engine coolant MITSUBISHI SPYDER 1990 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 278 of 2103

ENGINE O n - v e h i c l e

Press the scan tool clear key (select aforced driving

cancel mode) to release the ACTUATOR TEST

NOTE

If the test is not a forced driving will continue

for 27 minutes. Driving under this condition may damage

the engine.

Check that the actual ignition timing is at the st andard

value.

Standard value: Approx. BTDC

NOTE

Ignition timing is variable within about even under

normal operating.

2. And it is automatically further advanced by abou t

from BTDC at higher altitudes.

CURB IDLE SPEED CHECK

Before inspection and adjustment, set vehicles in the

following condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with A/T)

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Select No. 17 of the SCAN TOOL ACTUATOR TEST

4. Check the basic ignition timing.

Standard value: BTDC

5. Run the engine at idle for 2 minutes.

6. Select No. 22 of the SCAN TOOL DATA LIST.

7. Check the curb idle speed.

Standard value: 750 100

NOTE

The idle speed is controlled automatically by the i dle air

control system.

8. If the idle speed is outside the standard value, check

the components by referring to GROUP Trou-

bleshooting.

IDLE MIXTURE CHECK

Before inspection, set vehicles in the following co ndition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

4.Check that the basic ignition timing is within the standard

value..

Standard value:

TSB Revision

Page 279 of 2103

On-vehicle

Run the engine.

8. Set CO, HC tester.

7. Check the CO contents and the HC contents at idle.

Standard value:

CO contents: 0.5% or less

HC contents: 100 ppm or less

8. the standard value is exceeded, check the following

items:

l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the heated

oxygen sensor and

at idle.)

l

Injector

lIgnition coil, spark plug

l system the

l Evaporative emission

Compression ,

NOTE,

Replace the three-way CO and

HC contents do not

the value.

(even though the

of the” on

all items.)

PRESSURE CHECK

1.Before inspection, check that the engine oil, start er and

battery are normal. Also, set the vehicle to the fo llowing

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2. Disconnect the spark plug cables.

3. Remove all of the spark plugs.

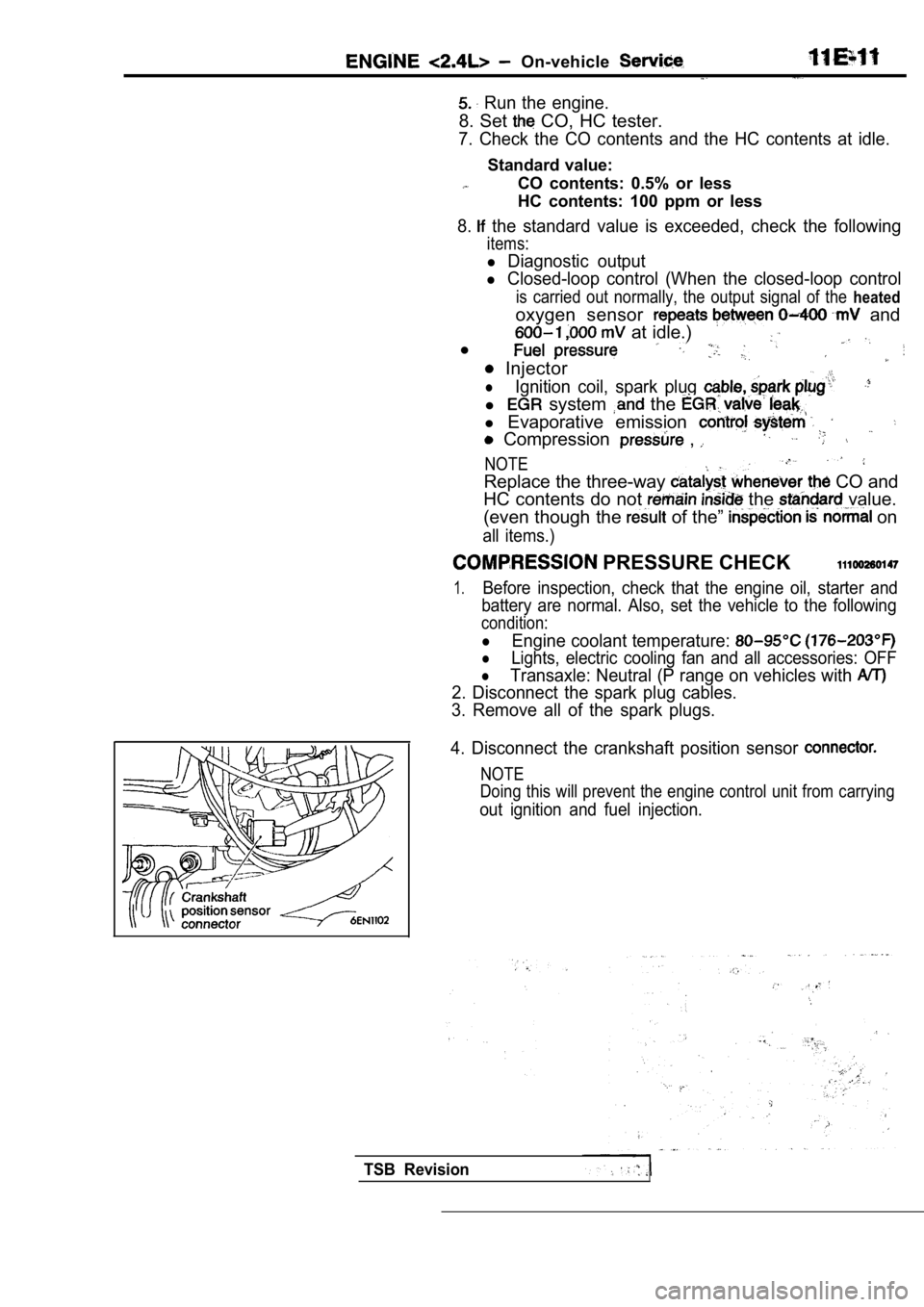

4. Disconnect the crankshaft position sensor

NOTE

Doing this will prevent the engine control unit fro m carrying

out ignition and fuel injection.

