fuel tank R e t a i n e d

P u r g e l i n e

l Evaporative emission

ventilation solenoid

Evaporative emission

ventilation solenoid

circuit

Evaporative emission

ventilation solenoid

switch or mechanical

fault

l Harness and connector Retained

l E v a p o r a t i v e e m i s s i o n

ventilation solenoid

l Harness and connector Retained*“’

l Vacuum hose routing

l Evaporative emission

ventilation solenoid

EVAP leak monitor

pinched hose found P u r g e l i n e R e t a i n e d ’

l

Evaporative emission

ventilation solenoid

MIL: Check engine/Malfunction Indicator Lamp (MIL)

The number shown represents the number of pulses ob served at the MIL.

A d i a g n o s t i c t r o u b l e

TSB Revision