TSB Revision

Page 280 of 2103

ENGINEOn-vehicle

5. Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

Caution

1.Keep away from the spark plug hole when crank-

ing.

2. If compression is measured with water, fuel,

etc., that has come from cracks inside the

these materials will become heated and gush

out from the spark plug hole, which is dangerous.

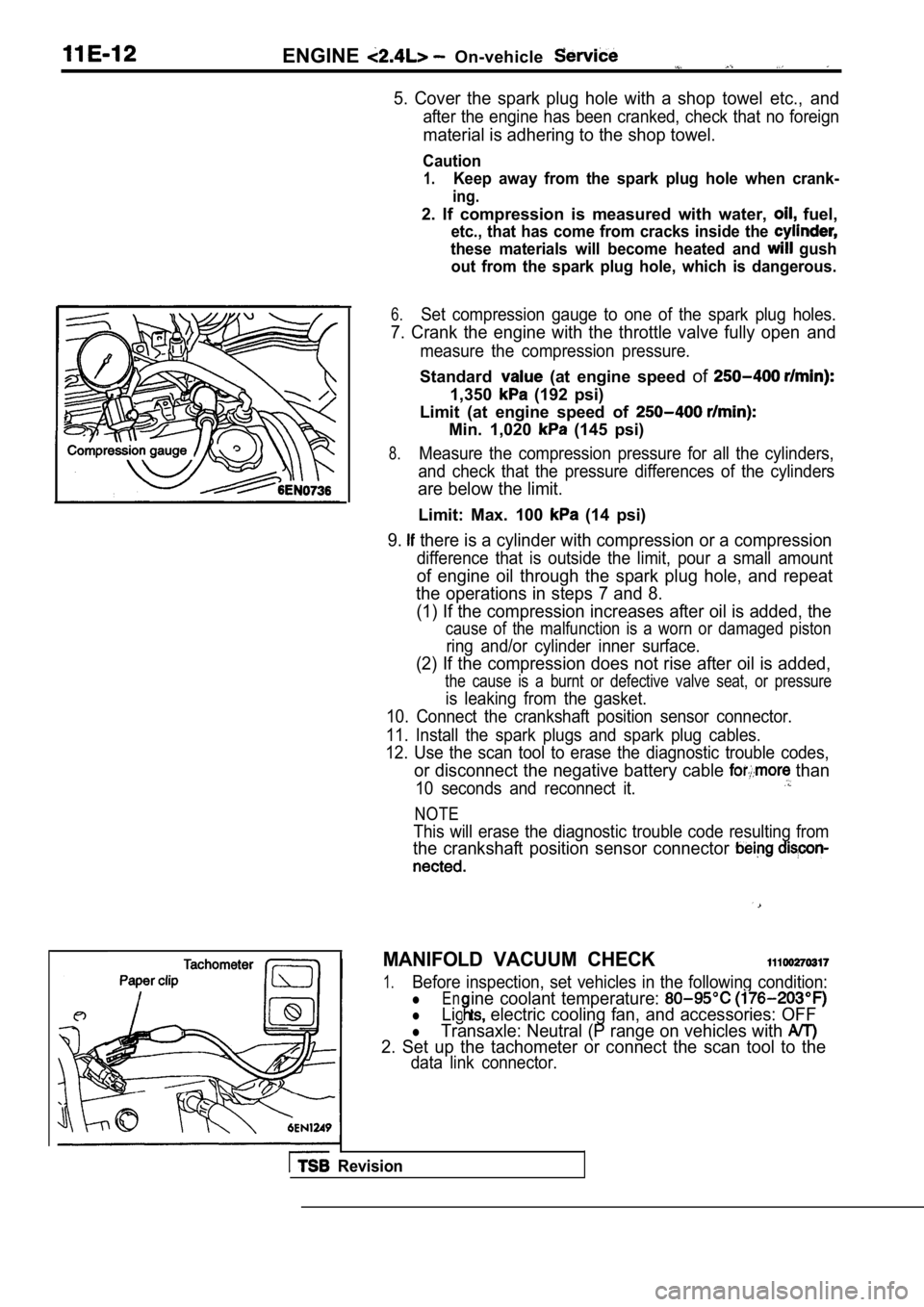

6.Set compression gauge to one of the spark plug hole s.

7. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard (at engine speed of

1,350 (192 psi)

Limit (at engine speed of

Min. 1,020 (145 psi)

8.Measure the compression pressure for all the cylind ers,

and check that the pressure differences of the cyli nders

are below the limit.

Limit: Max. 100 (14 psi)

9. there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repe at

the operations in steps 7 and 8.

(1) If the compression increases after oil is added , the

cause of the malfunction is a worn or damaged pisto n

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pr essure

is leaking from the gasket.

10. Connect the crankshaft position sensor connecto r.

11. Install the spark plugs and spark plug cables.

12. Use the scan tool to erase the diagnostic troub le codes,

or disconnect the negative battery cable than

10 seconds and reconnect it.

NOTE

This will erase the diagnostic trouble code resulting from

the crankshaft position sensor connector

MANIFOLD VACUUM CHECK

1.Before inspection, set vehicles in the following co ndition:

lEn

lLig electric cooling fan, and accessories: OFF

ine coolant temperature:

lTransaxle: Neutral (P range on vehicles with

2. Set up the tachometer or connect the scan tool t o the

data link connector.

Revision

Page 283 of 2103

Engine Assembly11

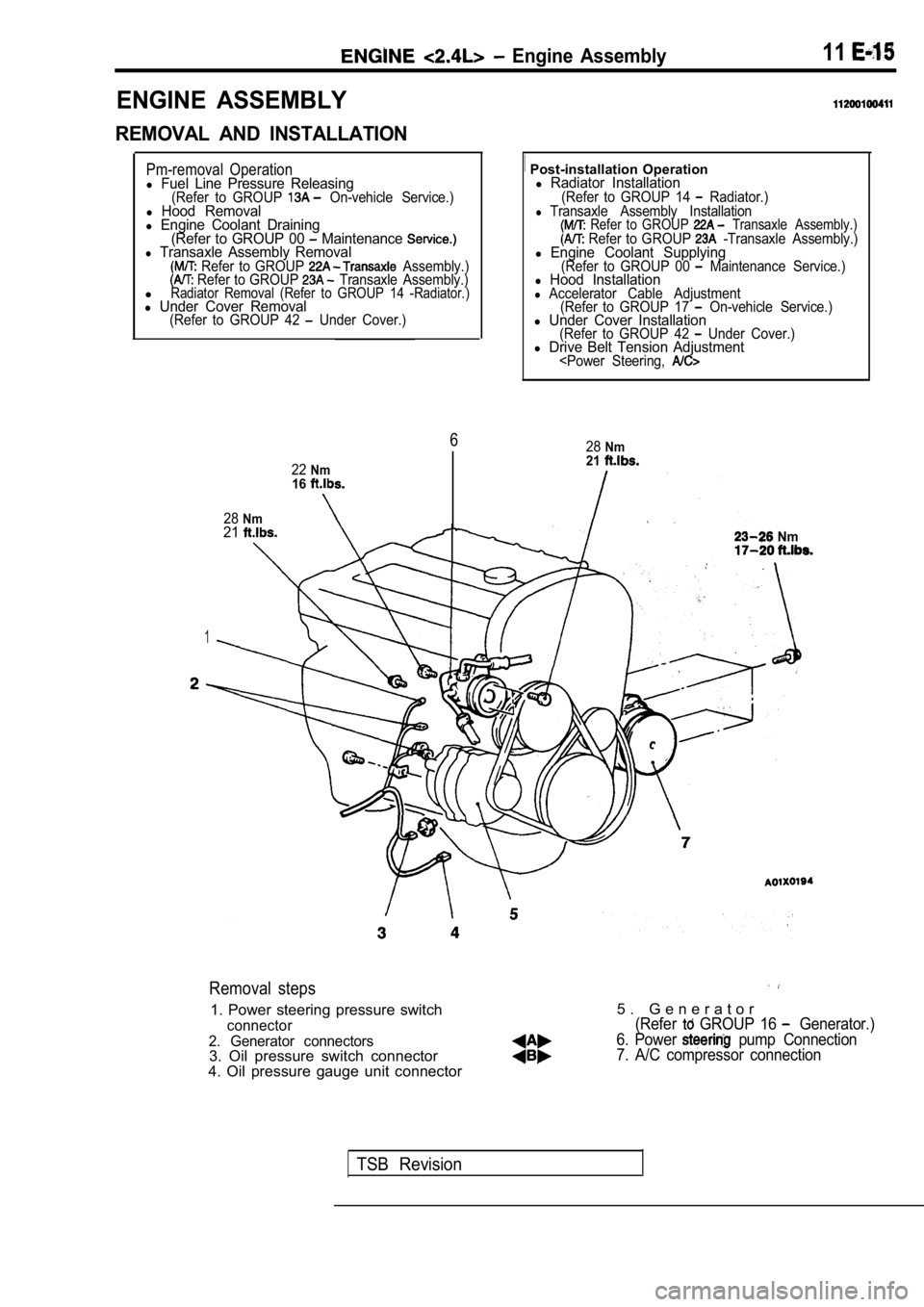

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

Pm-removal Operationl Fuel Line Pressure Releasing(Refer to GROUP On-vehicle Service.)l Hood Removall Engine Coolant Draining(Refer to GROUP 00 Maintenance l Transaxle Assembly Removal Refer to GROUP Assembly.) Refer to GROUP Transaxle Assembly.)lRadiator Removal (Refer to GROUP 14 -Radiator.)l Under Cover Removal(Refer to GROUP 42 Under Cover.)

1

22Nm16

6

28Nm

Post-installation Operationl Radiator Installation(Refer to GROUP 14 Radiator.)l Transaxle Assembly Installation Refer to GROUP Transaxle Assembly.) Refer to GROUP -Transaxle Assembly.)l Engine Coolant Supplying(Refer to GROUP 00 Maintenance Service.)l Hood Installationl Accelerator Cable Adjustment (Refer to GROUP 17 On-vehicle Service.)l Under Cover Installation(Refer to GROUP 42 Under Cover.)l Drive Belt Tension Adjustment

21 Nm

Removal steps

1. Power steering pressure switch

connector

2. Generator connectors

3. Oil pressure switch connector

4. Oil pressure gauge unit connector

5 . G e n e r a t o r(Refer GROUP 16 Generator.)

6. Power

pump Connection

7. A/C compressor connection

TSB Revision

Page 284 of 2103

.

4 . 9 N m

\ / X L - -3.6

. .

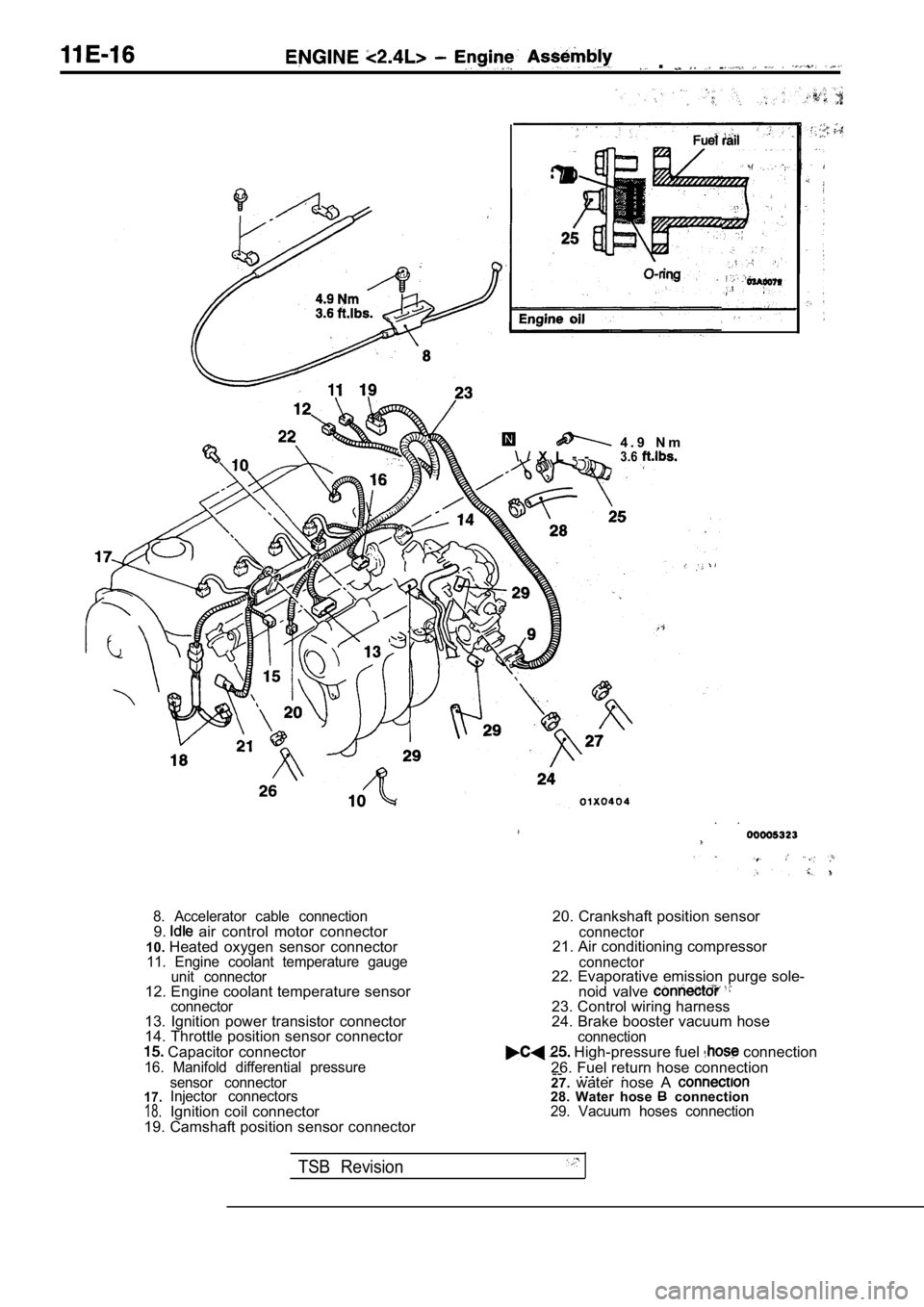

8. Accelerator cable connection9. air control motor connector

10. Heated oxygen sensor connector

11. Engine coolant temperature gauge

unit connector

12. Engine coolant temperature sensorconnector13. Ignition power transistor connector

14. Throttle position sensor connector

Capacitor connector16. Manifold differential pressure

20. Crankshaft position sensor

connector21. Air conditioning compressor

connector22. Evaporative emission purge sole-

noid valve

23. Control wiring harness

24. Brake booster vacuum hose

connection High-pressure fuel connection

26. Fuel return hose connection --

. .. .

17.18.

sensor connector

Injector connectors

Ignition coil connector

19. Camshaft position sensor connector 27.

water nose A 28. Water hose connection29. Vacuum hoses connection

TSB Revision

Page 336 of 2103

ENGINE OVERHAUL intake Manifold

sealant

3 mm

bead sealant

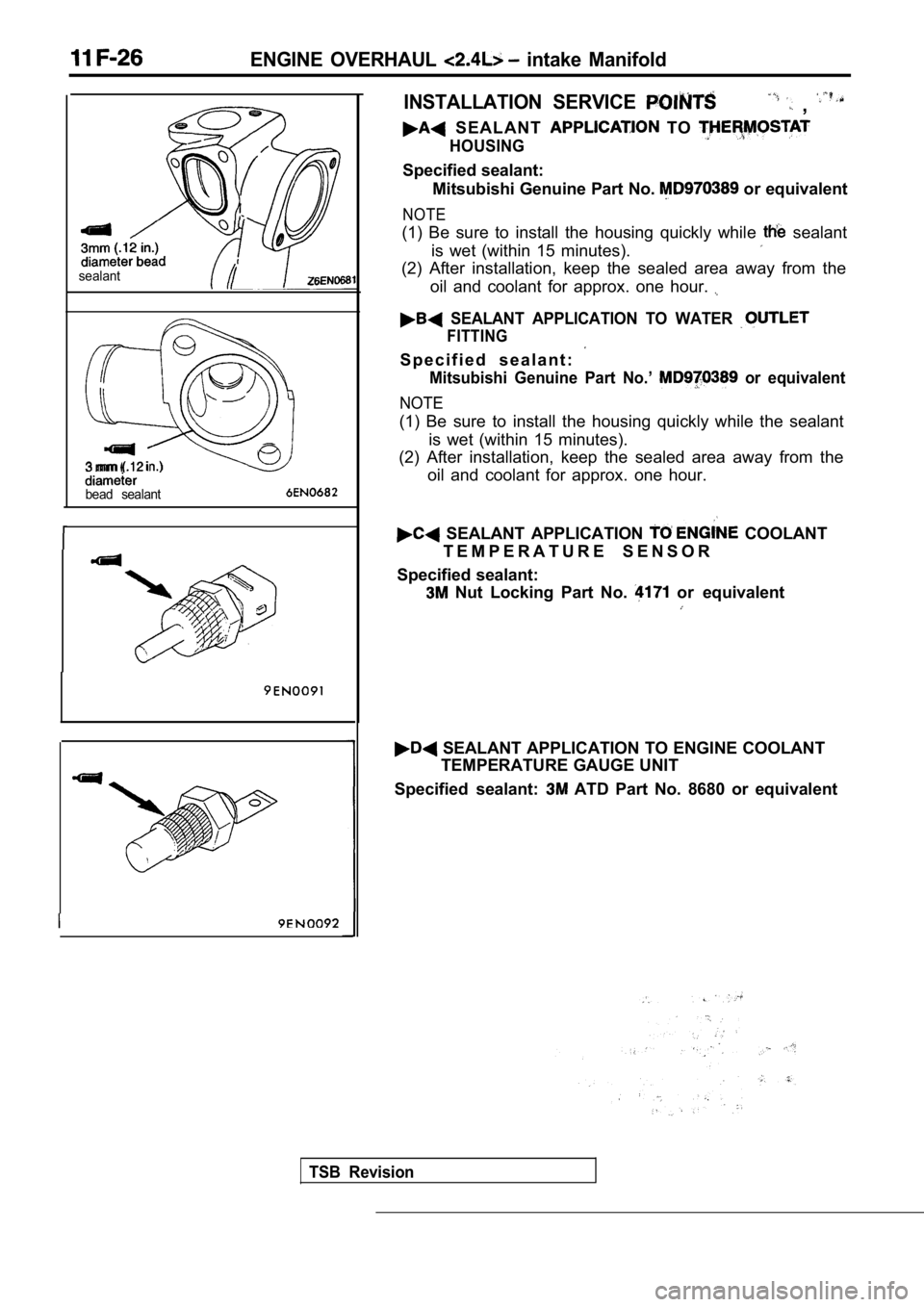

INSTALLATION SERVICE ,

S E A L A N T TO

HOUSING

Specified sealant:Mitsubishi Genuine Part No.

or equivalent

NOTE

(1) Be sure to install the housing quickly while sealant

is wet (within 15 minutes).

(2) After installation, keep the sealed area away f rom the

oil and coolant for approx. one hour.

SEALANT APPLICATION TO WATER

FITTING

S p e c i f i e d s e a l a n t :

Mitsubishi Genuine Part No.’ or equivalent

NOTE

(1) Be sure to install the housing quickly while th e sealant

is wet (within 15 minutes).

(2) After installation, keep the sealed area away f rom the

oil and coolant for approx. one hour.

SEALANT APPLICATION COOLANT

T E M P E R A T U R E S E N S O R

Specified sealant:

Nut Locking Part No. or equivalent

SEALANT APPLICATION TO ENGINE COOLANT TEMPERATURE GAUGE UNIT

Specified sealant:

ATD Part No. 8680 or equivalent

TSB Revision

Page 355 of 2103

ENGINE OVERHAUL Shaft and Can

Case,

62

Crank pulley side

0

mm bolts

0

Oil pan viewed from lower side

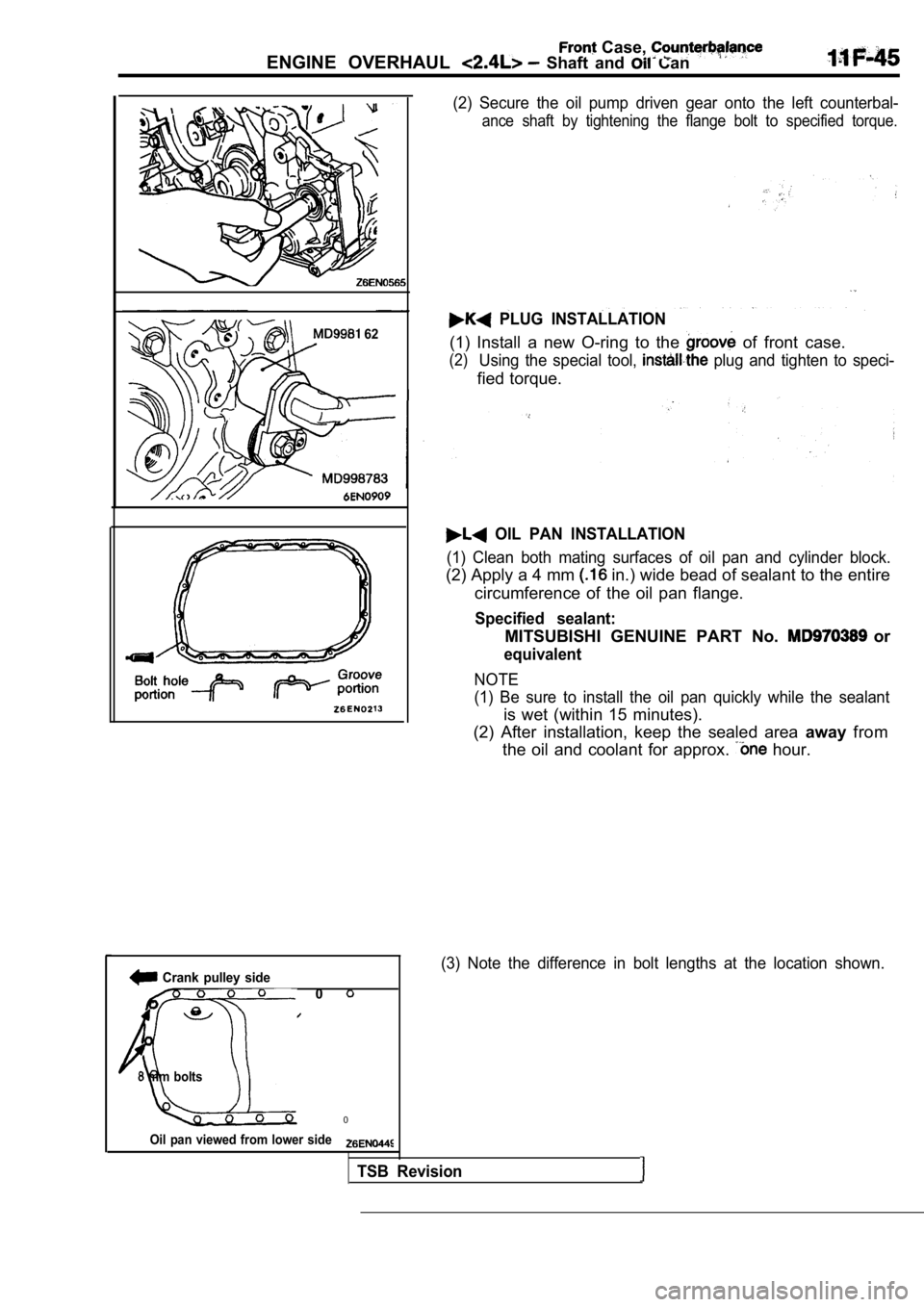

(2) Secure the oil pump driven gear onto the left counterbal-

ance shaft by tightening the flange bolt to specified torque.

PLUG INSTALLATION

(1) Install a new O-ring to the of front case.

(2)Using the special tool, plug and tighten to speci-

fied torque.

OIL PAN INSTALLATION

(1) Clean both mating surfaces of oil pan and cylin der block.

(2) Apply a 4 mm in.) wide bead of sealant to the entire

circumference of the oil pan flange.

Specified sealant:

MITSUBISHI GENUINE PART No. or

equivalent

NOTE

(1) Be sure to install the oil pan quickly while th e sealant

is wet (within 15 minutes).

(2) After installation, keep the sealed area awayfrom

the oil and coolant for approx.

hour.

(3) Note the difference in bolt lengths at the loca tion shown.

TSB Revision

Page 370 of 2103

ENGINE O V E R H A U L Crankshaft. Drive

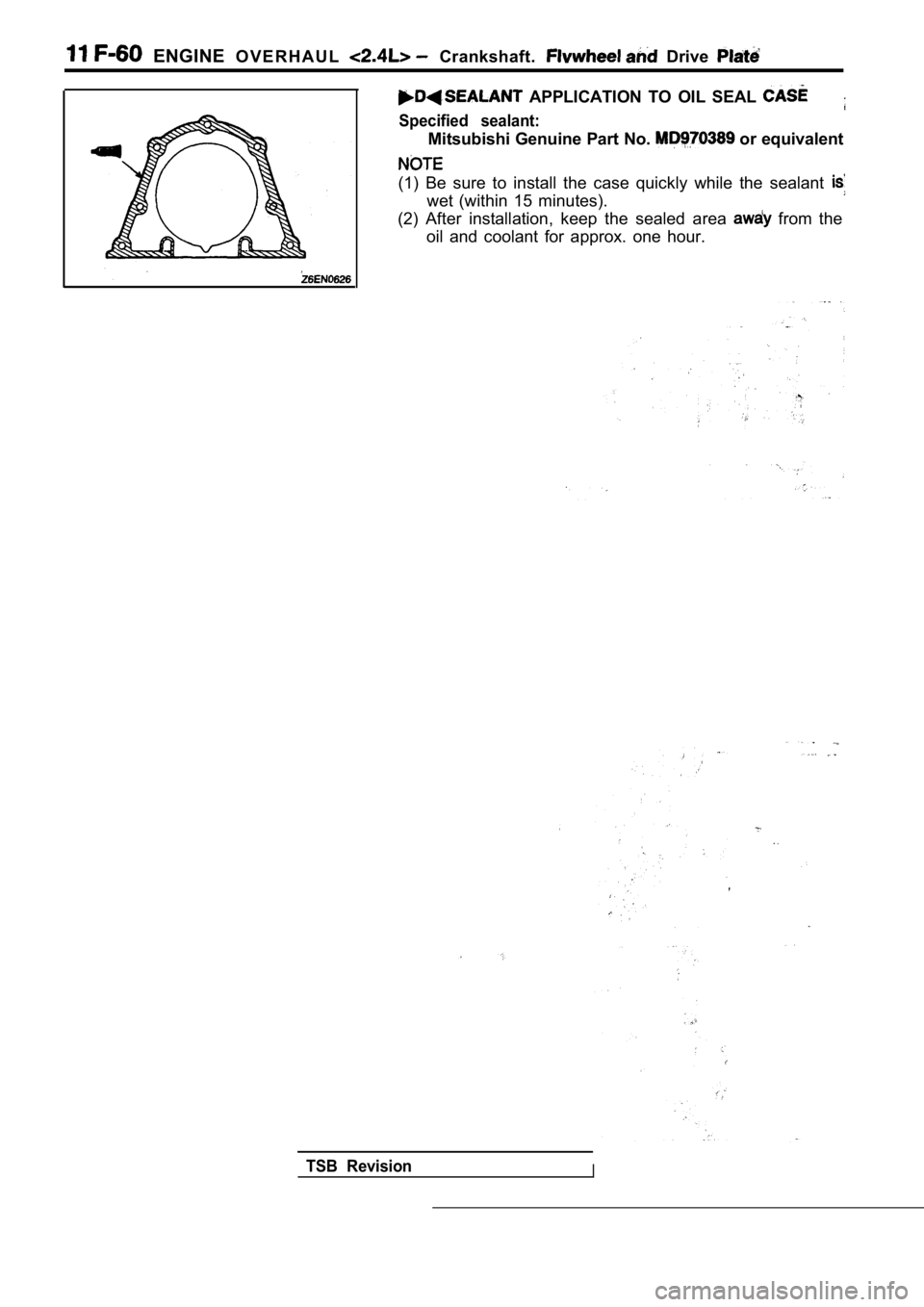

APPLICATION TO OIL SEAL

Specified sealant:

Mitsubishi Genuine Part No. or equivalent

(1) Be sure to install the case quickly while the s ealant

wet (within 15 minutes).

(2) After installation, keep the sealed area

from the

oil and coolant for approx. one hour.

TSB RevisionI

Page 375 of 2103

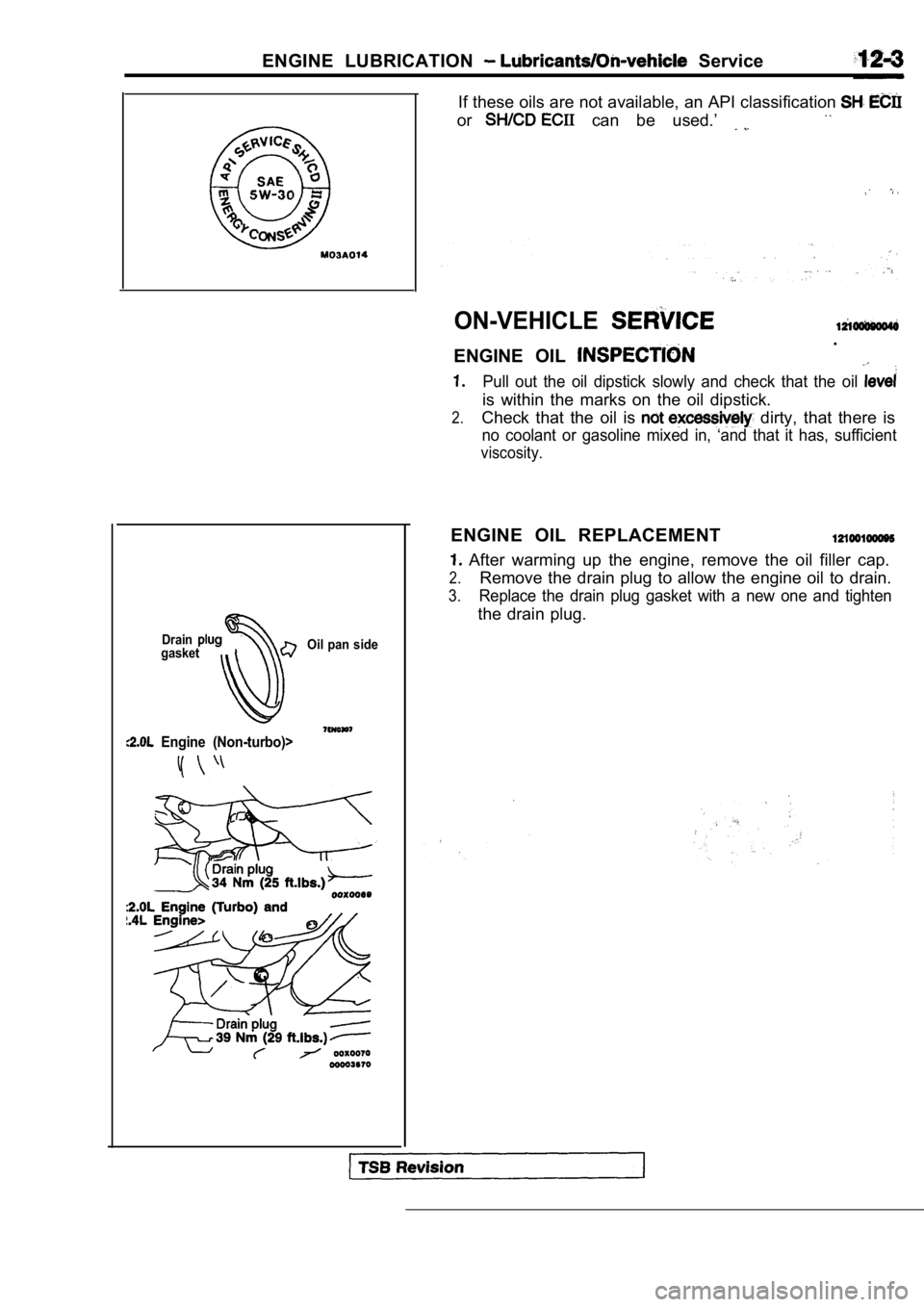

ENGINE LUBRICATION Service

DraingasketOil pan side

Engine (Non-turbo)>

If these oils are not available, an API classificat

ion

or can be used.’ . .

ON-VEHICLE

ENGINE OIL

.

Pull out the oil dipstick slowly and check that the oil

is within the marks on the oil dipstick.

2.Check that the oil is dirty, that there is

no coolant or gasoline mixed in, ‘and that it has, sufficient

viscosity.

ENGINE OIL REPLACEMENT

After warming up the engine, remove the oil filler cap.

2.Remove the drain plug to allow the engine oil to drain.

3.Replace the drain plug gasket with a new one and ti ghten

the drain plug.

Page 377 of 2103

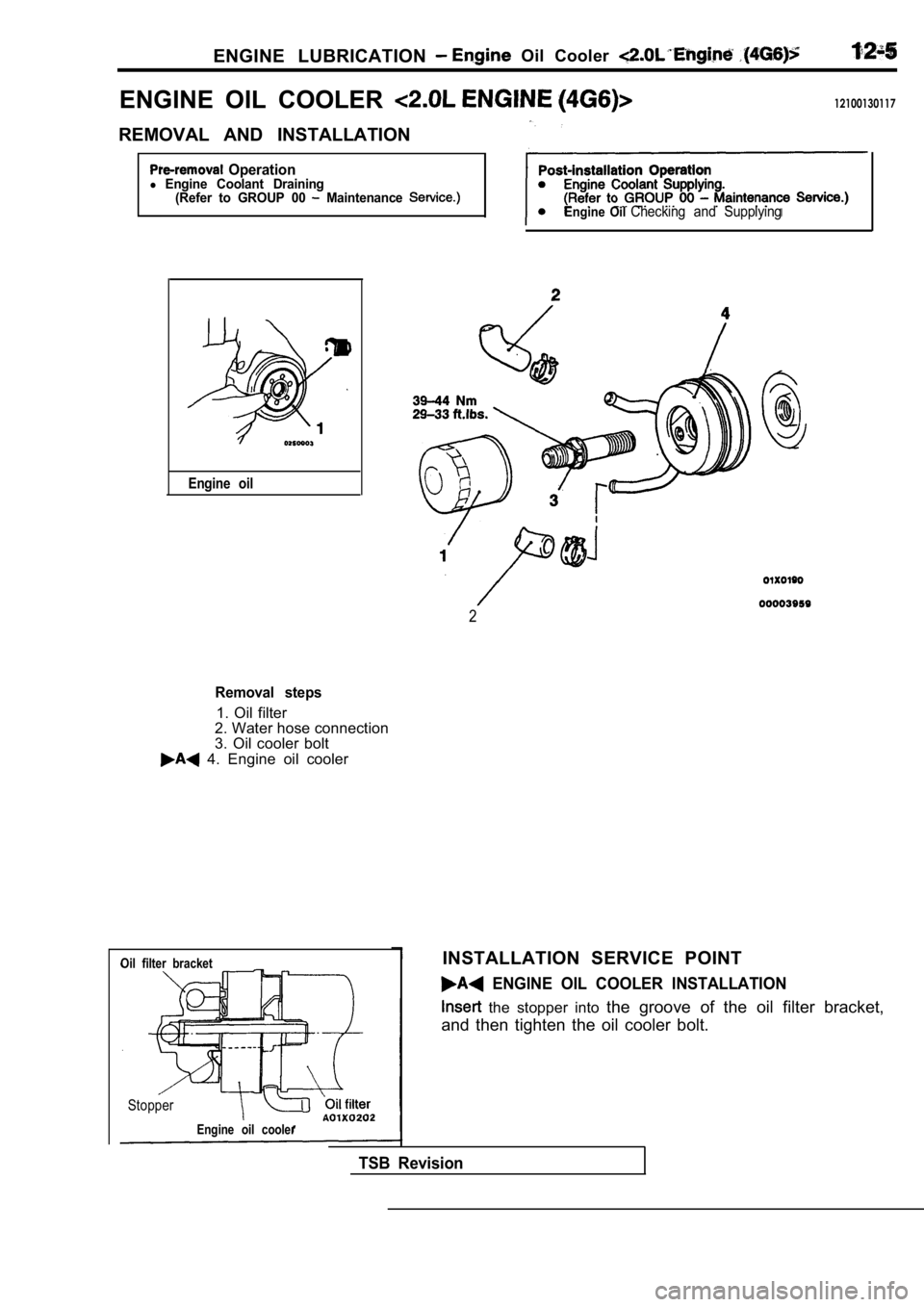

ENGINE LUBRICATION Oil Cooler

ENGINE OIL COOLER 12100130117

REMOVAL AND INSTALLATION

Operationl Engine Coolant Draining(Refer to GROUP 00 Maintenance

Engine oil

Engine Oil Checking and Supplying

2

Removal steps

1. Oil filter

2. Water hose connection

3. Oil cooler bolt

4. Engine oil cooler

Oil filter bracket

Stopper

Engine oil cooler

INSTALLATION SERVICE POINT

ENGINE OIL COOLER INSTALLATION

the stopper into the groove of the oil filter bracket,

and then tighten the oil cooler bolt.

TSB Revision